In the realm of air-powered firearms, ensuring optimal performance and longevity is essential for enthusiasts and casual users alike. This section serves as a vital resource for individuals seeking to maintain and enhance the functionality of their equipment. By familiarizing yourself with the intricate components and mechanisms, you can extend the lifespan of your device and improve accuracy and reliability.

Proper maintenance is crucial in avoiding common pitfalls that can lead to diminished performance or malfunction. Through careful examination and understanding of each part, you can identify potential issues before they escalate into significant problems. This guide will provide you with the necessary insights to tackle routine tasks and troubleshoot effectively.

Whether you’re a seasoned veteran or a newcomer to the world of air-powered devices, having access to detailed instructions and tips can make all the difference. With a focus on practical advice and straightforward steps, this resource aims to empower you to take control of your equipment’s upkeep. Embrace the opportunity to learn and enhance your experience in this engaging hobby.

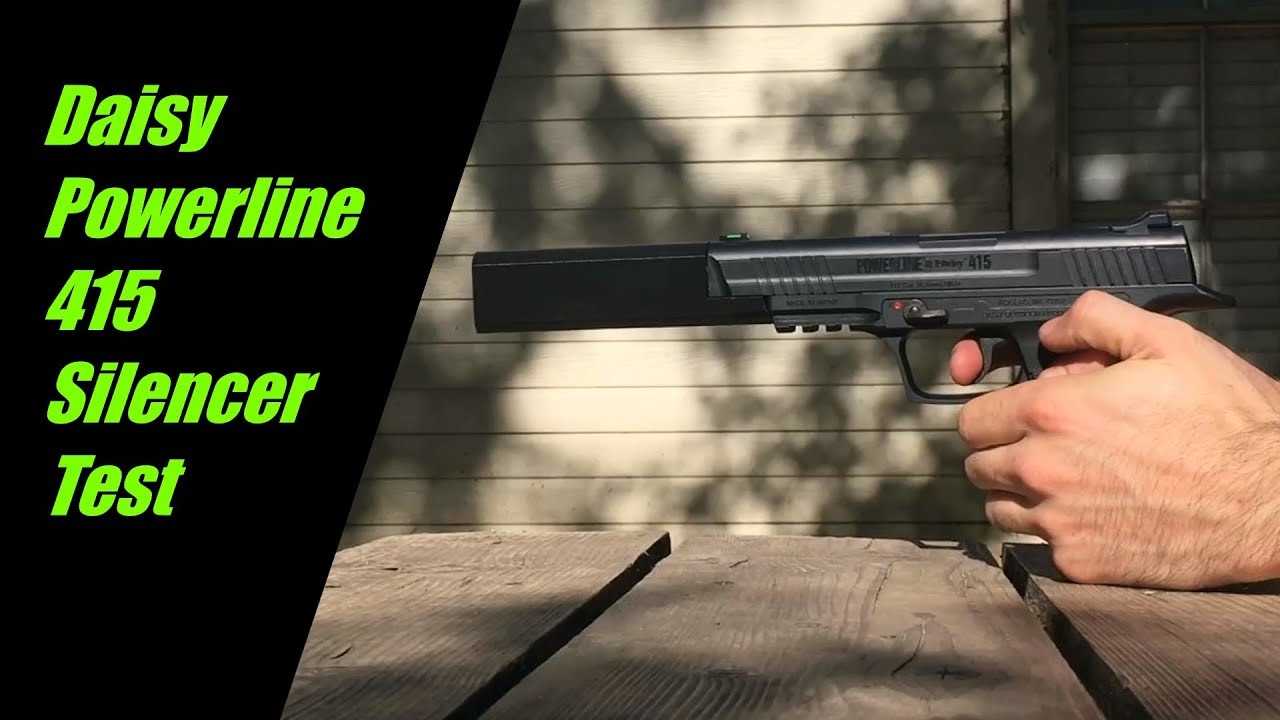

Daisy Powerline 415 Overview

This section provides a comprehensive look at a popular air gun designed for recreational shooting and training. Renowned for its reliability and ease of use, this model is a favorite among enthusiasts. With a blend of performance and affordability, it serves as an excellent choice for both beginners and seasoned users.

