Ensuring the longevity and optimal performance of your aquatic vehicle is essential for a seamless experience on the water. This section provides comprehensive insights into the upkeep and troubleshooting of your watercraft, enabling users to tackle common issues effectively. A well-maintained vessel not only enhances performance but also guarantees safety and reliability during every outing.

In this guide, you’ll find detailed instructions on routine checks, necessary adjustments, and potential repairs that may arise during usage. By following these guidelines, owners can foster a deeper understanding of their craft, allowing for more confident navigation and enjoyment. The focus is on empowering individuals with the knowledge to identify problems and apply suitable solutions.

From routine maintenance tasks to troubleshooting specific challenges, this resource is designed to equip users with practical skills and insights. With the right approach, any enthusiast can ensure their vehicle remains in excellent condition, ready for the next adventure.

Overview of Polaris 280 Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of aquatic cleaning equipment. By following a structured maintenance routine, users can minimize wear and tear, enhance functionality, and prolong the lifespan of their devices.

Key aspects of routine maintenance include:

- Inspection: Regularly examine all components for signs of damage or wear.

- Cleaning: Remove debris and buildup from filters, brushes, and hoses to maintain efficient operation.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent rust.

- Parts Replacement: Identify and replace worn or broken parts promptly to avoid further damage.

- Performance Testing: Conduct tests to ensure all systems are functioning as intended, addressing any issues immediately.

Implementing these practices on a regular schedule will contribute significantly to the effective functioning of the equipment, allowing users to enjoy hassle-free operation and cleaner aquatic environments.

Common Issues with Polaris 280

In the realm of aquatic cleaning equipment, certain challenges frequently arise, impacting the efficiency and performance of these devices. Understanding these common complications can aid users in troubleshooting and maintaining optimal functionality.

Performance Problems

One of the prevalent concerns is reduced efficiency during operation. Users may notice that the unit fails to move properly or does not clean as thoroughly as expected. This issue can often be attributed to clogged filters or debris obstructing the moving parts. Regular maintenance and inspection are crucial in addressing these performance-related hurdles.

Power Supply Issues

Another common challenge involves power supply interruptions. Devices may exhibit erratic behavior or fail to start altogether due to faulty connections or damaged cables. Ensuring that the power source is stable and connections are secure can significantly enhance reliability and functionality. Addressing these power issues promptly can prevent further complications down the line.

Tools Required for Repairs

When it comes to maintaining and fixing various mechanical systems, having the right instruments is essential for ensuring efficiency and accuracy. This section outlines the essential equipment needed to perform effective maintenance tasks, making the process smoother and more manageable.

Essential Hand Tools

Hand tools are indispensable for any maintenance task. These instruments provide the necessary leverage and precision required for various repairs. Below is a table listing the fundamental hand tools typically used:

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen nuts and bolts |

| Screwdriver Set | For inserting or removing screws |

| Pliers | To grip and manipulate objects |

| Socket Set | For quick fastening of bolts |

| Hammer | To drive or break objects |

Specialized Equipment

In addition to hand tools, certain specialized instruments can enhance the effectiveness of maintenance operations. These tools cater to specific tasks that require precision and care:

| Tool | Purpose |

|---|---|

| Torque Wrench | To ensure proper torque settings |

| Multimeter | For electrical diagnostics |

| Pressure Gauge | To measure fluid pressure |

| Diagnostic Scanner | For assessing electronic systems |

Step-by-Step Repair Procedures

This section outlines the systematic approach to fixing common issues in recreational vehicles. Following a structured methodology can significantly enhance the effectiveness and efficiency of maintenance tasks.

Preparation

Before beginning any work, ensure that you have the necessary tools and components at hand. Here are the essential steps to prepare:

- Gather all required tools, including wrenches, screwdrivers, and pliers.

- Obtain replacement parts based on the specific issue being addressed.

- Read through any relevant documentation for guidance on the specific components.

- Prepare a clean and organized workspace to facilitate the repair process.

Repair Process

Follow these general steps to execute the maintenance effectively:

- Identify the problem area and assess the extent of the damage.

- Remove any necessary panels or covers to gain access to the affected components.

