When it comes to ensuring the longevity and optimal performance of your off-road vehicle, understanding its intricacies is essential. This section delves into the vital practices that can help enthusiasts and riders alike navigate the challenges of keeping their machines in peak condition. Whether you are addressing minor issues or embarking on significant overhauls, having the right information at your fingertips can make all the difference.

Knowledge is Power. Familiarizing yourself with the core components and systems of your machine can prevent potential pitfalls and costly repairs down the line. By engaging with detailed procedures and insights, owners can cultivate a deeper appreciation for their vehicles and enhance their riding experiences.

In this guide, we will explore essential topics related to maintenance, including troubleshooting techniques, common problems, and effective solutions. With a focus on practical advice and user-friendly explanations, this resource aims to empower you to take control of your vehicle’s upkeep, ensuring it remains a reliable companion for many adventures to come.

Understanding the 1987 Honda 250X

This section delves into the intricacies of a beloved model from the late 80s, a machine cherished by enthusiasts for its blend of power and versatility. By exploring its features, maintenance needs, and performance characteristics, owners can enhance their experience and ensure longevity.

Key Features

The model is renowned for its robust engineering and reliable performance. With a well-balanced frame and a potent engine, it caters to both novice riders and seasoned veterans. Its lightweight construction allows for agility, making it suitable for various terrains. Additionally, the design incorporates user-friendly controls, providing an intuitive riding experience.

