Understanding the upkeep of your ceiling circulators can significantly enhance their performance and longevity. This section offers insights into common issues that may arise and how to effectively address them, ensuring optimal operation throughout the year.

Regular attention to these devices not only improves air circulation but also contributes to energy efficiency in your home. By following a few straightforward procedures, you can maintain peak functionality and avoid unnecessary disruptions.

In this guide, you will discover step-by-step suggestions for troubleshooting various problems and performing essential maintenance tasks. With the right knowledge, you can ensure that your circulators remain a reliable source of comfort in your living space.

Common Issues with Ceiling Fans

Ceiling-mounted appliances are essential for enhancing comfort in living spaces, but they can encounter various complications over time. Recognizing and addressing these common challenges can help maintain optimal performance and extend their lifespan.

Frequent Problems

Users may experience issues such as unusual noises, inadequate airflow, or irregular operation. These symptoms can stem from multiple factors, including improper installation, wear and tear, or electrical concerns.

Troubleshooting Table

| Issue | Possible Cause | Solution |

|---|---|---|

| No movement | Power supply issue | Check connections and reset the circuit |

| Unusual noise | Loose components | Tighten screws and check for debris |

| Poor airflow | Dirty blades | Clean blades regularly |

| Inconsistent speed | Faulty switch | Inspect and replace if necessary |

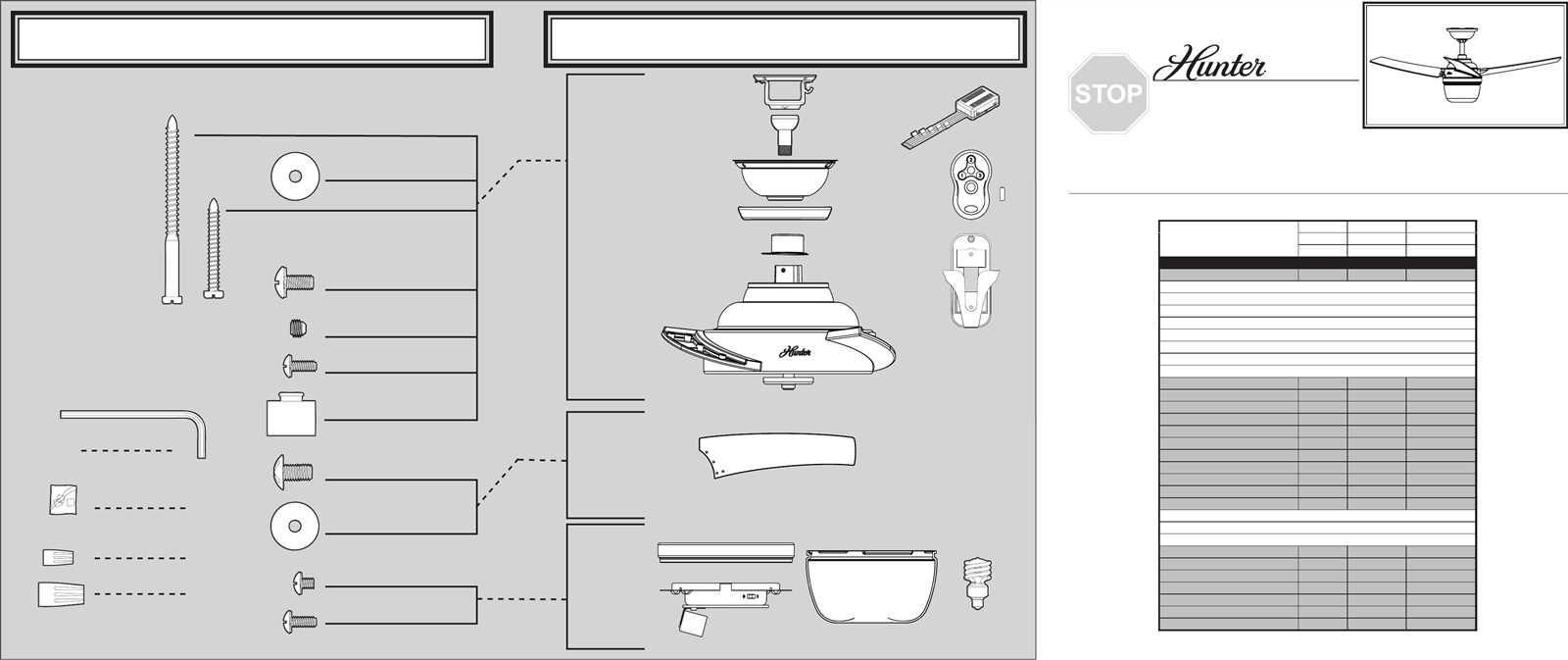

Tools Required for Repairs

When addressing issues with your ceiling apparatus, having the appropriate instruments at your disposal is crucial for effective maintenance. Various tools will assist in diagnosing problems, facilitating adjustments, or replacing components to restore functionality.

Essential Instruments

Commonly needed instruments include a screwdriver set, pliers, and a voltage tester. A screwdriver set allows for the removal of covers and securing fasteners, while pliers can help in gripping and twisting wires. A voltage tester is vital for ensuring safety when dealing with electrical connections.

Additional Equipment

For more intricate tasks, consider having wire strippers, a ladder, and a flashlight. Wire strippers enable precise handling of electrical wiring, and a ladder provides safe access to elevated fixtures. A flashlight is beneficial for illuminating darker areas, ensuring visibility during the process.

Safety Precautions Before Repairing

Before engaging in any maintenance tasks on household appliances, it is essential to prioritize safety. Ensuring a secure environment not only protects the individual performing the work but also prevents potential damage to the equipment itself.

First and foremost, always disconnect the power source before beginning any procedure. This simple action significantly reduces the risk of electric shock and accidents. Additionally, using insulated tools can provide extra protection during the process.

