Owning a versatile off-road vehicle requires a solid understanding of its upkeep to ensure longevity and optimal performance. This section aims to equip enthusiasts with essential knowledge to tackle various issues that may arise during regular use.

From minor adjustments to more complex troubleshooting, the following content will delve into the fundamental aspects of vehicle maintenance. Having a comprehensive resource at hand can significantly enhance the overall experience and efficiency of your machine.

Ultimately, a proactive approach to maintenance not only saves time and money but also maximizes your enjoyment of outdoor adventures. Embracing this guide will empower owners to address common challenges and keep their vehicles in peak condition.

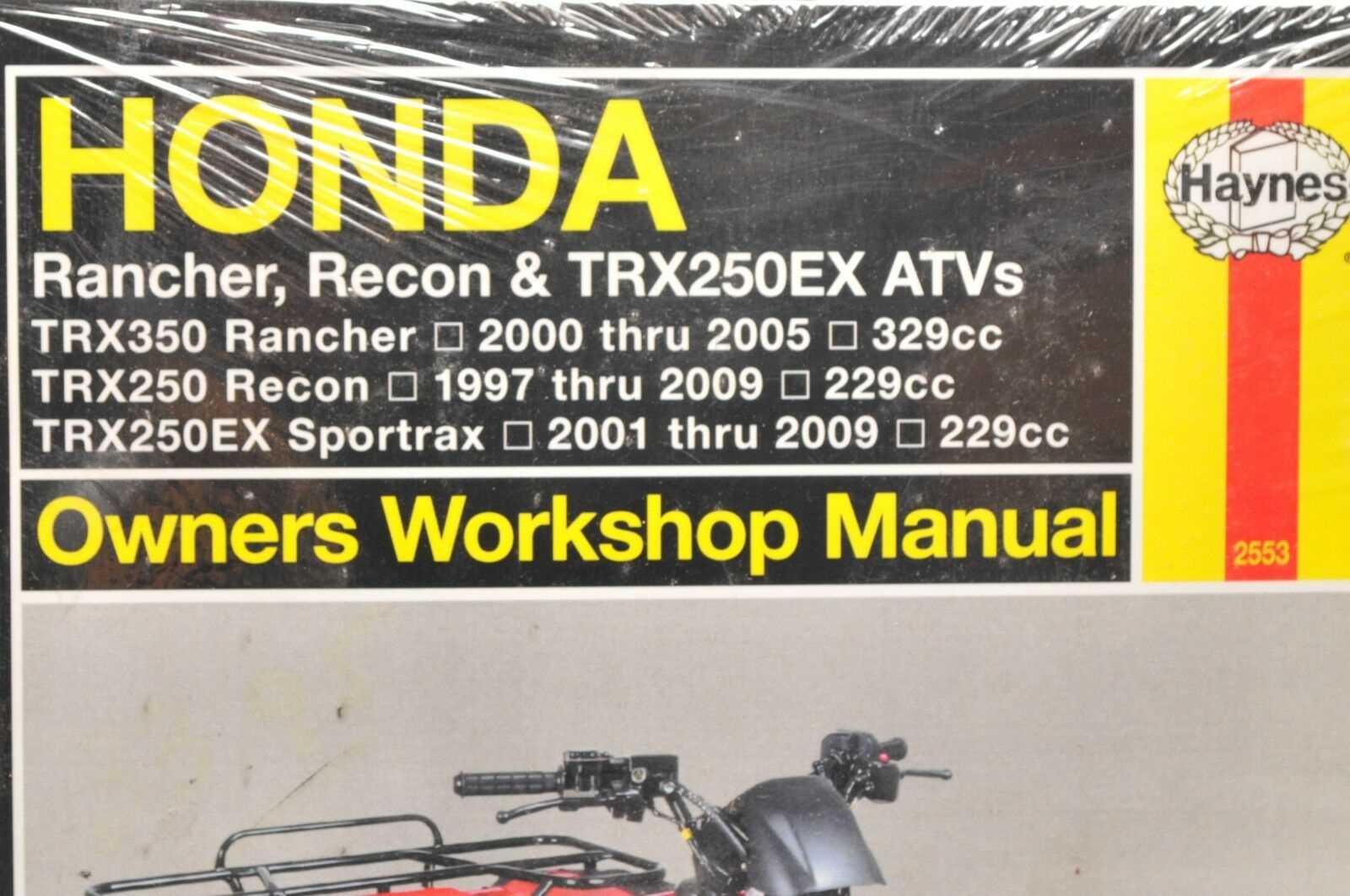

Overview of the 2001 Honda Recon

This section provides a comprehensive look at a popular utility vehicle known for its durability and versatility. It is designed to tackle a variety of terrains and tasks, making it a favorite among outdoor enthusiasts and professionals alike.