Specifications

| Feature | Details |

|---|---|

| Caliber | .177 |

| Action Type | Single-shot |

| Velocity | Up to 400 fps |

| Weight | Approximately 2.5 lbs |

| Material | Plastic and metal components |

Usage and Applications

This air gun is well-suited for target practice, plinking, and educational purposes. Its straightforward design makes it easy to operate, while its performance allows for accurate shooting experiences. Users appreciate its versatility and the enjoyable nature of its operation.

Common Issues with Daisy Powerline 415

Understanding the frequent problems encountered with this airgun can significantly enhance the shooting experience. Users often face various challenges that can affect performance and accuracy. Identifying these issues early can lead to effective solutions and improved functionality.

Frequent Problems

- Inconsistent Firing: Variability in power can lead to unpredictable shooting results.

- Jamming: Pellets may get stuck in the chamber, causing interruptions in use.

- Air Leaks: Loss of pressure can diminish the gun’s effectiveness.

- Trigger Issues: Malfunctions in the trigger mechanism may result in improper firing.

Troubleshooting Tips

- Regular Maintenance: Clean and lubricate moving parts to prevent jams and ensure smooth operation.

- Check Seals: Inspect for wear and replace any damaged components to address air leaks.

- Use Quality Ammunition: Choose the right type of pellets to enhance firing consistency.

- Test for Accuracy: Regularly check alignment and sighting to maintain precision in shooting.

Tools Needed for Repairs

Ensuring optimal functionality of your equipment requires specific instruments for effective maintenance and troubleshooting. Having the right tools on hand not only simplifies the process but also enhances the quality of the outcome. Below is a list of essential implements necessary for the task at hand.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To adjust screws of various sizes and types. |

| Pliers | Useful for gripping and bending components. |

| Cleaning Brush | To remove debris and dirt from intricate parts. |

| Lubricant | For ensuring smooth movement of mechanical parts. |

| Multimeter | For testing electrical components and connections. |

| Protective Gear | To ensure safety during the maintenance process. |

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a specific air gun model. Understanding the disassembly process is crucial for maintenance and troubleshooting. Follow these instructions carefully to ensure that every component is handled correctly.

Tools Required

- Screwdriver set (Phillips and flathead)

- Allen wrenches

- Soft cloth or mat

- Small container for screws and small parts

- Tweezers

Disassembly Steps

- Ensure the air gun is unloaded and safe to handle.

- Remove the magazine and set it aside.

- Using the appropriate screwdriver, unscrew the grip panels carefully.

- Detach the trigger assembly by locating and removing its retaining screws.

- Remove the main housing screws and gently pull apart the casing.

- Carefully take out the internal components, noting their positions for reassembly.

- Inspect each part for wear and damage during the disassembly process.

By following these steps, you will effectively dismantle the air gun, making it easier to clean, repair, or replace any components as needed.

Repairing the Airgun Trigger

The functionality of a compressed-air shooting device is heavily reliant on its mechanism for releasing the projectile. An effective and responsive trigger is essential for precision and user satisfaction. This section delves into the steps necessary to restore optimal performance to the triggering system, ensuring smooth operation and reliability.

Identifying Common Issues

Before proceeding with any adjustments, it is crucial to diagnose typical problems that may hinder the trigger’s performance. These can include sticking components, misalignment, or wear and tear on springs and pins. Regular inspection can help detect these issues early, preventing more extensive complications down the line.

Step-by-Step Restoration Process

To begin the restoration, disassemble the device carefully, ensuring to keep track of all parts. Clean the trigger assembly using appropriate solvents to remove dirt and residue. Once cleaned, inspect each component for damage or excessive wear. If any parts are found to be defective, replacing them with compatible alternatives is necessary. Finally, reassemble the mechanism, ensuring that all parts are correctly aligned and lubricated where required for smooth operation.

Fixing the Barrel and Muzzle

Addressing issues related to the tube and the front opening is essential for restoring optimal performance. Proper alignment and sealing are critical to ensure accuracy and safety during operation. This section outlines effective techniques for troubleshooting and rectifying common problems associated with these components.

