When it comes to ensuring the longevity and optimal performance of your watercraft’s propulsion system, having a comprehensive resource at your fingertips is invaluable. This guide offers insights into the intricacies of marine engine care, catering to both novice enthusiasts and seasoned experts alike. Understanding the core elements of maintenance can significantly enhance the reliability of your vessel on the water.

From troubleshooting common issues to performing routine service tasks, this resource delves into practical advice that empowers you to tackle various challenges confidently. Whether you’re facing performance hiccups or simply aiming to maintain peak efficiency, acquiring knowledge about your engine’s workings is crucial.

Investing time in familiarizing yourself with the mechanics and procedures not only ensures a smoother sailing experience but also saves you from potential setbacks. With clear, step-by-step guidance, you can navigate the complexities of marine engine upkeep, allowing you to enjoy your time on the water without worry.

Understanding Chrysler Outboard Motors

In the world of marine propulsion, certain engines stand out due to their robust design and reliability. These power units are engineered for both performance and ease of use, making them a popular choice among boating enthusiasts. A solid grasp of their components and functionality is essential for maximizing their potential on the water.

The construction of these marine engines typically includes a combination of durable materials and innovative technology. This ensures not only longevity but also efficient operation under various conditions. Familiarity with the key parts, such as the fuel system, ignition, and cooling mechanisms, can greatly enhance the user experience.

Moreover, understanding the maintenance requirements is crucial for ensuring optimal performance. Regular inspections and timely interventions can prevent common issues, prolonging the lifespan of the engine. By becoming acquainted with troubleshooting techniques, users can address minor problems before they escalate, ultimately saving time and resources.

Whether used for leisurely outings or more demanding applications, these marine engines provide a reliable means of travel on the water. Knowledge of their workings fosters a deeper appreciation and confidence in managing such equipment, paving the way for memorable adventures on the waves.

Common Issues with Chrysler Outboards

Many boat enthusiasts encounter a range of challenges with their marine propulsion systems. Understanding these frequent problems can aid in effective troubleshooting and maintenance, ensuring a smoother experience on the water.

Engine Performance Problems

One of the most common difficulties faced is related to engine performance. This can manifest as poor acceleration, stalling, or rough idling. Often, these issues are linked to fuel delivery or ignition system malfunctions.

Cooling System Failures

Another critical area of concern is the cooling system. Overheating can lead to severe damage if not addressed promptly. Clogged water intakes or faulty thermostats are typical culprits in these scenarios.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Poor acceleration | Fuel blockage or ignition failure | Inspect fuel lines and spark plugs |

| Stalling | Air intake obstruction | Clean air filters and check intake |

| Overheating | Clogged water intake | Clear debris and flush cooling system |

| Rough idling | Improper fuel mixture | Adjust fuel and oil mixture ratio |

Tools Required for Repairs

To effectively maintain and service marine engines, a variety of instruments and equipment are essential. Having the right tools at your disposal not only facilitates the process but also enhances accuracy and safety during maintenance tasks.

Essential Tools

Basic maintenance requires a selection of fundamental instruments. Wrenches and screwdrivers in various sizes are indispensable for loosening and tightening components. Additionally, pliers and cutters assist in handling wires and hoses efficiently.

Advanced Equipment

For more complex tasks, specific diagnostic and measurement tools become necessary. Multimeters are crucial for electrical testing, while compression gauges help assess engine performance. Moreover, an engine hoist can be invaluable when lifting heavy components for thorough inspection or replacement.

Step-by-Step Maintenance Guide

Regular upkeep of your marine engine is essential for ensuring optimal performance and longevity. This guide provides a comprehensive approach to maintaining your equipment, focusing on key areas that require attention and care. By following these steps, you can enhance reliability and prevent potential issues during operation.