Key features that define this model include:

- Robust construction, ensuring longevity and reliability.

- Efficient engine performance, providing ample power for different activities.

- Compact design, facilitating easy maneuverability in tight spaces.

- Comfortable seating, allowing for extended use without fatigue.

In addition to its practical applications, this vehicle is known for:

- Low maintenance requirements, making it economical over time.

- A variety of available accessories to customize for specific needs.

- Excellent handling characteristics, enhancing control on rough terrain.

Overall, this vehicle stands out as a reliable option for those seeking performance and efficiency in an all-terrain machine.

Common Issues with Honda Recon

Every vehicle has its quirks, and certain models often exhibit recurring problems that owners should be aware of. Understanding these typical issues can help in both prevention and timely intervention, ensuring a smoother experience for the user. Here, we explore some of the most frequent challenges encountered by enthusiasts of this particular all-terrain vehicle.

Engine Performance Problems

One of the primary concerns relates to engine performance. Many users report issues such as hard starting or stalling during operation. These problems can often be traced back to factors like fuel quality, clogged air filters, or irregular maintenance schedules. Regular checks and timely replacements of essential components can significantly mitigate these issues.

Electrical System Failures

Another common area of concern is the electrical system. Owners frequently experience battery drainage or malfunctioning lights. These issues may arise from faulty wiring or poor connections. Regular inspections and ensuring that all electrical components are in good condition can help prevent unexpected breakdowns and enhance reliability.

Essential Tools for Repairs

When it comes to maintaining and fixing your vehicle, having the right equipment is crucial. The appropriate instruments not only facilitate the process but also ensure that tasks are completed efficiently and safely. Below is a list of essential items you should consider having in your toolkit for optimal performance and ease of use.

- Socket Set: A comprehensive socket set is vital for loosening and tightening various fasteners.

- Wrenches: Both open-end and adjustable wrenches are necessary for tackling different sizes of nuts and bolts.

- Screwdrivers: A set of screwdrivers, including both Phillips and flathead, is essential for working on various components.

- Pliers: Needle-nose pliers and regular pliers are useful for gripping, twisting, and cutting.

- Torque Wrench: This tool ensures that you apply the correct amount of force when fastening components.

- Jack and Jack Stands: A reliable jack is crucial for lifting the vehicle safely, while jack stands provide stability during work.

- Multimeter: This device helps diagnose electrical issues by measuring voltage, current, and resistance.

- Shop Manual: Having access to a detailed guide can provide valuable information for troubleshooting and specifications.

Equipping yourself with these tools will not only streamline the maintenance process but also enhance your ability to address various challenges that may arise. Invest in quality instruments to ensure longevity and effectiveness in your tasks.

Step-by-Step Maintenance Guide

This guide aims to provide a comprehensive approach to the upkeep of your all-terrain vehicle. Regular maintenance not only enhances performance but also prolongs the lifespan of your machine. By following these structured steps, you can ensure that your vehicle remains in top condition, ready for any adventure.

Regular Inspections

Start with routine inspections of critical components. Check the tires for proper inflation and tread wear. Examine the brakes for responsiveness and wear. Regularly inspect the suspension system and make sure there are no leaks in the hydraulic components. Pay attention to the battery condition; clean the terminals and ensure it holds a charge.

Fluid Levels and Changes

Maintaining proper fluid levels is essential for optimal operation. Regularly check engine oil, coolant, and brake fluid levels. Change the oil according to the manufacturer’s recommended schedule to ensure smooth engine performance. Replace the coolant and other fluids as necessary to prevent overheating and ensure efficient operation.

Emphasizing preventive care is crucial. By adhering to this systematic maintenance guide, you will not only enhance the reliability of your vehicle but also enjoy peace of mind during your rides.

