Understanding the intricacies of your cutting tool is essential for its longevity and efficiency. This section delves into the crucial aspects of ensuring your equipment operates at peak performance. By familiarizing yourself with the essential techniques and practices, you can extend the lifespan of your device while enhancing its functionality.

Regular upkeep not only safeguards the equipment from common issues but also promotes safety during usage. Knowledge about the inner workings and necessary care procedures will empower you to address minor problems before they escalate. This guide will provide insights into best practices for maintaining your chainsaw, ensuring that it remains a reliable companion for your outdoor projects.

Moreover, embracing a proactive approach to maintenance can lead to better results in your tasks. From simple adjustments to thorough examinations, understanding these methods will aid in optimizing your device’s performance. Equip yourself with the knowledge presented here to foster a greater connection with your tool, ensuring it meets your expectations consistently.

When undertaking maintenance tasks for outdoor equipment, having the right instruments at hand is crucial for efficiency and effectiveness. This section outlines the fundamental implements necessary for ensuring proper functioning and longevity of your device. Equipped with the correct tools, users can carry out tasks with confidence and precision.

Basic Instruments

- Screwdrivers: Essential for adjusting and securing components.

- Wrenches: Important for loosening and tightening bolts.

- Replacement Parts: Having spare components on hand ensures quick fixes.

Safety Gear

- Gloves: Protects hands from sharp edges and injuries.

- Goggles: Shields eyes from debris and particles during work.

- Mask: Keeps out harmful dust and fumes when dealing with machinery.

Common Issues and Solutions

This section addresses frequent problems encountered with certain power tools and provides effective resolutions to enhance performance and longevity.

| Issue | Description | Solution |

|---|---|---|

| Starting Difficulties | The tool may struggle to start or may not start at all. | Check the fuel level, ensuring it is fresh and properly mixed. Inspect the spark plug for wear and replace if necessary. |

| Loss of Power | The equipment operates at reduced efficiency or power. | Examine the air filter for blockages and clean or replace it as needed. Ensure the cutting chain is sharp. |

| Excessive Vibration | There may be increased vibrations during operation. | Check for loose components and tighten as required. Inspect the chain tension and adjust accordingly. |

| Overheating | The machine may become excessively hot during use. | Ensure proper lubrication of moving parts and allow for cooling periods during extended use. |

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment is essential for optimal performance and longevity. By following systematic procedures, you can ensure that all components function efficiently and prevent potential issues down the line. This section outlines the key steps needed for effective maintenance.