Here is a structured plan for effective maintenance:

| Step | Action | Frequency |

|---|---|---|

| 1 | Inspect and clean the fuel system components. | Every 100 hours or before long trips |

| 2 | Check the oil levels and replace if necessary. | Every 50 hours |

| 3 | Examine the cooling system for debris and blockages. | Every season |

| 4 | Test and clean electrical connections and battery terminals. | Every 6 months |

| 5 | Inspect the propeller for damage and ensure it is securely fastened. | Before each use |

| 6 | Verify the integrity of all hoses and seals. | Annually |

Following this systematic approach will not only keep your engine running smoothly but will also save you time and resources in the long run. Always refer to specific guidelines and safety precautions relevant to your equipment.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a marine engine can be a challenging yet crucial task. Understanding how to systematically approach these malfunctions is essential for effective troubleshooting. By following a structured method, one can pinpoint the source of the problem and ensure reliable operation.

Start by gathering tools such as a multimeter and a wiring diagram. These instruments will assist in measuring voltage, current, and resistance, which are vital for diagnosing faults. Familiarizing oneself with the layout of the electrical components will streamline the inspection process.

Begin with visual inspections. Look for signs of corrosion, loose connections, or damaged wires. Pay close attention to terminals and connectors, as these are common points of failure. A thorough check can often reveal issues that are easy to fix, saving time and effort in the long run.

Next, test the battery. A weak or dead battery can lead to numerous complications. Use the multimeter to check the voltage; it should typically read around 12.6 volts when fully charged. If the reading is low, consider recharging or replacing the battery.

Evaluate the fuses as well. A blown fuse can interrupt the flow of electricity, causing specific systems to malfunction. Replace any faulty fuses and retest the affected circuits to see if functionality is restored.

Lastly, examine the electrical components themselves, such as the starter and ignition system. Testing these parts individually can help isolate the issue. By applying methodical troubleshooting techniques, one can effectively identify and rectify electrical challenges, ensuring optimal performance and safety.

Fuel System Troubleshooting Techniques

Identifying and resolving issues within the fuel delivery system is essential for optimal engine performance. A well-functioning fuel mechanism ensures that the engine receives the right amount of fuel at the right time. By systematically diagnosing potential problems, users can restore functionality and efficiency to their equipment.

Here are some common troubleshooting methods:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | No fuel reaching the engine | Check fuel lines and connections for blockages or leaks |

| Engine misfires | Incorrect fuel mixture | Inspect and adjust the fuel mixture settings |

| Poor acceleration | Clogged fuel filter | Replace the fuel filter |

| Excessive smoke | Overrich fuel mixture | Inspect the carburetor or fuel injectors for malfunction |

| Unusual engine noise | Air in the fuel system | Purge the fuel system and check for air leaks |

Regular maintenance and careful observation of the fuel system can prevent many common issues. Following a structured approach to troubleshooting can save time and improve the overall reliability of the engine.

