Understanding the ins and outs of household devices is essential for ensuring their smooth operation and longevity. Whether it’s due to natural wear over time or minor issues that arise, having the knowledge to address these needs effectively can make a big difference. This guide aims to offer clear, step-by-step information for those looking to keep their machines in top condition.

For those who seek to maintain their equipment independently, this section provides a practical and detailed outline. It covers essential techniques, common concerns, and insightful tips for resolving various situations that may occur during regular use. With accessible explanations, it’s tailored for both beginners and more experienced individuals who value the reliability of their devices.

By following the instructions and guidelines here, users will gain the skills needed to handle routine adjustments and troubleshoot occasional malfunctions confidently. This resource ensures that caring for your appliance becomes a straightforward and efficient task, promoting optimal performance and extending its lifespan.

Troubleshooting Common Washer Issues

In this section, we will explore typical issues that can arise during the operation of a washer, as well as ways to identify and address them effectively. Whether it’s unusual noises, water not draining, or the machine not spinning, understanding these challenges can help ensure a smoother laundry experience and extend the life of the appliance.

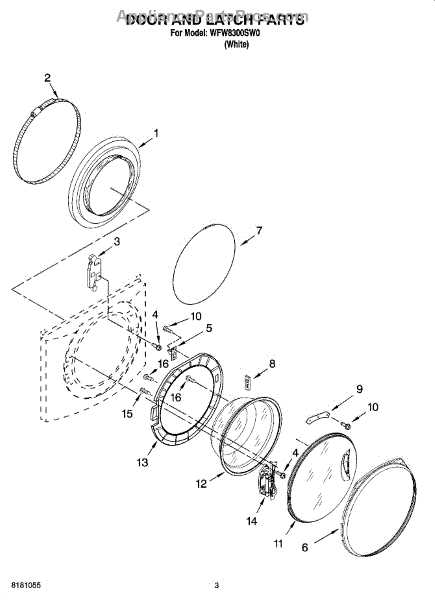

Identifying the Source of Unusual Noises

When your washer begins making unexpected sounds, it may indicate a problem with internal components or an imbalance in the load. Inspect the drum for items that may have slipped out of pockets or ensure that the load is evenly distributed. If sounds persist, check the bearings and other parts for wear.

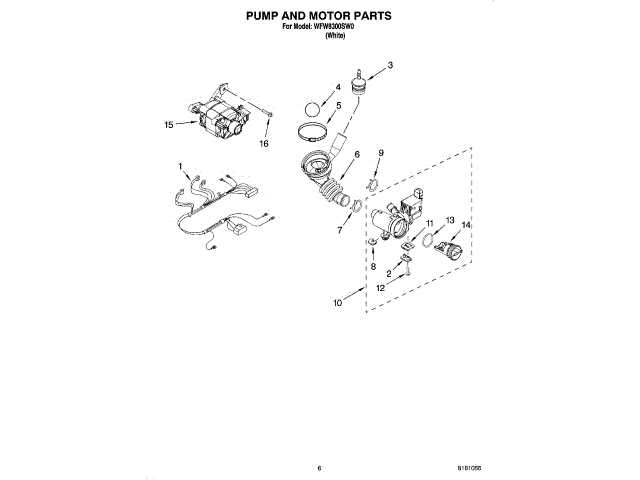

Resolving Water Drainage Problems

If the water fails to drain, it’s often a sign of a clogged hose or a pump issue. Begin by examining the drain hose for obstructions, then check the filter for any buildup that could be blocking the flow. Regularly cleaning these elements can help prevent drainage issues and improve washer efficiency.

