Understanding the intricacies of hydraulic systems is essential for anyone involved in their operation and upkeep. This guide offers valuable insights into the procedures necessary for ensuring optimal performance and longevity of critical machinery components. By familiarizing yourself with effective strategies for addressing potential issues, you can enhance efficiency and prevent costly downtime.

In the world of hydraulic technology, knowledge is power. This resource aims to equip technicians and engineers with the essential techniques and troubleshooting methods needed for successful maintenance. Detailed instructions will assist you in diagnosing problems, performing routine checks, and implementing corrective measures with confidence.

Whether you are an experienced professional or just starting in the field, mastering the upkeep of these complex systems is vital. By following the outlined steps and recommendations, you can achieve a deeper understanding of operational mechanics and ensure your equipment remains in peak condition. Prepare to dive into the specifics of service procedures and maintenance strategies that can significantly extend the life of your hydraulic apparatus.

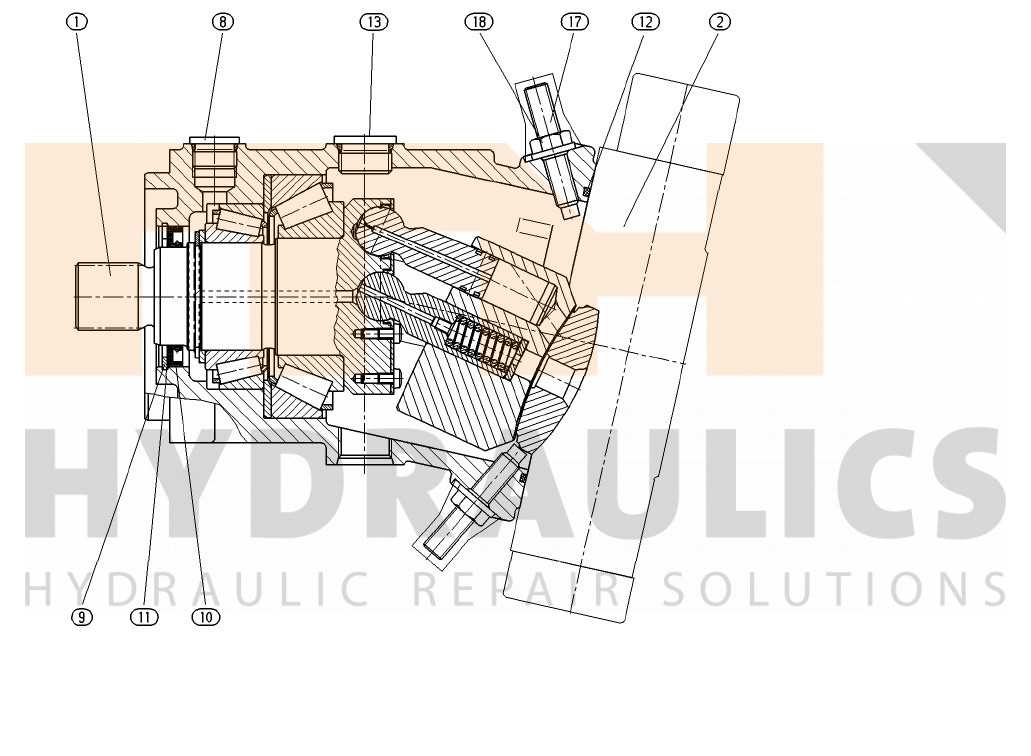

Understanding Rexroth A6VM Components

Grasping the intricacies of hydraulic systems involves delving into their essential elements. Each part plays a pivotal role in ensuring the overall efficiency and functionality of the unit. By familiarizing oneself with these components, one can enhance operational performance and troubleshoot potential issues more effectively.

Main Components Overview

The primary parts of a hydraulic unit contribute to various functions, from fluid movement to pressure regulation. Understanding these elements is crucial for anyone involved in maintenance or operation. Below is a brief overview of the key components:

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure and moves fluid through the system. |

| Motor | Converts hydraulic energy back into mechanical energy for driving machinery. |

| Valves | Control fluid flow and pressure within the system. |

| Reservoir | Holds hydraulic fluid and provides a space for expansion. |

| Filters | Remove contaminants from the hydraulic fluid to ensure system cleanliness. |

Importance of Understanding Components

A comprehensive understanding of these components allows for better maintenance practices and more informed decision-making. Each part interacts within the system, and recognizing their functions can lead to more efficient troubleshooting and enhanced longevity of the equipment.