- Carefully disconnect any electrical connectors or hoses that may obstruct your work.

- Replace or repair the damaged parts, ensuring proper alignment and fit.

- Reconnect all components and secure any panels or covers that were removed.

- Test the vehicle to ensure everything is functioning correctly after the work is completed.

By adhering to these steps, individuals can effectively troubleshoot and resolve issues, ensuring optimal performance and longevity of the vehicle.

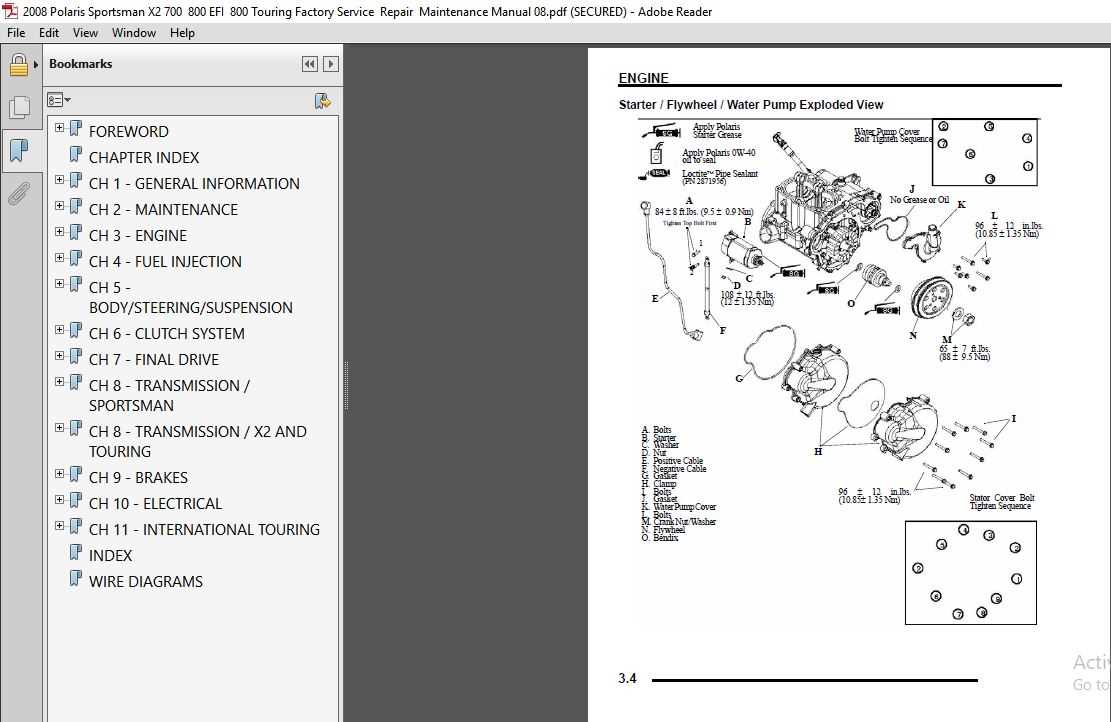

Maintaining Electrical Components

Proper upkeep of electrical elements is crucial for ensuring the reliable operation of your vehicle. Regular attention to these components can prevent malfunctions, enhance performance, and extend the overall lifespan of the system. This section outlines best practices for maintenance, focusing on inspection, cleaning, and troubleshooting techniques.

Routine Inspection

Conducting frequent checks on electrical parts is essential for early detection of issues. Pay attention to the following:

- Inspect wiring for signs of wear or damage.

- Look for corrosion on terminals and connectors.

- Ensure all connections are secure and free of moisture.

- Check for any unusual odors that may indicate overheating.

Cleaning Electrical Components

Keeping electrical parts clean can significantly improve their performance. Follow these steps:

- Disconnect the power source before cleaning.

- Use a soft brush or cloth to remove dirt and debris.

- For corrosion, apply a suitable cleaner specifically designed for electrical components.

- After cleaning, ensure all parts are completely dry before reassembling.

By adhering to these maintenance practices, you can help ensure the electrical system functions efficiently and reliably for years to come.

