Maintaining outdoor machinery is crucial for ensuring longevity and optimal performance. This section provides essential insights and practical advice for troubleshooting and enhancing the functionality of your gardening tools. Whether you are a hobbyist or a professional, understanding the intricacies of your equipment can lead to more efficient and enjoyable gardening experiences.

Effective maintenance involves not only addressing minor issues but also implementing preventive measures. By familiarizing yourself with the common challenges that arise during operation, you can save time and resources. This guide aims to equip you with the knowledge necessary to tackle various tasks confidently.

Furthermore, adopting a systematic approach to upkeep can help identify potential problems before they escalate. From routine checks to more in-depth procedures, a thorough understanding of your tools is essential for maintaining their peak performance. With the right information at hand, you can ensure that your equipment serves you well for years to come.

Dixon Lawn Mower Repair Manual Overview

This section provides a comprehensive look at essential guidelines and insights for maintaining and troubleshooting your outdoor equipment. It serves as a valuable resource for both novice and experienced users, ensuring that you can efficiently manage any issues that may arise during operation. Understanding the fundamental principles and procedures will not only enhance performance but also prolong the lifespan of your machinery.

Key Features of the Guide

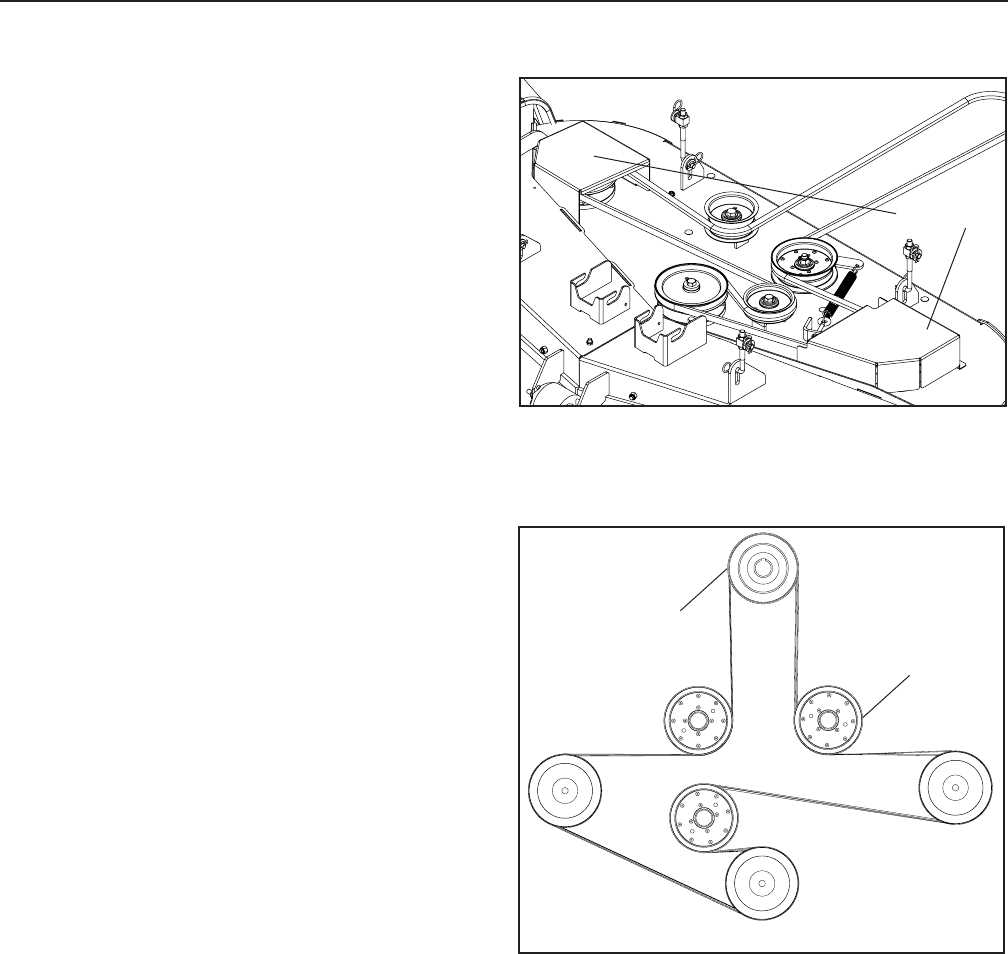

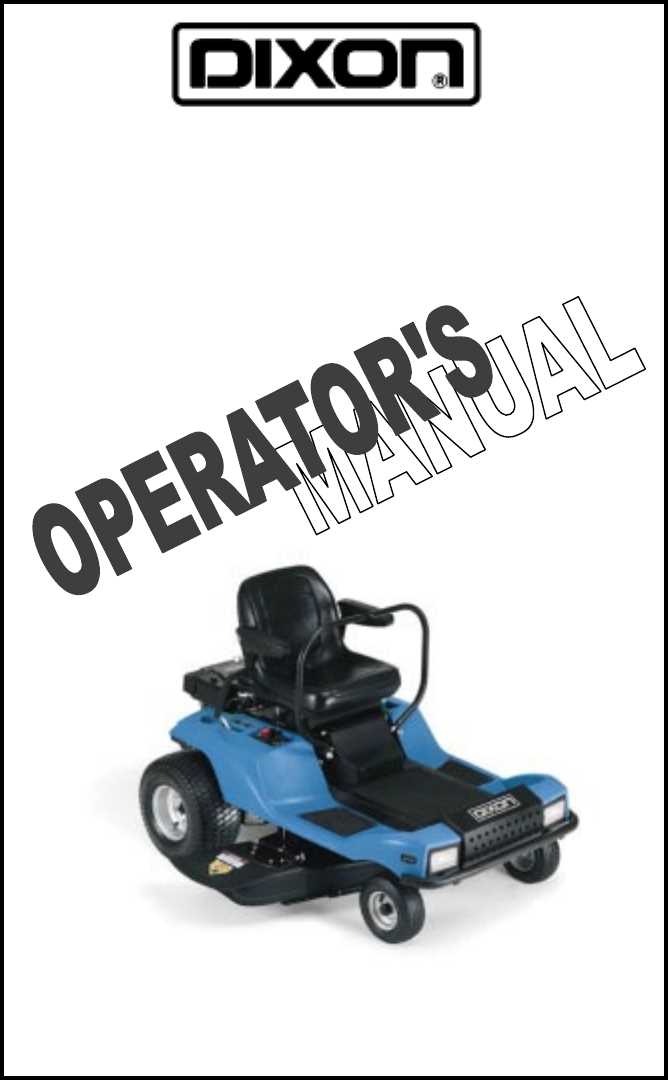

The document includes detailed instructions on various aspects, from routine maintenance to complex troubleshooting. It covers necessary tools, safety precautions, and step-by-step processes to address common problems. With clear illustrations and user-friendly language, it simplifies even the most challenging tasks.

Benefits of Regular Maintenance

Common Issues with Dixon Mowers

Owning a grass cutting machine can come with its share of challenges. Understanding the typical problems that may arise can help users maintain performance and extend the lifespan of their equipment. Identifying these issues early can lead to more efficient solutions and minimize downtime.

One frequent concern involves the engine not starting. This can be caused by various factors, such as fuel delivery issues or a malfunctioning ignition system. Regular checks of the fuel lines and battery condition can often prevent this headache.

Another common issue is uneven cutting. This can stem from dull blades or improper deck height settings. Keeping blades sharp and adjusting the cutting height as needed ensures a clean and uniform finish on your lawn.

Moreover, users may encounter problems with the transmission. Slipping gears or difficulty shifting can indicate low fluid levels or wear in the drive components. Routine maintenance and fluid checks can help mitigate these concerns.