| Step | Procedure | Frequency |

|---|---|---|

| 1 | Inspect the cutting chain for wear and tension. | After every use |

| 2 | Clean the air filter to prevent clogging. | Weekly |

| 3 | Check and tighten all screws and bolts. | Monthly |

| 4 | Sharpen the chain to ensure clean cuts. | As needed |

| 5 | Examine the fuel system for leaks or damage. | Before each use |

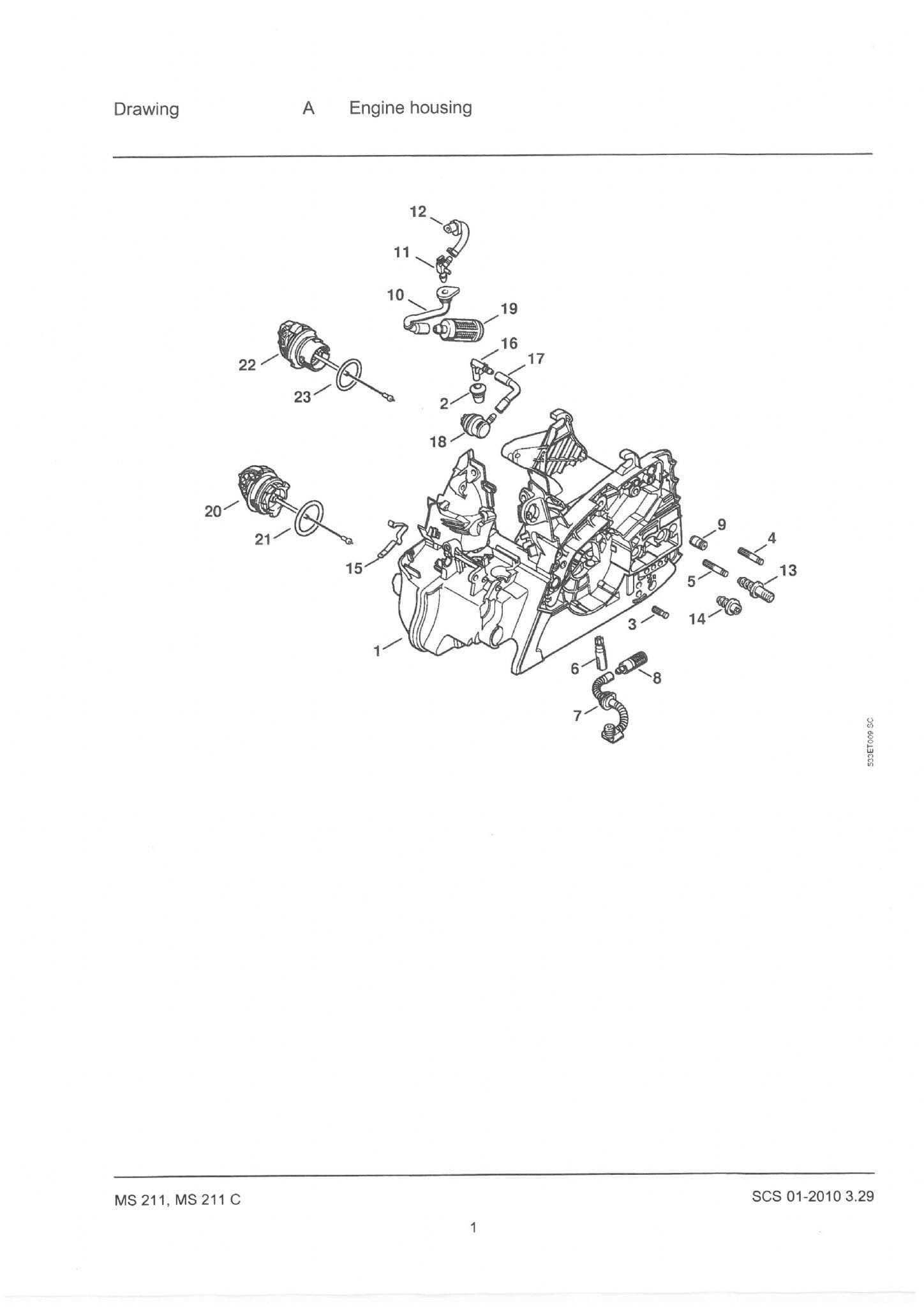

Understanding Engine Components

Engines consist of several essential elements that work together to convert fuel into mechanical energy. Each component plays a crucial role in the overall functionality and efficiency of the system. By comprehending these parts, users can enhance their knowledge and maintenance practices, ensuring optimal performance.

The power unit is at the heart of the engine, responsible for generating energy through combustion. This process involves a mixture of air and fuel that ignites to produce force. Surrounding the power unit are various components that support its operation, including the ignition system, which initiates combustion, and the fuel delivery system, which ensures the correct mixture reaches the engine.

Additionally, the exhaust system plays a vital role by directing harmful gases away from the engine, thereby maintaining efficiency and reducing environmental impact. Understanding these key elements helps users identify issues and perform necessary adjustments or replacements, promoting longevity and reliability.

Safety Precautions During Repairs

When undertaking maintenance tasks on equipment, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines ensures a secure environment for both the individual performing the work and those nearby. This section outlines critical measures that should be observed during maintenance activities.

Before starting any work, it is vital to equip oneself with appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to guard against potential hazards. Additionally, a well-organized workspace contributes significantly to overall safety.

| Precaution | Description |

|---|---|

| Inspect Tools | Ensure that all tools are in good condition and suitable for the task at hand. |

| Work in a Well-Lit Area | Adequate lighting helps to identify hazards and perform tasks more effectively. |

| Maintain a Clear Workspace | Keep the area free of clutter to avoid tripping hazards and facilitate safe movement. |

| Disconnect Power Sources | Before beginning any maintenance, ensure that all power sources are turned off and disconnected. |

| Stay Focused | Avoid distractions to maintain concentration during the task, reducing the risk of accidents. |

How to Troubleshoot Electrical Problems

Tackling issues related to the electrical system of your equipment can often seem daunting. However, by following a systematic approach, you can identify and rectify common faults. This section provides guidance on diagnosing various electrical anomalies, ensuring your machinery operates efficiently.

Identifying Symptoms

Start by observing the equipment for any irregularities, such as unusual sounds, failure to start, or inconsistent performance. Carefully inspect all visible wiring and connections for signs of wear, damage, or corrosion. Paying attention to these symptoms can lead you to the root of the issue more swiftly.

Performing Tests

Utilize a multimeter to check the voltage levels and continuity in the circuits. Testing components like fuses, switches, and relays can help isolate the malfunctioning part. Make sure to refer to the specifications for normal operating values to compare your findings accurately. Understanding the electrical layout will also aid in troubleshooting effectively.

Replacing the Chain and Bar

Regular maintenance of cutting equipment is essential for optimal performance and safety. One of the crucial aspects of upkeep involves the timely replacement of the cutting chain and guide bar. Understanding the procedure not only enhances efficiency but also prolongs the lifespan of the tool.

Steps for Replacement

To ensure a successful exchange of the chain and bar, follow these systematic steps:

| Step | Description |

|---|---|

| 1 | Ensure the tool is powered off and disconnected from any power source. |

| 2 | Loosen the nuts on the guide bar using the appropriate tool. |

| 3 | Remove the old chain and bar from the machine. |

| 4 | Install the new guide bar, aligning it correctly. |

| 5 | Fit the new chain onto the bar, ensuring it follows the proper tensioning path. |

| 6 | Tighten the nuts securely, adjusting the tension of the chain as necessary. |

Maintenance Tips

To maintain the effectiveness of the cutting tool, check the chain tension regularly and keep the components clean. Proper lubrication is also essential to reduce friction and wear.