It is also advisable to wear appropriate personal protective equipment, such as gloves and safety goggles. This helps safeguard against any unexpected debris or hazardous materials that may arise while handling the device. Lastly, familiarize yourself with the specific model’s characteristics and potential issues to enhance your understanding and approach to the task at hand.

How to Remove the Fan Blades

Removing the rotating blades from an overhead apparatus can be a straightforward process if approached with care. This guide will outline the essential steps to safely detach the blades, ensuring a smooth workflow for subsequent maintenance or replacement.

Before starting, gather the necessary tools, including a screwdriver and a soft cloth. Following these steps will help you successfully complete the task:

- Ensure the device is powered off and unplugged to prevent any accidental activation.

- Locate the screws or fasteners securing the blades. These are typically found at the base where the blades attach to the central hub.

- Using the screwdriver, carefully remove the screws, placing them in a secure location for reassembly.

- Gently pull each blade away from the hub. If there is any resistance, double-check for remaining screws or clips.

- Once all blades are removed, clean the area to remove any dust or debris that may have accumulated.

Following these steps will ensure that the blades are detached safely and effectively, preparing the apparatus for further service or upkeep.

Inspecting the Motor and Components

When addressing issues related to performance, it is essential to evaluate the motor and associated elements carefully. This process involves a thorough examination to identify any irregularities or signs of wear that may impact functionality.

Visual Examination

Start with a detailed visual inspection of the motor and its surrounding components. Look for any visible damage, such as cracks or rust, which could indicate underlying problems. Ensure that all connections are secure and free from debris.

Functional Assessment

Next, conduct a functional assessment to check the operational efficiency. This includes listening for unusual noises that may suggest mechanical issues. Pay attention to vibrations that feel abnormal, as they can signal misalignment or other concerns. Regular monitoring of these aspects can greatly enhance the longevity of the unit.

Troubleshooting Electrical Problems

Addressing issues related to electrical components is essential for ensuring the optimal performance of any apparatus. Identifying and resolving these challenges can enhance reliability and efficiency.

To effectively troubleshoot electrical difficulties, consider the following steps:

- Check the power source to ensure that it is functioning correctly.

- Inspect wiring for any visible damage or loose connections.

- Examine switches and controls to verify their proper operation.

- Test the circuit using a multimeter to confirm voltage levels.

