The world of automotive craftsmanship encompasses a wide range of knowledge, particularly when it comes to the upkeep of power sources. Understanding the intricacies of these mechanical systems can greatly enhance performance and longevity. This guide aims to provide enthusiasts with the essential insights needed to ensure their vehicles operate smoothly and efficiently.

Exploring the nuances of these systems involves delving into various techniques and practices that can aid in diagnosing and resolving common challenges. From routine inspections to detailed procedures, each step plays a vital role in maintaining optimal functionality. Gaining familiarity with the components and their interactions will empower individuals to take charge of their automotive journey.

Moreover, this resource will highlight the significance of regular maintenance schedules, offering tips and tricks for maximizing efficiency and minimizing wear. Whether tackling minor adjustments or addressing more significant issues, having a comprehensive understanding of these mechanical marvels is crucial for any dedicated enthusiast. Join us as we embark on this informative exploration, paving the way for successful vehicle management.

Toyota 2F Engine Overview

The 2F power unit represents a blend of robust design and dependable performance, tailored for various applications. Renowned for its durability, this system is a preferred choice among enthusiasts and professionals alike. Its construction reflects a commitment to strength and efficiency, making it suitable for a range of tasks.

Featuring a inline six-cylinder layout, this model is known for its smooth operation and reliable torque delivery. The configuration aids in achieving a harmonious balance between power and fuel economy. Moreover, its simple maintenance requirements enhance its appeal, allowing users to perform essential tasks with ease.

The 2F variant incorporates advanced features that contribute to its versatility. These enhancements ensure optimal performance in both on-road and off-road conditions. Whether utilized in recreational vehicles or commercial applications, this unit has established a reputation for resilience and adaptability, providing users with confidence in their choice.

Common Issues with the 2F Engine

The 2F powertrain is known for its robustness, yet it is not without its challenges. Over time, several typical problems may arise, affecting performance and reliability. Understanding these issues can assist in identifying symptoms early, ultimately prolonging the lifespan of this power unit.

Some frequent concerns include overheating, oil leaks, and irregular noise. Regular maintenance and prompt attention to these matters can make a significant difference in maintaining optimal functionality.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Overheating | Temperature gauge rising, coolant loss | Check coolant levels, inspect radiator, and replace thermostat |

| Oil Leaks | Visible oil spots, low oil levels | Examine seals and gaskets; replace worn components |

| Irregular Noise | Knocking, tapping, or grinding sounds | Inspect for loose components; check for proper lubrication |

Essential Tools for Engine Repair

Having the right instruments is crucial for maintaining and restoring vehicle performance. The following items will assist in achieving effective results during the maintenance process. Each tool plays a specific role, ensuring that tasks are completed efficiently and safely.

- Wrenches: These are vital for loosening and tightening various fasteners.

- Sockets: A socket set allows for easy access to nuts and bolts in tight spaces.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Impact Driver: A powerful tool for removing stubborn screws and bolts.

- Diagnostic Scanner: Helps in identifying issues by reading error codes from the system.

In addition to these essentials, consider incorporating the following items into your toolkit:

- Jack and Jack Stands: For safely lifting the vehicle to access the underside.

- Oil Filter Wrench: Designed specifically for removing oil filters without damaging them.

- Pliers: Useful for gripping and manipulating small components.

- Screwdrivers: A variety of sizes and types for different screws.

- Shop Manual: A reference guide for specific procedures and specifications.

Equipping yourself with these essential instruments will pave the way for successful maintenance and restoration tasks. Understanding the purpose of each tool and utilizing them effectively can enhance your overall efficiency.

Step-by-Step Disassembly Guide

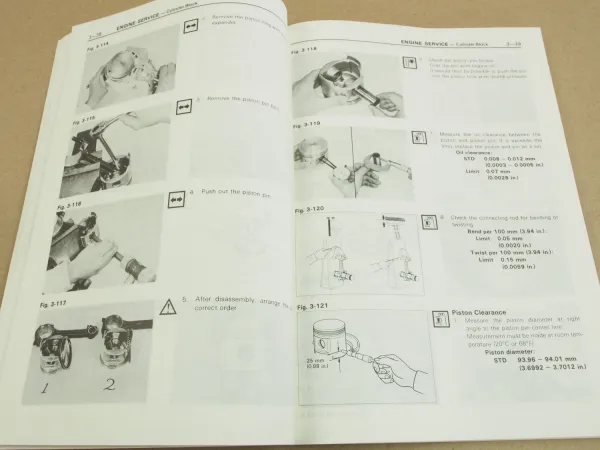

This section provides a detailed approach to the careful breakdown of a mechanical unit. By following these steps, you will ensure that each component is methodically removed and organized, facilitating a smooth reassembly process. Understanding the order and techniques involved will greatly aid in preventing damage to delicate parts.

Preparation and Tools Needed

Before starting the disassembly process, gather the necessary tools, including wrenches, screwdrivers, and pliers. It’s crucial to work in a clean, well-lit environment. Additionally, ensure that you have a workspace where you can lay out components and keep track of small items, such as nuts and bolts.

