This section provides essential information for maintaining and troubleshooting a compact utility vehicle. Proper upkeep and timely intervention can significantly enhance performance and longevity, ensuring a smooth driving experience.

Understanding the intricacies of automotive systems is crucial for any vehicle owner. This resource offers insights into various components, their functions, and common issues that may arise. By familiarizing oneself with these elements, one can effectively address challenges and execute necessary adjustments.

Whether you are a novice or a seasoned enthusiast, this guide aims to empower you with the knowledge needed to manage your vehicle effectively. With detailed explanations and practical tips, you’ll be better equipped to navigate routine maintenance tasks and repairs.

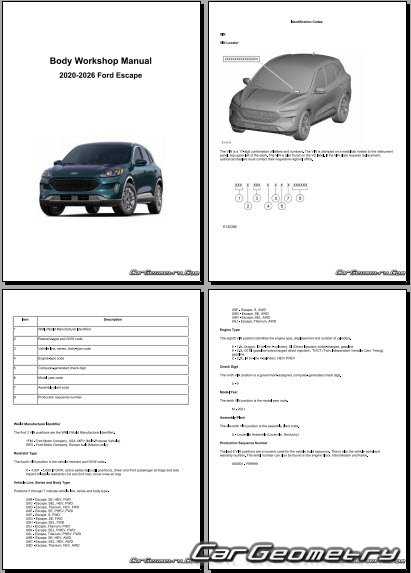

This section provides a comprehensive overview of a compact utility vehicle designed for versatility and efficiency. Known for its modern design and functional features, this model caters to a diverse range of drivers, from families to adventure enthusiasts. The integration of advanced technologies and a focus on safety enhances its appeal in a competitive market.

Key Features and Specifications

Equipped with a powerful engine and efficient transmission options, this vehicle offers a balance of performance and fuel economy. Its spacious interior is complemented by innovative infotainment systems and comfort features, ensuring a pleasant driving experience for all passengers. Safety technologies such as collision warning systems and lane-keeping assist are also significant highlights.

Maintenance and Care

Regular upkeep is essential to prolong the lifespan and maintain optimal performance of the vehicle. Following scheduled service intervals for oil changes, brake inspections, and tire rotations is crucial. Additionally, keeping an eye on fluid levels and battery health will contribute to a smoother ride.

Common Issues and Solutions

Vehicle owners often encounter various challenges that can impact performance and reliability. Understanding these frequent problems and their resolutions is essential for maintaining optimal function and safety. Here are some prevalent issues along with effective solutions.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Excessive engine temperature can lead to significant damage. | Check the coolant level and radiator for leaks. Replace the thermostat if necessary. |

| Transmission Slippage | Difficulty in shifting gears may indicate transmission issues. | Inspect the transmission fluid level and quality. Consider fluid change or professional evaluation. |

| Electrical Problems | Malfunctioning electrical components can disrupt various systems. | Examine fuses, connections, and battery health. Replace faulty parts as needed. |

| Brake Wear | Squeaking or grinding noises can indicate worn brake pads. | Regularly inspect brakes and replace pads if thickness is below recommended levels. |

| Fuel Efficiency Decline | Decreased fuel economy may suggest engine or fuel system issues. | Check air filters and fuel injectors. Regular maintenance can improve efficiency. |

Maintenance Schedule for Optimal Performance

Establishing a systematic maintenance routine is crucial for ensuring the longevity and efficient operation of your vehicle. Regular attention to key components not only enhances performance but also minimizes the risk of unexpected breakdowns. By adhering to a well-structured schedule, owners can enjoy a smoother driving experience while preserving the vehicle’s value.

Regular Maintenance Tasks

- Change engine oil and filter every 5,000 to 7,500 miles.

- Inspect and rotate tires every 5,000 miles.

- Check brake fluid and coolant levels regularly.

- Replace air filters every 15,000 to 30,000 miles.

- Examine battery connections and test battery health annually.

Seasonal Checkups

- Winter preparation:

- Check antifreeze levels and replace as needed.

- Inspect windshield wipers and replace if worn.

- Summer preparation:

- Test air conditioning functionality.

- Inspect hoses and belts for signs of wear.

Following this schedule can help prevent costly repairs and maintain the vehicle’s overall efficiency. Keeping a detailed log of maintenance activities ensures that no task is overlooked, allowing for better tracking of vehicle performance over time.

