The journey of automobile ownership often entails a deep understanding of the intricacies involved in maintaining one’s vehicle. Proper upkeep is essential not only for ensuring optimal performance but also for prolonging the lifespan of the automobile. This section aims to provide insights into effective maintenance practices that can enhance the overall driving experience.

Comprehending the various components and systems within a car is fundamental for any owner. By familiarizing oneself with the mechanical aspects, individuals can more effectively address issues as they arise. This knowledge empowers owners to make informed decisions regarding necessary interventions, ultimately leading to a more reliable and efficient vehicle.

In this guide, practical advice and helpful tips will be shared to assist car enthusiasts and everyday drivers alike. Whether you are tackling routine checks or seeking solutions to specific challenges, the information provided here will serve as a valuable resource in navigating the world of automobile care.

This section outlines a comprehensive framework for an informative guide aimed at assisting individuals with the maintenance and troubleshooting of a specific vehicle model. The content will be organized into several key areas, focusing on essential procedures, common issues, and helpful tips to ensure optimal performance.

Essential Maintenance Procedures

Regular upkeep is crucial for enhancing the longevity and reliability of the vehicle. This part will cover vital tasks that owners should perform periodically, such as checking fluid levels, inspecting brakes, and maintaining tire pressure. Following these practices can prevent more significant problems down the line.

Common Issues and Solutions

Identifying frequent problems that users may encounter with this vehicle type is essential. This section will provide insights into typical malfunctions, along with step-by-step solutions to address them effectively. By being informed, owners can tackle minor issues before they escalate into major repairs.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Excessive temperature rise due to coolant leaks or radiator failure. | Check coolant levels, inspect hoses, and replace the thermostat if necessary. |

| Braking Problems | Unresponsive or squeaky brakes indicating wear or malfunction. | Inspect brake pads and rotors, and replace them if worn. |

| Electrical Issues | Faulty lights or power accessories due to battery or wiring problems. | Test the battery and check wiring connections for damage. |

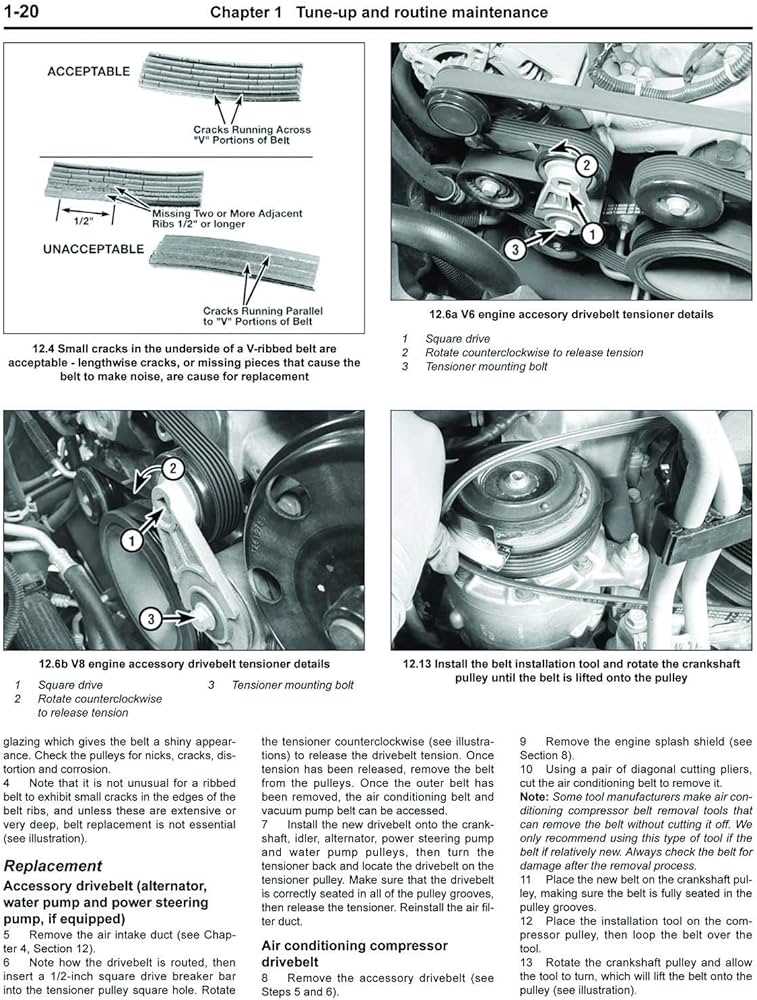

Essential Tools for Repairs

Having the right set of instruments is crucial for any maintenance task. Whether tackling minor adjustments or significant overhauls, proper tools enhance efficiency and ensure the job is done correctly. Understanding which implements to have on hand can significantly impact the success of your projects.