Disassembly Steps

1. Disconnect Power Sources: Always begin by disconnecting any power supplies to avoid accidents. This includes removing batteries and unplugging electrical connections.

2. Remove Outer Covers: Start by taking off any protective coverings or casings. This will give you access to the internal components that need to be disassembled.

3. Document the Process: As you proceed, take notes or photos of each step. This documentation will serve as a valuable reference during reassembly.

4. Carefully Take Off Components: Begin removing parts in a systematic manner, starting from the top and working your way down. Always use the appropriate tools to prevent stripping screws or damaging fittings.

5. Organize Parts: As you remove each piece, place it in labeled containers or areas. This practice will save you time and effort when you need to locate specific items later.

Following these guidelines will help maintain order and minimize the risk of losing parts during the breakdown process.

Inspecting Engine Components Effectively

Assessing the various parts of a power unit is crucial for maintaining optimal performance and longevity. By conducting thorough examinations, individuals can identify potential issues before they escalate into significant problems. This process not only enhances reliability but also ensures that the system operates smoothly.

Key Areas of Focus

When evaluating the critical elements of a power unit, it’s essential to concentrate on specific areas that often require attention. Regular inspections can help in pinpointing wear, damage, or any irregularities that may affect functionality.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Piston Rings | Excessive oil consumption, low compression | Replace if worn |

| Gaskets | Oil leaks, coolant leaks | Inspect and replace if damaged |

| Valves | Unusual noises, loss of power | Adjust or replace as necessary |

| Crankshaft | Vibration, knocking sounds | Check alignment and replace if needed |

Utilizing Appropriate Tools

Employing the right instruments during the inspection process significantly enhances accuracy. Tools such as calipers, pressure gauges, and inspection mirrors can provide insights into the condition of the parts being assessed. Consistent use of these instruments facilitates more informed decisions regarding maintenance and necessary interventions.

Reassembling the 2F Engine Correctly

Putting everything back together after disassembly is a crucial step in ensuring optimal performance and longevity. A careful approach during reassembly helps to prevent issues and ensures that all components function harmoniously. This section outlines essential practices for achieving a successful assembly process, focusing on precision and attention to detail.

Essential Tools and Equipment

Having the right tools at your disposal is vital for a smooth reassembly experience. Below is a list of recommended tools that will aid in the process:

| Tool | Purpose |

|---|---|

| Torque Wrench | To apply precise torque settings on bolts and fasteners |

| Socket Set | For loosening and tightening various fasteners |

| Gasket Scraper | To remove old gaskets and ensure a clean sealing surface |

| Cleaning Supplies | For keeping parts free of dirt and debris |

| Sealant | To create a reliable seal between components |

Step-by-Step Assembly Process

Following a systematic approach to reassembly can significantly reduce the risk of errors. Begin by organizing parts and ensuring that everything is clean and free from contaminants. Then, proceed with the following steps:

1. Install the crankshaft, ensuring that it is aligned properly.

2. Attach connecting rods and pistons, using the appropriate torque specifications.

3. Secure the cylinder head, making sure to follow the recommended sequence for tightening.

4. Finally, connect all ancillary components, such as the intake and exhaust systems.

Understanding Engine Timing Adjustments

The precision of a power unit’s operation is vital for optimal performance and longevity. Adjustments to the synchronization of various components ensure that the system runs smoothly and efficiently. Understanding how these modifications impact overall functionality is essential for anyone looking to maintain or enhance performance.

Proper calibration of timing elements is crucial. If the alignment is off, it can lead to a range of issues, from decreased efficiency to more serious malfunctions. Regular checks and adjustments can prevent such problems, helping to keep the system running at its best.

It’s important to recognize that timing settings can vary based on several factors, including wear and tear, usage patterns, and environmental conditions. Regular monitoring and timely adjustments will contribute to a reliable and robust system, making it imperative for users to stay informed about best practices.

Common Engine Seals and Gaskets

In any mechanical system, maintaining optimal performance often hinges on the integrity of various components that ensure proper sealing. These elements play a crucial role in preventing fluid leaks and maintaining the efficiency of the system. Understanding the most frequently used seals and gaskets can significantly enhance the longevity and reliability of the machinery.

Types of Seals

There are several types of seals commonly found in various systems. O-rings, typically circular in shape, are designed to fit snugly into a groove, creating a tight seal when compressed. Lip seals, which consist of a flexible lip that contacts the surface of a shaft, help in retaining lubricants while keeping contaminants at bay. Additionally, flat seals are often employed between two surfaces to prevent fluid escape, making them essential for maintaining pressure integrity.

Common Gaskets

Gaskets serve as critical barriers in preventing leaks between two mating surfaces. The most common types include cork, paper, and silicone gaskets, each offering unique benefits depending on the application. Cork gaskets provide a good seal in low-pressure situations, while silicone variants excel in high-temperature environments. Understanding the specific needs of a system will help in selecting the appropriate gasket to ensure optimal performance.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your vehicle’s internal components. By following a few fundamental practices, you can enhance performance, prevent premature wear, and maintain overall efficiency.