Fuel and Oil Recommendations

Proper maintenance of a power tool relies heavily on the quality of fuel and lubricants used. Selecting the right mixtures not only enhances performance but also prolongs the lifespan of the equipment. It is essential to adhere to specific guidelines to ensure optimal functioning and to avoid potential damage.

Recommended Fuel Types

For optimal performance, it is advised to use a high-quality gasoline with a minimum octane rating of 89. This will ensure efficient combustion and reduce the risk of engine knocking. Additionally, avoid using fuel that contains more than 10% ethanol, as higher concentrations can lead to engine complications.

Lubrication Guidelines

When it comes to oil, it is crucial to utilize a premium two-stroke oil specifically formulated for air-cooled engines. Mixing the oil with fuel should follow a precise ratio, commonly 50:1, unless otherwise specified. This ratio helps maintain adequate lubrication while preventing the build-up of residues.

| Type | Recommendation |

|---|---|

| Fuel | 89 Octane Gasoline (Max 10% Ethanol) |

| Oil | Premium Two-Stroke Oil (50:1 Ratio) |

Cleaning and Caring for the Unit

Maintaining the functionality and longevity of your equipment is essential for optimal performance. Regular cleaning and proper care not only enhance efficiency but also ensure safety during operation. By implementing a few simple practices, you can keep your device in excellent condition, ready for use whenever needed.

Routine Cleaning Procedures

- Disconnect the power source before cleaning to ensure safety.

- Use a soft brush or cloth to remove debris and dust from the exterior surfaces.

- Inspect air filters and clean or replace them as necessary to prevent clogs.

- Check the chain and bar for buildup; clean them thoroughly to maintain smooth operation.

Storage and Care Tips

- Store the equipment in a dry, cool place to avoid moisture damage.

- Cover the unit with a protective cloth to prevent dust accumulation during storage.

- Regularly check for any signs of wear or damage and address issues promptly.

- Follow the manufacturer’s guidelines for maintenance intervals and specific care recommendations.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is crucial for maintaining optimal performance and safety of your equipment. Regularly inspecting components can prevent unexpected failures and prolong the lifespan of the device.

Visual Inspection: Begin with a thorough visual assessment of the equipment. Look for any obvious signs of damage, such as cracks, chips, or excessive wear on parts that experience friction. These may compromise functionality and should be addressed promptly.

Performance Issues: Pay attention to any changes in the device’s performance. If you notice unusual noises, vibrations, or a decrease in efficiency, it may indicate underlying problems. Addressing these symptoms early can prevent more severe issues down the line.

Component Examination: Regularly check critical components, including the chain, bar, and air filter. Excessive wear on the chain links or bar can affect cutting performance. Additionally, a clogged air filter may hinder the engine’s airflow, leading to decreased performance.

Staying vigilant about these signs ensures your equipment remains in top condition, ready for any task you undertake.

Finding Replacement Parts

Locating suitable components for your equipment is essential for maintaining its optimal performance and longevity. Whether you are looking to replace worn-out pieces or upgrade specific functionalities, there are various avenues to explore when sourcing the right parts.

Here are some effective strategies to find the components you need:

- Visit authorized dealers to access a wide range of genuine parts that ensure compatibility and quality.

- Check online retailers that specialize in tool components; they often have extensive inventories and detailed product descriptions.

- Utilize manufacturer websites, which typically provide resources for part identification and availability.

- Join online forums and communities related to your equipment, where fellow users share recommendations and experiences.

By exploring these options, you can effectively find and procure the necessary parts to keep your machinery in top shape.

When to Seek Professional Help

Determining the right time to consult a specialist can significantly impact the longevity and performance of your equipment. While many maintenance tasks can be handled independently, some issues require the expertise of a trained technician to ensure proper resolution and safety.

Complex Problems: If you encounter issues that seem complicated or unfamiliar, it is wise to seek assistance. A professional can diagnose underlying problems that may not be apparent and provide effective solutions.

Safety Concerns: Any situation that poses a risk of injury or further damage should prompt you to contact a professional. When handling equipment that has the potential for hazardous operation, prioritizing safety is crucial.

Persistent Issues: If you have attempted to resolve a problem multiple times without success, enlisting the help of an expert can save time and resources. They possess the knowledge and tools necessary to address recurring difficulties effectively.

Warranty Considerations: If your equipment is still under warranty, it may be beneficial to seek professional help for repairs. This ensures that any work done is in compliance with warranty requirements and maintains your coverage.

In summary, while DIY maintenance can be rewarding, recognizing the limits of your expertise is essential. Seeking professional help when necessary ensures that your equipment remains in optimal condition and reduces the risk of complications.