In the realm of automotive care, comprehensive resources play a pivotal role in ensuring optimal performance and longevity of heavy-duty vehicles. These essential guides serve as invaluable tools for owners and technicians alike, offering insights into the intricate systems that keep vehicles operational. From troubleshooting common issues to executing detailed procedures, the importance of having access to accurate information cannot be overstated.

Equipped with step-by-step instructions and illustrations, these resources enable individuals to approach maintenance tasks with confidence. Whether it’s routine servicing or addressing specific malfunctions, a well-structured document can significantly enhance the efficiency of the process. The clarity and organization of such guides not only save time but also minimize the risk of errors during repairs.

Moreover, the availability of detailed specifications and recommendations fosters a deeper understanding of the vehicle’s mechanics. By delving into the intricacies of various components, users can make informed decisions about care and upgrades, ultimately leading to a more reliable and durable vehicle. This foundational knowledge empowers vehicle enthusiasts to maintain their assets effectively, ensuring they remain roadworthy for years to come.

Understanding Isuzu Trucks

This section explores the intricacies of a well-known manufacturer specializing in robust commercial vehicles. Renowned for their reliability and efficiency, these machines play a vital role in various industries, supporting transportation and logistics needs across the globe.

Key Features

These vehicles are designed with a focus on durability and performance. Equipped with powerful engines and advanced technology, they offer superior handling and fuel efficiency. The ergonomic design enhances driver comfort, making long hours on the road more manageable.

Maintenance Insights

Regular upkeep is essential to ensure optimal functioning. Understanding common issues and preventive measures can extend the lifespan of these vehicles. Proper diagnostics and timely servicing contribute significantly to their overall reliability and performance, allowing operators to maximize productivity.

Common Issues in Isuzu Trucks

Many vehicles face challenges over time, leading to a variety of operational concerns. Understanding these frequent problems can help owners maintain performance and safety, ultimately extending the lifespan of their vehicles. This section explores some prevalent issues that can arise, along with potential solutions.

Engine Performance Problems

One of the most significant concerns involves engine functionality. Symptoms such as rough idling, decreased power, or unusual noises can indicate underlying issues. Regular checks of components like the fuel system, ignition parts, and air intake can help identify these problems early. Routine maintenance is essential to prevent serious damage and ensure optimal performance.

Electrical System Failures

Another common area of difficulty lies within the electrical framework. Drivers may encounter difficulties with starting, flickering lights, or malfunctioning accessories. These issues can often stem from a failing battery, corroded connections, or a faulty alternator. Addressing electrical problems promptly is crucial to avoid further complications and ensure reliability on the road.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance tasks. A well-stocked toolkit not only streamlines the process but also enhances safety and efficiency. Knowing which instruments to keep on hand can make all the difference when tackling various challenges.

Basic Hand Tools

Every toolkit should include fundamental hand tools that are versatile and reliable. Wrenches, screwdrivers, and pliers are essential for loosening and tightening components. A good set of sockets is also invaluable, providing the ability to handle nuts and bolts of various sizes with ease.

Specialized Equipment

In addition to basic tools, having specialized gear can facilitate more complex tasks. Torque wrenches ensure that fasteners are tightened to the correct specifications, preventing damage. Diagnostic scanners are critical for identifying issues efficiently, helping to pinpoint problems quickly. Investing in these tools can significantly improve the quality of maintenance performed.

