For enthusiasts of freshly brewed beverages, maintaining the functionality of your favorite brewing device is essential. This guide delves into common issues that may arise with these machines, providing insights into effective solutions. Understanding the inner workings and potential pitfalls can help ensure a consistently delightful coffee experience.

Identifying Problems: Over time, various components may exhibit signs of wear or malfunction. From irregular brewing cycles to unexpected leaks, recognizing these symptoms is the first step toward restoring optimal performance. This section will outline typical challenges faced by users and offer strategies for diagnosis.

Step-by-Step Solutions: With a clear understanding of the issues, users can proceed with practical steps to address them. Each recommendation will be tailored to enhance the longevity and efficiency of your brewing appliance. By following the outlined procedures, you can enjoy your daily ritual without interruption.

Keurig K10 Repair Manual

This section provides guidance for addressing common issues with a popular single-serve beverage machine. Users can benefit from step-by-step instructions and troubleshooting tips to enhance the longevity and performance of their appliance.

Common Issues and Solutions

- Machine Not Brewing:

- Check the water reservoir for sufficient liquid.

- Ensure the lid is closed securely.

- Examine the power source and connections.

- Weak Beverage Flavor:

- Use fresh pods to ensure quality.

- Clean the brew basket and needle.

- Run a cleaning cycle to remove any buildup.

Maintenance Tips

- Regularly descale the unit to prevent mineral buildup.

- Keep the exterior clean and free of dust.

- Store in a dry place when not in use.

Common Issues with Keurig K10

Many users experience similar challenges when using their single-serve brewing machines. Understanding these frequent problems can help identify solutions and enhance the overall experience of enjoying a fresh cup of coffee.

| Issue | Description | Possible Solution |

|---|---|---|

| Water Not Heating | The appliance fails to heat water properly, resulting in cold beverages. | Check the power supply and ensure the machine is plugged in. Run a descaling cycle. |

| Brewing Cycle Not Starting | The brewing process does not initiate when the button is pressed. | Ensure the water reservoir is filled and properly seated. Restart the machine. |

| Clogged Needle | The needle that punctures the coffee pod can become obstructed, affecting flow. | Use a paperclip to clean the needle carefully. Perform regular maintenance. |

| Weak Coffee | The brewed coffee lacks flavor and strength. | Use fresh, high-quality coffee pods. Adjust the brew size settings. |

| Water Leakage | Water may leak from the machine, causing mess and potential damage. | Check for cracks in the reservoir and ensure all components are secured properly. |

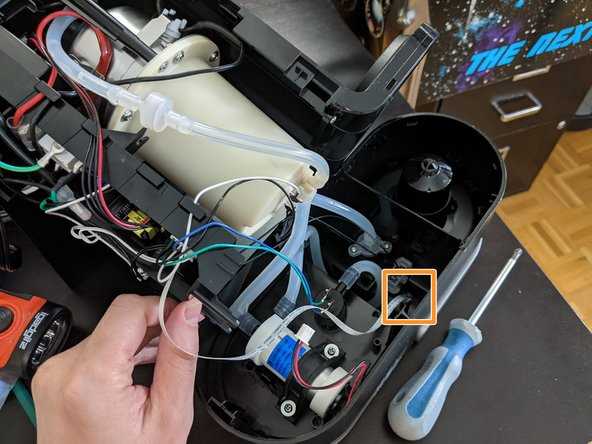

Essential Tools for Repairs

To effectively address common issues with your coffee brewing system, having the right instruments is crucial. These tools not only facilitate the process but also enhance the quality of the work performed, ensuring a smoother and more efficient experience.

Basic Tool Requirements

- Screwdrivers (flathead and Phillips)

- Pliers for gripping and bending

- Multimeter for electrical testing

- Wrenches for tightening components

Additional Helpful Items

- Cleaning brushes for maintaining hygiene

- Replacement parts specific to the model

- Protective gloves for safety

- Flashlight for visibility in tight spaces

Step-by-Step Brewing Troubleshooting

This section offers a comprehensive guide to identify and resolve common issues encountered during the brewing process. By following these steps, you can ensure a smoother experience and achieve that perfect cup of coffee every time.

Identify the Problem

- Inadequate Brewing: If the beverage is weaker than expected, it may indicate a malfunction in the machine.

- Inconsistent Temperature: If the drink is not hot enough, check the heating element.

- No Water Flow: If water is not being dispensed, there may be a blockage.

