Maintaining a high-performance automobile involves understanding its intricate systems and components. This section provides valuable insights into troubleshooting and ensuring optimal functionality for a luxury sedan renowned for its elegance and engineering excellence. By delving into essential service procedures, owners can enhance their knowledge and skill set to effectively address various challenges that may arise.

From routine inspections to more complex repairs, this guide is designed to empower enthusiasts and owners alike. It encompasses a variety of topics, including system diagnostics, component replacements, and preventative measures that can extend the life of the vehicle. Furthermore, the information presented aims to demystify the repair processes, making them accessible and comprehensible for all.

Whether you are a seasoned mechanic or a novice looking to enhance your capabilities, this resource will serve as a crucial tool in your automotive journey. By equipping yourself with the right information, you can ensure that your vehicle continues to deliver a smooth and reliable driving experience.

Overview of 2003 Jaguar X-Type

This section provides a comprehensive insight into a luxury compact vehicle that combines style, comfort, and performance. Renowned for its elegant design and sophisticated engineering, this automobile appeals to those seeking a blend of sportiness and refinement. With a focus on driving experience and quality craftsmanship, this model showcases features that enhance both aesthetic appeal and functionality.

The vehicle is equipped with a range of engines that deliver impressive power while maintaining fuel efficiency. The well-appointed interior boasts premium materials and advanced technology, ensuring a pleasurable driving environment. Furthermore, safety is a priority, with numerous features designed to protect occupants in various conditions.

In summary, this model stands out in its segment for its harmonious balance of elegance, performance, and innovation, making it a compelling choice for discerning drivers. Whether navigating city streets or embarking on longer journeys, it promises a delightful experience on the road.

Common Issues and Troubleshooting Tips

Vehicles can encounter a variety of challenges over time, impacting performance and driving comfort. Identifying these common problems early can save both time and expense. This section provides insights into frequent complications that may arise and offers practical solutions to address them effectively.

Engine Performance Problems

One of the most prevalent issues involves engine performance. Drivers may experience rough idling, stalling, or decreased acceleration. These symptoms can often be traced back to issues with fuel delivery, such as clogged filters or malfunctioning fuel injectors. Regular maintenance of fuel components is crucial. If problems persist, consider examining the ignition system, including spark plugs and coils, as faulty components can lead to poor engine performance.

Electrical System Failures

Another common area of concern is the electrical system. Symptoms such as flickering lights, malfunctioning power windows, or issues with the central locking system may indicate underlying problems. Check the battery condition and ensure that all connections are clean and tight. Additionally, blown fuses should be replaced promptly. If electrical issues continue, a thorough inspection of the wiring harness and control modules may be necessary to pinpoint faults.

Maintenance Schedule for Jaguar X-Type

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. Establishing a systematic timetable for maintenance tasks not only enhances reliability but also promotes safety and efficiency. Adhering to this schedule will help you identify potential issues early and maintain the integrity of your automobile.

Routine Checks

It is advisable to conduct inspections on a regular basis. These should include monitoring fluid levels, examining tire pressure, and checking the condition of wipers and lights. Additionally, keeping an eye on brake performance is crucial for safe operation.

Scheduled Services

Incorporate comprehensive servicing at specified intervals, such as changing the oil, replacing air filters, and rotating tires. Timing belt replacements and brake fluid exchanges are also key components of the service schedule that require attention at appropriate mileage intervals. Following this structured approach will ensure your vehicle operates smoothly and efficiently.

Essential Tools for Repairs

Maintaining and restoring vehicles requires a variety of instruments to ensure effective and safe work. Having the right equipment can significantly impact the efficiency of tasks, leading to better outcomes and reduced time spent. From basic hand tools to specialized devices, each plays a crucial role in the overall process of enhancing vehicle functionality.

Basic hand tools, including wrenches, screwdrivers, and pliers, are fundamental for a wide range of tasks. They allow for easy access to components and facilitate adjustments or replacements. Additionally, power tools, such as drills and impact wrenches, provide the necessary force for more demanding operations, making them indispensable in any workshop.

