In the world of aviation, ensuring the longevity and safety of an aircraft is paramount. This guide serves as a comprehensive resource, aimed at assisting both novice and seasoned technicians in understanding the essential aspects of maintaining a specific model. By delving into systematic procedures, users can gain valuable insights into the complexities of aircraft upkeep.

Regular maintenance is crucial for preventing unexpected issues and enhancing performance. The following sections will cover a variety of topics, including routine checks, troubleshooting techniques, and detailed assembly instructions. Each part has been designed to provide clarity and practical guidance, ensuring that users are well-equipped to tackle any challenge that may arise.

With a focus on safety and efficiency, this resource emphasizes the importance of following established protocols and using appropriate tools. Whether you are working on a minor adjustment or a significant overhaul, a thorough understanding of the processes involved is essential. Embracing the knowledge contained within these pages can lead to improved reliability and a smoother flight experience.

Cessna 172 Overview

This section provides a comprehensive understanding of a popular light aircraft known for its reliability and ease of use. Ideal for both novice pilots and experienced aviators, this model has become a staple in general aviation, serving various purposes from training to personal travel.

Key Features

- Stable flight characteristics

- Spacious cockpit and cabin

- Robust design and construction

- Versatile performance capabilities

Applications

- Pilot training and education

- Private and recreational flying

- Aerial photography and surveying

- Light cargo transport

The combination of its user-friendly controls and dependable engine makes this aircraft a favored choice among flying enthusiasts. With a rich history and continuous improvements, it remains a relevant option in today’s aviation landscape.

Importance of a Repair Manual

A comprehensive guide is essential for anyone involved in the maintenance and upkeep of aircraft. Such resources not only provide detailed instructions but also ensure safety and efficiency in operations. Understanding the significance of these guides can greatly enhance the effectiveness of maintenance tasks.

Here are some key reasons why having an informative guide is crucial:

- Safety Assurance: Proper procedures reduce the risk of accidents and ensure the aircraft remains in optimal condition.

- Standardization: A structured approach helps maintain consistency across maintenance practices, leading to better performance.

- Time Efficiency: Clear instructions help technicians complete tasks more quickly, minimizing downtime for the aircraft.

- Cost Savings: Preventive maintenance guided by comprehensive resources can help avoid costly repairs down the line.

In summary, an informative guide is an indispensable tool for any technician, providing the knowledge necessary to maintain aircraft safely and efficiently.

Common Issues in Cessna 172

Aviation enthusiasts often encounter several recurring challenges with a particular type of light aircraft. Understanding these common problems is crucial for ensuring optimal performance and safety during flights. This section highlights some of the frequent issues that owners and operators may face, along with potential solutions and preventative measures.

Engine Performance Problems

One of the most prevalent concerns involves engine efficiency. Pilots may notice symptoms such as rough idling or decreased power output. These issues can stem from various factors, including fuel contamination, worn spark plugs, or clogged filters. Regular maintenance and thorough pre-flight checks can help mitigate these problems. Monitoring engine gauges and addressing any irregularities promptly can ensure reliable operation.