Lastly, the electrical system can be a source of frustration. Issues like blown fuses or faulty connections can disrupt operation. Inspecting wiring and replacing worn components can enhance reliability and prevent further complications.

Essential Tools for Repairing Lawnmowers

When it comes to maintaining and fixing outdoor equipment, having the right instruments is crucial for achieving efficient and effective results. A well-equipped toolbox can make the difference between a frustrating experience and a smooth process. Below are some of the most important tools that every enthusiast should consider.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts, making them essential for any mechanical work.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws in various components.

- Pliers: Needle-nose and standard pliers can be useful for gripping small parts and manipulating wires.

- Spark Plug Socket: This specific tool is designed to remove and replace spark plugs efficiently, ensuring optimal engine performance.

In addition to these basics, there are other items that can enhance your toolkit:

- Multimeter: Useful for diagnosing electrical issues, ensuring that all connections are working properly.

- Fuel Stabilizer: Helps maintain the quality of fuel and prevents engine problems over time.

- Oil Filter Wrench: Essential for changing the oil filter during maintenance sessions.

- Cleaning Brushes: Various brushes aid in keeping parts clean, preventing buildup that can hinder performance.

By assembling these fundamental instruments, you can tackle a wide range of tasks and ensure that your outdoor equipment operates at peak efficiency.

Step-by-Step Maintenance Procedures

Proper upkeep of your equipment is essential for optimal performance and longevity. This section provides a comprehensive guide to the necessary actions you should take to ensure everything runs smoothly. Following these procedures will help prevent potential issues and enhance efficiency.

Essential Tools and Supplies

Before starting maintenance, gather the following tools and supplies:

- Wrench set

- Oil and oil filter

- Air filter

- Fuel stabilizer

- Cleaning cloths

Maintenance Steps

- Check Oil Levels:

- Remove the dipstick and wipe it clean.

- Reinsert and remove again to check the level.

- Add oil if necessary to reach the recommended level.

- Replace Air Filter:

- Locate the air filter housing.

- Remove the old filter and discard it.

- Insert a new filter, ensuring a snug fit.

- Inspect and Clean the Blades:

- Turn off the engine and disconnect the spark plug.

- Examine blades for wear or damage.

- Sharpen or replace blades as needed.

- Check Fuel System:

- Examine fuel lines for cracks or leaks.

- Replace old fuel with fresh fuel mixed with a stabilizer.

- Test Battery Condition:

- Ensure terminals are clean and connections are tight.

- Charge the battery if necessary.

By following these straightforward procedures, you can maintain your equipment’s performance and extend its lifespan. Regular attention to these details will lead to a more reliable and efficient operation.

Diagnosing Engine Performance Problems

Understanding the nuances of engine performance can be crucial for effective maintenance and troubleshooting. When an engine exhibits signs of poor functionality, it is essential to systematically evaluate various components to identify underlying issues. This section outlines common symptoms and diagnostic steps to enhance engine efficiency.

| Symptoms | Possible Causes | Recommended Actions |

|---|---|---|

| Difficulty starting | Weak battery, fuel issues, or ignition failure | Check battery charge, inspect fuel lines, and test spark plugs |

| Loss of power | Clogged air filter, fuel blockage, or engine wear | Replace air filter, clean fuel system, and assess engine condition |

| Excessive vibration | Imbalance or damaged components | Inspect and balance moving parts, check for wear |

| Unusual noises | Loose parts or mechanical failure | Tighten components, investigate noise sources |

| Poor fuel efficiency | Improper tuning or faulty sensors | Adjust engine settings, test sensor functionality |

Regular maintenance and attention to these symptoms can prevent further complications. By following a structured diagnostic approach, one can effectively address performance-related issues and ensure optimal operation.

Replacing Blades: A How-To Guide

Ensuring optimal performance of your outdoor equipment involves routine maintenance, including the replacement of cutting edges. This guide will walk you through the essential steps to safely and effectively change the blades, enhancing the efficiency of your machine and prolonging its lifespan.