Common Issues with A6VM Motors

When working with hydraulic motors, various challenges may arise that can affect their performance and longevity. Understanding these common problems is crucial for effective troubleshooting and maintenance. This section explores frequent issues encountered in these systems, providing insights into their causes and potential solutions.

Performance Degradation

One of the primary concerns is a noticeable decline in operational efficiency. This can manifest as reduced power output or erratic performance. Common culprits include contamination of hydraulic fluid, wear of internal components, and improper settings. Regular monitoring and maintenance are essential to prevent these issues from escalating.

Leakage Problems

Fluid leakage is another prevalent issue that can lead to significant operational inefficiencies and environmental concerns. This can occur at seals, fittings, or any junctions within the system. Identifying the source of the leak promptly is vital, as it can not only affect performance but also cause further damage if left unaddressed. Ensuring proper installation and routine checks can mitigate these risks.

Essential Tools for A6VM Repair

To effectively maintain and restore hydraulic units, having the right equipment is crucial. The tools required can significantly influence the efficiency and accuracy of the process, ensuring that components function optimally after servicing.

Here’s a list of essential instruments you should consider:

- Torque Wrench: Necessary for applying precise torque to bolts and screws, preventing over-tightening or under-tightening.

- Hydraulic Test Kit: Used to measure pressure and flow rates, helping diagnose potential issues within the system.

- Socket Set: A comprehensive set is vital for removing and installing various fasteners.

- Digital Multimeter: Essential for checking electrical components and ensuring proper connectivity.

- Seal Puller: Designed to safely remove seals without damaging surrounding parts.

- Cleaning Supplies: Including solvents and brushes, these help maintain component cleanliness, which is crucial for proper operation.

Investing in high-quality tools not only enhances the repair process but also extends the lifespan of hydraulic systems, ensuring they run smoothly and efficiently.