First and foremost, routine inspections of vital systems such as the cooling and lubrication circuits can help identify potential issues before they escalate. Keeping an eye on fluid levels and replacing them as needed is crucial for optimal functionality.

Additionally, adhering to a consistent schedule for replacing filters and belts can prevent blockages and breakdowns. These components play a significant role in the smooth operation of your vehicle, and timely replacements can save you from costly repairs down the line.

Lastly, ensuring that all connections and fasteners are secure will mitigate the risk of vibrations causing damage. Regularly checking and tightening these elements can significantly contribute to the longevity of your vehicle’s performance.

Tuning the 2F Engine for Performance

Enhancing the 2F’s capabilities offers enthusiasts a chance to unlock hidden potential, delivering more power, improved efficiency, and greater responsiveness. This segment will explore essential upgrades and fine-tuning strategies to achieve noticeable gains in both strength and endurance.

Optimizing Airflow and Fuel Delivery

A crucial step in maximizing output involves refining the balance of airflow and fuel intake. Upgraded intake manifolds, combined with high-performance carburetors or fuel injectors, enhance the combustion process. This harmony of air and fuel ensures smoother acceleration and more efficient fuel consumption, leading to enhanced overall performance.

Enhancing Ignition and Exhaust Systems

To further improve results, consider upgrading the ignition and exhaust components. High-quality spark plugs and an advanced ignition coil can lead to more effective power delivery. Paired with a free-flow exhaust system, these adjustments reduce back pressure, allowing for quicker throttle response and a more powerful output, making for a noticeably spirited drive.

Wiring Diagrams and Electrical System

The electrical configuration plays a crucial role in ensuring all components work harmoniously. A thorough understanding of the layout is essential for identifying connections, checking for continuity, and troubleshooting potential issues within the circuitry. This section provides structured visuals and instructions to support efficient electrical maintenance and modifications.

Main Circuits Overview

The vehicle’s circuitry includes several key circuits that power various systems, from lighting to ignition. Each of these circuits has specific pathways, and familiarizing oneself with their layout helps in maintaining optimum performance.

- Power Circuit: Supplies energy to the primary systems.

- Grounding Circuit: Ensures all components have a stable connection.

- Accessory Circuit: Powers additional devices, such as audio and lighting features.

Common Electrical Components

Within the system, several components are crucial to maintaining the flow of power. Knowing each part’s function aids in diagnostics and upkeep.

- Battery: Provides the initial power source for all circuits.

Replacing the Carburetor: A Guide

When it comes to improving the performance and longevity of your vehicle, replacing an aging carburetor can be a key step. Over time, this component can accumulate buildup or wear down, affecting fuel efficiency and overall power. Understanding the process can help ensure a smooth replacement, enhancing drivability and optimizing the mix of fuel and air for better performance.

Step 1: Disconnecting the Fuel Lines

Before you begin, make sure the vehicle is off and the engine is cool. Carefully disconnect the fuel lines connected to the carburetor. Use a wrench or pliers as needed, ensuring no fuel spills or leaks. Having a container to catch any stray fuel can help maintain safety and cleanliness.

Step 2: Removing the Old Carburetor

Next, locate and unscrew the bolts holding the carburetor in place. Keep track of all parts, such as washers and bolts, as you remove them. Gently lift the carburetor off, being mindful of any remaining connections to avoid damage to surrounding components.

Step 3: Installing the New Carburetor

Position the new carburetor where the old one was removed, aligning it with the intake manifold. Secure it by tightening the bolts evenly, ensuring a snug fit. Reconnect the fuel lines and any additional attachments, double-checking each connection for tightness.

Finding Replacement Parts for 2F

When maintaining your classic 2F, sourcing high-quality parts can be essential for preserving its performance and longevity. Components specifically designed for this type ensure compatibility and durability, making them an ideal choice for those looking to keep everything in peak condition. However, finding the right items may require some research, especially for items no longer in production. This guide provides insights on locating suitable parts from various sources.

Exploring Specialized Vendors

For parts tailored to 2F specifications, specialty vendors are often a reliable resource. Many suppliers offer both original parts and aftermarket alternatives, ensuring you have options based on your needs. Check for vendors known for their expertise with classic models and ensure the components meet the required specifications. Reviewing customer feedback can also give you a clearer idea of the quality and reliability of the parts.

Considering Salvage and Online Marketplaces

Sometimes, salvage yards and online marketplaces can be invaluable when searching for unique or rare components. Salvage facilities often carry parts from retired models, while online marketplaces may connect you with sellers worldwide. When using these options, verify the part’s condition, and if possible, request detailed photos or descriptions to avoid surprises upon delivery. These platforms are ideal for those looking for budget-friendly solutions or rare finds.

Quality assurance remains key regardless of the source. Whether new, aftermarket, or used, each part should be inspected to confirm its reliability and fit for the best possible results with your 2F.