Understanding the intricacies of maintaining and servicing marine engines can greatly extend their lifespan and enhance performance. Proper care and timely adjustments ensure that these powerful machines continue to run smoothly, even in challenging conditions. With a structured approach to each stage of maintenance, even complex issues can be addressed effectively.

In this section, we explore the essentials for identifying and resolving common mechanical challenges encountered during regular operation. Detailed resources and step-by-step instructions are invaluable tools for both novice enthusiasts and seasoned mechanics. By familiarizing yourself with specific components and their functions, you can tackle minor and major issues confidently.

Moreover, knowing the basics of engine upkeep not only saves on costs but also minimizes unexpected breakdowns.

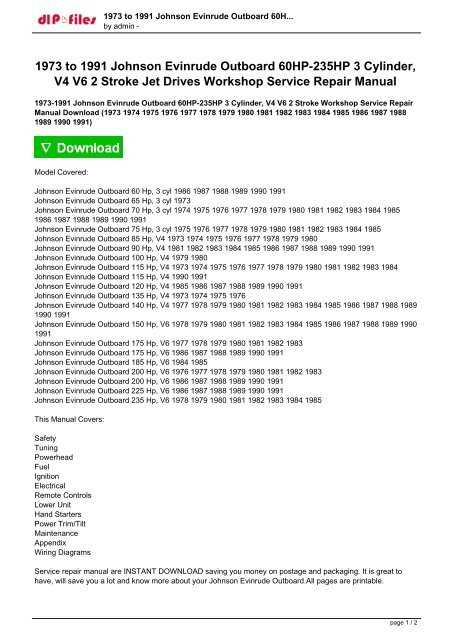

Understanding Evinrude Outboard Repair Manuals

Familiarity with engine service guides is essential for anyone who seeks to maintain smooth and efficient motor function. These resources offer comprehensive information on mechanisms, maintenance practices, and essential diagnostics, enabling users to address common mechanical challenges and enhance engine performance.

Key Components Explained

Engine service guides typically include detailed diagrams, system overviews, and step-by-step instructions that clarify the inner workings of the machinery. They cover core parts such as the propulsion system, fuel circuits, and electronic modules, giving users the knowledge to assess and resolve issues effectively.

Troubleshooting and Preventative Tips

A well-organized guide is invaluable for identifying potential issues before they escalate. Troubleshooting sections offer insights into typical symptoms, recommended tools, and safe practices

Common Issues with Evinrude Engines

Understanding typical complications that arise in marine motors can be essential for anyone looking to maintain smooth operation on the water. These challenges often require a blend of practical knowledge and careful inspection to ensure engines continue to run efficiently.

Engine Starting Problems

A frequently encountered issue is difficulty with ignition. This could stem from battery wear, spark plug faults, or even clogged fuel lines. Checking each component systematically helps to isolate the source and address it swiftly.

Overheating During Operation

Overheating can occur when cooling mechanisms are impaired, often due to blockages in the intake or a malfunctioning thermostat. Inspecting water flow and keeping the cooling system clear helps to prevent such issues.

Irregular Power Delivery

Unstable power output can be linked to fuel system inconsistencies or air intake disruptions. Regularly cleaning f

Basic Maintenance Tips for Outboards

Regular care is essential to ensure the long-term performance and reliability of marine engines. By dedicating time to essential upkeep, boat owners can reduce the risk of issues and keep their engine running smoothly during each outing. Below are key steps to maintaining a dependable engine that performs consistently on the water.

Inspect and Clean Key Components

Frequent checks and cleaning of crucial elements, such as the cooling system and fuel lines, prevent clogging and overheating. Cleaning the fuel filter and inspecting it for debris or wear helps maintain smooth operation. Proper fuel flow is vital, so regularly clear any buildup that could obstruct the system.

Lubricate and Replace Parts as Needed

Ensuring moving parts are well-lubricated reduces friction and extends the life of the engine. Apply

Identifying Signs of Engine Wear

Recognizing early symptoms of engine wear is crucial for maintaining optimal performance and longevity. Over time, various internal and external factors can affect the efficiency of engine components, often leading to subtle changes in how the engine operates. Spotting these indicators promptly allows for timely intervention and can prevent more serious issues.

Common warning signs include unusual noises, diminished power, and increased fuel consumption. An engine experiencing wear may produce knocking sounds or vibrations, indicating that moving parts may no longer function smoothly. Reduced output can also be a clear indicator, as the engine might struggle to reach usual speeds or performance levels. Additionally, a significant rise in fuel usage can point to internal inefficiencies that often accompany wear.

Monitoring exhaust color can provide further insights. For instance, blue smoke can signal oil burning, while black smoke suggests f

Steps to Troubleshoot Fuel Problems

When engines experience performance issues, fuel delivery complications are often the cause. Addressing these concerns systematically can help in pinpointing the root problem and ensure smoother operation. This guide covers essential steps to identify and resolve common fuel-related challenges efficiently.

Check Fuel Lines and Connections

Begin by inspecting the fuel lines for any signs of wear, cracks, or leaks, as these can lead to poor fuel flow. Ensure all connections are secure, especially at joints and clamps. A visual check can often reveal obvious issues that interfere with the fuel supply.