If problems persist, further investigation may be necessary:

- Consult the specifications for any unique electrical requirements.

- Look for any blown fuses or tripped breakers in the electrical panel.

- Evaluate any connected devices for faults that could impact performance.

By following these guidelines, users can efficiently address electrical issues and maintain their equipment in optimal working condition.

Cleaning and Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your appliances. Keeping them clean not only enhances their appearance but also contributes to their efficiency. Implementing simple maintenance routines can prevent common issues and improve functionality over time.

Dust Removal: Accumulated dust can hinder performance. Use a soft, dry cloth or a microfiber duster to gently wipe surfaces regularly. For hard-to-reach areas, consider a vacuum attachment designed for delicate tasks.

Inspection of Components: Periodically check all parts for signs of wear or damage. Look for loose connections or frayed wiring. Addressing these issues promptly can help avoid more serious problems later.

Lubrication: Some mechanisms may benefit from occasional lubrication. Use a suitable oil as recommended by the manufacturer, applying it sparingly to moving parts to ensure smooth operation.

Humidity Control: Maintaining a balanced humidity level in your environment can also aid in preserving the condition of your equipment. Excessive moisture can lead to corrosion and mold growth, which are detrimental to performance.

By incorporating these straightforward practices into your routine, you can significantly extend the life of your devices while maintaining their effectiveness.

