Home appliances are essential for smooth daily operations, yet over time they may develop issues due to regular use. Learning how to handle common malfunctions and perform upkeep can ensure these devices continue to serve you efficiently. This guide offers a detailed look at the steps involved in diagnosing issues, understanding functionality, and restoring optimal performance for a popular household appliance model.

In the following sections, you’ll find step-by-step instructions and valuable tips on various topics, from initial inspections to targeted solutions for common breakdowns. Emphasis is placed on empowering users with the knowledge to address issues independently, saving both time

Maytag Centennial Troubleshooting Guide

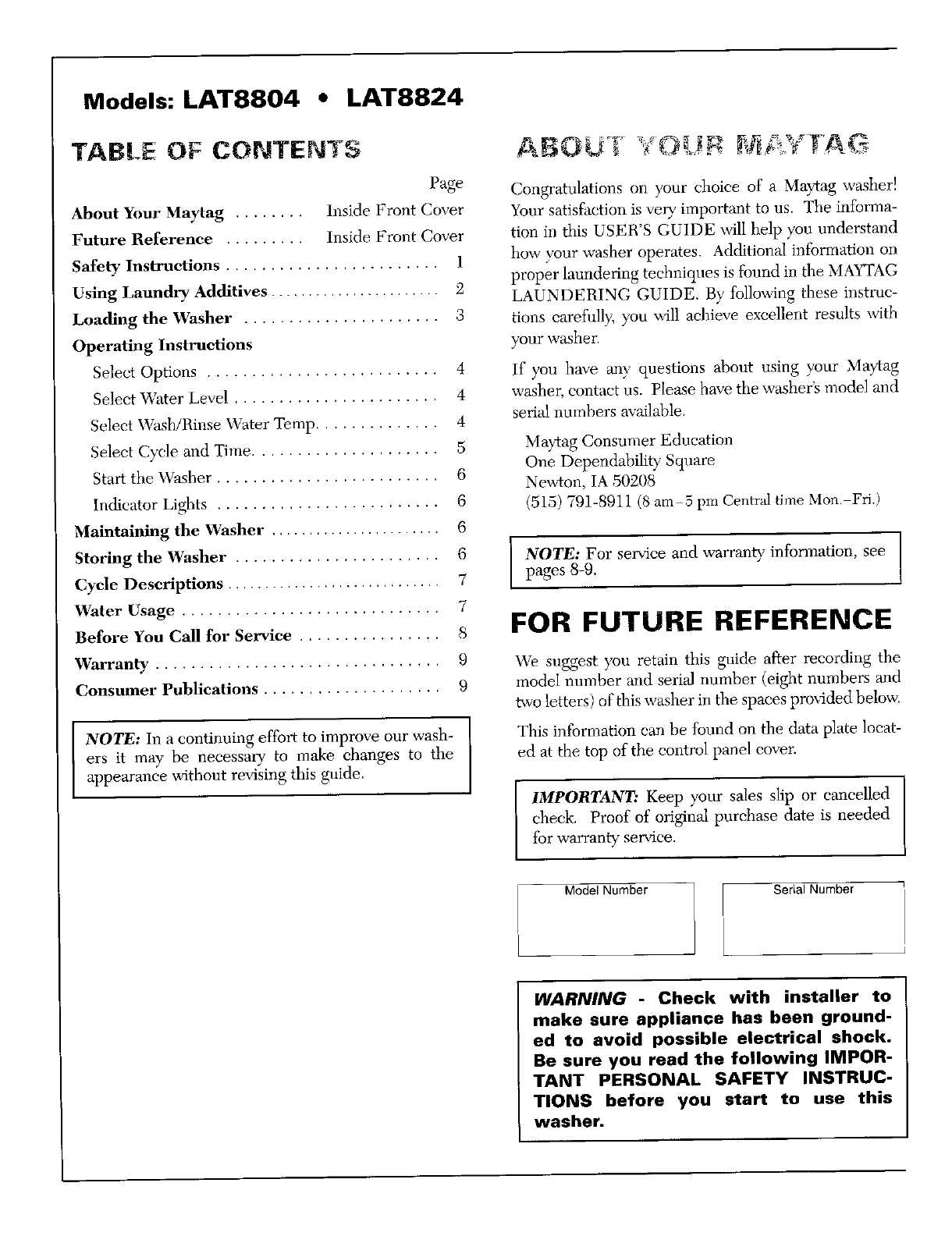

This guide provides practical steps to help diagnose and resolve common issues with your household laundry appliance. By following these instructions, you can identify underlying causes for typical functional problems and determine whether you can address them with simple adjustments or minor repairs at home. The guide aims to empower users with knowledge to extend the operational life of their equipment.

