This section provides essential insights and instructions for the upkeep and enhancement of a specific vehicle’s power unit. By following a structured approach, users can ensure optimal performance and longevity of their machinery.

Understanding the fundamental components and their interactions is crucial. This resource outlines various techniques and recommendations to address common issues, ensuring a seamless operation. Each topic is designed to empower users with the knowledge necessary for effective handling and care.

From basic maintenance tips to advanced troubleshooting methods, this guide serves as a valuable tool for enthusiasts and professionals alike. Emphasizing practical advice, it aims to foster confidence in managing and improving the functionality of the unit.

Isuzu C240 Engine Overview

This section provides a comprehensive look at a specific power unit designed for various applications. Known for its durability and efficiency, this model is widely used in commercial vehicles and machinery. Its robust construction and reliable performance make it a preferred choice among users who demand longevity and consistency in their operations.

Specifications and Features

The power unit boasts an array of features that contribute to its effectiveness. With a moderate displacement, it strikes a balance between power output and fuel efficiency. Additionally, the configuration allows for smooth operation under varying load conditions, making it suitable for both urban and rural settings.

Applications

This power source is versatile, finding its place in numerous vehicles and equipment types. From light-duty trucks to agricultural machinery, its adaptability ensures that it meets the diverse needs of different sectors. Users appreciate its reliability, especially in demanding environments where performance is critical.

Common Issues with Isuzu C240

This section discusses frequent problems encountered with this particular model, highlighting key aspects that may affect performance and reliability. Understanding these issues can aid in better maintenance and troubleshooting for optimal functionality.

Overheating Problems

One of the most prevalent concerns involves excessive heat generation. This can stem from various factors, including inadequate coolant levels, malfunctioning thermostats, or blocked radiators. Regular checks on cooling systems are essential to prevent serious damage.

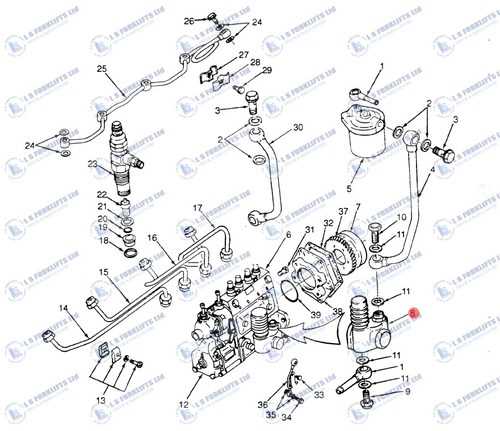

Fuel System Complications

Challenges within the fuel delivery system can lead to decreased efficiency and power loss. Issues may arise from clogged filters, failing injectors, or fuel pump malfunctions. Timely inspection and cleaning can significantly enhance performance and longevity.

Essential Tools for Engine Repair

When tackling the intricate task of revitalizing a vehicle’s internal components, having the right instruments at hand is crucial. The proper equipment not only enhances efficiency but also ensures precision in every task, leading to a successful outcome.

Basic Tool Set

- Wrenches: A variety of sizes is necessary to handle different fasteners.

- Sockets: A socket set will facilitate access to tight spaces and provide leverage.

- Screwdrivers: Both flathead and Phillips options are essential for various screws.

- Pliers: A sturdy pair can assist with gripping and twisting tasks.

Advanced Instruments

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications.

- Compression Tester: It helps assess the internal pressure of the components.

- Timing Light: Useful for setting the ignition timing accurately.

- Multimeter: Essential for diagnosing electrical issues within the system.

Equipping yourself with these fundamental and advanced tools will greatly enhance your capability to address complex issues effectively, leading to improved performance and longevity of the machinery.