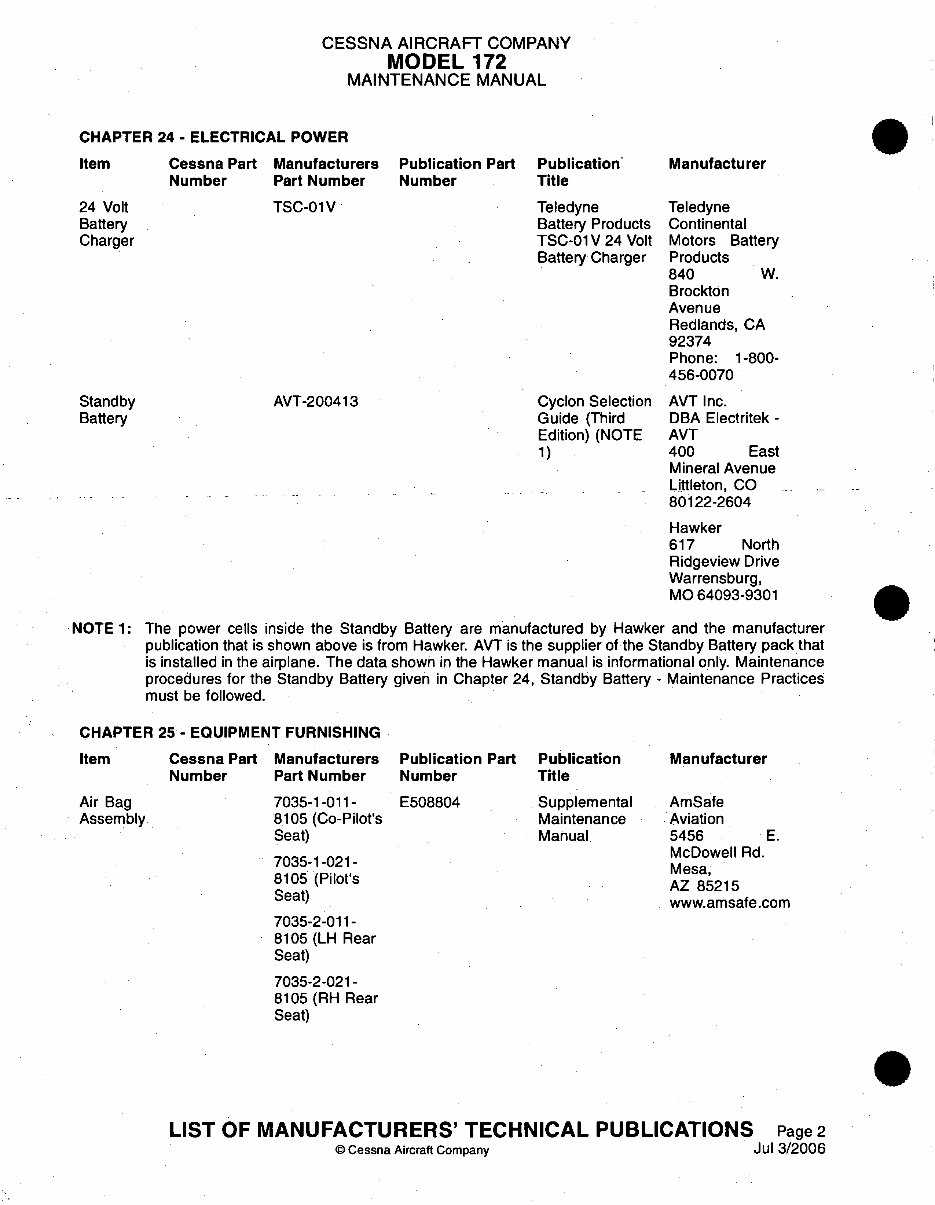

Electrical System Failures

Electrical malfunctions are another common issue that can disrupt flight operations. Problems may manifest as flickering lights, dead instruments, or a failing battery. Such failures often arise from corroded connections, faulty wiring, or aging components. Implementing a routine inspection of the electrical system can help identify potential failures before they escalate. Keeping connections clean and secure is essential for maintaining overall system integrity.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing common issues encountered in aircraft maintenance. A systematic approach ensures that every task is performed efficiently and safely, minimizing the risk of errors and enhancing overall performance.

1. Identify the Issue: Begin by gathering all relevant information regarding the malfunction. Conduct visual inspections and consult flight logs to determine the symptoms and possible causes.

2. Gather Necessary Tools: Assemble the required equipment and components before starting the work. Having everything on hand helps streamline the process and reduces downtime.

3. Follow Manufacturer Guidelines: Refer to the specific instructions provided by the manufacturer. These guidelines are crucial for ensuring that all repairs are conducted according to safety and performance standards.

4. Execute Repairs: Carefully perform the necessary adjustments or replacements. Take your time to avoid mistakes, and ensure each step is completed accurately.

5. Test the System: After completing the repair, conduct thorough testing to confirm that the issue has been resolved. Monitor all functions closely during this phase to ensure everything operates smoothly.

6. Document the Process: Record all findings, actions taken, and parts used. This documentation is essential for future reference and can aid in troubleshooting similar problems down the line.

By following these structured procedures, maintenance professionals can enhance the reliability and safety of aircraft operations.

Required Tools for Maintenance

Effective upkeep of aircraft relies heavily on having the right instruments and equipment at hand. A well-equipped maintenance workspace not only enhances efficiency but also ensures safety and compliance with industry standards. This section outlines essential tools necessary for thorough inspections and repairs, enabling technicians to perform their tasks proficiently.

Basic Hand Tools

Fundamental hand tools form the backbone of any maintenance operation. Commonly needed items include wrenches, screwdrivers, pliers, and hammers. These instruments are critical for various tasks, from tightening components to making minor adjustments. Precision tools such as torque wrenches are vital for ensuring that fasteners are tightened to manufacturer specifications.

Specialized Equipment

In addition to standard hand tools, specialized equipment is often required for specific maintenance tasks. This may include multimeters for electrical diagnostics, compression testers for engine performance evaluations, and hydraulic jacks for safe lifting of the aircraft. Having access to these specialized instruments allows technicians to conduct thorough assessments and ensure optimal functioning of all systems.

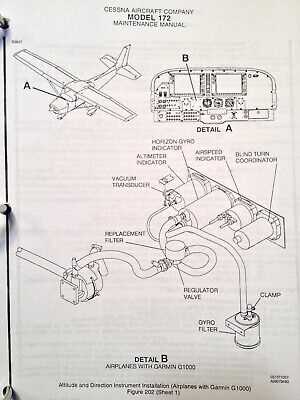

Understanding Electrical Systems

The electrical systems of an aircraft play a crucial role in ensuring safe and efficient operations. These systems are responsible for powering various components, from navigation aids to essential cockpit instruments. A comprehensive understanding of these systems is vital for maintenance and troubleshooting.