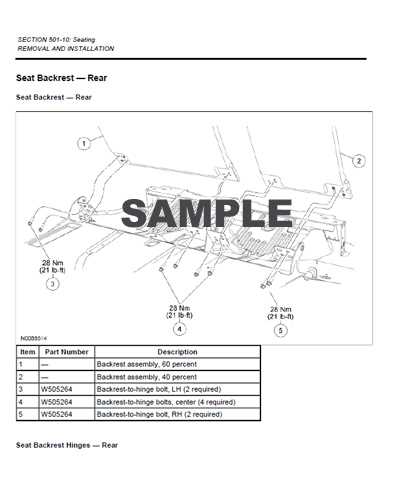

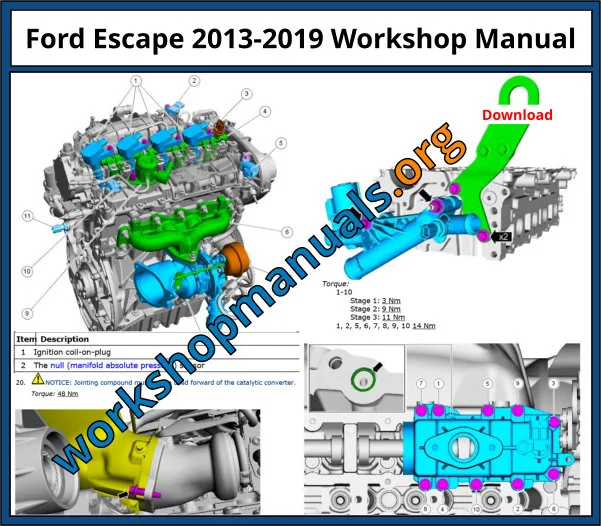

Step-by-Step Repair Instructions

This section provides a comprehensive guide to performing various maintenance and troubleshooting tasks on your vehicle. By following these detailed steps, you can enhance your understanding of the system and ensure optimal performance.

Before starting any work, gather the necessary tools and equipment. A clean and organized workspace will help streamline the process. Here are some key points to consider:

- Ensure the vehicle is parked on a flat surface.

- Disconnect the battery to avoid any electrical issues.

- Wear appropriate safety gear, including gloves and goggles.

Follow these general procedures for effective maintenance:

- Identify the specific area that needs attention.

- Refer to the vehicle’s specifications for detailed information on components.

- Loosen any fasteners or connectors that may be obstructing access.

- Replace or repair the component as necessary, ensuring proper alignment.

- Tighten all fasteners securely to manufacturer specifications.

- Reconnect the battery and test the system to verify functionality.

By adhering to these outlined steps, you can efficiently address common issues and maintain the longevity of your vehicle.

Diagnostic Tools and Equipment Needed

To effectively troubleshoot and maintain a vehicle, it is essential to have the right diagnostic instruments and tools. These devices help identify issues, analyze performance, and ensure that various systems function properly. Investing in quality equipment can save time and resources during the maintenance process.

Essential Diagnostic Instruments

- OBD-II Scanner: This tool reads trouble codes from the vehicle’s computer, providing valuable insights into system malfunctions.

- Multimeter: Useful for measuring voltage, current, and resistance, this device aids in diagnosing electrical issues.

- Compression Tester: This equipment assesses the engine’s health by measuring cylinder pressure, helping identify potential internal problems.

- Fuel Pressure Gauge: This tool checks the fuel delivery system’s performance, ensuring adequate pressure for optimal operation.

Additional Helpful Tools

- Torque Wrench: Ensures that bolts and nuts are tightened to the manufacturer’s specifications.

- Vacuum Gauge: Aids in diagnosing issues related to the intake system and engine performance.

- Battery Tester: Evaluates battery health and charging capabilities, preventing unexpected failures.

- Scan Tool Software: Enhances the functionality of an OBD-II scanner by providing in-depth analysis and data logging.

Understanding the Electrical System

The electrical framework of a vehicle plays a pivotal role in its overall functionality and performance. This intricate system encompasses various components that work collaboratively to ensure efficient operation and communication between different parts of the automobile.

Key Components of the Electrical System

- Battery: Acts as the primary power source, supplying energy to start the engine and power electrical accessories.

- Alternator: Converts mechanical energy into electrical energy, replenishing the battery and powering the electrical system while the engine runs.

- Fuses: Protect electrical circuits by breaking the connection in case of overload, preventing damage to components.

- Wiring Harness: A network of wires that transmits electrical signals and power throughout the vehicle.

- ECU (Electronic Control Unit): Manages various electrical functions and communicates between components for optimal performance.

Troubleshooting Common Electrical Issues

- Check the Battery: Ensure the battery terminals are clean and securely connected.

- Inspect Fuses: Examine fuses for any signs of damage or breakage.

- Test the Alternator: Verify the alternator is charging the battery properly.

- Examine Wiring: Look for any frayed or damaged wires that may affect connectivity.

