In the world of small engines, comprehending the intricacies of maintenance and troubleshooting is essential for ensuring optimal performance and longevity. Various models exhibit unique characteristics, and familiarizing oneself with these details can significantly enhance the user experience. This section aims to provide insight into the essential components and procedures that contribute to effective engine upkeep.

Regular maintenance is crucial for preventing potential issues and extending the lifespan of your equipment. By following systematic approaches to care, users can easily identify and rectify common malfunctions. This not only saves time but also reduces costs associated with professional services.

Furthermore, understanding the key features of your engine empowers you to make informed decisions during the repair process. Whether it’s troubleshooting minor issues or executing more complex tasks, having a solid foundation of knowledge facilitates a smoother and more efficient operation. Dive into the specifics and discover the best practices that will keep your machinery running like new.

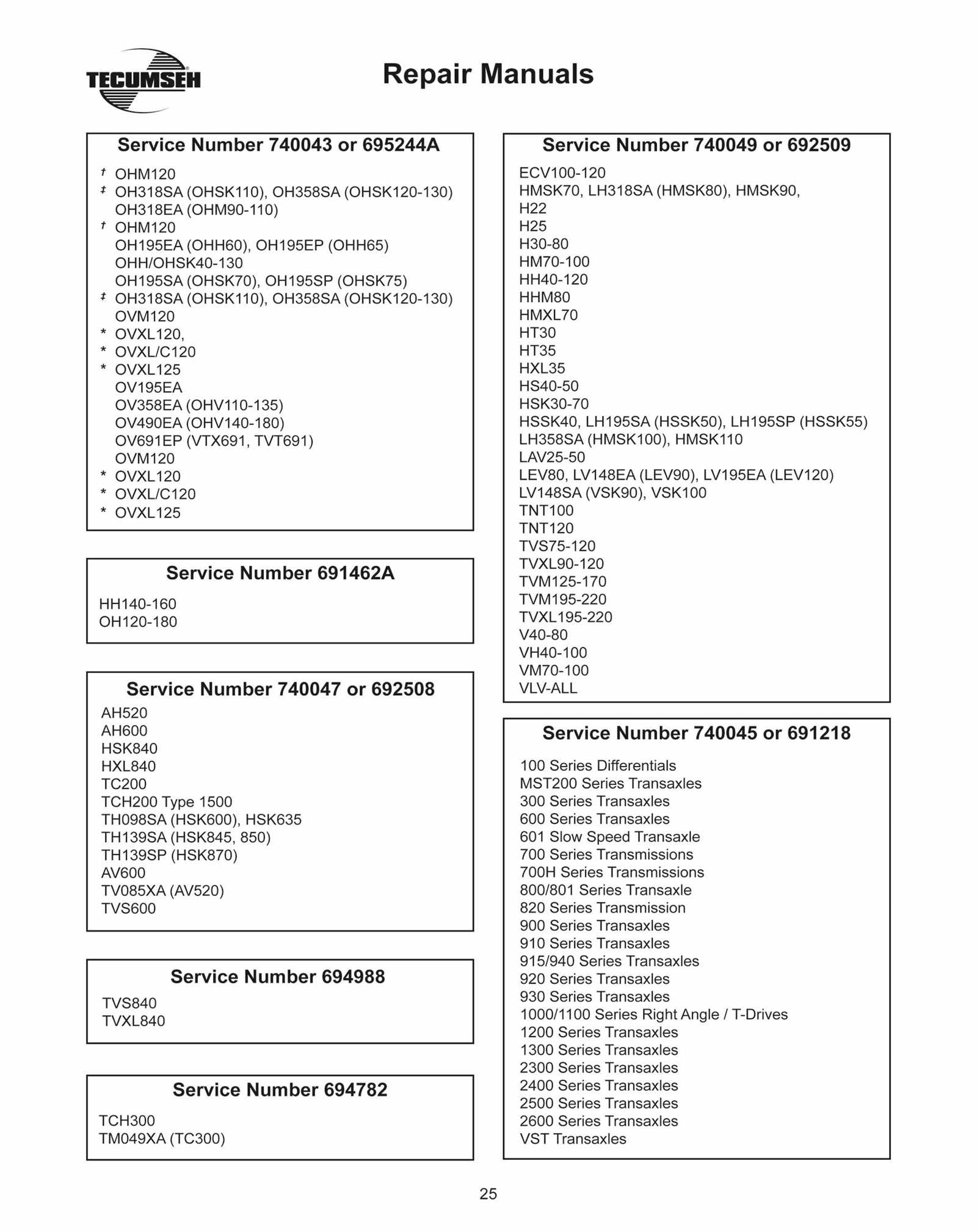

Tecumseh OV358EA Overview

This section provides an insightful look into a specific engine model, highlighting its key features and applications. Designed for reliable performance, this engine is commonly utilized in various outdoor equipment, ensuring efficiency and durability in demanding tasks.

The engine is characterized by its robust construction and user-friendly design, making it suitable for both novice and experienced operators. Its versatility allows it to power a range of machinery, including lawn mowers, generators, and snow throwers, thus serving multiple industries effectively.

| Feature | Description |

|---|---|

| Type | Air-cooled, single-cylinder engine |

| Displacement | Approx. 358 cc |

| Power Output | 15-20 HP depending on configuration |

| Fuel Type | Gasoline |

| Lubrication | Splash lubrication system |

| Applications | Lawn care, snow removal, and other outdoor machinery |

In summary, this engine exemplifies the blend of efficiency and strength, making it a favored choice for various applications. Its reliable performance and ease of maintenance contribute to its widespread use in the industry.

Common Issues with Tecumseh Engines

Engines from this manufacturer, known for their reliability, can experience a variety of problems over time. Understanding these common issues can help users diagnose and address concerns effectively, ensuring optimal performance and longevity.

Typical Problems Encountered