Issues such as unusual noises, ineffective spinning, or irregular drainage can often stem from straightforward causes. Here, we examine frequent challenges, outline potential fixes, and offer preventative tips. Users will find clear explanations and step-by-step guidance designed to restore smooth performance without requiring extensive technical skills.

Remember, keeping your appliance in optimal condition

Understanding Common Washer Issues

Household washing appliances are complex machines, and over time, various complications can emerge, disrupting their functionality. Recognizing and addressing these frequent challenges can help keep the machine running smoothly, prevent long-term damage, and extend its overall lifespan.

1. Draining Difficulties

One common issue involves improper draining. This often results from blockages or clogs within the drainage system, causing water to accumulate inside the drum. Inspecting hoses and ensuring they are free from debris or kinks can resolve this problem. Regularly checking for signs of obstructions can help maintain efficient water flow.

2. Strange Noises During Operation

Unusual sounds, such as banging or ratt

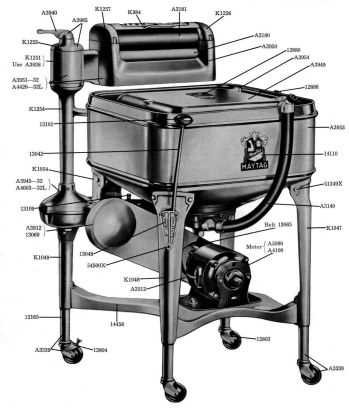

How to Diagnose Motor Problems

Understanding how to identify motor issues in a household appliance is essential for effective troubleshooting. This section provides guidance on recognizing common motor-related problems, enabling you to address them with confidence.

- Start by listening for any unusual sounds when the appliance runs, as grinding or buzzing can often indicate internal motor issues.

- Observe whether the motor starts and stops intermittently or fails to operate altogether; this can signal a power or connection problem.

- Check for any visible signs of damage on motor wiring or connectors, which may contribute to inconsistent performance.

- Inspect the motor for any overheating during use. Excessive heat can indicate an overload or inadequate ventilation around the motor.

- Identifying Drum Malfunctions

In this section, we’ll focus on recognizing common issues that affect the performance of a washing machine’s drum. Understanding the signs of malfunction can help prevent further issues and prolong the appliance’s functionality.

Unusual Noises – One of the first indicators of a problem is unusual sounds during operation. If you notice loud banging, grinding, or rattling noises, it may suggest loose components or worn bearings within the drum assembly. These sounds can often indicate an imbalance or foreign objects stuck inside.

Drum Movement Issues – If the drum does not rotate smoothly or feels overly stiff, there might be a misalignment or an obstruction. Difficulty in movement could also point to a problem with internal drive components, which may affect the appliance’s overall efficiency.

Water Drainage

Fixing Drainage Blockages

One of the common issues with appliances is water failing to exit properly. Blockages can build up over time, impacting performance and potentially causing overflow. Addressing these obstructions promptly helps maintain efficient operation and prolongs the unit’s functionality.

- Check the drain hose for visible clogs. A kinked or obstructed hose can restrict flow, preventing water from leaving the system effectively.

- Inspect the filter. Small items and debris often accumulate here, leading to slow drainage. Clean the filter regularly to avoid these build-ups.

- Examine the pump. Sometimes, objects find their way into the pump area, causing blockage. Remove any visible obstructions to ensure smooth water movement.

- Run

Resolving Agitation Problems

Issues with the stirring function can significantly hinder the efficiency of laundry processes. This section focuses on identifying common challenges and offers practical solutions to restore optimal performance. Understanding the root causes of agitation failures can lead to effective troubleshooting and restore the appliance’s functionality.