- Scan for Error Codes: Use diagnostic tools to identify any electronic issues flagged by the ECU.

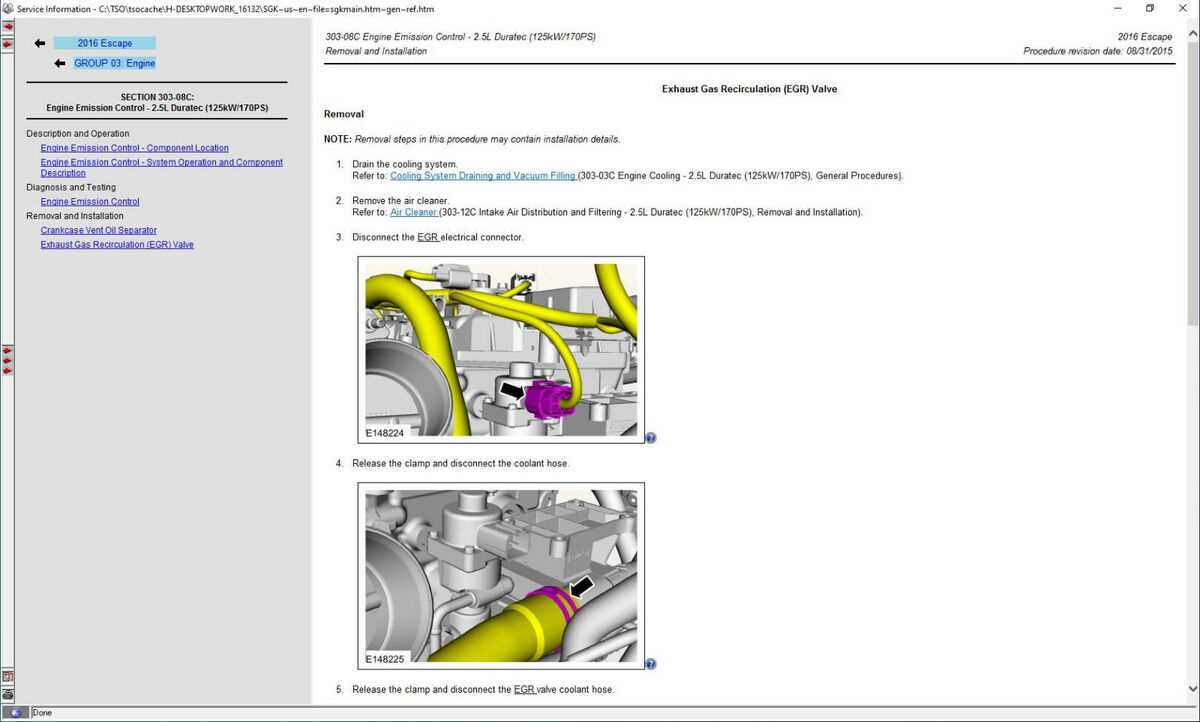

Engine Troubleshooting Techniques

Troubleshooting engine issues is essential for maintaining vehicle performance and reliability. Understanding common problems and employing effective diagnostic methods can save time and money. This section outlines several techniques to identify and resolve engine-related complications, ensuring smooth operation and longevity.

Identifying Symptoms

Recognizing symptoms is the first step in diagnosing engine issues. Unusual noises, decreased power, or warning lights on the dashboard can indicate underlying problems. Observing these signs and documenting their occurrence helps in pinpointing the specific area of concern.

Utilizing Diagnostic Tools

Employing diagnostic tools such as OBD-II scanners can provide valuable insights into engine performance. These devices read error codes and monitor various engine parameters, assisting in identifying malfunctions. Regular usage of these tools enhances troubleshooting efficiency and promotes proactive maintenance.

In summary, mastering troubleshooting techniques empowers vehicle owners to address engine issues effectively, ultimately contributing to improved performance and reduced repair costs.

Transmission Problems and Fixes

Issues with the transmission system can significantly impact the performance and reliability of a vehicle. Understanding common problems and their solutions is essential for maintaining optimal functionality. This section delves into frequent transmission-related complications, providing insights into their causes and effective methods for resolution.

One prevalent issue is slipping, where the vehicle unexpectedly changes gears or loses power during acceleration. This can stem from low fluid levels or worn components. Regularly checking and replenishing transmission fluid can help mitigate this problem. If slipping persists, it may be necessary to inspect and possibly replace the transmission fluid filter.

Another common concern is overheating. This often occurs when the transmission fluid is contaminated or insufficient. Overheating can lead to serious damage if not addressed promptly. Maintaining proper fluid levels and ensuring the cooling system is functioning efficiently are crucial preventive measures.