Identifying Issues

Start by examining the exterior and interior of the tube for any signs of wear, dents, or obstructions. Carefully check the opening for misalignment, which can lead to inconsistencies in firing. Any visible damage should be documented, as this will guide the repair process.

Repair Techniques

To correct misalignments, gently manipulate the tube back into place using appropriate tools. For minor dents, a rubber mallet can be used to restore shape without damaging the finish. Ensure that all connections are tight and that seals are intact to prevent air leaks, which can significantly affect performance.

Replacing Internal Components

This section outlines the process of swapping out essential parts within the device to restore optimal functionality. Understanding the significance of each component is crucial for efficient maintenance and longevity.

Identifying Components

Prior to disassembly, it is important to recognize which elements require replacement. Common issues may arise from worn-out circuitry or malfunctioning mechanisms that hinder performance. A thorough inspection helps in determining the necessary replacements.

Step-by-Step Replacement Guide

Follow these steps to ensure a smooth transition when replacing internal parts:

| Step | Description |

|---|---|

| 1 | Power down the device and disconnect from any power source to ensure safety. |

| 2 | Open the casing carefully using appropriate tools to avoid damage. |

| 3 | Identify the components that need to be replaced based on your initial assessment. |

| 4 | Remove the faulty components gently, noting their connections for proper installation of new ones. |

| 5 | Install the new components, ensuring all connections are secure and correctly oriented. |

| 6 | Close the casing and restore power to the device, testing functionality. |

Maintaining the Powerline 415

Regular upkeep is essential for ensuring optimal performance and longevity of your device. By adhering to a few fundamental practices, users can effectively prevent issues and enhance the overall functionality of their equipment.

Essential Maintenance Practices

- Keep the device clean and free from dust and debris.

- Regularly check connections to ensure they are secure and free from corrosion.

- Inspect for any signs of wear or damage in cables and connectors.

- Update firmware as needed to benefit from the latest enhancements.

Periodic Checks

- Schedule inspections every few months to evaluate the system’s performance.

- Monitor operational efficiency and address any anomalies promptly.

- Document any maintenance performed for future reference.

By implementing these strategies, users can maintain the functionality and reliability of their equipment, ensuring it remains in peak condition for years to come.

Safety Precautions During Repair

Ensuring a secure environment is paramount when undertaking any maintenance or servicing tasks. Proper precautions can mitigate risks associated with electrical equipment and prevent accidents. Awareness of potential hazards and adherence to safety guidelines is essential for both personal safety and the integrity of the device.

Understanding the Risks

Before initiating any work, it is crucial to comprehend the potential dangers involved. Electrical components can pose risks such as electric shock or short circuits. Additionally, sharp edges and moving parts may lead to physical injuries. Assessing the situation and preparing adequately can help in minimizing these risks.

Essential Safety Measures

Always disconnect the device from its power source before beginning any work. Utilize appropriate protective gear, such as gloves and safety goggles, to safeguard against accidental injuries. Following the manufacturer’s guidelines and using the correct tools is vital to avoid damaging the equipment or causing harm. Regularly inspecting your workspace for hazards can further enhance safety during the maintenance process.

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and troubleshooting of specific equipment. Understanding these frequently posed questions can help users navigate challenges and enhance their operational experience.

What are the common issues faced with this equipment?

Users often report problems such as connectivity failures, performance inconsistencies, and difficulties during setup. Recognizing these challenges is the first step towards effective resolution.

How can I perform basic troubleshooting?

Basic troubleshooting typically involves checking power sources, verifying connections, and ensuring that all components are functioning properly. In many cases, resetting the system can resolve minor glitches.

Where can I find replacement parts?

Replacement components can usually be sourced from authorized dealers or online retailers specializing in electronic equipment. It’s essential to ensure compatibility with your specific model to avoid further complications.

Is there a warranty on the product?

Most manufacturers offer a warranty that covers defects in materials or workmanship. It is advisable to check the terms and conditions of the warranty to understand the coverage and duration.