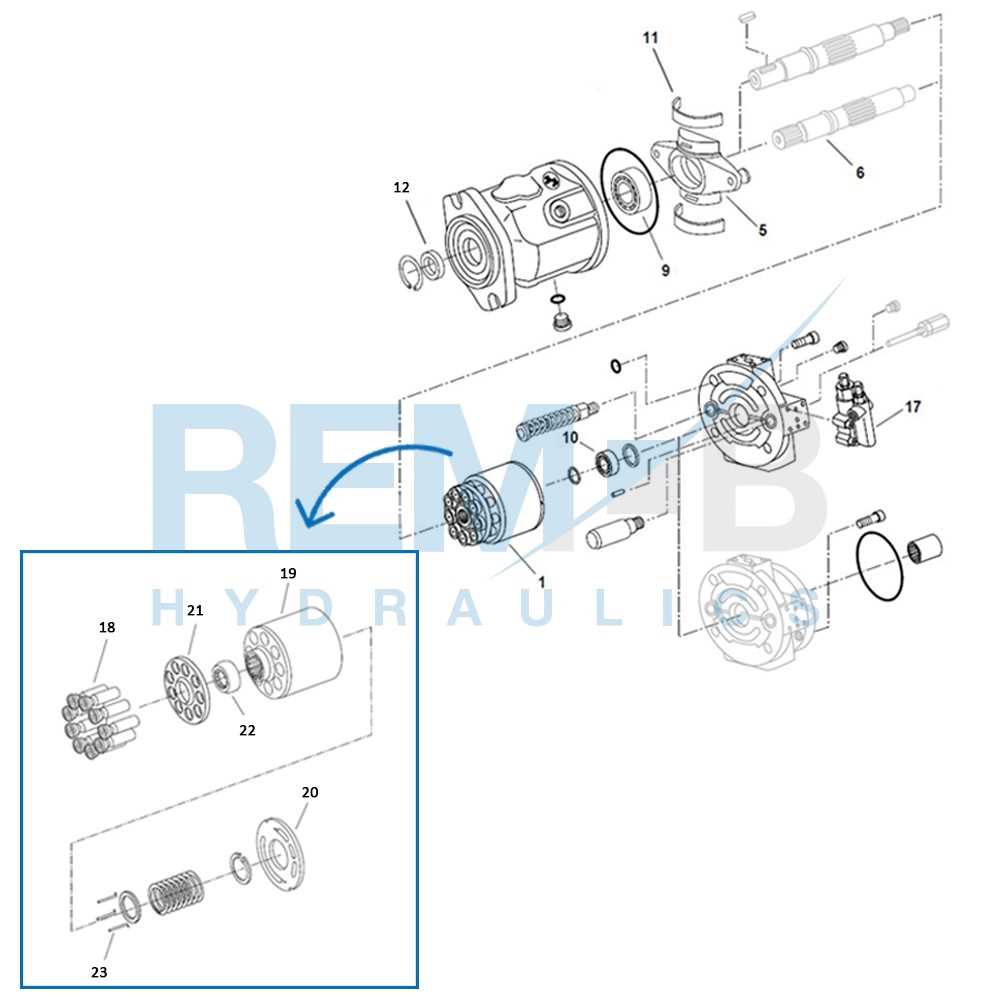

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues in hydraulic units. Following these guidelines will ensure effective troubleshooting and restoration, enhancing overall performance and reliability.

Preparation and Safety Measures

Before initiating any maintenance tasks, it is crucial to take the necessary precautions. Ensure the work area is clean and organized, and gather all required tools and materials. Personal protective equipment should be worn at all times to safeguard against potential hazards.

Diagnostic Steps

Start by identifying the symptoms of malfunction. Utilize diagnostic tools to assess performance parameters and isolate the source of the issue. Document all findings for reference during the repair process.

| Step | Description |

|---|---|

| 1 | Gather tools and materials needed for the task. |

| 2 | Conduct a thorough inspection of the unit. |

| 3 | Identify and document any faults detected. |

| 4 | Follow specific protocols for disassembly. |

| 5 | Replace or repair defective components. |

| 6 | Reassemble the unit carefully, ensuring all parts are secure. |

| 7 | Test the system to verify proper functionality. |

By adhering to these procedures, you can effectively address issues and maintain optimal operation of hydraulic systems.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when addressing mechanical issues. Proper precautions not only protect individuals but also enhance the effectiveness of the maintenance process. By adhering to safety guidelines, potential accidents can be minimized, leading to a smoother and more efficient troubleshooting experience.

Before commencing any work, it is essential to disconnect power sources to prevent accidental activation of machinery. Utilize appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets, to safeguard against hazards. Always keep the workspace organized to avoid tripping hazards and ensure tools are in good condition.

Familiarize yourself with the equipment’s specifications and operational guidelines to prevent misuse. In cases where heavy components need to be handled, employing lifting devices or assistance from colleagues can significantly reduce the risk of injury. Additionally, be aware of potential chemical hazards and follow correct procedures for handling and disposal.

Regular communication with team members during the process is vital. Ensure that everyone involved is informed about ongoing tasks and potential risks. By fostering a culture of safety and awareness, the likelihood of mishaps can be substantially decreased, creating a more productive environment for all involved.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of hydraulic systems requires regular attention and care. By implementing effective maintenance practices, operators can significantly extend the lifespan of their machinery and reduce the risk of unexpected failures. Here are some essential tips to help you maintain your equipment effectively.

1. Regular Inspections: Conduct frequent inspections to identify any signs of wear or damage. Check for leaks, unusual noises, and vibrations that may indicate underlying issues.

2. Fluid Quality: Use high-quality hydraulic fluids and ensure they are free from contaminants. Regularly monitor fluid levels and replace fluids according to the manufacturer’s recommendations to maintain optimal performance.

3. Temperature Control: Keep an eye on operating temperatures. Excessive heat can lead to premature wear and system failure. Ensure that cooling systems are functioning correctly to prevent overheating.

4. Component Cleaning: Regularly clean components to remove debris and buildup. Accumulated dirt can affect performance and lead to component failure over time.

5. Proper Storage: When not in use, store equipment in a dry and clean environment. Protect it from moisture and extreme temperatures to prevent deterioration.

6. Training and Knowledge: Ensure that operators are well-trained in the correct handling and operation of the machinery. Understanding how to respond to potential issues can prevent costly repairs.

7. Scheduled Maintenance: Establish a routine maintenance schedule that includes checks and replacements of critical components. Following a planned approach helps to catch issues early and keeps systems running smoothly.

