Understanding the intricacies of fastening equipment is essential for ensuring optimal performance and longevity. This section provides valuable insights into common issues that may arise during the operation of these devices and offers guidance on addressing them effectively. By familiarizing oneself with the mechanisms involved, users can enhance their overall experience and maintain the functionality of their tools.

Through systematic troubleshooting and thoughtful maintenance practices, individuals can prevent minor problems from escalating into significant disruptions. Proper care not only extends the lifespan of the equipment but also ensures safety during use. This guide aims to empower users with knowledge and techniques necessary to keep their fastening devices in top condition, facilitating efficient work processes.

Proper upkeep of your tool is essential for ensuring its longevity and optimal performance. By following some basic practices, you can significantly extend the lifespan of your equipment and reduce the likelihood of malfunctions.

Regular Cleaning

- Remove debris and dust after each use.

- Use a soft brush or cloth to clean hard-to-reach areas.

- Inspect the components for signs of wear or damage.

Lubrication

- Apply appropriate lubricant to moving parts regularly.

- Ensure that the lubrication is evenly distributed to avoid build-up.

- Consult the manufacturer’s guidelines for recommended products.

How to Troubleshoot Nail Gun Problems

Addressing issues with your fastening device can enhance its performance and prolong its lifespan. Recognizing common malfunctions and knowing how to resolve them effectively is essential for optimal functionality.

| Problem | Possible Cause | Solution |

|---|---|---|

| Device not firing | Empty fuel source or dead battery | Replace fuel canister or recharge battery |

| Jammed fasteners | Incorrect loading | Remove jammed fasteners and reload correctly |

| Inconsistent fastening | Worn parts or debris | Clean and inspect internal components; replace worn parts |