Tools and Materials Needed

- New cutting blades

- Socket wrench

- Screwdriver

- Safety gloves

- Protective eyewear

- Grease or lubricant

Step-by-Step Instructions

- Prepare Your Equipment: Ensure the machine is turned off and disconnected from any power source to prevent accidental starts.

- Remove the Existing Blades: Use the socket wrench to unscrew the fasteners securing the blades. Keep these screws for later use.

- Clean the Area: Clear any debris or grass clippings from the blade attachment area. This helps in maintaining the new blades.

- Install the New Blades: Align the new blades with the attachment points and secure them with the screws you previously removed. Tighten them adequately to avoid loosening during operation.

- Lubricate the Mechanism: Apply grease to moving parts as recommended to ensure smooth operation.

- Check Your Work: Before starting the equipment, double-check that all parts are securely fastened and that no tools are left on or around the machine.

Regular blade replacement not only improves cutting performance but also contributes to better overall health of your equipment. Following these steps will help you maintain a well-functioning machine that meets your outdoor maintenance needs.

Understanding Electrical Components in Mowers

Electrical systems in garden machinery play a crucial role in their functionality and performance. Grasping the key elements of these systems is essential for effective maintenance and troubleshooting. This section delves into the various components that ensure smooth operation and provide the power needed for optimal performance.

- Batteries: The heart of the electrical system, providing the necessary power to start the engine and operate various features.

- Wiring Harness: A network of wires that connects different components, facilitating the flow of electricity throughout the machine.

- Switches: These control the operation of electrical circuits, allowing the user to start or stop the engine and manage other functions.

- Ignition Systems: Responsible for initiating the combustion process, these systems ensure that the engine starts smoothly and runs efficiently.

- Fuses: Protect the electrical system from overloads and short circuits, safeguarding components from damage.

- Relays: Act as switches that control larger currents, enabling the operation of components such as lights and starters.

Understanding these components allows for better diagnostics and maintenance practices. Proper care of electrical systems not only prolongs the lifespan of the equipment but also enhances overall efficiency and performance.

Seasonal Care Tips for Lawn Equipment

Maintaining outdoor machinery throughout the year is essential for optimal performance and longevity. By implementing a seasonal care routine, users can ensure that their equipment remains in top condition, ready to tackle any task. This guide outlines effective strategies to keep your tools running smoothly, regardless of the season.

Spring Maintenance: As the growing season begins, it’s crucial to inspect and prepare your equipment. Start by cleaning any debris and checking for wear and tear. Replace worn-out parts and sharpen blades to enhance cutting efficiency. Additionally, ensure that all fluids are at the proper levels and consider changing the oil for optimal performance.

Summer Upkeep: During the warmer months, frequent use can lead to overheating and increased wear. Regularly check air filters and clean them to prevent dust accumulation. Keep an eye on fuel quality; using fresh fuel can help avoid starting issues. Staying hydrated is essential for both the operator and the machinery, so schedule breaks to allow the engine to cool down.

Fall Preparation: As the season changes, it’s time to winterize your equipment. Begin by draining fuel or using a fuel stabilizer to prevent corrosion in the fuel system. Clean all components thoroughly and inspect for any damage that may need repair. Storing equipment in a dry, protected area will help extend its life.

Winter Care: Even in the off-season, regular maintenance is vital. Check on your machinery periodically to ensure it remains in good condition. Keep moving parts lubricated and protect exposed areas from moisture and rust. Preparing for the upcoming season will make the transition smoother when it’s time to return to work.

By following these seasonal care tips, you can significantly enhance the performance and durability of your outdoor equipment. Regular maintenance not only saves time and money but also ensures that your tools are always ready for action.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor machinery, ensuring personal safety is paramount. Proper precautions not only protect the individual performing the work but also contribute to a safer environment for those nearby. Adhering to established safety protocols can significantly reduce the risk of accidents and injuries.