For more intricate tasks, diagnostic equipment is essential. Devices that read error codes and monitor system performance help identify issues that may not be visible through manual inspection. Furthermore, safety gear, including gloves and goggles, is vital for protecting oneself during maintenance activities. Overall, a well-equipped workspace not only improves the quality of work but also ensures a safer environment.

Step-by-Step Engine Repair Guide

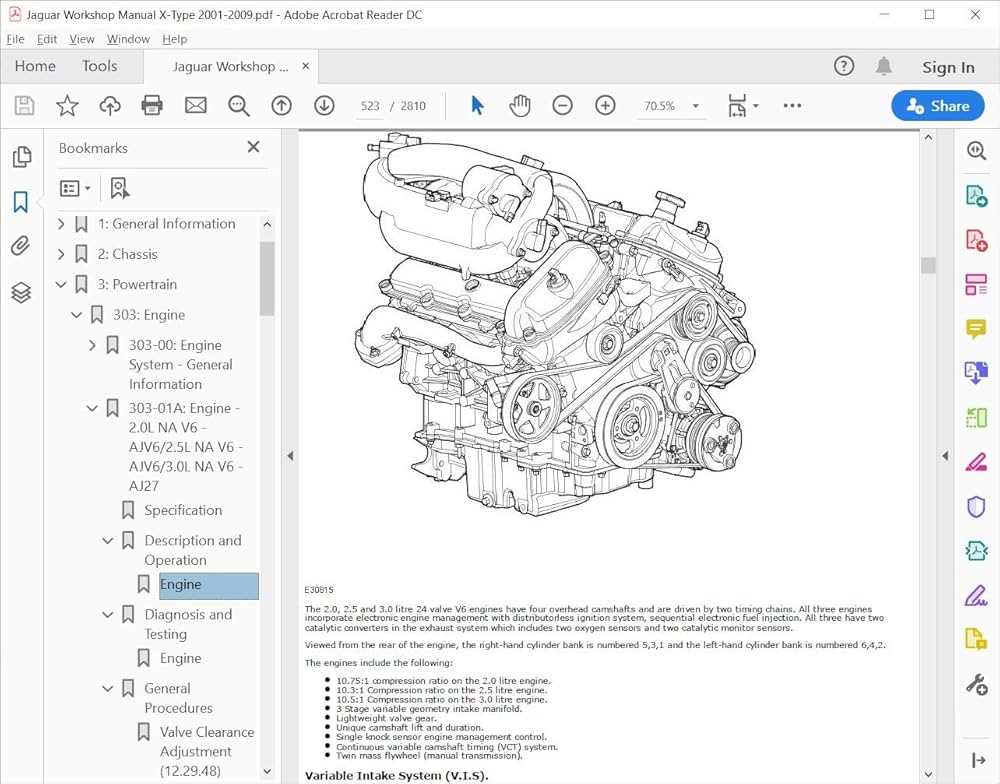

This section provides a comprehensive approach to addressing engine issues through a systematic procedure. Understanding the intricacies of engine components and their functions is vital for effective resolution of mechanical problems. By following these detailed steps, you can enhance your knowledge and skill set, ensuring optimal performance of your vehicle’s power unit.