- Starting Difficulties: Many users report issues with the engine not starting. This can often be attributed to fuel delivery problems, electrical system failures, or issues with the ignition components.

- Overheating: Excessive heat can lead to engine damage. Common causes include low oil levels, clogged air filters, or insufficient cooling airflow.

- Fuel Leaks: Leaks in the fuel system can lead to reduced efficiency and pose safety risks. Regular inspections of hoses and connections are essential.

Maintenance Tips

- Regularly check and change the oil to maintain proper lubrication.

- Inspect and replace air filters as needed to ensure proper airflow.

- Keep fuel lines clean and free from debris to prevent leaks and starting issues.

Addressing these common challenges promptly can significantly enhance the performance and lifespan of the engine.

Understanding Engine Specifications

Engine specifications provide crucial insights into the performance and functionality of a power unit. They encompass various parameters that define how an engine operates, influencing everything from efficiency to power output. Grasping these details is essential for anyone looking to optimize engine performance or troubleshoot issues effectively.

Key specifications include displacement, which refers to the total volume of the engine’s cylinders, affecting power generation. Horsepower and torque ratings indicate the engine’s capability to perform work, while RPM (revolutions per minute) provides insight into operational speed. Additionally, fuel type and efficiency ratings inform users about the best practices for fuel consumption and overall cost-effectiveness.

Understanding these elements allows for better decision-making regarding maintenance, upgrades, and replacements. By familiarizing oneself with engine specifications, users can ensure they maximize the lifespan and performance of their equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of any machinery requires a proactive approach to upkeep. Regular attention to specific components can prevent premature wear and enhance overall performance. Following a few simple guidelines can make a significant difference in durability and efficiency.

Regular Inspections

Conduct frequent checks to identify signs of wear or potential issues. Look for leaks, unusual noises, and performance inconsistencies. Early detection of problems can prevent more significant damage and costly repairs down the line.

Proper Lubrication

Maintaining adequate lubrication is crucial for reducing friction and wear between moving parts. Use the recommended type of lubricant and ensure that all necessary components are well-greased. This practice not only enhances functionality but also minimizes the risk of overheating and mechanical failure.