Shifting delays may also indicate underlying issues. This can be caused by various factors, including low fluid levels or malfunctioning sensors. Timely diagnosis is key; utilizing a diagnostic scanner can aid in identifying sensor faults or electronic issues. If necessary, replacing defective components can restore normal operation.

Finally, unusual noises during gear shifts may signal potential problems within the transmission. Grinding, clunking, or whining sounds warrant immediate attention. These noises can indicate worn gears or insufficient lubrication. Conducting a thorough inspection and addressing any identified wear can prevent further complications.

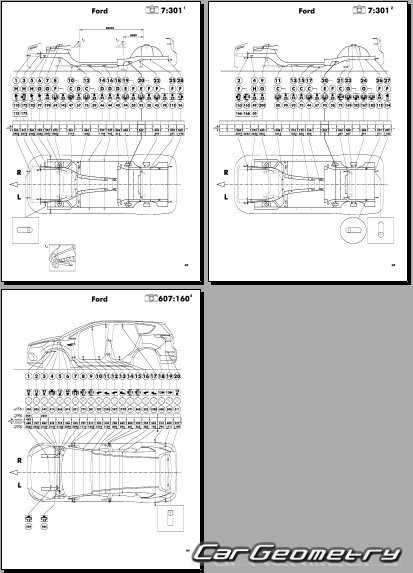

Suspension and Steering Components

The suspension and steering systems are essential for the overall performance and safety of a vehicle. These components work together to ensure a smooth ride, effective handling, and optimal tire contact with the road surface. Understanding the functions and configurations of these systems is crucial for proper maintenance and troubleshooting.

The suspension system primarily consists of springs, shock absorbers, and various linkages that support the vehicle’s weight and absorb road irregularities. The steering system, on the other hand, allows the driver to control the direction of the vehicle through a series of mechanical linkages and gears.

| Component | Function | Common Issues |

|---|---|---|

| Shock Absorber | Dampens the impact of bumps and maintains tire contact | Leaking fluid, reduced performance |

| Spring | Supports the vehicle’s weight and absorbs road shocks | Broken or sagging springs |

| Control Arm | Connects the wheel hub to the vehicle’s frame | Worn bushings, bending |

| Steering Rack | Converts rotational motion from the steering wheel into lateral movement of the wheels | Leakage, play in the steering |

| Ball Joint | Allows for smooth movement between the control arm and wheel hub | Worn joint, noise during movement |

Regular inspection and maintenance of these components can prevent many issues that lead to decreased performance and safety concerns. It is advisable to follow recommended service intervals and address any signs of wear or damage promptly.

Brake System Maintenance Guidelines

Regular upkeep of the braking mechanism is crucial for ensuring optimal vehicle performance and safety. A well-maintained braking system enhances responsiveness and extends the lifespan of components, ultimately providing a safer driving experience.

Inspection of Brake Components: Periodically examine the pads, rotors, and calipers for signs of wear and tear. Look for uneven surfaces, cracks, or significant thickness reduction in pads. Replace components that show signs of damage to prevent further issues.

Fluid Checks: Ensure the brake fluid is at the appropriate level and free from contaminants. Low or dirty fluid can lead to decreased braking efficiency. It is advisable to flush and replace the fluid as recommended by the manufacturer to maintain system integrity.

Testing Brake Performance: Conduct regular tests on the braking system to assess its responsiveness. Pay attention to any unusual noises, vibrations, or changes in pedal feel. Address any issues promptly to avoid compromising safety.

Professional Servicing: While some maintenance tasks can be performed independently, consulting a professional for complex issues or routine checks is advisable. Expert mechanics can provide insights and ensure that all components are functioning correctly.

Safety Features and Their Repairs

Modern vehicles are equipped with an array of safety systems designed to protect occupants and enhance driving stability. Understanding these features is crucial for effective maintenance and ensuring the longevity of the vehicle’s safety performance. Regular inspections and timely interventions can prevent malfunctions and keep all safety mechanisms functioning optimally.

Common Safety Systems

Among the essential safety components are airbags, anti-lock braking systems (ABS), and electronic stability control (ESC). Each of these systems plays a pivotal role in accident prevention and injury mitigation. Regular diagnostics can help identify issues such as sensor failures or warning light activations, ensuring that safety systems are responsive when needed.

Repair Considerations

Addressing safety feature malfunctions requires specialized knowledge and tools. For instance, airbag systems must be handled with care to avoid accidental deployment during repairs. Furthermore, software updates may be necessary for systems like ABS to maintain effectiveness. Engaging qualified professionals for these repairs not only ensures compliance with safety standards but also guarantees the reliability of crucial safety systems.