Inspecting and Replacing Seals

Seals play a crucial role in maintaining the integrity of various components in machinery. Regular inspection and timely replacement are essential to prevent leaks and ensure optimal performance. This section outlines the steps to effectively assess and swap out seals to maintain functionality and extend the lifespan of the equipment.

When it comes to inspecting seals, follow these guidelines:

- Check for visible signs of wear, such as cracks, tears, or deformation.

- Examine the surrounding areas for any fluid leaks, which may indicate a failing seal.

- Assess the fit of the seal in its designated groove to ensure it is seated properly.

- Monitor the condition of nearby components that could affect seal performance.

If any issues are detected during inspection, it is advisable to replace the seals promptly. Here’s a straightforward approach to the replacement process:

- Gather necessary tools, including seal pullers, lubricants, and replacement seals.

- Carefully remove the old seal using a seal puller, taking care not to damage the housing.

- Clean the sealing surface to ensure a proper fit for the new seal.

- Apply a suitable lubricant to the new seal to facilitate installation.

- Position the new seal in its groove, ensuring it is aligned correctly.

- Reassemble any components that were removed and test for leaks.

By following these inspection and replacement steps, you can maintain the efficiency and reliability of your equipment, minimizing downtime and costly repairs.

Cleaning and Maintenance Tips

Regular upkeep and thorough cleaning are essential for ensuring optimal performance and longevity of your watercraft. This section provides useful advice and strategies to help keep your equipment in top condition, allowing for a seamless experience on the water.

General Cleaning Practices

To maintain the appearance and functionality of your vessel, adhere to the following practices:

| Task | Frequency | Instructions |

|---|---|---|

| Rinse After Use | Every Use | Flush out saltwater and debris using fresh water. |

| Inspect and Clean Filters | Weekly | Remove and clean filters to prevent clogs. |

| Wipe Down Surfaces | Daily | Use a soft cloth to remove dirt and grime. |

| Check for Damage | Monthly | Look for signs of wear or damage, addressing any issues promptly. |

Seasonal Maintenance Tasks

In addition to regular cleaning, performing seasonal maintenance is crucial. Here are key tasks to consider:

- Inspect the hull for scratches or signs of wear.

- Replace any worn-out parts, such as seals and gaskets.

- Apply a protective wax or coating to safeguard against environmental damage.

- Examine the electrical systems and battery connections.

Replacing the Filter System

Maintaining optimal performance in your cleaning equipment involves periodically replacing the filtration components. This ensures that debris and contaminants are effectively removed, allowing for a cleaner environment. Proper filtration not only enhances the efficiency of the device but also prolongs its lifespan.