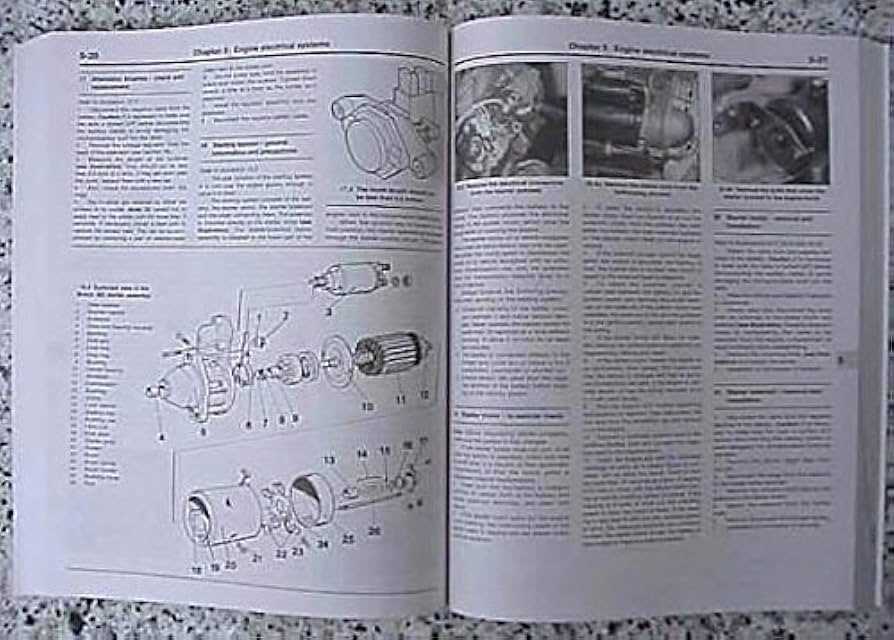

Engine Troubleshooting Techniques

Identifying and resolving issues within an engine can be a complex task, requiring a systematic approach. Understanding the various symptoms and their potential causes is essential for effective diagnostics. By utilizing a combination of observational skills and technical knowledge, one can pinpoint the source of problems and implement appropriate solutions.

Visual Inspection: Start with a thorough examination of the engine. Look for any signs of wear, leaks, or damage. Check hoses, belts, and connections for integrity. A clean and organized workspace can aid in spotting abnormalities.

Listening for Unusual Noises: Pay attention to any irregular sounds during operation. Knockings, hissing, or grinding noises can indicate specific issues. Document these sounds for further analysis, as they can provide valuable clues.

Monitoring Performance: Evaluate how the engine performs under various conditions. Note any fluctuations in power, acceleration, or responsiveness. Changes in performance often signal underlying problems that require further investigation.

Utilizing Diagnostic Tools: Employ diagnostic equipment to assess the engine’s health. Tools like multimeters and compression testers can provide quantitative data, helping to identify issues that may not be apparent through visual inspection alone.

Reviewing Engine Codes: If equipped with an onboard diagnostic system, retrieving error codes can simplify the troubleshooting process. These codes serve as a starting point for identifying specific malfunctions within the engine system.

Conducting Systematic Tests: Implement a series of tests to isolate the issue. For instance, checking fuel delivery, spark quality, and compression levels can provide insight into the engine’s operation. Systematic testing ensures a comprehensive understanding of potential failures.

By applying these techniques methodically, one can effectively troubleshoot engine issues, leading to timely repairs and enhanced performance. Maintaining a proactive approach can prevent minor problems from escalating into major failures, ensuring longevity and reliability.