Common Causes of Agitation Failures

Several factors may contribute to inadequate stirring action. A worn-out agitator dog or a malfunctioning transmission can disrupt the movement required for proper fabric care. Additionally, issues with the drive belt or motor can lead to insufficient power, preventing the stirring mechanism from engaging fully.

Troubleshooting Steps

Begin by checking the drive belt for wear and ensuring it is properly tensioned. Inspect the agitator components for damage and replace any faulty parts as necessary. If the problem persists, evaluate the motor’s performance and consider consulting a professional for further assistance. Regular maintenance can also help prevent agitation issues from arising in the future.

Replacing the Control Panel

When the interface of a household appliance becomes unresponsive or shows signs of wear, it may be necessary to replace it. This section outlines the essential steps to successfully switch out the control panel, ensuring the device functions properly once again. Proper handling and attention to detail are critical during this process.

Tools Required

Before starting, gather the necessary tools to facilitate a smooth replacement. Here’s a list of items you’ll need:

Tool Purpose Screwdriver To remove screws securing the panel Pliers For gripping and manipulating wires Replacement Panel New interface for the device Multimeter To check electrical connections Step-by-Step Instructions

Follow these steps to replace the interface:

- Unplug the appliance to ensure safety.

- Remove screws from the existing panel using the screwdriver.

- Carefully disconnect any wiring attached to the old panel.

- Attach the new panel, ensuring all wires are securely connected.

- Reassemble the appliance by securing it with screws.

- Plug in the device and test the new control panel for functionality.

Repairing a Leaking Washer

Addressing a leaking appliance is crucial to maintaining its efficiency and longevity. Identifying the source of the issue is the first step in resolving it. Various components may contribute to water escaping, and understanding these elements can aid in effective troubleshooting.

Common Causes: Leaks often stem from worn-out seals, loose connections, or damaged hoses. Inspecting these areas can reveal whether they require attention. A thorough examination of the machine’s interior and exterior can pinpoint the origin of the leakage.

Steps to Take: Begin by disconnecting the appliance from the power source and water supply. Check the hoses for cracks or kinks and replace them if necessary. Next, examine the door seal for any signs of wear; a compromised seal can lead to significant leaks. Tightening connections can also help mitigate water loss.

Testing: Once repairs are completed, reconnect the appliance and run a short cycle. Observe for any signs of leakage during operation. If issues persist, further investigation may be required, possibly involving the assistance of a qualified technician.

Maintaining a leak-free environment is essential for the optimal performance of any washing machine. Regular inspections can help catch potential problems early, ensuring the appliance functions smoothly for years to come.

Maintaining the Drum Bearings

Ensuring the longevity and efficiency of your appliance involves regular upkeep of its internal components. One critical aspect of this maintenance is the care of the drum bearings, which play a vital role in the smooth operation of the drum. Proper attention to these elements can prevent unnecessary wear and enhance performance.

To maintain the drum bearings effectively, it is essential to regularly check for signs of wear or damage. Listening for unusual noises during operation can indicate issues that need to be addressed. Additionally, ensuring that the bearings are well-lubricated can significantly reduce friction and prevent overheating.

Cleaning around the bearings is also crucial. Debris and residue can accumulate, leading to decreased functionality. Use a soft cloth to remove any buildup, and be cautious not to damage the components during this process. Regular inspections and prompt action when problems arise will help ensure optimal performance and extend the life of the drum assembly.

Understanding Error Codes and Solutions

Error codes can often be perplexing for users, as they signify various issues that may arise during the operation of household appliances. Grasping these codes is essential for effective troubleshooting and ensuring optimal performance. This section aims to elucidate the meanings behind common indicators and provide actionable solutions to resolve them efficiently.