Adhering to these maintenance tips will help in maximizing the life of your equipment, allowing for reliable operation and optimal performance over time. Regular care is essential to achieve the best results and prevent unexpected interruptions in service.

Essential Tools for Repairs

When it comes to maintaining and fixing small engines, having the right equipment is crucial for efficiency and effectiveness. The appropriate tools not only facilitate smoother operations but also enhance the quality of the work performed. Below is a list of essential items every enthusiast should have on hand.

- Wrenches: A set of adjustable and socket wrenches is vital for loosening and tightening various bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will be necessary for accessing different components.

- Pliers: Needle-nose and standard pliers are helpful for gripping, twisting, and cutting wire or small parts.

- Torque Wrench: Ensuring proper tension on fasteners is essential; a torque wrench helps achieve the manufacturer’s specifications.

- Multimeter: This device is invaluable for diagnosing electrical issues and testing circuits.

In addition to the basic tools, consider adding the following items for a more comprehensive toolkit:

- Fuel System Cleaner: Helps in maintaining the efficiency of the fuel delivery system.

- Oil Change Kit: Includes the necessary equipment for a proper oil replacement, ensuring optimal engine performance.

- Diagnostic Software: Useful for advanced troubleshooting and performance monitoring.

- Safety Gear: Gloves, goggles, and masks should always be worn to protect against potential hazards.

Having these essential tools at your disposal will significantly enhance your ability to conduct maintenance and address issues as they arise, leading to better performance and longevity of your equipment.

Step-by-Step Repair Instructions

This section provides detailed guidance for addressing common issues with small engines. Following these instructions will help ensure a thorough understanding of the process and lead to effective solutions.

1. Gather Necessary Tools and Materials

Before starting, assemble all required tools such as wrenches, screwdrivers, and pliers. Having replacement parts on hand will also facilitate a smoother workflow.

2. Disconnect Power Source

Ensure safety by disconnecting the power supply. This step is crucial to prevent any accidental starts while working on the equipment.