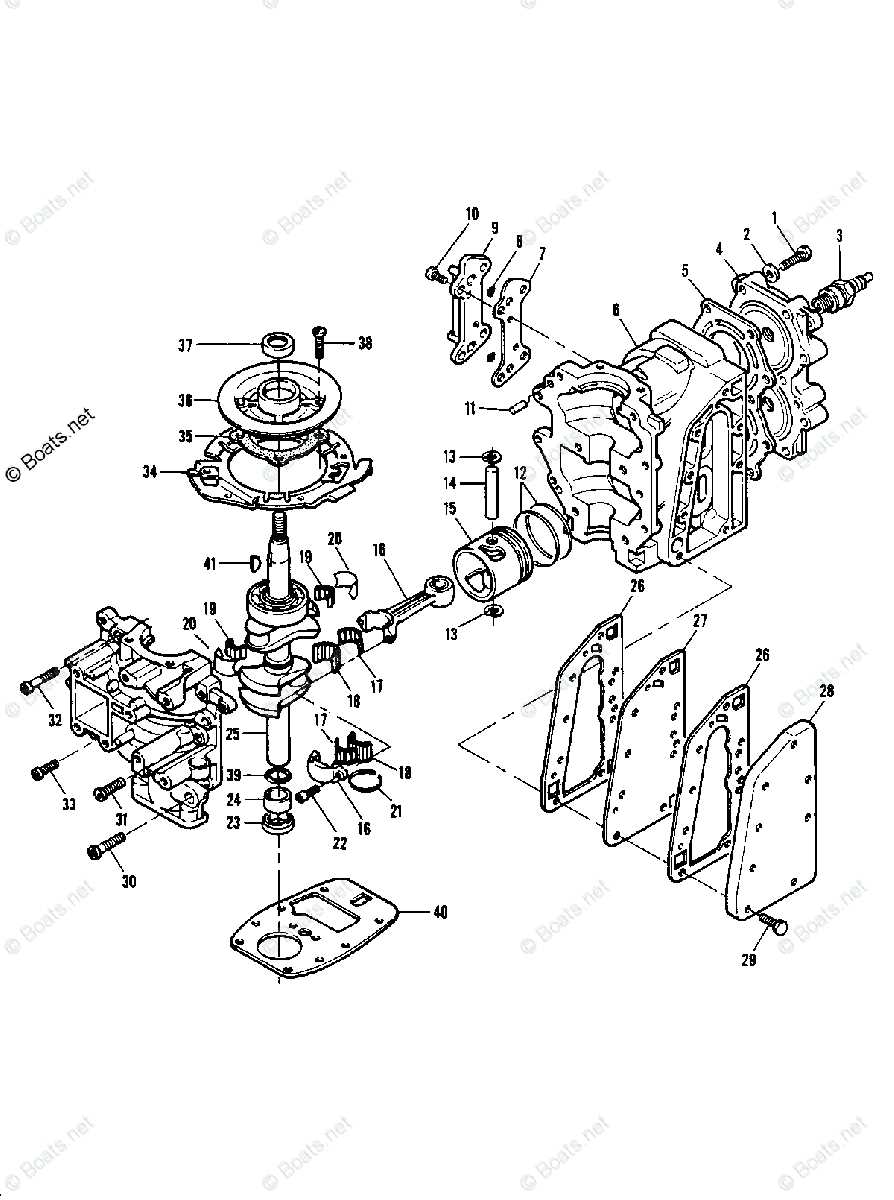

Rebuilding the Carburetor Effectively

Revitalizing the fuel delivery system is a crucial aspect of enhancing performance. This process ensures that the engine runs smoothly and efficiently, reducing issues related to fuel mixture and combustion. A thorough approach not only improves functionality but can also extend the lifespan of the engine components.

Gathering Necessary Tools and Parts

Before diving into the refurbishment, assemble the essential tools and replacement components. Standard tools include screwdrivers, wrenches, and cleaning supplies. Ensure you have gaskets, O-rings, and jets ready for installation. Having everything on hand will streamline the process and minimize downtime.

Step-by-Step Rebuilding Process

Begin by disassembling the unit carefully, taking note of the arrangement of parts for easier reassembly. Clean all components thoroughly to remove dirt and deposits that may hinder performance. Inspect each piece for wear and tear, replacing any that are damaged. Once cleaned and checked, reassemble the unit in the reverse order, ensuring all seals are tight. Proper adjustment of the mixture screws is vital for optimal performance, so refer to specifications during this stage.

By following these guidelines, you can effectively enhance the efficiency and reliability of your engine’s fuel system.

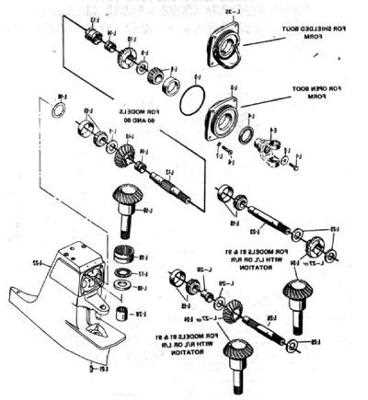

Replacing Worn Propellers and Parts

Maintaining optimal performance of your vessel requires attention to various components, particularly those that are subject to wear over time. This section focuses on the significance of replacing damaged or inefficient elements to ensure smooth operation and enhance efficiency. Regular checks can prevent further complications and improve overall handling.

Identifying Worn Components

Recognizing signs of deterioration is essential. Common indicators include vibrations, reduced speed, and increased fuel consumption. Regular inspections can help in identifying parts that may need replacement before they lead to more significant issues.