Common Error Codes

Familiarizing yourself with frequent error messages can significantly ease the troubleshooting process. Below is a table summarizing some of the most prevalent codes and their implications:

Error Code Meaning Suggested Solution E1 Indicates a problem with the water supply. Check the water source and ensure hoses are not kinked or blocked. E2 Signifies a drainage issue. Inspect the drain hose for clogs and ensure it is properly positioned. E3 Represents an imbalance during operation. Redistribute the load evenly in the drum. E4 Indicates a door latch malfunction. Ensure the door is securely closed; if the issue persists, inspect the latch mechanism. Troubleshooting Steps

When faced with an error code, following a systematic approach can lead to effective resolution. First, consult the appliance’s documentation to verify the specific error code. Next, execute the suggested solutions sequentially, observing any changes in the appliance’s operation. If issues persist despite following these steps, seeking professional assistance may be necessary to address more complex problems.

Replacing the Washer Door Seal

Maintaining the integrity of your laundry appliance is essential for optimal performance. One crucial component that may require attention over time is the door seal. This part not only prevents leaks but also ensures that your machine functions efficiently. In this section, we will discuss the steps involved in replacing the door seal, helping you restore your appliance to its best condition.

Identifying the Need for Replacement

Before starting the replacement process, it is important to recognize the signs indicating that the door seal is worn or damaged. Look for cracks, tears, or any mold buildup around the seal. If you notice water pooling around the machine or a persistent musty smell, these could be clear indicators that it’s time for a new seal. Addressing these issues promptly will help prevent further damage and maintain the effectiveness of your appliance.

Step-by-Step Replacement Process

To begin the replacement, ensure that the appliance is unplugged for safety. Carefully remove the old seal by detaching it from its retaining clips or screws. Clean the area thoroughly to remove any debris or detergent residue. Next, position the new seal into place, ensuring it fits snugly. Secure it with the appropriate clips or screws, and check for any gaps. Finally, run a short cycle without laundry to test for leaks and ensure proper installation.

Regular maintenance of the door seal will prolong the life of your appliance and improve its efficiency. By taking these simple steps, you can enhance your laundry experience and avoid unnecessary repairs in the future.

Calibrating the Washer Sensor

Proper adjustment of the washing device’s sensor is crucial for ensuring optimal performance and efficiency. Calibration helps the appliance accurately detect load size, water levels, and cycle duration, ultimately enhancing the washing experience. This process involves a few straightforward steps to ensure the sensor functions correctly, leading to improved results with each wash.

Understanding the Calibration Process

To begin calibration, it is essential to gather the necessary tools and materials. Generally, you will need a multimeter, a screwdriver, and a cleaning cloth. The first step involves accessing the sensor unit, typically located within the control panel or beneath the lid. Carefully remove any coverings to expose the sensor connections.

Executing the Calibration

Once the sensor is accessible, use the multimeter to check for proper readings. Adjust the settings as needed to ensure the sensor accurately reflects the correct measurements. After making adjustments, reassemble the washer and perform a test cycle to confirm that the calibration was successful. Regularly checking and calibrating the sensor can prevent issues and prolong the lifespan of the appliance.

Optimizing Washer Performance

Enhancing the efficiency of your laundry appliance can significantly improve cleaning results and extend the lifespan of the machine. By implementing a few simple strategies, users can ensure that their unit operates at peak capacity while conserving resources.

Regular Maintenance: Routine upkeep is essential for optimal functionality. This includes checking hoses for any signs of wear, ensuring filters are clean, and periodically inspecting drum seals for leaks. Addressing these minor issues promptly can prevent more significant problems down the line.

Correct Loading: Avoid overloading the appliance, as this can hinder performance and lead to inadequate cleaning. Follow the manufacturer’s guidelines regarding load sizes to ensure proper agitation and water distribution during cycles.

Water Temperature: Utilizing the appropriate water temperature for different fabric types can enhance cleaning efficacy. For instance, cold water is suitable for delicate items, while hot water can be effective for heavily soiled fabrics.

Detergent Usage: Selecting the right detergent and using the correct amount is crucial. Too much detergent can leave residue on clothes, while too little may not clean effectively. Refer to the detergent packaging for guidance on the appropriate dosage.

Cycle Selection: Different laundry cycles cater to various fabric types and soil levels. Familiarize yourself with the cycle options available on the appliance and select the one that best suits your laundry needs.

By incorporating these practices, users can maximize the performance of their laundry appliance, leading to cleaner clothes and increased efficiency.