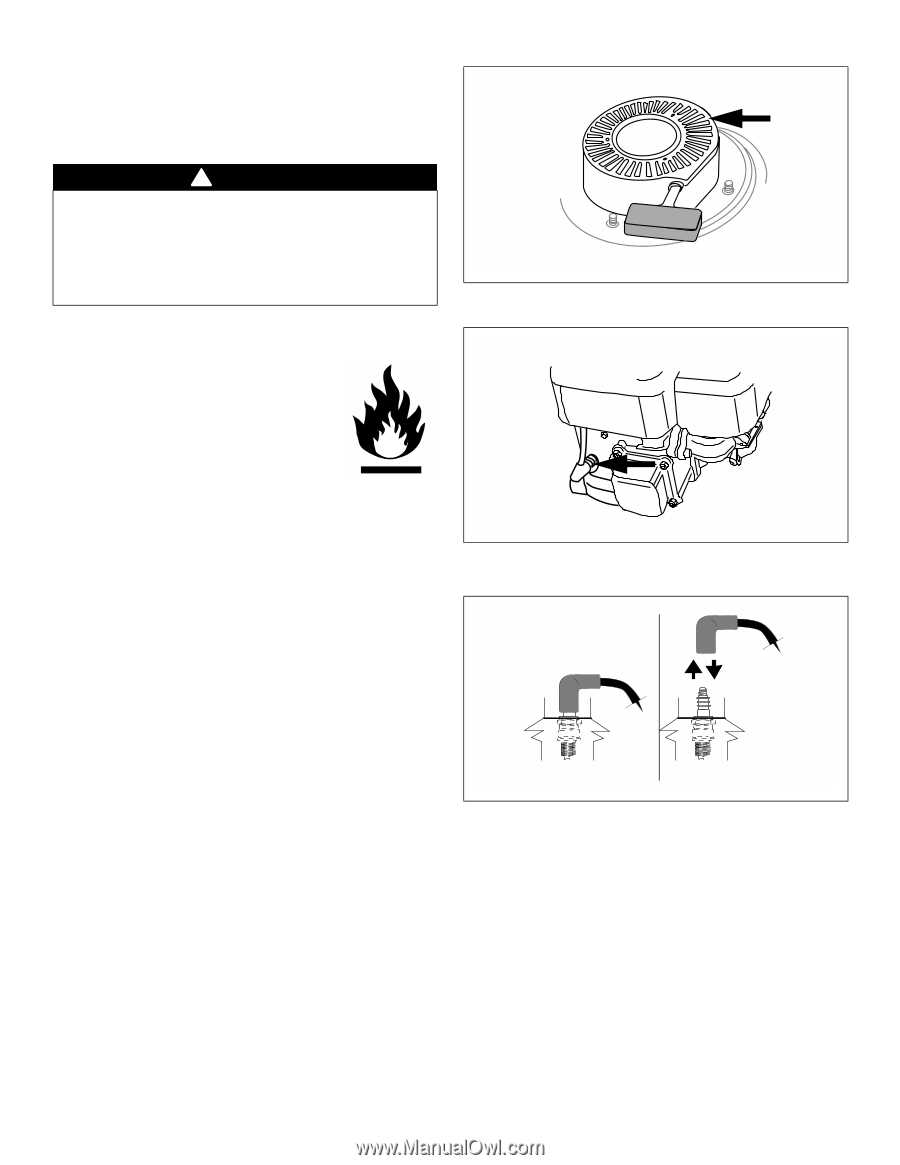

3. Remove Exterior Covers

Carefully unscrew and detach any outer covers to gain access to the internal components. Keep track of screws and parts to make reassembly easier.

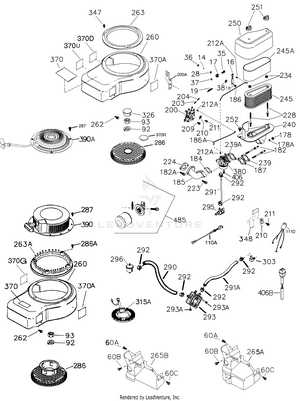

4. Inspect Internal Components

Examine the internal parts for signs of wear or damage. Look for cracks, corrosion, or any other issues that may require attention.

5. Replace or Repair Damaged Parts

If you identify any faulty components, either replace them with new parts or repair them as necessary. Ensure all replacements are compatible with the existing setup.

6. Reassemble and Test

After making necessary changes, carefully reattach the exterior covers and secure them properly. Once everything is back in place, reconnect the power source and perform a test run to ensure functionality.

7. Final Checks

After testing, conduct a final inspection to confirm everything is operating smoothly. Address any remaining concerns before returning the equipment to service.

Diagnosing Performance Problems

Identifying issues related to engine efficiency can be a challenging task. Proper evaluation is essential for ensuring optimal functionality and prolonging the lifespan of the equipment. A systematic approach helps isolate the root causes of poor performance, allowing for effective solutions.

Common Symptoms to Observe

When assessing the performance of an engine, several symptoms may indicate underlying issues. Pay attention to the following:

- Unusual noises during operation

- Difficulty starting or frequent stalling

- Poor acceleration or power loss

- Increased fuel consumption

- Excessive smoke or emissions

Steps for Diagnosis

To systematically diagnose performance problems, follow these steps:

- Visual Inspection: Examine the engine for visible damage, leaks, or loose connections.

- Check Fuel System: Ensure that the fuel supply is clean and unobstructed. Inspect filters and lines for blockages.

- Examine Air Intake: Confirm that the air filter is clean and that there are no obstructions in the air intake.