Understanding Error Codes and Their Solutions

Modern washing machines are equipped with diagnostic features that help identify and solve operational issues. Each code displayed by the machine points to a specific type of problem, allowing for targeted troubleshooting. In this section, we’ll explore common error codes and straightforward methods to address them, enhancing your machine’s efficiency and longevity.

| Error Code | Description | Suggested Solution | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F01 | Indicates an electronic control system issue, usually related to power disruptions or surges. | Restart the machine by unplugging it for a few minutes, then plug it back in. If the error persists, a more thorough system reset may be necessary. | ||||||||||||||

| F20 | Water supply problem; the machine detects insufficient or no water flow. | Check the water inlet hoses and ensure they are securely connected and free of obstructions. Confirm the water source is turned on and has adequate pressure. | ||||||||||||||

| F21 | Draining issue, usually due to a blockage in the drain system. | Inspect the drain hose and filter for clogs. Clear any obstructions and restart the wash cycle. |

| Step | Description | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Disconnect the machine from the power and water supply to ensure safe handling. | |||||||||||||||

| 2 | Locate the water inlet valve, typ

Dealing with Drainage Blockages Effectively

Addressing drainage issues is crucial for maintaining optimal performance and preventing further complications in your laundry appliance. Blockages can arise from various sources, leading to inefficient drainage and possible malfunctions. This section provides practical approaches to effectively manage and resolve such obstructions. Identifying the root cause of drainage problems is the first step in addressing them. Common culprits include lint buildup, foreign objects, or even residue from detergents. Regular inspection and maintenance can prevent these issues from escalating.

By following these steps, you can effectively manage drainage blockages and maintain the functionality of your laundry device, ensuring it operates smoothly for years to come. Adjusting Water Temperature SettingsProper management of water temperature is crucial for achieving optimal washing results. By fine-tuning these settings, users can enhance the effectiveness of their laundry routine, ensuring that garments are cleaned efficiently while preserving their quality. Understanding Temperature OptionsMost washing machines offer a variety of temperature choices. Familiarizing yourself with these options allows for informed decisions based on fabric type and soil level. Here are common temperature settings:

Adjusting Settings

To modify the water temperature settings, follow these steps:

Checking and Replacing Washer Belts

Maintaining the performance of your laundry appliance often involves inspecting and changing the drive belts. These components play a crucial role in ensuring that the machine operates smoothly and efficiently. A worn or damaged belt can lead to issues such as noise during operation or failure to spin properly. Follow these steps to check and replace the belts:

Regularly checking and replacing these belts can help prolong the lifespan of your washing appliance and maintain its efficiency. Control Board Repair and Replacement GuideThis section offers a comprehensive overview of addressing issues related to the control board of your washing appliance. The control board plays a vital role in the operation of your unit, managing various functions and ensuring efficient performance. Understanding how to troubleshoot, fix, or replace this component can significantly enhance the longevity and reliability of your machine. Troubleshooting Common IssuesBefore proceeding with any modifications, it’s essential to identify typical problems that may arise with the control board. Here are some common symptoms:

Steps for Replacement

If troubleshooting indicates a need for replacement, follow these steps:

After installation, test the appliance to ensure it operates correctly. Proper handling and installation can prevent future issues and extend the lifespan of your machine. Cleaning the Washer’s Filter ProperlyRegular maintenance of the washing machine is essential to ensure optimal performance. One critical aspect of this upkeep is the proper cleaning of the filter. A clean filter can prevent clogs, reduce noise, and enhance the efficiency of your appliance. To effectively clean the filter, follow these steps:

By following these steps, you can maintain the filter in excellent condition, leading to better performance and longevity of your washing machine. Diagnosing and Fixing Motor Issues

Understanding the problems that may arise with the motor in your appliance is crucial for effective troubleshooting. Various symptoms can indicate motor-related difficulties, and recognizing these early can prevent further damage. This section provides insights into identifying and resolving common motor malfunctions. Common Symptoms of Motor Problems

Troubleshooting Steps

By following these diagnostic steps, you can identify and resolve motor-related issues effectively. Regular maintenance and attention to these components will enhance the longevity of your appliance. Maintenance Tips for Longevity

Ensuring the extended lifespan of your appliance requires consistent care and attention. Regular upkeep can prevent common issues and enhance performance. Here are some essential practices to keep in mind:

By following these straightforward guidelines, you can significantly extend the life of your appliance while maintaining its efficiency. |