Basic Hand Tools: A fundamental toolkit should include wrenches, pliers, and screwdrivers in various sizes. These versatile items allow for adjustments and replacements in tight spaces.

Specialized Equipment: For more intricate tasks, specialized gear such as torque wrenches and socket sets becomes indispensable. These tools provide precision and ease when working on complex components.

Safety Gear: Always prioritize safety by equipping yourself with gloves, goggles, and other protective clothing. This precaution helps prevent injuries while working.

Diagnostic Tools: Incorporating diagnostic devices, such as multimeters and OBD-II scanners, enables quick identification of issues. This technology aids in troubleshooting and can save time during the repair process.

By assembling a well-rounded toolkit, you’ll be prepared to handle a variety of maintenance tasks effectively. Investing in quality tools not only enhances your capability but also fosters confidence in your skills.

Common Issues with Dodge Neon

Many vehicle owners encounter various challenges that can affect performance and reliability. Understanding these frequent concerns can assist in proactive maintenance and enhance the longevity of the automobile. Below are some prevalent issues that may arise, along with insights into their potential causes and solutions.

Engine Problems

Engine misfires are often reported, leading to reduced power and efficiency. These misfires may be attributed to faulty spark plugs or ignition coils. Regular checks and timely replacements of these components can help mitigate such issues and ensure smooth operation.

Electrical System Failures

Another common challenge involves the electrical system, where components like the battery or alternator may fail. Symptoms such as dimming lights or difficulty starting the vehicle can indicate these problems. Routine inspection of the electrical connections and components is essential to prevent unexpected breakdowns.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to regular upkeep, ensuring optimal performance and longevity of your vehicle. Following a systematic routine allows for the identification of potential issues before they escalate, enhancing safety and reliability on the road.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 3,000 – 5,000 miles | Replace engine oil and filter to ensure smooth operation and prevent engine wear. |

| Tire Rotation | Every 6,000 – 8,000 miles | Change the position of tires to promote even wear and extend tire life. |

| Brake Inspection | Every 10,000 miles | Check brake pads, rotors, and fluid levels to maintain effective braking performance. |

| Fluid Check | Monthly | Inspect and top off essential fluids, including coolant, brake, and transmission fluids. |

| Battery Maintenance | Every 6 months | Clean terminals and check charge level to avoid starting issues. |

Engine Diagnostics and Troubleshooting

Proper evaluation and resolution of issues related to the engine are essential for maintaining optimal performance and longevity. This section focuses on identifying symptoms, employing diagnostic techniques, and implementing solutions to common engine-related problems. A systematic approach not only aids in accurate diagnosis but also enhances efficiency during the troubleshooting process.

Understanding Symptoms: The first step in diagnosing engine issues is recognizing various indicators of malfunction. Unusual noises, decreased performance, or warning lights on the dashboard can signal underlying problems. Paying attention to these signs can help in pinpointing the root cause.

Diagnostic Techniques: Utilizing diagnostic tools, such as an OBD-II scanner, can provide valuable insights into the engine’s performance. These tools help retrieve error codes that indicate specific faults, allowing for a more targeted approach in addressing issues.

Troubleshooting Common Problems: Common engine issues may include rough idling, overheating, or starting difficulties. Addressing these concerns often involves checking vital components such as spark plugs, fuel injectors, and the cooling system. Ensuring all parts function correctly is crucial for restoring the engine’s performance.