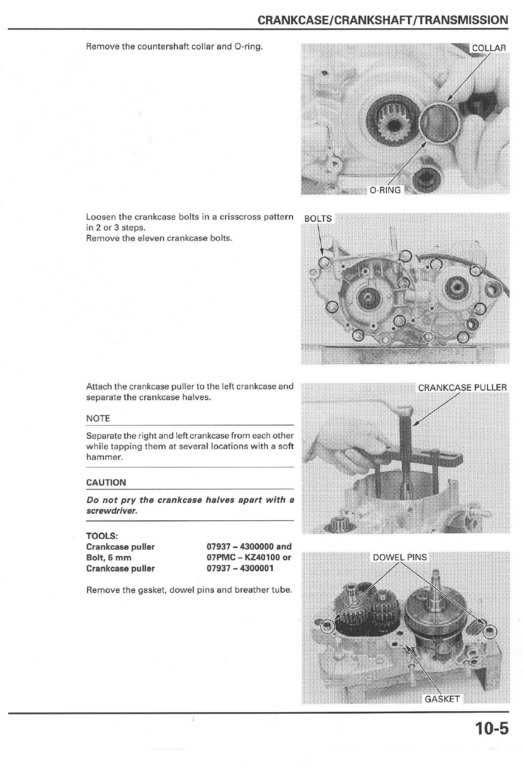

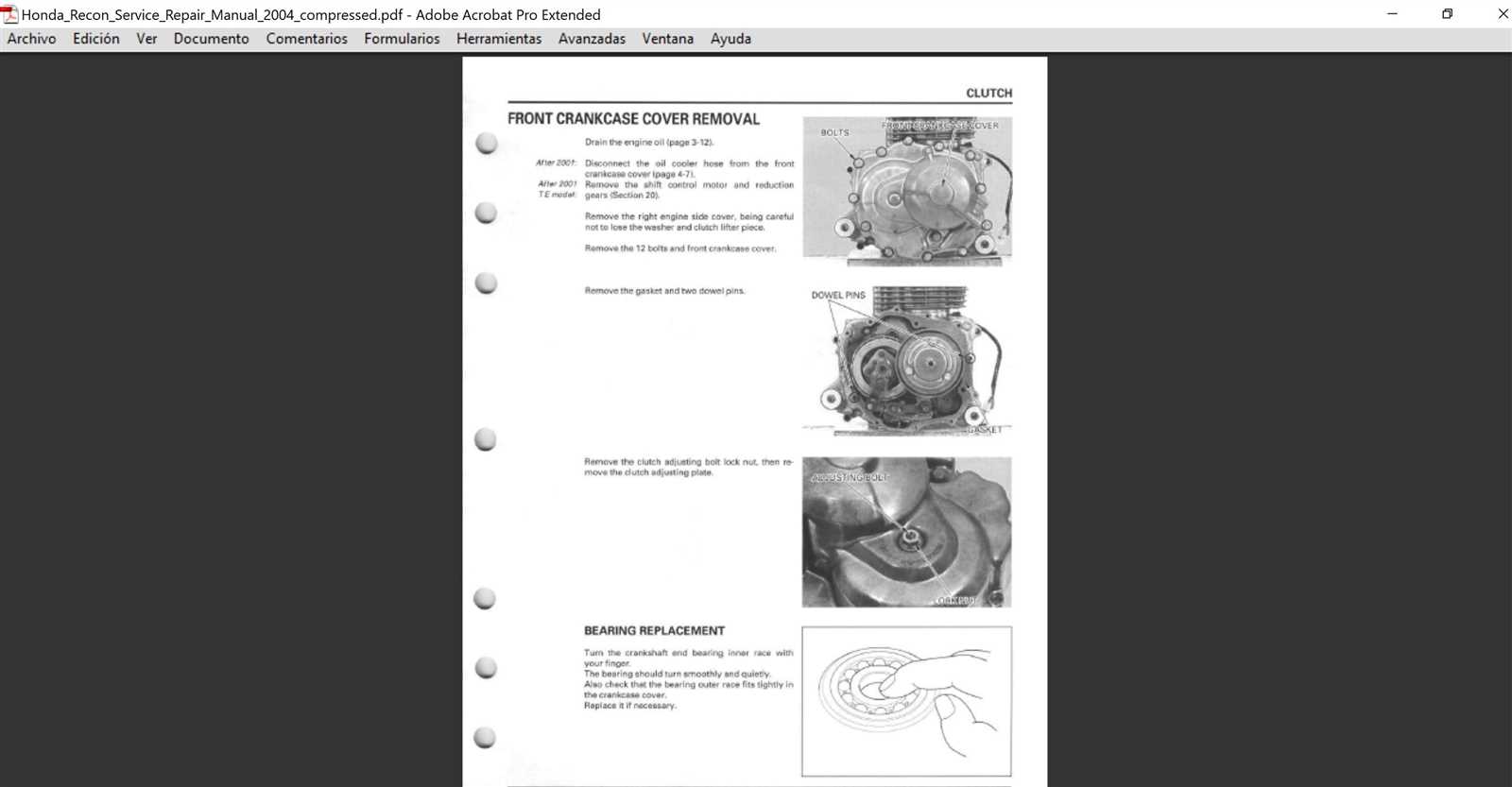

Transmission Repair and Adjustments

The functionality of the transmission is crucial for the overall performance of any vehicle. Proper maintenance and timely adjustments can enhance efficiency and longevity. This section outlines the essential steps for troubleshooting and fine-tuning the transmission system to ensure smooth operation.