| Leakage | Deteriorated seals | Replace damaged seals to stop leaks |

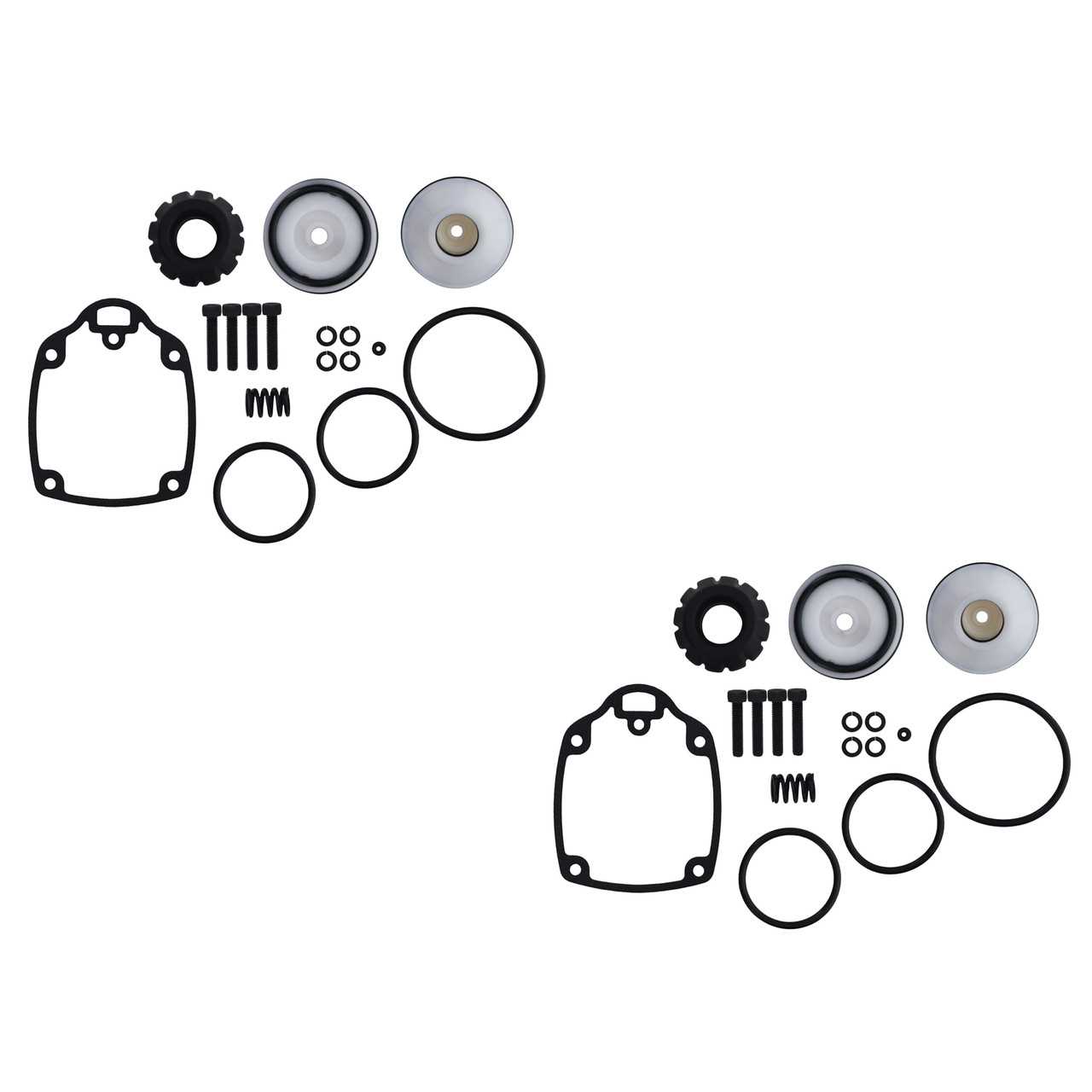

Parts Replacement Guide

This section provides essential information for individuals looking to replace components in their device. Understanding the process and identifying the necessary parts can enhance performance and extend the lifespan of the equipment.

Here are key steps to follow for successful part replacement:

- Identify the malfunctioning component.

- Gather the required tools and materials.

- Carefully disassemble the unit, taking note of the arrangement of parts.

- Replace the faulty part with a compatible replacement.

- Reassemble the device, ensuring all components are securely fitted.

Below is a list of common components that may require replacement:

- Power supply units

- Trigger mechanisms

- Housing sections

- Fastening mechanisms

- Air seals

Before proceeding with any replacements, refer to the specifications for compatibility and safety guidelines. Proper care during the process will prevent further issues and ensure optimal functionality.

Cleaning Techniques for Efficiency

Maintaining the optimal performance of your tool requires regular cleaning and proper techniques. By implementing effective cleaning methods, you can enhance functionality and prolong the lifespan of the equipment.

Regular Maintenance is essential. Set a schedule for cleaning to remove debris and dust that can accumulate over time. Using a soft brush or compressed air can effectively clear out hard-to-reach areas.

Appropriate Cleaning Agents should be selected based on the materials involved. Utilize mild solvents or cleaners that won’t damage surfaces, ensuring they are suitable for the specific components of your device.

Inspection during cleaning can also help identify any wear or damage. Regular checks allow for timely interventions, preventing potential malfunctions.

By adopting these techniques, you ensure that your tool operates at its best, improving overall efficiency and reliability.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on tools is essential to prevent accidents and injuries. Adhering to proper guidelines can significantly reduce risks and create a secure working environment.

- Wear Protective Gear: Always use safety glasses, gloves, and ear protection to shield yourself from potential hazards.

- Disconnect Power Source: Before starting any work, make sure to unplug the device or remove batteries to avoid accidental activation.

- Work in a Well-Lit Area: Proper lighting helps in identifying issues and reduces the likelihood of mistakes.

- Keep Workspace Organized: A clutter-free environment minimizes distractions and allows for safe movement.

- Follow Manufacturer Guidelines: Refer to official instructions for best practices related to your specific equipment.

- Use the Right Tools: Ensure that you are using appropriate tools for the job to avoid damaging the equipment or causing injury.

By taking these precautions seriously, you can enhance your safety and the effectiveness of your work, leading to better outcomes in maintenance tasks.

Upgrading Your Nail Gun

Improving your fastening tool can significantly enhance its performance and efficiency. Upgrading various components not only extends the tool’s lifespan but also increases its versatility for different tasks.

Benefits of Upgrading

- Increased speed and efficiency in fastening

- Enhanced precision for various materials

- Improved durability and reliability

- Access to advanced features for diverse projects

Key Upgrades to Consider

- Adjustable Depth Settings: Allows for precise control over the depth of fasteners.

- Upgraded Motor: Provides better power and performance, reducing jams and misfires.

- Improved Grip: Enhances comfort and reduces fatigue during extended use.

- New Fastener Types: Expands the range of materials that can be handled effectively.

Warranty Information and Support

This section provides essential details regarding coverage and assistance available for your tool. Understanding the terms of warranty and support options is crucial for ensuring optimal performance and longevity of your equipment.

Typically, warranties cover defects in materials and workmanship for a specified period. It’s advisable to keep your proof of purchase as it may be required for any claims.

| Coverage | Duration | Contact Information |

|---|---|---|

| Defects in materials | 1 year | 1-800-XXX-XXXX |

| Workmanship issues | 1 year | [email protected] |

For additional help, please refer to the official website or customer support channels. They can guide you through any issues and provide further assistance with your tool.

FAQs about Nail Gun Repairs

This section addresses common inquiries related to the maintenance and troubleshooting of fastening tools. Understanding these aspects can enhance the longevity and performance of your equipment.

Common Issues and Solutions

Users often encounter various challenges when operating fastening devices. Here are some frequent problems along with their potential solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Tool fails to fire | Insufficient power supply | Check battery or air pressure |

| Fasteners jammed | Incorrect loading | Unload and reload properly |

| Poor fastening performance | Worn components | Inspect and replace as needed |

Maintenance Tips

Regular upkeep is essential for optimal functionality. Here are some recommendations:

- Clean the device after each use to prevent debris buildup.

- Lubricate moving parts as specified in the product guidelines.

- Store in a dry, secure place to avoid damage.