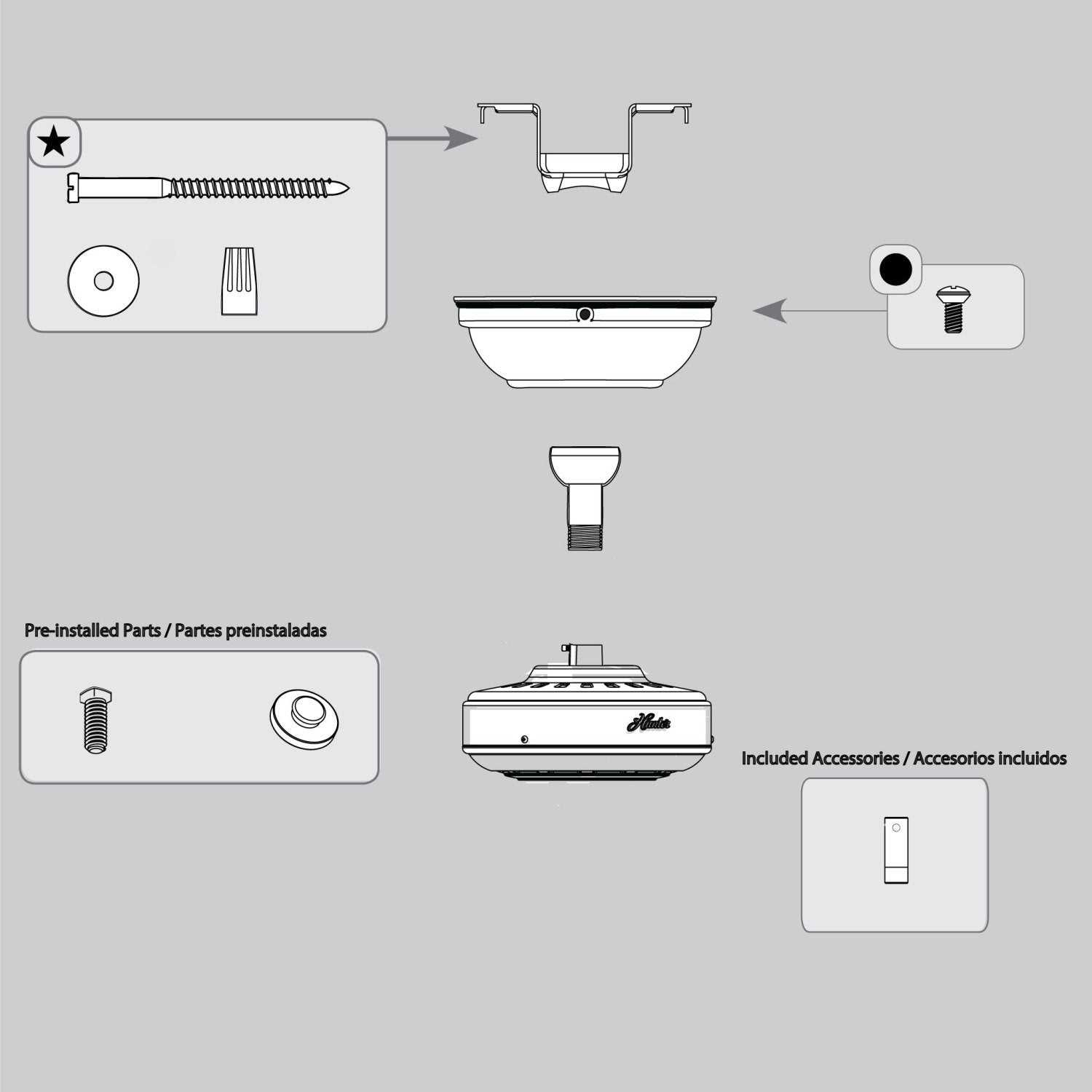

Rewiring Your Ceiling Fan

When it comes to enhancing the performance of your overhead fixture, understanding the intricacies of its electrical connections is essential. Properly reconfiguring these connections can lead to improved functionality and safety. This process involves a few crucial steps that ensure everything operates smoothly and effectively.

Understanding the Wiring System

Before diving into the reconfiguration process, it’s vital to familiarize yourself with the wiring setup. Typically, the fixture will have a series of color-coded wires, each serving a specific purpose. Knowing which wire corresponds to power, ground, and control functions is crucial for a successful operation.

Steps to Reconfigure

Start by turning off the power supply to the overhead unit. Carefully detach the existing wiring, taking note of how each wire is connected. Use wire nuts to secure connections and ensure they are tightly fastened. When reattaching, follow the original color coding to maintain proper functionality. After everything is securely connected, restore the power and test the fixture to confirm everything is working as intended.