Common Issues and Diagnostics

Identifying transmission problems early can prevent further damage. Here are some common issues to look for:

- Unusual noises during operation

- Slipping gears or difficulty shifting

- Fluid leaks

- Warning lights on the dashboard

To diagnose these problems, follow these steps:

- Check fluid levels and quality.

- Inspect for leaks around the transmission casing.

- Listen for abnormal sounds during gear changes.

- Test the vehicle’s responsiveness during acceleration.

Adjustment Procedures

After diagnosing the issues, specific adjustments may be necessary. Here are key procedures to follow:

- Ensure the transmission fluid is at the correct level.

- Adjust the linkage to guarantee precise gear engagement.

- Calibrate the shift points for optimal performance.

- Replace worn components, if necessary.

Regular maintenance and timely adjustments will help maintain the integrity of the transmission, ensuring reliable performance for years to come.

Electrical System Diagnostics

The ability to effectively assess the electrical system is crucial for ensuring optimal performance and longevity of your vehicle. A systematic approach to diagnosing electrical issues can save time and prevent unnecessary expenses. Understanding the components and their interconnections allows for accurate identification of malfunctions and effective troubleshooting.

Common Electrical Problems

Electrical systems may experience a range of issues, including but not limited to poor connections, short circuits, and component failures. Symptoms often include dimming lights, erratic starting, and non-functioning accessories. Regular inspection and testing of key elements, such as the battery, wiring, and switches, are essential in maintaining system integrity.

Diagnostic Tools and Techniques

Utilizing the right tools is vital for accurate diagnosis. A multimeter can measure voltage, current, and resistance, aiding in pinpointing faulty components. Additionally, visual inspections of wiring and connectors can reveal signs of wear or corrosion. For a comprehensive analysis, consider following a systematic diagnostic flowchart that guides you through troubleshooting steps.

In summary, a thorough understanding of the electrical system and its components empowers you to effectively address issues as they arise, ensuring reliable operation and enhanced safety.

Suspension and Steering Maintenance

Maintaining the components that support ride quality and steering precision is crucial for the overall performance and safety of your vehicle. Proper care ensures a smooth driving experience and extends the lifespan of essential parts, minimizing the risk of more significant issues down the road.

Inspecting Suspension Components

Regularly examining suspension parts is vital. Look for signs of wear such as cracks, leaks, and corrosion on springs, shocks, and struts. Any unusual noises during operation can indicate problems that require immediate attention. Keeping these components in good condition not only enhances comfort but also improves handling and stability.

Steering System Care

The steering mechanism plays a critical role in vehicle control. Ensure that linkages, tie rods, and steering gear are well-lubricated and free of debris. Routine checks for alignment are essential to prevent uneven tire wear and ensure accurate steering response. Addressing any irregularities promptly can prevent further complications and ensure a safer driving experience.

Brake System Overhaul Tips

Ensuring the optimal performance of a vehicle’s braking mechanism is essential for safety and reliability. This segment outlines critical considerations and practical steps for maintaining and enhancing the functionality of the braking system. Proper attention to this area can prevent potential failures and enhance overall driving experience.

Preparation Steps

Before diving into the overhaul process, it is vital to gather all necessary tools and parts. Proper preparation can significantly streamline the task and reduce the risk of errors. Here’s a checklist of items to consider:

| Item | Description |

|---|---|

| Brake Pads | Check for wear and replace if necessary. |

| Brake Fluid | Ensure fluid is clean and at the appropriate level. |

| Rotors | Inspect for warping or damage; consider resurfacing. |

| Calipers | Check for leaks and proper function. |

| Tools | Gather wrenches, sockets, and a brake bleeder kit. |

Overhaul Process

When proceeding with the maintenance, follow these systematic steps to ensure a thorough job:

- Lift the vehicle securely and remove the wheels.