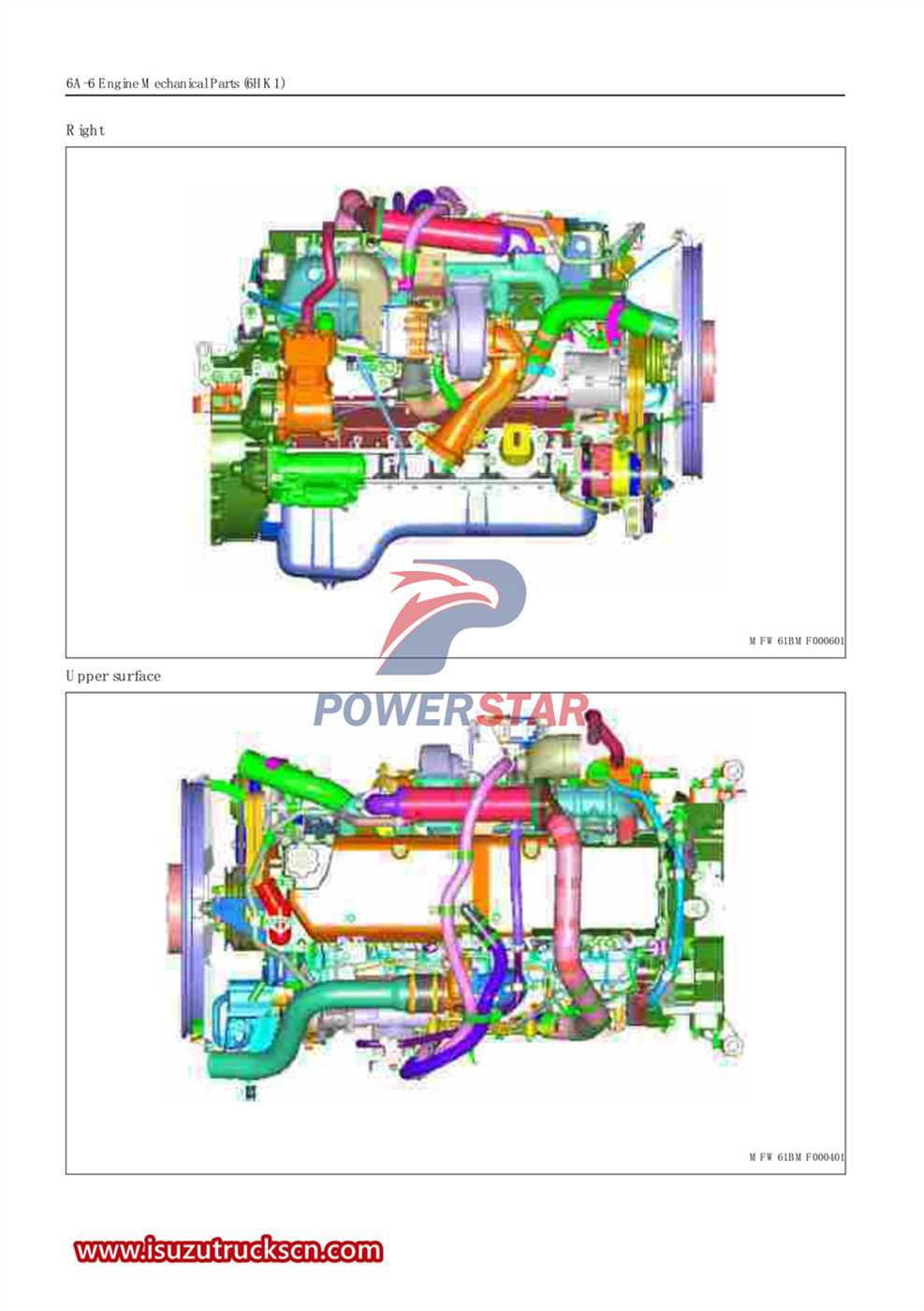

Engine Maintenance Guidelines

Proper upkeep of your vehicle’s power unit is crucial for ensuring optimal performance and longevity. Regular attention to key components can prevent unforeseen issues and enhance efficiency. By following a systematic approach, you can safeguard against potential breakdowns and extend the life of the engine.

1. Regular Oil Changes: Frequent replacement of engine oil is essential for reducing friction and preventing wear. Check the manufacturer’s recommendations for oil change intervals and always use quality lubricants suitable for your engine type.

2. Air Filter Inspection: A clean air filter allows for better airflow and improves combustion efficiency. Inspect and replace the air filter at regular intervals, especially if operating in dusty environments.

3. Cooling System Maintenance: Overheating can cause severe damage. Regularly check the coolant levels, inspect hoses for wear, and ensure the radiator is functioning properly to maintain optimal operating temperatures.

4. Fuel System Care: Keeping the fuel system clean is vital for performance. Use quality fuel and consider periodic cleaning of injectors and filters to prevent clogs and enhance fuel efficiency.

5. Spark Plug Replacement: Worn or fouled spark plugs can lead to misfiring and reduced performance. Check and replace them according to the service schedule to ensure smooth operation.

6. Belt and Hose Checks: Regularly inspect belts and hoses for signs of wear, cracks, or leaks. Replace any components that show signs of deterioration to avoid unexpected failures.

By adhering to these guidelines, you can help ensure that your engine remains in peak condition, thereby enhancing performance and reliability. Regular maintenance not only contributes to a smoother ride but also promotes safety on the road.

Transmission Troubleshooting Techniques

Addressing issues within a vehicle’s power delivery system requires a systematic approach to identify and resolve potential problems. Understanding the underlying mechanics and employing effective diagnostic methods can significantly enhance the efficiency and longevity of the system. This section explores various techniques for diagnosing and rectifying common complications associated with the transmission mechanism.