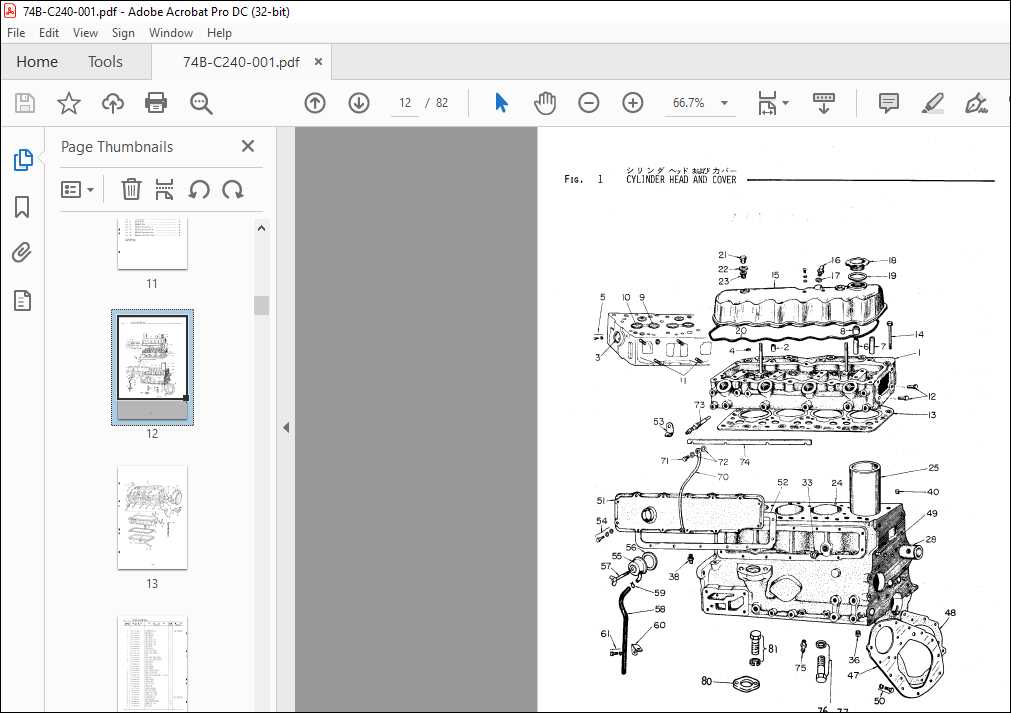

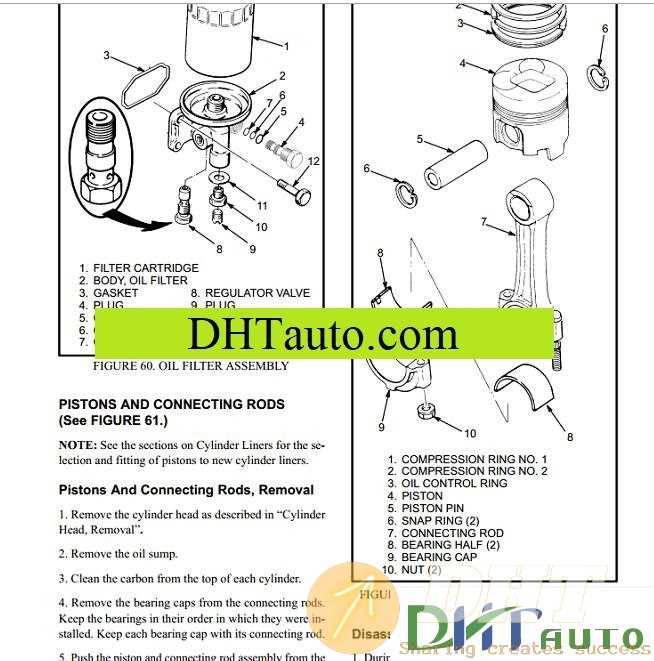

Disassembling the C240 Engine

Taking apart a mechanical unit is a crucial process that requires careful attention and methodical execution. This section outlines the steps necessary to successfully dismantle the power unit, ensuring that each component is handled with care to prevent damage and facilitate reassembly.

Begin by ensuring that all tools are organized and that the work area is clean. Start by removing any external attachments that may hinder access to the core components. Label each part as it is removed to simplify the reassembly process later on.

Next, proceed to detach the main housing carefully, taking note of the positioning of gaskets and seals. Pay close attention to the orientation of fasteners, as this information will be vital when putting everything back together. Using appropriate torque specifications for each bolt during disassembly will help avoid stripping threads.

Once the housing is off, inspect internal elements for wear or damage. Document any irregularities found, as this will be important for future maintenance or replacement. Continue disassembling additional parts, following the order specified in the documentation to ensure nothing is overlooked.

After all parts are removed, clean each component thoroughly before inspection. Proper disassembly sets the foundation for a successful rebuild, ensuring longevity and performance in the operational cycle.