Replacement Procedure

The process of swapping out worn elements involves several steps. First, ensure the vessel is securely positioned. Gather necessary tools and replacement components. Follow the steps outlined below for a seamless replacement:

| Step | Description |

|---|---|

| 1 | Secure the vessel and ensure it is stable. |

| 2 | Remove the damaged part using appropriate tools. |

| 3 | Inspect the surrounding area for any additional wear. |

| 4 | Install the new component, ensuring proper alignment. |

| 5 | Test the system to confirm functionality and stability. |

By promptly addressing wear and tear, you not only maintain the performance of your vessel but also prolong its lifespan, ensuring many enjoyable outings on the water.

Winterizing Your Outboard Motor

Preparing your marine engine for the colder months is essential to ensure its longevity and optimal performance. This process involves a series of steps that protect key components from the harsh effects of winter weather, preventing damage and wear during storage.

Start by thoroughly cleaning the engine and removing any debris or salt buildup. Next, ensure the fuel system is treated with a stabilizer to prevent degradation. It’s crucial to run the engine for a short period after adding the stabilizer, allowing it to circulate throughout the fuel lines and injectors.

After handling the fuel, drain the cooling system to eliminate any remaining water, which can freeze and cause significant damage. This may involve flushing the system with a suitable solution. Additionally, check and replace the oil if necessary, as old oil can contain contaminants that may harm the engine over time.

Finally, inspect all electrical components and connections, ensuring they are clean and secure. Covering the engine with a protective tarp will shield it from dust and moisture during the off-season. By taking these precautionary measures, you will help maintain your marine engine’s reliability and efficiency for the next boating season.

Choosing the Right Oil and Lubricants

Selecting the appropriate oil and lubricants is crucial for maintaining the efficiency and longevity of your marine engine. The right products ensure smooth operation, reduce wear, and enhance performance under various conditions. Understanding the specific requirements of your engine can help you make informed decisions and protect your investment.

Types of Oils and Their Uses

Different types of oils serve distinct purposes, and choosing the correct one depends on several factors, including engine type and operating environment. Below is a summary of common oil types used in marine applications:

| Oil Type | Use Case |

|---|---|

| Mineral Oil | Basic lubrication for older engines |

| Synthetic Oil | Enhanced performance in high-stress conditions |

| Biodegradable Oil | Environmentally friendly option for eco-conscious users |

| Two-Stroke Oil | Designed specifically for two-stroke engines |

| Four-Stroke Oil | Best for four-stroke engines, offering better protection |

Choosing the Right Lubricants

Lubricants play a vital role in reducing friction and heat within your engine. Selecting the right lubricants based on manufacturer specifications can significantly enhance performance and reliability. Be sure to consult your engine’s guidelines to determine the ideal products that match its operational demands.

Essential Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the integrity of the equipment. Adhering to fundamental safety guidelines can prevent accidents and promote a secure working environment.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the work area is well-lit and free from clutter to minimize hazards.

- Disconnect power sources before beginning any maintenance to avoid accidental activation.

In addition to general precautions, it’s vital to follow specific safety measures tailored to the equipment in use:

- Review and understand the equipment’s specifications and limitations before starting work.

- Use tools that are suitable for the job and in good condition to prevent malfunctions.

- Keep a first-aid kit readily accessible in case of emergencies.

By implementing these precautions, individuals can ensure a safer and more efficient maintenance experience.

Resources for Chrysler Outboard Owners

For enthusiasts and owners of marine engines, having access to reliable information and tools is essential for optimal performance and longevity. This section provides valuable resources, including guides, forums, and parts suppliers, to help users maintain and troubleshoot their watercraft propulsion systems effectively.

Online Communities

Joining online forums and communities dedicated to marine engines can be incredibly beneficial. These platforms allow users to share experiences, ask questions, and find solutions to common issues.

Essential Resources

| Resource Type | Description | Link |

|---|---|---|

| Forums | Active discussions and advice from experienced users. | Boating Forum |

| Parts Suppliers | Reputable sellers for replacement components and accessories. | Marine Parts |

| Tutorial Videos | Step-by-step visual guides on maintenance tasks. | YouTube |

| Technical Blogs | In-depth articles covering troubleshooting and care. | Boat Engineer |