Maintenance Insights

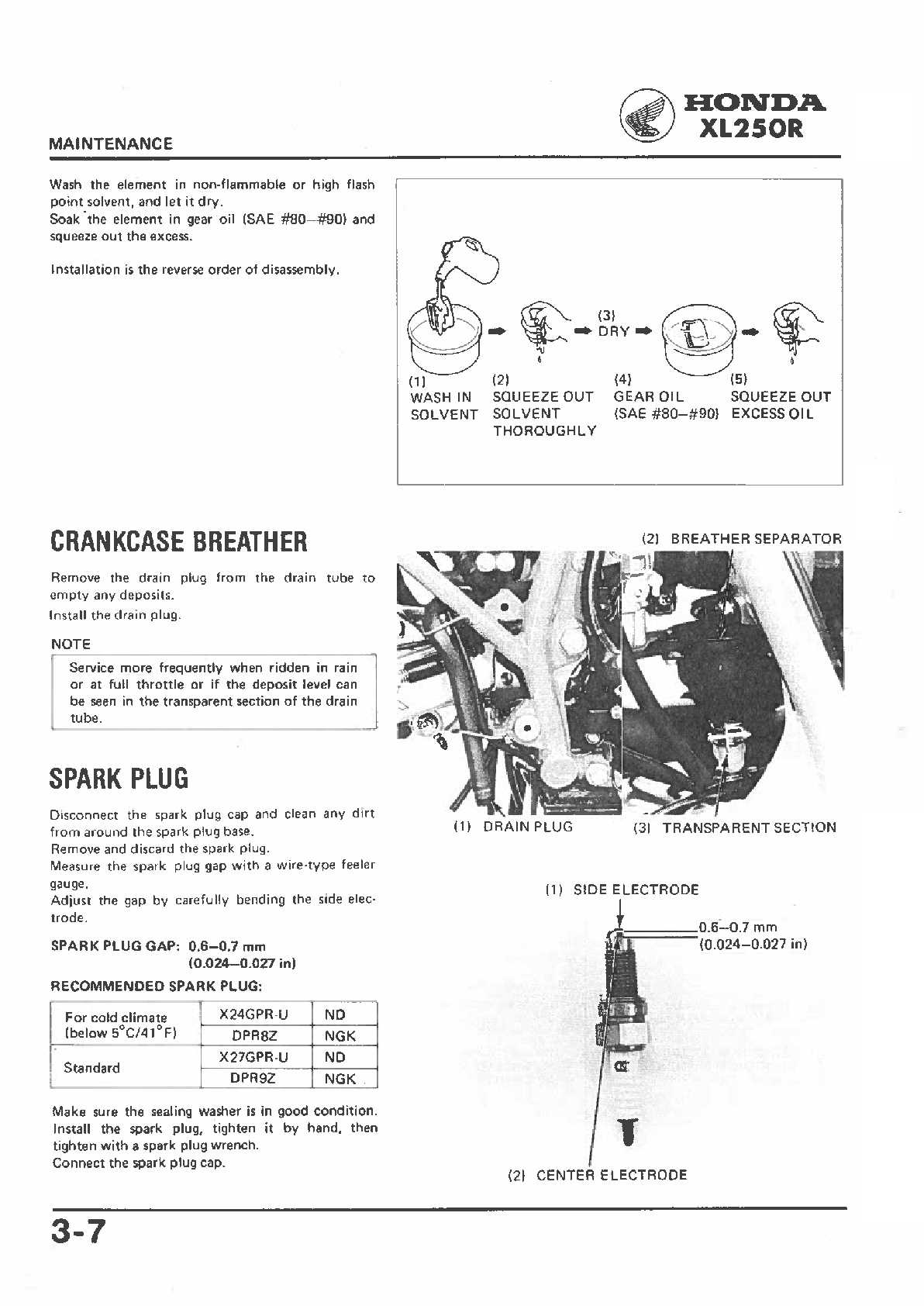

Regular upkeep is crucial for maximizing performance and preventing issues. Owners should pay close attention to the engine’s oil levels and ensure that the air filter is clean to promote efficient combustion. Periodic checks on the brakes and suspension components are essential to maintain safety and handling. Investing time in routine inspections can lead to a more enjoyable and reliable ride.

Common Issues with Honda 250X

This section highlights typical problems that riders may encounter with their off-road vehicles. Understanding these common challenges can help in maintaining performance and ensuring a smooth riding experience.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | Difficulty in starting the engine can occur due to fuel delivery or electrical system issues. | Check the battery, fuel lines, and spark plug condition. |

| Overheating | Excessive heat can lead to engine performance degradation and potential damage. | Ensure proper coolant levels and check the radiator for blockages. |

| Transmission Issues | Shifting difficulties may arise from worn gears or clutch problems. | Inspect the clutch cable and fluid levels, and consider a fluid change. |

| Brake Problems | Inadequate braking response can be due to worn pads or fluid leaks. | Replace brake pads and check for leaks in the brake lines. |

| Suspension Wear | Worn suspension components can affect handling and comfort. | Regularly inspect and replace shocks and springs as needed. |

Essential Tools for Repair

Having the right equipment is crucial for maintaining and restoring any machine. A well-stocked toolkit not only makes tasks easier but also ensures safety and efficiency during the process. This section will outline the fundamental instruments needed for effective maintenance and troubleshooting.

Basic Hand Tools

Start with a set of hand tools, which are indispensable for any maintenance task. This includes wrenches, screwdrivers, and pliers. Each tool serves a specific purpose, allowing you to tighten, loosen, or manipulate various components. Investing in high-quality tools will enhance durability and performance.

Specialized Equipment

In addition to basic hand tools, consider acquiring specialized equipment for more intricate tasks. Items such as torque wrenches, feeler gauges, and multimeters are essential for precision work. These tools facilitate accurate adjustments and diagnostics, ensuring your machinery operates smoothly and efficiently.

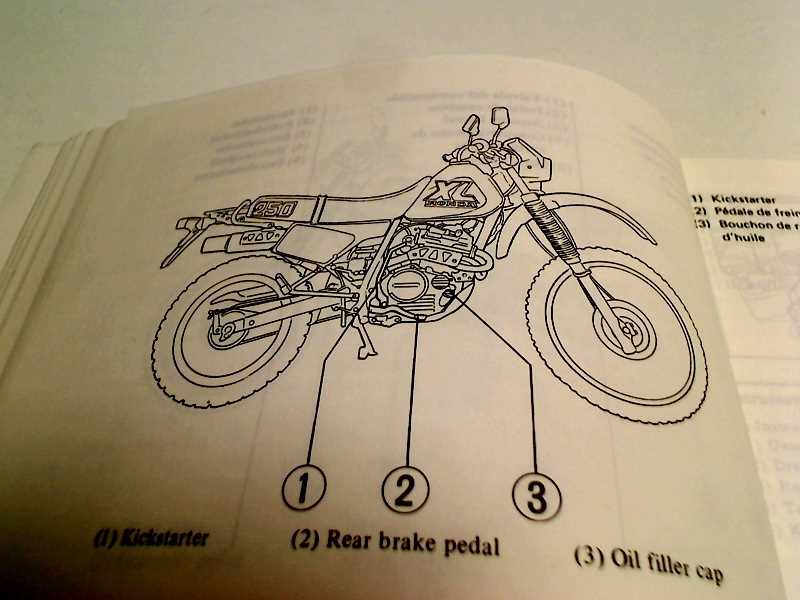

Step-by-Step Maintenance Procedures

Proper upkeep of your off-road vehicle is essential for optimal performance and longevity. By following a series of systematic steps, you can ensure that all components function smoothly and safely. This section outlines essential maintenance tasks that should be performed regularly to keep your machine in top condition.

Routine Checks

Begin by conducting regular inspections of key elements such as the brakes, tires, and fluid levels. Ensure that the brake pads are not worn out and that the tire pressure is at the recommended level. Checking the oil level and coolant fluid should be a routine part of your maintenance schedule, as these are crucial for engine health.