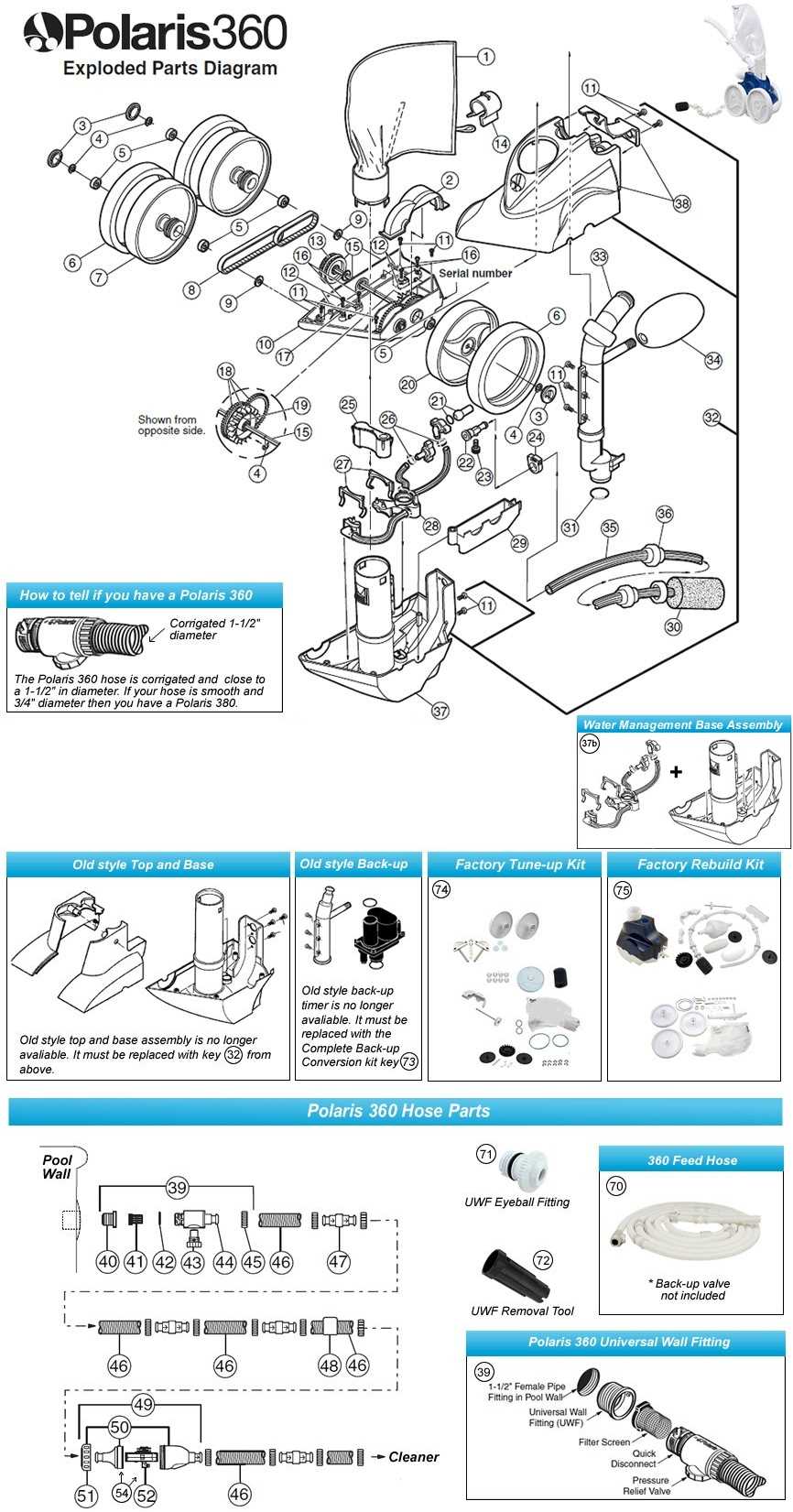

Identifying the Filter Components

Before proceeding with the replacement process, it’s essential to familiarize yourself with the various filter elements. Typically, these systems consist of a primary filter, which captures larger particles, and a secondary filter designed for finer debris. Understanding the location and function of each component will streamline the replacement process.

Steps for Replacement

To begin, disconnect the equipment from the power source to ensure safety. Remove the cover or access panel to expose the filtration system. Carefully detach the old filters by following the manufacturer’s guidelines. When installing the new filters, ensure they are securely fitted and properly oriented. After replacement, reassemble the cover and reconnect the power supply. Performing a brief test run can confirm that the new filters are functioning correctly.

Regularly checking and replacing the filtration system will contribute significantly to the efficiency and effectiveness of your equipment.

Adjusting the Drive System

Fine-tuning the propulsion mechanism is essential for optimal performance and efficiency of your aquatic vehicle. Proper adjustments can enhance maneuverability and extend the lifespan of the components involved. This process involves checking various aspects of the drive system to ensure everything is functioning harmoniously.

Begin by inspecting the alignment of the drive components. Misalignment can lead to excessive wear and tear, resulting in reduced efficiency. Ensure that the drive shaft is positioned correctly and that the couplings are secure. Additionally, verify that all connections are tight and free from any obstructions.

Next, evaluate the tension on the belts or chains, depending on the type of system installed. Proper tension is crucial; too tight can cause strain on the motor, while too loose may lead to slippage. Refer to the specifications provided by the manufacturer to achieve the correct tension levels.

Finally, take the time to lubricate moving parts as necessary. A well-lubricated system operates more smoothly and reduces the risk of corrosion or damage. Regular maintenance checks will ensure that your propulsion system remains in peak condition, ready for your next aquatic adventure.