Common Symptoms and Their Diagnosis

Recognizing the signs of transmission malfunction is the first step toward effective resolution. Below is a table summarizing frequent symptoms and suggested diagnostic actions.

| Symptom | Potential Cause | Recommended Action |

|---|---|---|

| Slipping gears | Low fluid levels or contaminated fluid | Check and replenish or replace fluid |

| Unusual noises | Worn components or lack of lubrication | Inspect parts and lubricate or replace as necessary |

| Delayed engagement | Faulty solenoids or hydraulic issues | Test solenoids and examine hydraulic lines |

| Warning light activation | Sensor failure or system error | Run diagnostic tests to identify error codes |

Preventive Measures

Implementing routine maintenance can prevent many transmission-related issues. Regular fluid changes, thorough inspections, and timely repairs are crucial in ensuring optimal functionality. By adhering to a scheduled maintenance plan, vehicle owners can mitigate risks and enhance the reliability of their systems.

Electrical System Diagnostics

Effective assessment of the electrical components in vehicles is crucial for maintaining optimal performance and safety. This section outlines essential practices and techniques for diagnosing electrical issues, ensuring that all systems operate smoothly.

To begin the diagnostic process, it is important to gather the right tools and follow a systematic approach:

- Visual Inspection: Check for obvious signs of damage, corrosion, or loose connections.

- Testing Tools: Utilize multimeters, oscilloscopes, and circuit testers to measure voltage, current, and resistance.

- Wiring Diagrams: Refer to comprehensive schematics to understand the layout and connections of the electrical system.

Common symptoms that may indicate electrical problems include:

- Inconsistent lighting or flickering headlights.

- Difficulty starting the engine or frequent battery drain.

- Malfunctioning accessories or gauges.

Once issues are identified, follow these steps for effective resolution:

- Isolate the problematic circuit or component.

- Perform tests to pinpoint the source of the malfunction.

- Replace or repair damaged parts as needed.

- Reassemble and test the system to ensure proper function.

By following these guidelines, one can efficiently diagnose and address electrical issues, leading to improved reliability and performance of the vehicle.

Brake System Repair Procedures

This section outlines essential steps for maintaining and restoring the functionality of the braking system. Proper attention to this critical component ensures safety and performance, preventing potential hazards on the road.

Before beginning any work, gather the necessary tools and materials:

- Wrenches and sockets

- Brake fluid

- Replacement pads or shoes

- Brake cleaner

- Protective gear

Follow these procedures to effectively service the braking components:

- Inspection: Examine the brake pads, rotors, and lines for wear and damage. Look for signs of leaking fluid.

- Fluid Replacement: If the fluid appears discolored or contaminated, replace it with fresh fluid. Ensure the system is properly bled to remove air bubbles.

- Pad or Shoe Replacement: Remove the wheel and caliper. Replace the worn pads or shoes, ensuring proper alignment and secure fitting.

- Rotor Servicing: Check the rotors for scoring or warping. Resurface or replace as necessary.

- Reassembly: Carefully reassemble all components, ensuring all fasteners are tightened to the specified torque. Reinstall the wheel.

- Testing: Conduct a test drive to assess braking performance. Listen for unusual noises and check for effective engagement.

Regular maintenance of the braking system enhances safety and prolongs the lifespan of components. Always refer to manufacturer specifications for detailed guidance on specific models.

Suspension and Steering Checks

Ensuring optimal performance of the vehicle’s handling and ride comfort requires thorough inspection of the suspension and steering systems. Regular assessments can help identify potential issues before they escalate, promoting safety and enhancing driving experience.

Visual Inspection

Begin with a comprehensive visual examination of all components. Look for any signs of wear, such as cracked bushings, leaking shock absorbers, or damaged tie rods. Rust or corrosion on metal parts can indicate deterioration that may compromise functionality. Pay close attention to the alignment of wheels and suspension components to ensure they are positioned correctly.

Functional Tests

Perform functional checks by assessing the vehicle’s response during steering maneuvers. Test for excessive play in the steering wheel and listen for unusual noises while turning. Evaluate the suspension’s ability to absorb shocks by pushing down on each corner of the vehicle and observing its rebound. A vehicle that bounces excessively may require further attention to the shock absorbers or springs.

Fuel System Maintenance Tips

Maintaining the fuel delivery system is essential for optimal performance and longevity of any vehicle. Regular care can prevent issues related to fuel quality, efficiency, and overall engine health. Here are some valuable tips to ensure your system remains in peak condition.

- Regular Fuel Filter Replacement: Change the fuel filter according to the manufacturer’s recommendations to prevent contaminants from clogging the system.

- Use Quality Fuel: Always choose high-quality fuel from reputable stations to reduce the risk of impurities affecting system performance.