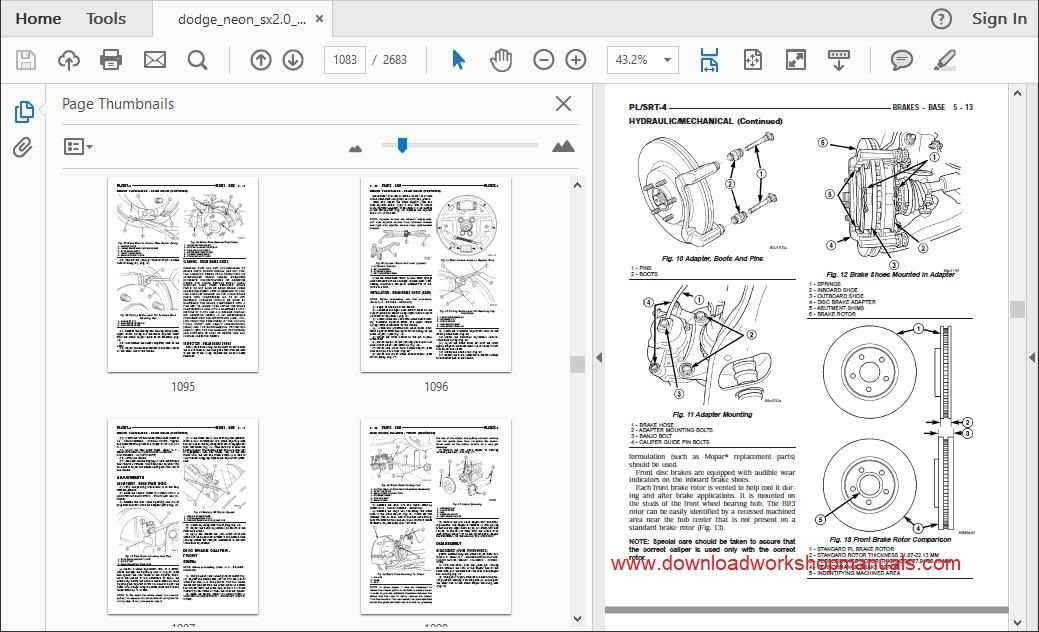

Brake System Inspection Techniques

Ensuring the functionality of the braking system is crucial for vehicle safety and performance. Regular inspection techniques play a significant role in identifying potential issues before they escalate. This section outlines various methods to assess the braking components, helping maintain optimal operation and safety standards.

Visual Inspection

A thorough visual examination of the braking system is the first step in the inspection process. Inspect the brake pads, rotors, and calipers for any signs of wear or damage. Look for uneven wear patterns on the pads and ensure that there are no fluid leaks around the calipers or lines. This initial check can reveal critical issues that require immediate attention.

Functional Testing

After the visual inspection, conducting functional tests is essential. This involves checking the responsiveness of the brake pedal and assessing how the vehicle reacts during braking. Listen for unusual noises, such as grinding or squeaking, which may indicate worn components. Additionally, test the anti-lock braking system (ABS) if equipped, ensuring it engages correctly during emergency stops.

Transmission Fluid Replacement Process

Regular maintenance of a vehicle’s transmission system is crucial for optimal performance and longevity. One key aspect of this maintenance is the timely replacement of transmission fluid, which ensures smooth operation and prevents potential issues related to wear and overheating.

Required Tools and Materials

Before beginning the fluid replacement process, gather the necessary tools and materials. This will streamline the procedure and ensure that all components are properly addressed.

| Tools | Materials |

|---|---|

| Wrench set | New transmission fluid |

| Fluid pump | New transmission filter (if applicable) |

| Drain pan | Gasket or sealing compound |

| Funnel | Cleaning rags |

Step-by-Step Process

Start by safely elevating the vehicle and placing it on jack stands. Locate the transmission fluid pan and drain the old fluid into the drain pan. After the fluid has fully drained, remove the transmission filter if applicable. Clean the pan and replace the filter if necessary, ensuring that any old gaskets are removed. Reinstall the pan and secure it with the appropriate fasteners. Using the fluid pump and funnel, refill the transmission with the new fluid through the designated fill tube. Finally, start the engine and let it idle for a few minutes while checking for leaks and ensuring proper fluid levels.

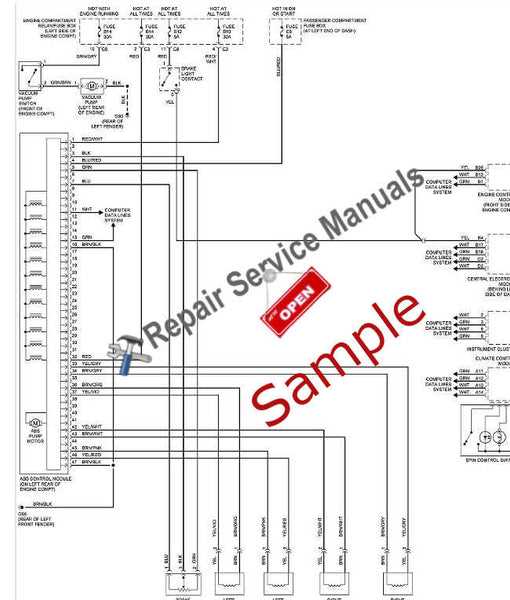

Electrical System Troubleshooting Tips

Troubleshooting issues within an electrical system can be a challenging yet rewarding process. By systematically identifying and addressing potential faults, vehicle owners can ensure optimal performance and safety. This section provides practical guidance on how to diagnose common electrical problems effectively.

Begin by checking the battery condition. A weak or dead battery is often the primary culprit behind electrical failures. Utilize a multimeter to measure the voltage, ensuring it falls within the manufacturer’s specifications. If the voltage is low, consider charging or replacing the battery.