Electrical systems can be broadly categorized into several components:

- Power Generation: This includes alternators and batteries that supply the necessary electrical energy.

- Distribution: The wiring and circuit breakers that route power to various systems throughout the aircraft.

- Control Systems: Instruments and switches that allow the pilot to manage electrical output effectively.

- Lighting: Systems that provide visibility for both the cockpit and exterior areas during operations.

Key points to consider when examining these systems include:

- Voltage Levels: Understanding the standard voltage used in the aircraft is essential for compatibility with various devices.

- Load Management: Assessing how much power each component requires helps prevent overloads.

- Wiring Integrity: Regular checks for wear, corrosion, and damage are crucial for safety and performance.

- System Redundancy: Many aircraft incorporate backup systems to ensure functionality in case of failure.

A thorough grasp of these elements enables effective diagnostics and enhances the reliability of the aircraft’s electrical infrastructure.

Engine Maintenance Guidelines

Proper upkeep of the powerplant is essential for ensuring optimal performance and longevity of any aircraft. Regular attention to engine components helps prevent unexpected failures and enhances overall safety. Following systematic procedures can significantly improve reliability and efficiency, making it crucial for operators to adhere to established practices.

Routine inspections should be performed at specified intervals to assess the condition of various engine parts, including the ignition system, fuel delivery mechanisms, and lubrication components. A detailed checklist can help identify potential issues before they escalate, allowing for timely intervention and repairs.

It is vital to monitor fluid levels regularly, including oil and coolant, to maintain adequate lubrication and temperature control. Engine oil should be changed according to the manufacturer’s recommendations, using the appropriate type for the specific engine model. Keeping filters clean and replacing them as needed can also prevent contaminants from causing damage.

Pay close attention to any unusual sounds or vibrations during operation, as these may indicate underlying problems. Conducting performance checks, such as compression tests and temperature readings, will provide valuable insights into the engine’s health. Additionally, ensuring that all connections are secure and that there are no signs of leaks will further safeguard against mechanical issues.

Lastly, maintaining detailed records of all maintenance activities is crucial for tracking the engine’s performance history. This documentation not only aids in future maintenance decisions but also serves as a valuable reference in case of warranty claims or inspections.

Flight Control System Repairs

The flight control system is crucial for maintaining the stability and maneuverability of the aircraft. Proper functionality ensures that pilots can safely navigate and execute various maneuvers. Addressing any issues within this system is essential to guarantee flight safety and operational efficiency.

Common Issues

- Wear and tear of control surfaces

- Malfunctions in the control cables

- Improper alignment of control surfaces

- Hydraulic system failures

Repair Procedures

- Conduct a thorough inspection of all components.

- Identify and replace any worn or damaged parts.

- Ensure that all control surfaces are properly aligned and functioning.

- Test the hydraulic system for leaks and pressure consistency.

- Perform final checks to verify the complete functionality of the system.

Parts Replacement Tips

When it comes to maintaining aircraft, ensuring that components are replaced correctly is crucial for safety and performance. This section offers practical advice for those undertaking the task of swapping out parts, helping to streamline the process and enhance reliability.

Preparation is Key

Before beginning any replacement procedure, it is essential to gather all necessary tools and parts. Create a checklist of items you will need, including any specific fasteners or fluids. Double-check that the replacement components meet the required specifications to avoid compatibility issues.

Follow Manufacturer Guidelines

Always consult the official documentation related to the aircraft model. Adhering to manufacturer recommendations ensures that you maintain the integrity of the aircraft. Pay attention to torque specifications and recommended practices for installation. This diligence will help prevent future complications and extend the lifespan of the replaced parts.

Safety Precautions During Repairs

When conducting maintenance on aircraft, prioritizing safety is crucial to ensure the well-being of personnel and the integrity of the aircraft. Adhering to proper protocols can prevent accidents and facilitate a smooth working environment. Understanding potential hazards and implementing preventative measures is essential for anyone involved in this field.

Before beginning any maintenance tasks, it is important to familiarize yourself with the tools and equipment required for the job. Ensure that all tools are in good condition and appropriate for the specific tasks at hand. Additionally, wearing personal protective equipment, such as gloves, goggles, and ear protection, can safeguard against injuries and exposure to harmful substances.

Proper ventilation is vital when working in enclosed spaces, as fumes and vapors from materials can pose health risks. Always check that ventilation systems are functioning properly, and if necessary, use fans or other equipment to circulate air. Furthermore, keeping the workspace organized and free from clutter reduces the likelihood of accidents and enhances efficiency.

In the event of an emergency, having a clear plan and accessible first aid supplies is indispensable. Personnel should be trained in basic first aid and know the location of emergency equipment. Regular safety drills can also help ensure that everyone is prepared to respond effectively in case of an incident.

Finally, maintaining open communication among team members during maintenance activities fosters a culture of safety. Reporting hazards or unsafe conditions promptly can help prevent accidents and ensure that everyone is aware of potential risks. Prioritizing safety not only protects individuals but also contributes to the overall success of aircraft maintenance operations.