- Inspect each component for wear, focusing on pads, rotors, and calipers.

- Replace any worn or damaged parts, ensuring all new components are correctly aligned.

- Bleed the braking system to eliminate air pockets, which can affect performance.

- Reassemble all components and conduct a test drive to confirm functionality.

By adhering to these guidelines, you can ensure that the braking system remains effective and safe for use. Regular checks and timely maintenance will prolong the lifespan of the components and enhance overall vehicle performance.

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity of any vehicle. Regularly scheduled cleaning helps to prevent issues related to fuel delivery, ensuring that the engine operates smoothly and efficiently. This section outlines the steps necessary to effectively clean the fuel system, enhancing both power output and fuel economy.

Preparation Steps

Before beginning the cleaning process, ensure that you have the appropriate tools and cleaning solutions at hand. Start by disconnecting the battery to avoid any electrical issues during the procedure. Next, drain the fuel tank to remove any contaminated fuel. It’s advisable to work in a well-ventilated area and wear safety gear, including gloves and goggles, to protect against harmful substances.

Cleaning Procedures

Utilize a specialized fuel system cleaner designed to dissolve deposits and varnish. Introduce the cleaner into the fuel system as per the manufacturer’s instructions. Running the engine allows the cleaner to circulate through the injectors and combustion chamber, effectively removing unwanted buildup. After the cleaning solution has been used, refill the tank with fresh fuel to dilute any remaining cleaner and restore optimal fuel quality.

In addition, inspect the fuel filter and replace it if necessary, as a clogged filter can impede fuel flow. Regular maintenance of the fuel system not only prolongs the life of the engine but also contributes to improved fuel efficiency and reduced emissions.

Body and Frame Restoration Advice

Restoring the body and structure of an off-road vehicle requires a careful approach and a clear understanding of the materials involved. This process not only enhances the vehicle’s aesthetics but also ensures its durability and performance on rugged terrains. Proper attention to detail can revive a machine that has seen better days, making it both functional and visually appealing.

Assessment is the first step in any restoration project. Thoroughly inspect the body for rust, dents, and other damages. Take note of areas where the frame might be compromised. Creating a comprehensive list of needed repairs will streamline the restoration process and prevent unexpected issues down the line.

When it comes to rust removal, there are various methods to consider. Depending on the extent of corrosion, you may choose to sandblast, use chemical rust removers, or simply sand down affected areas. After removal, applying a high-quality primer is essential to prevent future rust from developing.

For frame repairs, reinforcing weak spots may be necessary. Weld new metal into any areas showing signs of stress or damage. Ensure that all welds are clean and solid to maintain the integrity of the structure. After completing repairs, it’s advisable to paint the frame with a durable coating to protect against the elements.

Finally, reassembly should be approached methodically. As you put everything back together, double-check that all components align correctly and securely. A well-restored body and frame not only improve appearance but also contribute significantly to the overall safety and performance of the vehicle.

Finding Replacement Parts Easily

Locating suitable components for your vehicle can often feel overwhelming, especially when faced with numerous options and suppliers. However, with the right strategies, you can streamline the process and ensure that you acquire high-quality parts efficiently.

Start with Online Resources: The internet is a treasure trove of information. Numerous websites specialize in providing parts for various makes and models. Utilize search engines to find reputable suppliers and review customer feedback to gauge reliability.

Utilize Forums and Communities: Engaging with online forums and enthusiast communities can be incredibly beneficial. Fellow users often share their experiences, recommendations, and even sources for hard-to-find parts. These platforms can also provide insights into common issues and solutions.

Check Local Retailers: Don’t overlook local auto parts stores. Many of these retailers maintain a robust inventory and can often order specific components for you. Building a relationship with staff can also lead to personalized assistance in finding what you need.

Consider Salvage Yards: For those seeking budget-friendly options, salvage yards can be a goldmine. They offer a variety of used parts that are still in good condition, and negotiating prices is often possible. Just ensure you inspect the parts thoroughly before purchasing.

Stay Informed on Compatibility: When searching for replacements, always verify that the parts you choose are compatible with your vehicle’s specifications. This diligence will save you time and money by preventing mismatches that could lead to further issues.

By employing these methods, you can enhance your chances of finding the right components swiftly, ensuring your vehicle remains in excellent condition.