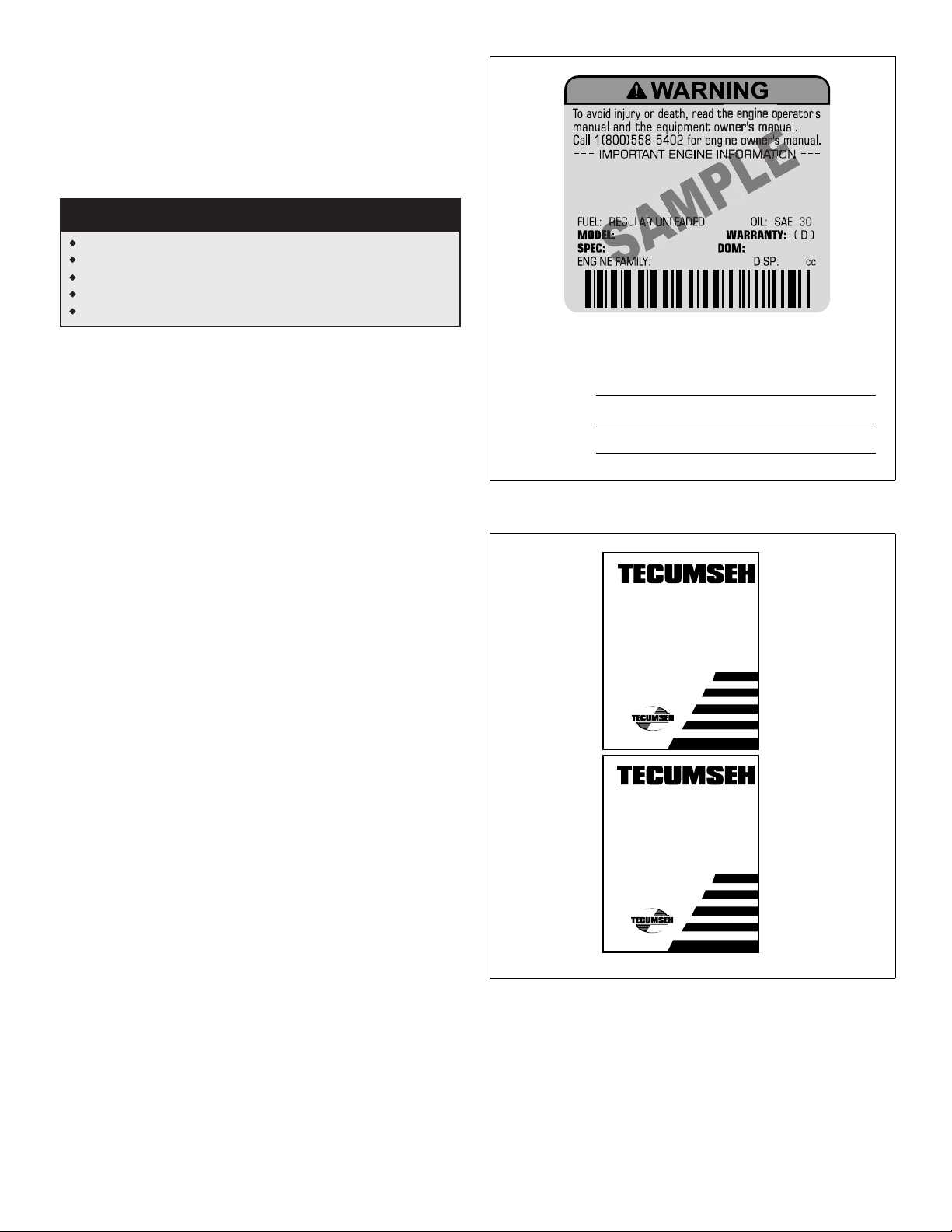

- Assess Spark Components: Inspect the spark plug and ignition system for wear or damage. Ensure proper firing.

- Monitor Performance: Take note of performance metrics during operation to identify patterns that correlate with the symptoms observed.

By following these steps, one can effectively pinpoint the factors contributing to performance degradation and implement appropriate corrective measures.

Replacing Key Engine Components

Maintaining optimal performance in small engines often requires the replacement of essential components. This process not only ensures longevity but also enhances efficiency and reliability. Understanding the correct procedures for component substitution is vital for achieving smooth operation.