Filter and Lubrication

Replacing air and oil filters is vital for maintaining efficiency. A clean air filter ensures that the engine receives adequate airflow, while a fresh oil filter aids in proper lubrication. Additionally, apply suitable lubricant to moving parts, including chains and bearings, to reduce friction and prevent wear.

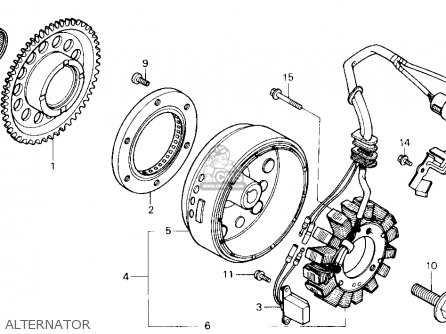

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a vehicle is crucial for maintaining optimal performance and reliability. This process involves systematically identifying faults, ensuring all components function correctly, and pinpointing any areas that require attention.

Common Symptoms of Electrical Problems

Recognizing signs of electrical issues can help in addressing them promptly. Here are some typical symptoms to watch for:

- Difficulty starting the engine

- Inconsistent or dim lighting

- Unresponsive electrical accessories

- Flickering dashboard indicators

Troubleshooting Steps

Follow these steps to effectively troubleshoot electrical problems:

- Check the battery voltage and connections for corrosion or looseness.

- Inspect the fuses for any blown components.

- Test the wiring harness for continuity and damage.

- Evaluate switches and relays for proper operation.

- Utilize a multimeter to measure voltages at various points in the system.

By systematically following these guidelines, one can effectively identify and rectify electrical issues, ensuring a smoother and more reliable ride.

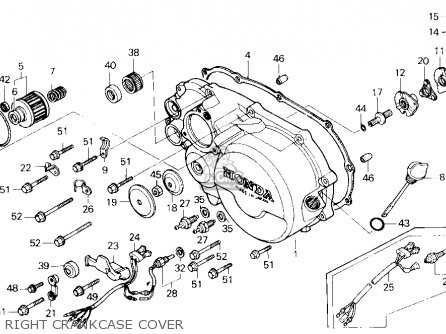

Engine Overhaul Guidelines

Performing an engine overhaul is essential for restoring performance and prolonging the life of your vehicle’s power unit. This process involves disassembling the engine, inspecting its components, and replacing worn or damaged parts. Proper planning and execution are key to ensuring a successful rebuild and optimal functioning.

Preparation Steps

Before commencing the overhaul, gather the necessary tools and materials. A clean workspace is crucial to avoid losing small components. Below is a table summarizing essential items needed for the task:

| Tool/Material | Purpose |

|---|---|

| Torque Wrench | To tighten bolts to specified settings |

| Socket Set | For removing and installing various engine components |

| Gasket Set | To replace old gaskets and prevent leaks |

| Cleaning Solvent | To clean parts and ensure proper functioning |

| New Filters | To maintain fluid cleanliness |

Step-by-Step Process

Once preparations are complete, follow these steps for a comprehensive overhaul:

1. Disassembly: Carefully remove the engine from the chassis and disassemble it, documenting each step to facilitate reassembly.

2. Inspection: Examine components such as pistons, crankshaft, and valves for wear and damage. Measure tolerances to determine if replacement is necessary.

3. Cleaning: Thoroughly clean all parts to eliminate dirt and debris that could cause operational issues.

4. Reassembly: Replace worn components with new ones and reassemble the engine, ensuring all parts are torqued to the manufacturer’s specifications.

5. Testing: After reassembly, conduct a thorough test to verify that the engine operates smoothly and meets performance expectations.

Adhering to these guidelines will facilitate a successful engine overhaul, ultimately enhancing performance and reliability.

Suspension Adjustments and Repairs

Proper maintenance and fine-tuning of the suspension system are crucial for ensuring optimal performance and ride quality. Adjustments can enhance handling characteristics, improve comfort, and extend the lifespan of the components. Understanding the basics of suspension setup will enable you to address issues effectively and customize your vehicle to suit your riding style.

Begin by assessing the current state of the suspension. Look for signs of wear, such as leaks from shock absorbers or unusual noises during operation. If necessary, consult the specifications for appropriate settings regarding preload, compression, and rebound damping. Making precise adjustments can significantly influence the balance and responsiveness of the ride.

When undertaking repairs, prioritize safety by using the right tools and following the recommended procedures. Replacing worn-out components, such as bushings or seals, can prevent further damage and enhance performance. Regularly inspect and maintain the suspension to avoid potential issues that could impact your riding experience.

Finally, test ride the vehicle after making adjustments or repairs. Pay attention to how the suspension feels on different terrains and tweak the settings as needed. A well-adjusted suspension will provide a smoother ride and better control, contributing to an overall enjoyable experience.