Next, inspect the wiring and connections. Look for signs of corrosion, fraying, or loose connections, as these can disrupt the flow of electricity. Pay particular attention to ground connections, as a poor ground can lead to various issues throughout the system.

Additionally, assess the fuses and relays. A blown fuse can prevent electrical components from functioning correctly. Refer to the vehicle’s fuse diagram to locate and test each fuse, replacing any that are faulty. Similarly, test relays to ensure they are operational.

Finally, utilize a diagnostic scanner to read any trouble codes from the vehicle’s onboard computer. These codes can provide valuable insights into underlying issues, helping to narrow down potential problems. Addressing the identified codes can lead to a more efficient troubleshooting process.

Suspension and Steering Maintenance

Proper upkeep of the suspension and steering systems is essential for ensuring optimal handling and comfort in a vehicle. These components work together to provide stability and a smooth ride, while also allowing for precise control during navigation. Regular inspections and maintenance can prevent costly repairs and enhance overall safety.

It is important to regularly check various elements within the suspension and steering systems. Key components include shock absorbers, struts, control arms, and tie rods. Each part plays a vital role in maintaining the integrity of the vehicle’s ride and handling characteristics.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Shock Absorbers | Inspect for leaks and performance issues | Every 30,000 miles |

| Control Arms | Check for wear and proper alignment | Every 50,000 miles |

| Tie Rods | Examine for looseness and wear | Every 40,000 miles |

| Struts | Assess for performance and leakage | Every 60,000 miles |

Timely maintenance of these systems contributes to prolonged vehicle life and enhanced driving experience. Addressing any issues promptly will ensure the vehicle remains safe and enjoyable to operate.

Cooling System Care and Repair

Maintaining an efficient cooling system is crucial for the longevity and performance of your vehicle. This section outlines essential practices for ensuring that the cooling apparatus functions optimally, preventing overheating and potential engine damage. Regular inspection and timely interventions can greatly enhance the overall health of the system.

Routine Maintenance Practices

Regularly checking coolant levels is fundamental to system performance. Ensure that the fluid is topped up to the recommended level and inspect for any leaks that may compromise the system’s integrity. Additionally, flushing the system periodically helps remove debris and contaminants, promoting better heat exchange.

Troubleshooting Common Issues

If the engine shows signs of overheating, it is essential to investigate the cooling system promptly. Common indicators include a malfunctioning thermostat, a damaged radiator, or a failing water pump. Identifying these issues early can prevent severe damage and costly repairs, ensuring a reliable driving experience.

Interior Repairs and Upgrades

Maintaining and enhancing the interior of your vehicle can significantly improve both comfort and aesthetic appeal. Whether you’re looking to fix minor issues or make substantial upgrades, understanding the essential aspects of interior modification is crucial. This section will explore various techniques and materials that can help you achieve a refreshed and functional space inside your car.

Common Interior Issues

Over time, interiors can suffer from wear and tear due to regular use. Common problems include worn upholstery, damaged trim pieces, and malfunctioning components. Identifying these issues early can prevent further deterioration and make it easier to implement fixes. Regular inspection and maintenance can also help maintain the overall quality of your vehicle’s interior.

Upgrading Your Space

Upgrades can range from simple enhancements, such as installing new floor mats, to more complex projects, like reupholstering seats or adding advanced audio systems. These improvements not only increase the functionality of the interior but also enhance the driving experience. Consider incorporating modern materials and technologies that align with your personal style and needs.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Upholstery | Replacing or refreshing the seat covers. | Increases comfort and enhances aesthetics. |

| Audio System | Installing upgraded speakers and head units. | Improves sound quality and user experience. |

| Lighting | Adding ambient or LED lights. | Enhances visibility and creates a modern feel. |

Safety Checks and Precautions

Ensuring a secure and reliable vehicle requires meticulous attention to safety measures and protocols. Regular evaluations and preventive actions not only enhance performance but also minimize the risk of accidents and mechanical failures. This section outlines essential safety checks that every vehicle owner should perform to maintain optimal operational conditions.

Regular Inspections

Routine assessments of critical components such as brakes, tires, and lights are vital for safe driving. Checking the condition of brake pads and fluid levels, ensuring proper tire pressure and tread depth, and verifying that all lighting systems function correctly can significantly reduce the likelihood of unforeseen incidents.

Protective Gear and Environment

When undertaking maintenance tasks, it is crucial to wear appropriate safety gear, including gloves and goggles, to protect against potential hazards. Additionally, working in a well-ventilated area reduces exposure to harmful fumes and promotes overall safety while performing any service activities.