Troubleshooting Steps

- Check the water reservoir for adequate levels and ensure it is properly seated.

- Inspect the brew head for any coffee grounds or debris that could obstruct flow.

- Run a cleaning cycle to remove mineral buildup that may affect performance.

- Verify that the coffee pod is correctly inserted and not damaged.

- Test the machine by brewing a plain water cycle to assess functionality.

Descaling Process Explained

Regular maintenance of coffee brewing equipment is essential to ensure optimal performance and longevity. One crucial aspect of this upkeep involves removing mineral buildup caused by water. This process not only enhances the quality of your beverages but also prevents potential malfunctions.

Why Descaling is Important

Descaling is vital for several reasons:

- Improves flavor by eliminating bitter notes from mineral deposits.

- Increases the efficiency of the machine, allowing for quicker brew times.

- Prevents clogs in the water pathways, reducing the risk of breakdowns.

Steps to Descale Your Brewer

Follow these steps for effective descaling:

- Prepare a descaling solution or use a commercial product designed for this purpose.

- Empty the water reservoir and fill it with the descaling solution.

- Run a brew cycle without any coffee, allowing the solution to circulate through the system.

- After the cycle completes, let the solution sit for the recommended time.

- Flush the system by running several cycles with clean water until all traces of the solution are gone.

Replacing the Water Reservoir

Over time, the container that holds water for brewing may develop issues such as cracks or a buildup of residue. This section outlines the steps to effectively swap out the water storage unit to ensure optimal performance and hygiene.

Step 1: Begin by disconnecting the appliance from its power source. This is crucial for safety during the replacement process.

Step 2: Carefully remove the existing water container from its position. Gently lift it straight up, being cautious of any attached components that may be connected.

Step 3: Clean the area where the container was located to remove any debris or buildup that may have accumulated.

Step 4: Take the new water reservoir and align it with the designated slot. Ensure that it fits snugly and securely into place.

Step 5: Reconnect the appliance to the power source. Perform a test run to verify that the new water container is functioning correctly.

Regular maintenance of the water storage unit is essential for maintaining the quality of your brewed beverages.

Fixing the Heating Element

The heating component is essential for ensuring that beverages are brewed at the optimal temperature. If this part fails, it can lead to lukewarm drinks and unsatisfactory performance. Identifying the issues with this element and understanding how to address them is crucial for restoring functionality.

Identifying the Problem

Start by checking for any visible signs of damage or corrosion. Unusual noises during operation may also indicate a malfunction. A multimeter can be used to measure continuity; a lack of continuity suggests that the heating unit may need replacement.

Steps to Replace the Heating Component

Begin by disconnecting the appliance from the power source for safety. Carefully remove any screws or clips securing the heating unit. Once detached, replace it with a new component that matches the specifications. Reassemble the unit, ensuring all connections are secure before testing the operation.

Note: Always refer to a guide for specific details related to disassembly and replacement to avoid damaging other parts.

Clearing Clogs in the System

Over time, build-up within the apparatus can hinder performance, leading to slow brewing or inconsistent water flow. Addressing these blockages is essential for ensuring optimal functionality. This section outlines effective methods for clearing these issues, allowing for a smoother brewing experience.

Identifying Common Blockages

Before attempting to resolve clogs, it’s important to recognize where they typically occur. Common areas include the water reservoir, brewing chamber, and exit needle. Inspecting these parts can help pinpoint the source of the obstruction.

Steps to Clear Clogs

Follow these steps to effectively remove any blockages:

| Step | Description |

|---|---|

| 1 | Unplug the unit and allow it to cool completely. |

| 2 | Remove the water reservoir and clean it thoroughly, ensuring no debris remains. |

| 3 | Use a paperclip or similar tool to gently clear any debris from the exit needle. |

| 4 | Run a cycle with a mixture of water and vinegar to dissolve any remaining build-up. |

| 5 | Rinse the system with clean water to remove any vinegar residue. |

By following these steps, the system can be restored to proper working condition, enhancing the overall brewing process and ensuring consistent results. Regular maintenance will help prevent future clogs and prolong the lifespan of the device.

Maintaining the Coffee Maker

Regular upkeep of your brewing device ensures its longevity and optimal performance. By following simple maintenance practices, you can enhance the quality of your beverages while preventing potential issues that may arise over time.