Always wear appropriate protective gear, such as gloves, safety goggles, and sturdy footwear. This equipment acts as a barrier against potential hazards, including sharp objects, chemicals, and flying debris. Additionally, loose clothing should be avoided to prevent entanglement in moving parts.

Before beginning any work, ensure that the equipment is completely powered down and disconnected from any power sources. This step is crucial to prevent accidental starts, which can lead to serious injuries. Furthermore, work in a well-ventilated area to minimize exposure to harmful fumes or dust generated during maintenance.

Lastly, keep the workspace organized and free of clutter. A tidy environment reduces the risk of tripping or mishandling tools, allowing for a smoother and safer maintenance experience. By prioritizing safety, you can effectively carry out the necessary tasks while minimizing risks.

Finding Replacement Parts for Dixon Mowers

Locating suitable components for your gardening equipment is essential for maintaining its performance and longevity. Whether you are dealing with worn-out blades, faulty belts, or other crucial parts, knowing where to find the right replacements can save you time and money. This guide will assist you in navigating various options for sourcing these necessary items.

Here are some effective strategies to consider when searching for the required components:

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers provide genuine parts that are designed specifically for your equipment. | High quality and warranty support. |

| Online Marketplaces | Websites like Amazon and eBay offer a wide range of components from various sellers. | Convenience and often lower prices. |

| Local Hardware Stores | Community shops may stock popular parts or be able to order them for you. | Personalized service and immediate availability. |

| Salvage Yards | Used parts can be found at salvage operations, which may have what you need at reduced prices. | Cost-effective and sustainable option. |

By exploring these resources, you can efficiently find the components necessary to keep your equipment running smoothly. Remember to verify compatibility with your specific model to ensure optimal performance.

Troubleshooting Starting Problems

When facing difficulties in initiating your outdoor equipment, it’s essential to systematically identify and address potential issues. Starting problems can stem from various sources, including fuel supply, electrical components, or mechanical faults. By methodically investigating these areas, you can often determine the root cause and implement effective solutions.

Begin by checking the fuel system. Ensure there is sufficient fuel in the tank and that it is fresh, as old or contaminated fuel can impede performance. Inspect the fuel lines and filters for blockages that may restrict flow. If necessary, replace the filters and purge any stale fuel.

Next, examine the electrical system. A weak or dead battery can prevent the engine from turning over. Check battery connections for corrosion and ensure they are tight. If the battery is low, consider jump-starting or replacing it. Additionally, inspect the ignition components, including the spark plug, for wear or damage. A faulty spark plug can result in poor ignition, so replacing it may resolve starting issues.

Finally, assess the mechanical aspects of the equipment. Verify that all safety features are engaged and functioning correctly, as many models have mechanisms that inhibit starting if certain conditions aren’t met. Inspect the starter motor and solenoid for proper operation, and listen for unusual sounds that may indicate internal problems.

By following these steps, you can effectively troubleshoot and resolve starting problems, ensuring your equipment operates reliably when you need it most.

Recommended Lubricants and Fluids

Ensuring optimal performance and longevity of your equipment hinges on the selection of appropriate lubricants and fluids. Using the right substances minimizes wear and tear, enhances efficiency, and prevents potential failures. This section outlines essential recommendations to keep your machinery running smoothly.

Essential Oils and Greases

Choosing the correct oil and grease is vital for maintaining engine health. High-quality motor oil tailored for small engines should be utilized, as it provides superior protection against friction and heat. Additionally, multi-purpose grease is ideal for various moving parts, ensuring a smooth operation and extending component life.

Cooling and Fuel Fluids

For optimal operation, utilizing a suitable coolant helps regulate temperature and prevents overheating. Make sure to use fluids recommended by the manufacturer for your specific machinery. Furthermore, ensuring that the fuel meets the necessary standards will promote efficient combustion and overall performance.