Inspecting Engine Components

Thorough evaluation of mechanical parts is essential for maintaining optimal performance and longevity of the system. This process involves checking various elements for wear, damage, and proper function. Regular inspections can help identify issues early, preventing more severe complications down the line.

During the assessment, focus on key components such as the ignition system, fuel delivery apparatus, and moving parts. Each of these elements plays a crucial role in the overall functionality of the system. The following table outlines the primary components to inspect and the specific checks to perform:

| Component | Inspection Check |

|---|---|

| Ignition System | Check for spark plug wear and electrode condition. |

| Fuel Delivery | Inspect lines for leaks and clogs; verify pump operation. |

| Cooling System | Examine hoses for cracks; check radiator for leaks. |

| Lubrication | Assess oil levels; inspect filters for contamination. |

| Moving Parts | Look for signs of wear; check for proper lubrication. |

By systematically evaluating these areas, one can ensure that all components function harmoniously, promoting efficiency and preventing potential failures.

Rebuilding the Isuzu C240

Restoring a specific type of power unit can be a rewarding project, enhancing performance and longevity. This process involves meticulous attention to detail and a thorough understanding of the components involved. By following systematic steps, one can ensure a successful overhaul that meets operational standards.

Key steps in the rebuilding process include:

- Disassembly: Carefully take apart the unit, ensuring to document each step for reassembly.

- Inspection: Assess each component for wear and damage, identifying parts that require replacement.

- Cleaning: Thoroughly clean all parts to remove debris and contaminants, utilizing appropriate solvents.

- Replacement: Substitute worn or damaged components with new or refurbished parts to restore functionality.

- Reassembly: Methodically reassemble the unit, adhering to specifications and torque settings to ensure reliability.

- Testing: Conduct thorough tests to confirm performance meets desired criteria before the final installation.

Each phase demands precision and careful execution. By adhering to established practices and guidelines, one can successfully complete the project, resulting in enhanced efficiency and performance.

Replacing Gaskets and Seals

Maintaining the integrity of various components is crucial for optimal performance. Over time, gaskets and seals can wear out, leading to leaks and inefficiencies. This section covers the essential steps for replacing these critical elements to ensure a tight fit and prevent fluid loss.

Preparation and Tools Needed

Before beginning the replacement process, gather the necessary tools and materials. Proper preparation ensures a smooth operation and reduces the risk of errors.

| Tool/Material | Description |

|---|---|

| Gasket scraper | Used to remove old gaskets without damaging surfaces. |

| New gaskets and seals | Ensure compatibility with the specific application. |

| Torque wrench | For applying precise torque to fasteners. |

| Cleaning solvent | To clean surfaces before installation. |

Steps for Replacement

Follow these steps to replace gaskets and seals effectively:

- Start by disconnecting any necessary components to access the gasket or seal location.

- Carefully remove the old gasket or seal using the scraper.

- Clean the mating surfaces thoroughly with a solvent to ensure a proper seal.

- Position the new gasket or seal carefully, ensuring it aligns correctly.

- Reassemble the components, tightening fasteners to the manufacturer’s specifications.

Timing Belt Installation Guide

Proper installation of a timing belt is crucial for ensuring the optimal performance of the mechanical system. This section provides a step-by-step approach to effectively install the timing belt, ensuring all components are aligned and functioning correctly.

Preparation Steps

Before starting the installation, gather all necessary tools and components. Make sure to disconnect the power source and remove any obstructions that may hinder access to the belt area. Familiarize yourself with the specific configuration and alignment requirements of the system to avoid any missteps during installation.

Installation Procedure

Begin by aligning the pulleys according to the specified timing marks. Once aligned, gently place the new belt onto the pulleys, ensuring it is seated properly in the grooves. Gradually tension the belt according to the manufacturer’s specifications, checking for any slack or misalignment. Finally, reassemble any removed components and perform a thorough inspection to confirm everything is securely in place.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for optimal performance and longevity. Regular attention to this critical component can prevent issues that lead to reduced efficiency and costly repairs.

- Regular Inspection: Periodically check for leaks and corrosion in fuel lines and connections. Look for any signs of wear that may require immediate attention.

- Replace Fuel Filters: Change fuel filters as per the manufacturer’s recommendations. Clogged filters can restrict flow and affect performance.