Diagnosing Performance Problems

Identifying issues that affect the operational efficiency of a vehicle is crucial for ensuring optimal functionality. Various factors can contribute to diminished performance, ranging from mechanical malfunctions to environmental conditions. This section provides a structured approach to pinpointing potential problems that may arise.

Common Symptoms of Performance Issues

When assessing performance, it’s essential to recognize common signs that indicate underlying problems. These symptoms may include:

| Symptom | Description |

|---|---|

| Reduced Speed | Noticeable decrease in maximum velocity, which may indicate engine troubles or drag. |

| Poor Acceleration | Delayed response when attempting to increase speed, often related to throttle or fuel system issues. |

| Unusual Noises | Strange sounds during operation can signal mechanical wear or component failure. |

| Vibration | Excessive shaking may suggest imbalance or alignment problems. |

Steps for Diagnosis

To effectively diagnose performance concerns, follow these systematic steps:

- Begin with a visual inspection of the main components.

- Check for any leaks or signs of wear.

- Test the operational systems to identify discrepancies.

- Utilize diagnostic tools to assess performance metrics.

- Consult service history for previous issues and repairs.

Winterization and Storage Guidelines

Preparing your watercraft for the colder months is essential to ensure its longevity and optimal performance. Proper winterization techniques safeguard various components against damage from freezing temperatures and prolonged inactivity. Following these steps will help you effectively store your vessel and minimize the risk of issues when the boating season resumes.

Steps for Effective Winterization

To properly prepare your craft for winter storage, follow these key procedures:

| Step | Description |

|---|---|

| 1 | Drain all water from the engine and cooling systems to prevent freezing and damage. |

| 2 | Flush the engine with antifreeze to protect internal components during freezing temperatures. |

| 3 | Disconnect the battery and store it in a dry, cool place to maintain its charge. |

| 4 | Clean the exterior and interior thoroughly to prevent corrosion and mold growth during storage. |

| 5 | Cover the watercraft with a breathable cover to protect it from dust and moisture while allowing ventilation. |

Storage Location Recommendations

Choosing the right location for storage is vital for maintaining the condition of your vessel. Consider the following options:

- Indoor storage facilities provide the best protection against harsh weather conditions.

- Outdoor storage should be in a shaded area to minimize sun exposure and temperature fluctuations.

- Elevated storage options prevent water accumulation around the vessel.

Finding Replacement Parts

Locating the necessary components for your equipment can be a straightforward process if you know where to look. Whether you are looking to maintain functionality or upgrade certain features, having access to quality parts is essential for optimal performance.

Sources for Parts

- Authorized Dealers: These suppliers often provide genuine components that are specifically designed for your model, ensuring compatibility and reliability.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of parts. Make sure to read reviews and verify the credibility of the seller.

- Local Shops: Many auto parts stores or specialized retailers may carry essential components or can order them for you.

- Second-Hand Options: Consider checking out salvage yards or online marketplaces for used parts at a lower cost.

Tips for Choosing Parts

- Always verify the part number to ensure it matches your requirements.

- Check for warranties or guarantees offered by the supplier to protect your purchase.

- Compare prices from different sources to ensure you are getting the best deal.

- Consult forums or user groups for recommendations on reliable parts and suppliers.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting tasks on machinery, ensuring safety should be the top priority. Proper precautions can prevent accidents and protect both the individual performing the work and the equipment being serviced.

Here are essential guidelines to follow:

- Wear Appropriate Gear: Always use personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear to shield against potential hazards.

- Work in a Well-Ventilated Area: Ensure proper airflow to avoid inhaling harmful fumes and to minimize the risk of fire.

- Disconnect Power Sources: Before starting any maintenance, make sure to disconnect power sources to prevent accidental activation.

- Keep the Workspace Organized: Maintain a clean and organized area to avoid tripping hazards and to easily locate tools and parts.

- Follow Manufacturer Guidelines: Refer to the specific guidelines provided by the manufacturer for detailed safety information and procedures.

- Use Tools Properly: Always use the right tools for the job and handle them according to instructions to prevent injury.

By adhering to these precautions, individuals can create a safer environment, thereby enhancing the efficiency and effectiveness of their work on machinery.