- Monitor Fuel Lines: Regularly inspect fuel lines for cracks, leaks, or wear to avoid fuel loss and ensure safe operation.

- Check Fuel Pump Functionality: Listen for unusual noises from the fuel pump and conduct periodic checks to ensure it operates quietly and efficiently.

- Clean Injectors: Use injector cleaning solutions periodically to maintain optimal spray patterns and improve fuel atomization.

By following these guidelines, you can enhance fuel efficiency and extend the lifespan of the delivery system, leading to a smoother and more reliable driving experience.

Regular Service Intervals Explained

Maintaining optimal performance and longevity of any vehicle relies heavily on adhering to a schedule of routine maintenance. This approach not only ensures smooth operation but also minimizes the risk of unexpected breakdowns and costly repairs. Understanding the importance of these intervals is essential for any owner.

Regular maintenance tasks generally fall into several categories, each with specific timelines. Here are some key aspects to consider:

- Oil Changes: Frequent oil changes are vital for engine health. Typically, this should be done every 3,000 to 7,500 miles, depending on the type of oil used.

- Fluid Levels: Regularly check and replenish essential fluids, including coolant, brake fluid, and transmission fluid. This ensures all systems function effectively.

- Filter Replacements: Air and fuel filters should be replaced at recommended intervals to maintain efficiency and prevent contaminants from entering the engine.

- Tire Maintenance: Rotating tires and checking alignment should be performed every 5,000 to 7,500 miles to promote even wear and enhance safety.

- Brake Inspections: Regular checks of the braking system help ensure safety and performance, typically every 10,000 to 15,000 miles.

By adhering to these recommended service intervals, vehicle owners can avoid premature wear and tear, enhance performance, and extend the lifespan of their vehicle. Keeping a detailed service log can also help in tracking maintenance history and planning future services effectively.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance is paramount. Adopting proper safety measures not only protects the individual performing the task but also enhances the overall efficiency of the process. Awareness of potential hazards and the implementation of preventive strategies can significantly reduce the risk of accidents.

Essential Safety Gear

Utilizing appropriate personal protective equipment (PPE) is crucial in any maintenance scenario. The right gear safeguards against various risks, such as mechanical injuries and exposure to harmful substances.

| Type of Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful chemicals. |

| Gloves | Prevents cuts and chemical exposure. |

| Steel-Toed Boots | Provides foot protection from heavy objects. |

| Ear Protection | Reduces noise exposure during loud operations. |

| Respirator | Protects against inhalation of harmful fumes. |

Work Area Organization

Maintaining a tidy workspace is essential for safety. Clutter can lead to accidents, making it vital to keep tools and materials organized. Implementing a systematic approach not only enhances efficiency but also minimizes the likelihood of slips and trips.

Parts Replacement: What to Know

When it comes to maintaining your vehicle’s performance, understanding the essentials of component substitution is crucial. This process not only ensures the longevity of your machine but also enhances its efficiency. Whether you’re a seasoned professional or a DIY enthusiast, being well-informed about the parts you need to replace can lead to better decision-making and successful outcomes.

Key Considerations

Before embarking on any substitution, several factors must be taken into account. Quality, compatibility, and sourcing are paramount. Using original components or high-quality alternatives can make a significant difference in performance and reliability.

Replacement Process Overview

The replacement process generally follows a systematic approach, ensuring that each step is performed accurately to avoid future complications. Familiarizing yourself with the specific requirements of your vehicle model can streamline this process.

| Step | Description |

|---|---|

| 1 | Identify the part that needs replacement. |

| 2 | Gather necessary tools and materials. |

| 3 | Carefully remove the old component. |

| 4 | Install the new part, ensuring proper alignment. |

| 5 | Test the vehicle to confirm successful installation. |

Finding Reliable Repair Resources

Locating dependable sources for maintenance information is essential for ensuring the longevity and efficiency of your vehicle. With a multitude of options available, it’s crucial to discern which resources provide accurate and trustworthy guidance. This section outlines effective strategies to identify and utilize reliable references for automotive upkeep.

Online Resources

- Official Websites: Check the manufacturer’s official site for technical bulletins and service tips.

- Forums and Community Groups: Engage with online communities where enthusiasts share their experiences and advice.

- Video Tutorials: Platforms like YouTube offer visual step-by-step guides that can enhance your understanding.

Printed Materials

- Service Guides: Look for published books that cover various aspects of vehicle maintenance.

- Industry Magazines: Subscribe to magazines that focus on automotive technologies and repair insights.

- Local Libraries: Utilize public resources to find manuals and technical documents available for reference.