Identifying Components for Replacement

Before initiating the replacement process, it is crucial to identify which parts are worn or malfunctioning. Common components that may need attention include the ignition system, carburetor, and fuel pump. Regular inspections can help detect issues early, allowing for timely intervention.

Steps for Successful Component Replacement

Once the necessary components have been identified, follow these steps to ensure a successful replacement:

- Preparation: Gather all tools and replacement parts required for the task.

- Disassembly: Carefully disassemble the engine components while keeping track of screws and parts.

- Replacement: Install the new components, ensuring they are securely fastened and properly aligned.

- Reassembly: Reassemble the engine, reversing the disassembly steps.

- Testing: After reassembly, conduct a thorough test to confirm that everything is functioning correctly.

Properly replacing key engine components will not only restore performance but also extend the life of the engine, providing peace of mind for users.

Safety Precautions During Repair

Ensuring safety while performing maintenance tasks is crucial for both the technician and the equipment. Following certain guidelines helps mitigate risks and fosters a secure working environment. Adopting a proactive approach to safety can prevent accidents and injuries.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Disconnect power sources before starting any work to avoid accidental energization.

- Work in a well-ventilated area to reduce the risk of inhaling harmful fumes or dust.

- Keep your workspace organized and free of clutter to prevent trips and falls.

- Use tools and equipment that are in good condition, ensuring they are suitable for the tasks at hand.

Additionally, be mindful of the following:

- Read all relevant documentation before beginning, ensuring you understand the processes involved.

- Be aware of potential hazards related to specific components, such as sharp edges or hot surfaces.

- Never work alone; having a partner can provide assistance in case of emergencies.

- Keep a first aid kit readily accessible and familiarize yourself with its contents.

By prioritizing safety, you contribute to a more efficient and productive work experience, minimizing the likelihood of unforeseen incidents.

Finding Replacement Parts Easily

Locating the right components for your equipment can be a straightforward process if you know where to look and how to approach it. Whether you are conducting maintenance or addressing an issue, having access to the necessary parts ensures that your machinery runs smoothly and efficiently.

Here are some effective strategies to help you find the right components:

- Online Retailers: Numerous online platforms specialize in parts for various machines. Websites such as Amazon, eBay, or specialized retailers often have extensive inventories.

- Local Suppliers: Visiting nearby hardware or machinery supply stores can yield immediate results. Local experts can also provide valuable advice.

- Manufacturer Websites: The official sites of manufacturers typically offer parts catalogs and can guide you to authorized dealers.

- Forums and Community Groups: Engaging with online communities can provide insights and recommendations on sourcing hard-to-find components.

By utilizing these resources, you can efficiently identify and obtain the necessary parts, ensuring that your equipment remains in optimal condition. Always verify compatibility before making a purchase to avoid unnecessary issues.

Resources for Further Assistance

When faced with challenges related to machinery, having access to reliable resources can significantly ease the troubleshooting process. This section highlights various avenues where individuals can seek help, from online communities to professional support services, ensuring that users can find the guidance they need effectively.

Online Communities

Engaging with fellow enthusiasts and experts in online forums can provide valuable insights and solutions. Here are some popular platforms:

| Platform | Description |

|---|---|

| A vast network of subreddits where users discuss a wide range of topics, including troubleshooting and maintenance. | |

| Facebook Groups | Dedicated groups focused on specific machinery types, offering peer support and shared experiences. |

| Specialized Forums | Forums tailored to specific brands or types of equipment, featuring expert advice and community-driven solutions. |

Professional Support

In situations requiring expert intervention, consider reaching out to certified technicians or authorized service centers. Their specialized knowledge can save time and ensure proper handling of complex issues.

| Service Type | Contact Method |

|---|---|

| Local Repair Shops | Visit in person or call for immediate assistance and advice. |

| Manufacturer Support | Contact through official websites or customer service lines for professional guidance. |

| Consulting Services | Engage with consultants who specialize in machinery for in-depth assessments and solutions. |