Daily Cleaning Routine

Incorporating a daily cleaning regimen can significantly impact the taste of your coffee. After each use, it’s essential to remove any used pods and rinse the brew basket to eliminate residue. Additionally, wiping down the exterior with a damp cloth keeps the machine looking new.

Descaling the Device

Over time, mineral buildup can affect the machine’s efficiency. It’s advisable to descale the unit every few months. A mixture of equal parts water and white vinegar works effectively for this process. Follow the steps outlined in your user guide for the best results.

| Maintenance Task | Frequency |

|---|---|

| Remove and rinse brew basket | After each use |

| Wipe exterior surfaces | Daily |

| Descale unit | Every 1-3 months |

Upgrading Parts for Better Performance

Enhancing the efficiency and longevity of your brewing system can significantly improve your overall experience. By replacing certain components with upgraded versions, users can achieve better results, including improved flavor extraction and increased reliability.

Consider the following parts for upgrades:

- Water Filter: A high-quality filter can ensure cleaner water, enhancing the taste of your beverages.

- Heating Element: Upgrading to a more efficient heating element can reduce brewing time and improve temperature consistency.

- Pump: A more powerful pump can enhance water flow, leading to better brewing pressure and extraction.

- Seal Kits: Replacing old seals with better materials can prevent leaks and maintain optimal performance.

Implementing these upgrades not only optimizes functionality but also prolongs the lifespan of your machine, making every cup a delight.

Understanding Warranty and Support

The warranty and support framework is essential for ensuring customer satisfaction and addressing issues that may arise with a product. It serves as a safety net for users, providing them with reassurance regarding their investment.

Warranty Coverage typically includes a specified duration during which repairs or replacements are offered at no additional cost. This can vary based on the manufacturer, so it is important to read the documentation carefully to understand what is included and any limitations that may apply.

Customer Support plays a crucial role in assisting users when problems occur. This support can take many forms, including online resources, phone assistance, and email consultations. Utilizing these services can help users troubleshoot issues effectively, ensuring that their experience remains positive.

Knowing how to navigate warranty details and support options can significantly enhance the longevity and functionality of the product.

Safety Precautions During Repairs

When engaging in maintenance or troubleshooting activities, it is essential to prioritize safety to prevent accidents and ensure effective work. Understanding and adhering to specific guidelines can significantly reduce the risk of injury and damage to the equipment.

1. Unplug the Device: Always disconnect the appliance from the power source before starting any intervention. This simple step eliminates the risk of electric shock and prevents accidental activation.

2. Use Proper Tools: Employ the appropriate tools designed for the task. Using incorrect or makeshift tools can lead to mishaps and compromise the integrity of the device.

3. Work in a Well-Lit Area: Ensure that your workspace is adequately illuminated. Poor visibility can lead to mistakes and increase the likelihood of accidents.

4. Handle Components with Care: Take extra caution when dealing with delicate parts. Mishandling can cause breakage or create safety hazards.

5. Wear Protective Gear: Consider using safety glasses, gloves, and other protective equipment. This can safeguard against potential injuries from sharp objects or chemical substances.

6. Follow Manufacturer Guidelines: Always refer to the recommended procedures and specifications provided by the manufacturer. This will help you avoid errors and ensure compliance with safety standards.

7. Stay Focused: Avoid distractions while working. Maintaining concentration is crucial for executing tasks correctly and safely.

By following these precautions, individuals can create a safer environment for themselves and ensure the longevity and functionality of the appliance being serviced.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and troubleshooting for popular brewing appliances. Below are some frequently posed questions that can guide users in resolving issues effectively.

-

What should I do if my machine won’t turn on?

First, check the power source and ensure the device is properly plugged in. Inspect the outlet for functionality and consider trying a different one. If the problem persists, consult the manufacturer’s support for further assistance.

-

Why is my beverage not brewing properly?

Inconsistent brewing can stem from several factors. Check for blockages in the water line or the brewing chamber. Regular cleaning and descaling can help maintain optimal performance.

-

How often should I clean my appliance?

It is recommended to clean the unit at least once a month, with more frequent cleanings for heavy usage. Regular maintenance helps prevent build-up that can affect brewing quality.

-

What can I do if my unit is leaking?

Leaks can occur due to improperly seated components or wear and tear over time. Inspect all seals and connections. If the issue continues, you may need to replace faulty parts.

Addressing these common concerns can enhance the longevity and efficiency of your appliance, ensuring a better brewing experience.