By adopting these strategies, you can enhance the reliability of your hydraulic systems and prolong their operational life, ultimately leading to improved productivity and reduced downtime.

Diagnosing Performance Problems

Identifying issues that affect the efficiency of hydraulic systems requires a systematic approach. Understanding the symptoms and potential causes can significantly improve troubleshooting processes. This section outlines essential steps to diagnose performance-related challenges effectively.

Common Symptoms of Performance Issues

- Unusual noises during operation

- Fluctuations in pressure readings

- Poor response time to control inputs

- Inconsistent flow rates

- Overheating components

Steps for Diagnosis

- Perform a visual inspection of the system for leaks or damage.

- Check fluid levels and quality; contamination can hinder performance.

- Measure pressure and flow rates at various points to identify anomalies.

- Examine electrical connections and control systems for faults.

- Consult the system’s specifications to ensure all parameters are within acceptable ranges.

By following these guidelines, technicians can pinpoint the root causes of performance issues and develop effective solutions to restore optimal operation.

Replacement Parts and Where to Find Them

Finding the right components for hydraulic systems is crucial for maintaining optimal performance and longevity. Identifying quality parts can prevent downtime and ensure efficient operation. Here are some avenues to explore when searching for necessary replacements.

- Authorized Dealers: Start with manufacturers’ authorized dealers. They typically offer genuine components that meet quality standards.

- Online Marketplaces: Websites like eBay, Amazon, and specialized industrial sites often list both new and refurbished items. Ensure to check seller ratings and reviews.

- Local Suppliers: Visit local hydraulic equipment suppliers. They may have stock on hand and can provide expert advice on suitable replacements.

- Distributors: Seek out distributors that focus on hydraulic systems. They often have a wide range of components and can assist in sourcing hard-to-find items.

- Salvage Yards: For those on a budget, consider hydraulic salvage yards. They can be a treasure trove for used parts at a fraction of the cost.

Before purchasing, verify compatibility with your existing equipment. This diligence will help you avoid issues and ensure seamless integration of new components.

Technical Specifications of A6VM

This section provides a comprehensive overview of the key characteristics and operational parameters of a specific hydraulic component. Understanding these specifications is crucial for ensuring optimal performance and longevity in various applications. The details covered here will assist users in making informed decisions regarding installation, maintenance, and compatibility.

General Characteristics

The hydraulic unit features a compact design that allows for efficient integration into diverse systems. It is engineered to operate under high pressure, delivering reliable power transmission. The system includes multiple displacement options, providing flexibility to meet varying performance demands. Additionally, its robust construction ensures durability, even in challenging environments.

Performance Parameters

Maximum operating pressure typically reaches significant levels, enabling effective performance across applications. The unit supports various flow rates, facilitating adaptability to different hydraulic circuits. Furthermore, it is designed to minimize energy loss, enhancing overall system efficiency. The temperature range for operation is broad, accommodating diverse working conditions.

Frequently Asked Questions about A6VM

This section addresses common inquiries related to the hydraulic unit known for its performance and efficiency. Here, we aim to provide clear answers to typical concerns, ensuring that users can maintain optimal functionality and longevity.

What are the most common issues associated with this hydraulic system?

Users often report problems such as unusual noise during operation, inconsistent pressure readings, or overheating. These issues can typically be traced back to inadequate maintenance or component wear.

How can I identify if my unit requires servicing?

Indicators include persistent operational noise, leakage of fluid, or erratic performance. Regular checks and listening for abnormal sounds are advisable to catch potential problems early.

What maintenance practices should I follow?

Routine inspections, fluid changes, and ensuring proper alignment are essential. Keeping the unit clean and free from contaminants will also help prevent premature wear.

Can I perform repairs on my own, or should I consult a professional?

While minor adjustments can be made by knowledgeable individuals, it is generally recommended to seek professional assistance for complex repairs to ensure safety and effectiveness.

Where can I find spare parts for this hydraulic equipment?

Parts can be sourced from authorized distributors or specialty suppliers. It’s crucial to verify that components meet the required specifications for compatibility.

How can I extend the lifespan of my hydraulic unit?

Regular maintenance, monitoring of operating conditions, and timely replacement of worn parts are key strategies. Adhering to manufacturer guidelines will also contribute to longevity.