Braking System Inspection Techniques

Proper examination of the braking system is essential for maintaining optimal performance and safety. Regular checks ensure that components are functioning effectively, preventing potential failures that could lead to hazardous situations. This section outlines various methodologies to assess the braking mechanism, focusing on critical aspects such as wear, fluid condition, and overall functionality.

| Inspection Area | Technique | Notes |

|---|---|---|

| Brake Pads | Visual Inspection | Look for signs of wear; replace if thickness is below specifications. |

| Brake Discs | Runout Measurement | Use a dial indicator to check for uneven surfaces. |

| Brake Fluid | Fluid Quality Check | Inspect for discoloration or contaminants; replace if necessary. |

| Brake Lines | Leak Detection | Look for any signs of leakage or deterioration in the lines. |

| Master Cylinder | Functional Test | Ensure smooth operation and check for pressure build-up. |

Employing these techniques regularly can greatly enhance the longevity and reliability of the braking system, ensuring a safe and enjoyable riding experience.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is crucial for ensuring optimal performance and longevity of your vehicle. Regular attention to various components can prevent issues such as poor fuel efficiency, starting difficulties, and engine stalling. This guide provides essential advice for maintaining a clean and efficient fuel system.

Regular Inspections

Conducting routine checks on the fuel system can help identify potential problems before they escalate. Look for signs of wear, leaks, or blockages. Pay special attention to the fuel lines and connections, as they can deteriorate over time.

Cleaning the Fuel Filter

The fuel filter plays a vital role in keeping contaminants out of the engine. It is recommended to clean or replace the filter periodically, depending on usage and environmental conditions. A clean filter ensures a steady flow of fuel, promoting better engine performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Fuel Lines | Every 6 months | Look for cracks or leaks |

| Replace Fuel Filter | Every 12 months | More frequently in dusty environments |

| Check Fuel Pump | Every 6 months | Listen for unusual noises |

Exhaust System Care and Repairs

The exhaust system plays a crucial role in vehicle performance, directly affecting efficiency and emissions. Regular maintenance ensures optimal function and longevity, preventing costly issues down the line.

Key aspects of exhaust system maintenance include:

- Regular inspections for rust and damage

- Checking for leaks in pipes and joints

- Ensuring proper mounting and support

Common repairs might involve:

- Replacing worn-out gaskets

- Fixing or replacing broken hangers

- Addressing rusted sections with patches or new components

By staying proactive, one can enhance performance while minimizing environmental impact.

Upgrading Parts for Performance

Enhancing the capabilities of your vehicle can significantly elevate your riding experience. By investing in quality components, you can improve power output, handling, and overall efficiency. This section explores various options for upgrading parts, ensuring you make informed decisions that align with your performance goals.

Engine Modifications are among the most impactful upgrades you can make. Replacing the stock air filter with a high-flow variant allows for better airflow, improving combustion efficiency. Additionally, installing an aftermarket exhaust system can enhance exhaust flow, resulting in increased horsepower and a more aggressive sound.

Suspension Enhancements play a crucial role in handling and stability. Upgrading to adjustable shocks or springs allows for customization to suit your riding style and terrain. Improved suspension can lead to better traction and control, especially in challenging conditions.

Tires are another essential area for improvement. Choosing performance tires designed for specific conditions can dramatically influence grip and maneuverability. High-quality tires provide better traction, allowing for more confident cornering and braking.

Braking Systems also warrant attention. Upgrading to performance brake pads and rotors can enhance stopping power and reduce fade during prolonged use. This ensures not only improved performance but also increased safety on the trails or tracks.

Each upgrade should be carefully considered based on your unique requirements and the intended use of your vehicle. Proper installation and tuning are vital to maximizing the benefits of these enhancements, ensuring a smooth and powerful ride.

Finding Replacement Parts Online

Locating suitable components for your vehicle can be a straightforward process if you know where to look. The internet offers a myriad of options for sourcing quality parts, ensuring that your machine stays in optimal condition. With just a few clicks, you can access a vast marketplace filled with both new and used items tailored to your needs.

Start by exploring specialized online retailers that focus on automotive components. These platforms often provide extensive catalogs, complete with detailed descriptions and compatibility information. Additionally, utilizing search engines to find forums or communities dedicated to your model can yield invaluable insights and recommendations from fellow enthusiasts.

When purchasing online, it is crucial to verify the credibility of the seller. Look for reviews and ratings from previous buyers to gauge their reliability. Compare prices across different websites to ensure you are getting the best deal, and don’t hesitate to reach out to sellers with any questions regarding the parts’ condition or fitment.

For those who prefer to support local businesses, many brick-and-mortar stores also have an online presence. Check their websites for inventory availability and options for in-store pickup, which can save on shipping costs and time. Utilizing local resources not only helps you find what you need but also fosters community connections.