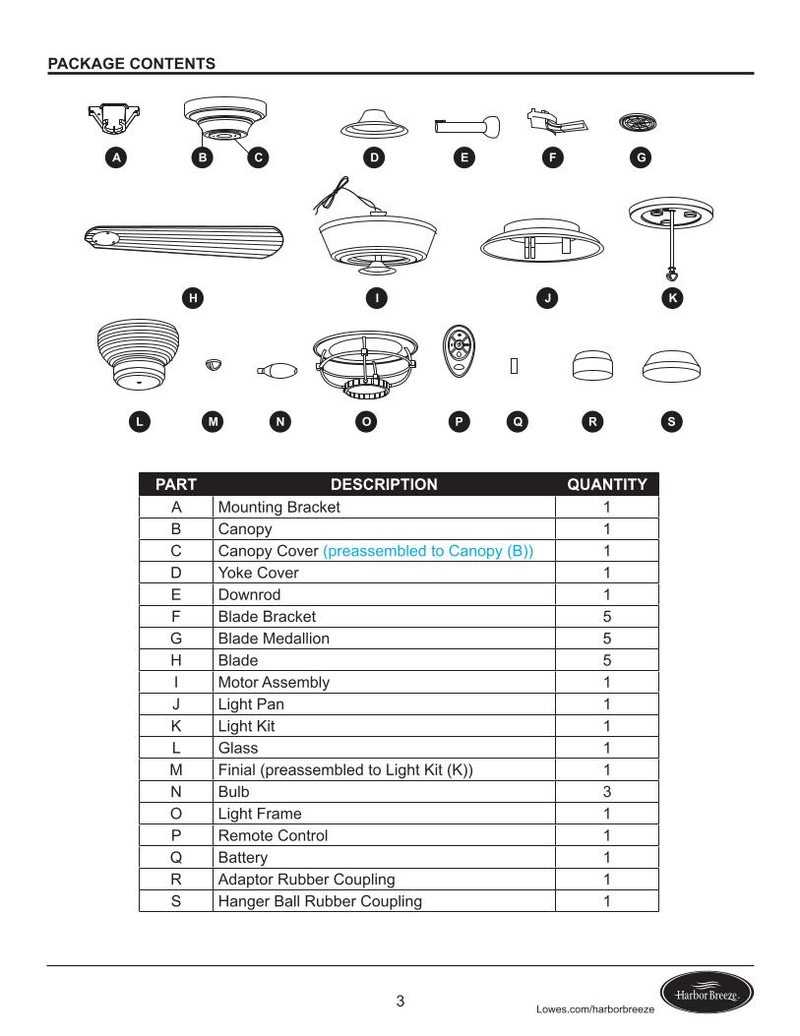

Replacing the Light Kit

Upgrading or changing the illumination assembly of a ceiling device can enhance both functionality and aesthetics. This process involves several steps that ensure the new unit is installed correctly and safely, providing optimal lighting for the space.

Preparation Steps

Before beginning the installation, it’s essential to prepare adequately:

- Turn off the power supply at the circuit breaker to avoid any electrical hazards.

- Gather necessary tools, including a screwdriver, pliers, and a voltage tester.

- Carefully read the instructions accompanying the new lighting unit for specific guidelines.

Installation Process

Follow these steps to successfully install the new lighting component:

- Remove the existing illumination kit by unscrewing it from the base.

- Disconnect the wiring, taking note of how the connections were made for reference.

- Connect the new lighting assembly, ensuring that the wires are securely attached according to the provided instructions.

- Attach the new kit to the base, ensuring it is firmly in place.

- Restore power at the circuit breaker and test the new lighting to confirm proper functionality.

Following these steps will help ensure a successful installation of the new illumination assembly, enhancing the overall experience of the room.

Adjusting Fan Speed Settings

Modifying the velocity settings of your ventilation device is essential for achieving optimal airflow and comfort within your space. Proper adjustments allow you to tailor the performance to your specific needs, whether you prefer a gentle breeze or a more robust airflow.

To effectively manage the speed, follow these straightforward steps:

- Identify the control mechanism: Most devices come with a wall switch, remote control, or an integrated pull chain.

- Locate the speed settings: Typically, there are multiple options ranging from low to high.

- Adjust according to your preference: Experiment with different settings to find the most comfortable level for your environment.

Regularly revisiting these settings can enhance energy efficiency and maintain a pleasant atmosphere. Consider the following tips:

- Use lower settings during cooler months to save energy.

- Increase speed on hot days for a refreshing effect.

- Check for any noise or irregularities during operation and adjust accordingly.

With the right adjustments, you can ensure your device operates smoothly and meets your airflow requirements efficiently.

Final Testing and Adjustments

This section outlines the crucial steps to ensure optimal performance of the unit after maintenance. Conducting thorough evaluations and making necessary modifications are vital for enhancing efficiency and reliability.

Begin by powering on the device to assess its operational capabilities. Listen for any unusual noises that may indicate underlying issues. Observing the unit’s performance during various settings can reveal areas needing adjustment.

Next, verify that all components are correctly aligned and securely attached. Any loose parts can lead to inefficiencies or potential hazards. Making small adjustments to settings can significantly impact overall functionality.

Finally, it is important to monitor the unit’s operation over a period to ensure that it runs smoothly under regular conditions. Keep a record of any irregularities encountered during testing, as this information is valuable for future reference.

When to Call a Professional

Certain situations may arise where seeking assistance from an expert becomes necessary. Recognizing the limits of your skills is crucial to ensure safety and efficiency. If complications arise during troubleshooting or if you encounter persistent issues that do not resolve with basic interventions, it may be time to reach out for professional help.

Furthermore, if you notice unusual noises, fluctuating performance, or signs of damage that could lead to further problems, consulting a skilled technician is advisable. Professionals possess the expertise to diagnose and address intricate issues that may not be immediately apparent, ensuring optimal functionality and extending the lifespan of the unit.

Lastly, if you feel uncomfortable or uncertain about handling specific tasks, prioritizing your safety and the integrity of the equipment is paramount. In such cases, relying on a qualified individual will provide peace of mind and ensure proper resolution of any underlying concerns.