Examine the Fuel Filter and Pump

A clogged fuel filter or a malfunctioning fuel pump can restrict fuel from reaching the engine properly. Check the filter for debris and consider replacing it if it appears dirty. Similarly, test the pump’s pressure to ensure it’s functioning within the optimal range.

Replacing Key Engine ComponentsMaintaining optimal performance in marine engines often involves the timely replacement of essential parts. This section outlines the crucial steps involved in ensuring these components are swapped out effectively, enhancing the overall functionality of the motor. Understanding the importance of each part helps in executing replacements accurately, ultimately extending the lifespan of the engine. Identifying Essential Parts

Before initiating any replacement process, it is vital to recognize the critical components that may require attention. These parts include the fuel system elements, ignition components, and cooling mechanisms. Each plays a significant role in the engine’s operation, and identifying wear or malfunction is key to maintaining performance. Step-by-Step Replacement Process

To ensure a successful component replacement, follow a systematic approach:

By adhering to these steps, users can effectively replace key components and maintain the engine’s performance. Electrical System Diagnosis and RepairThis section focuses on the evaluation and rectification of electrical components found in marine engines. Understanding the intricacies of these systems is essential for ensuring optimal performance and reliability. Effective troubleshooting techniques can help identify common issues, enabling timely interventions to enhance overall functionality. To properly diagnose electrical issues, it is vital to understand the basic components involved. Common elements include batteries, wiring harnesses, connectors, and circuit breakers. Each part plays a critical role in the seamless operation of the system.

When encountering issues, it is crucial to conduct a systematic inspection. Start by verifying the power source, followed by examining each component for signs of wear or damage. Addressing problems promptly can prevent further complications and maintain the longevity of the system. Best Practices for Winterizing OutboardsProper preparation for the colder months is essential for maintaining the longevity and functionality of your marine engine. Winterization involves a series of steps designed to protect the internal components from harsh temperatures and prevent damage caused by freezing conditions. Adhering to effective methods ensures that your vessel will be ready for smooth operation when the warm weather returns. 1. Thorough Cleaning: Begin by cleaning the exterior and the interior components of the engine. Remove any saltwater residue, dirt, and debris to prevent corrosion and buildup over time. A clean engine is crucial for identifying any potential issues before storage. 2. Fuel Stabilization: Add a fuel stabilizer to the tank to prevent fuel degradation during the off-season. Run the engine for a few minutes to ensure that the stabilizer circulates through the fuel system, reducing the risk of clogs and maintaining optimal performance. 3. Cooling System Maintenance: Flush the cooling system with fresh water to eliminate any contaminants. This process helps prevent freezing and ensures that the passages remain clear, reducing the risk of overheating when the engine is back in use. 4. Lubrication: Apply appropriate lubricants to moving parts and other key areas. This practice reduces friction and protects against rust, ensuring that everything operates smoothly when it’s time to hit the water again. 5. Battery Care: Disconnect and store the battery in a cool, dry location. Regularly check its charge level, and consider using a trickle charger to maintain optimal performance throughout the winter. Implementing these strategies will safeguard your marine engine from winter-related issues and set the stage for a successful season ahead. Lubrication and Cooling System Care

Maintaining proper lubrication and cooling is essential for the optimal performance and longevity of marine engines. Regular attention to these systems helps prevent overheating and ensures smooth operation, enhancing overall reliability. Understanding the components involved and their respective maintenance requirements can significantly impact the efficiency of your vessel. Lubrication plays a crucial role in reducing friction between moving parts, which minimizes wear and tear. It is important to regularly check and replenish lubricants as per the manufacturer’s recommendations. Utilizing high-quality oils can greatly improve engine performance and lifespan. Additionally, ensure that all seals and gaskets are in good condition to prevent leaks, which can compromise lubrication. Cooling systems are equally vital, as they regulate the engine temperature during operation. Regular inspection of the cooling system components, including hoses and water pumps, is necessary to avoid blockages and leaks. Flushing the cooling system periodically removes debris and prevents corrosion, ensuring effective heat dissipation. Monitoring the temperature gauge during use can help identify potential issues early on. By prioritizing both lubrication and cooling system care, you contribute to the overall health of your marine engine, leading to better performance and reduced risk of breakdowns. Consistent maintenance practices will ensure that your vessel remains reliable for all your adventures on the water. Guidelines for Safe Engine Storage

Proper storage of your engine is essential to ensure its longevity and reliable performance. Adhering to specific guidelines can help prevent damage during off-season periods and extend the lifespan of your machinery. This section outlines key practices for securely storing your engine while maintaining its functionality. Preparation Steps

Before storing your engine, it is crucial to perform a thorough inspection and necessary maintenance. Clean the exterior to remove any dirt or debris, and check for any signs of wear or damage. Drain all fluids, including fuel and oil, to prevent contamination and deterioration over time. Additionally, consider using a protective cover to shield the engine from dust and moisture. Storage Environment

Choosing the right environment for storage is vital. Ideally, the engine should be kept in a dry, temperature-controlled area to avoid exposure to extreme conditions. Humidity and temperature fluctuations can lead to corrosion and mechanical failures. If possible, elevate the engine off the ground to protect it from potential water damage. |

|---|