- Use Quality Fuel: Always opt for high-quality fuel from reputable sources. Contaminated fuel can lead to various problems in the fuel system.

- Check Fuel Pump Functionality: Ensure the fuel pump is operating correctly. Listen for unusual noises that may indicate a malfunction.

- Inspect Injectors: Clean or replace fuel injectors as necessary. Dirty injectors can cause poor combustion and reduced efficiency.

By following these maintenance practices, you can enhance the reliability of your fuel system and avoid unexpected issues down the road.

Electrical Troubleshooting Steps

Identifying and resolving electrical issues requires a systematic approach to ensure proper functionality. This section outlines key methods for diagnosing common problems related to the power system, focusing on testing components, verifying connections, and understanding potential faults.

Step 1: Visual Inspection

Begin by conducting a thorough visual examination of all electrical components. Look for signs of wear, corrosion, or loose connections. Damaged wires can often lead to operational failures. Ensure that all connectors are secure and that there are no exposed wires that could cause shorts.

Step 2: Testing Components

Utilize a multimeter to check voltage levels at various points within the circuit. Measuring resistance can also help identify faulty parts. If readings are outside the expected range, consider replacing the affected components. Follow the circuit path logically to isolate issues effectively.

Testing Engine Performance

Evaluating the functionality of a power unit is crucial for ensuring optimal operation and longevity. This process involves a systematic approach to assess various parameters that influence overall performance. By conducting thorough diagnostics, one can identify areas needing enhancement and achieve the desired efficiency.

To begin with, measuring compression levels is fundamental. Adequate compression ensures that the internal processes operate smoothly. Low readings may indicate issues with seals or valves, prompting further investigation.

Next, monitoring fuel delivery is essential. An inconsistent supply can hinder performance and lead to inefficiencies. Checking the injectors for clogs or faults is a necessary step in this evaluation.

Furthermore, analyzing exhaust emissions provides insights into combustion efficiency. High levels of pollutants can signal incomplete combustion, requiring adjustments in fuel mixture or timing.

Finally, testing the cooling system’s effectiveness is vital. Overheating can cause significant damage, so ensuring that the cooling mechanisms are functioning correctly is imperative for maintaining optimal conditions.

In conclusion, a comprehensive assessment of these elements will lead to improved functionality and reliability, ensuring that the unit operates at peak performance.

Preventive Maintenance Recommendations

Implementing regular maintenance practices is crucial for ensuring optimal performance and longevity of your vehicle’s components. By adhering to a systematic approach, you can significantly reduce the likelihood of unexpected failures and enhance the overall reliability of your machinery.

Routine Inspections: Conducting periodic assessments of critical parts is essential. Check for any signs of wear, leaks, or damage, and address issues promptly to prevent further complications.

Fluid Checks: Regularly monitor and replace essential fluids, including lubricants and coolants, to maintain efficient operation and safeguard against overheating or excessive friction.

Filter Replacements: Timely replacement of filters is vital for preserving the quality of fluids and preventing contaminants from affecting performance. Ensure that air, fuel, and oil filters are changed as recommended by the manufacturer.

Belts and Hoses: Inspect belts and hoses for signs of cracking or fraying. Replacing worn or damaged components before they fail can save time and avoid costly repairs.

Calibration: Regularly calibrate the various systems to ensure they function within the specified parameters. This helps in identifying any deviations early on and allows for corrective measures to be taken.

Record Keeping: Maintain detailed records of all maintenance activities, including dates and types of services performed. This information can help in tracking performance trends and scheduling future maintenance effectively.

Finding Replacement Parts

Locating suitable components for machinery maintenance can be a challenging task. Understanding where to search and what factors to consider in replacements is essential for achieving optimal functionality and extending equipment lifespan.

Key Considerations for Sourcing Parts

When looking for replacement components, it’s crucial to verify compatibility, quality, and availability. Prioritize parts from reputable suppliers and verify that they meet necessary specifications. This ensures they will integrate seamlessly, providing reliable performance.

Comparing Suppliers and Options

Comparing several suppliers can help you find the best value for quality parts. Review warranties, delivery times, and return policies to make informed choices. Often, specialist vendors can offer tailored advice and support that general suppliers may lack.

| Supplier |

|---|