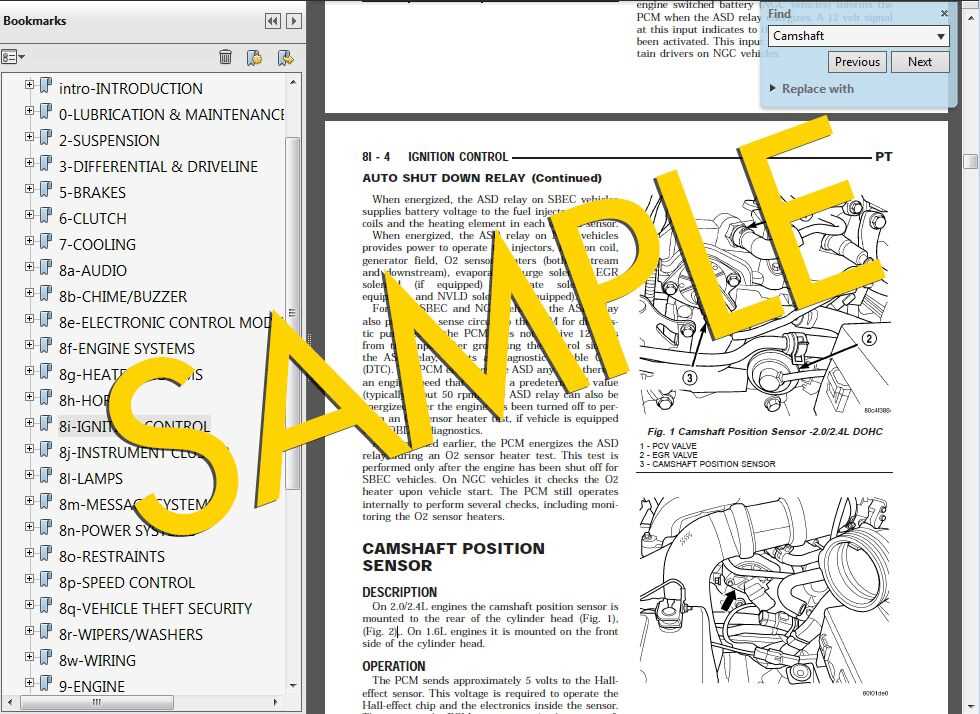

1. Diagnosis: Begin by accurately identifying the symptoms of the issue. Conduct thorough checks for any warning lights on the dashboard, unusual noises, or performance irregularities. Utilizing diagnostic tools can provide valuable insights into underlying faults.

2. Preparation: Gather all necessary tools and components before starting the process. Ensure that you have safety equipment, such as gloves and goggles, to protect yourself during the procedure. A clean and organized workspace will facilitate smoother operations.

3. Dismantling: Carefully remove any components obstructing access to the engine. This may include hoses, electrical connectors, and covers. Document each step to aid in reassembly and avoid losing small parts.

4. Inspection: Once the engine is accessible, conduct a detailed examination of critical parts such as the cylinders, pistons, and crankshaft. Look for signs of wear, damage, or contamination that may require attention. Taking notes at this stage is crucial for reference.

5. Replacement: If any components are found to be defective, replace them with high-quality parts. Ensure compatibility with the existing engine specifications. Take care to follow proper installation techniques to prevent future complications.

6. Reassembly: Once all repairs and replacements are completed, carefully reassemble the engine. Double-check all connections and fastenings to ensure everything is secure. Refer to your documentation for guidance during this stage.

7. Testing: After reassembly, start the engine and observe its performance. Listen for any unusual sounds and monitor for leaks. Conduct a test drive to ensure that the vehicle operates smoothly and effectively.

8. Final Checks: Perform a thorough inspection after the test drive to confirm that all systems are functioning correctly. Keep an eye on fluid levels and monitor for any signs of recurring issues.

Following these organized steps will empower you to tackle engine challenges with confidence. Each phase builds upon the previous one, fostering a deeper understanding of the mechanics at play.

Electrical System Diagnostics and Fixes

Addressing electrical issues in vehicles requires a systematic approach to ensure optimal functionality. This section outlines essential procedures for identifying and rectifying common electrical faults. Understanding the components involved and their interactions is crucial for effective troubleshooting and maintaining the overall performance of the vehicle’s electrical architecture.

Identifying Electrical Issues

Begin by checking the battery and its connections, as they are vital for powering various systems. Inspect the fuses for any signs of damage or blown elements. A thorough examination of wiring harnesses is also necessary to detect any frays, corrosion, or loose connections that could lead to intermittent faults. Utilize diagnostic tools to read error codes, which can provide insights into specific issues affecting the electrical network.

Fixing Common Problems

Once the source of the issue is identified, proceed with appropriate repairs. Replace any faulty fuses and ensure all connections are secure. For wiring issues, repairing or replacing damaged sections is essential to restore proper conductivity. If necessary, consult a professional for more complex electrical components, such as sensors or control modules, to guarantee accurate repairs and prevent further complications.

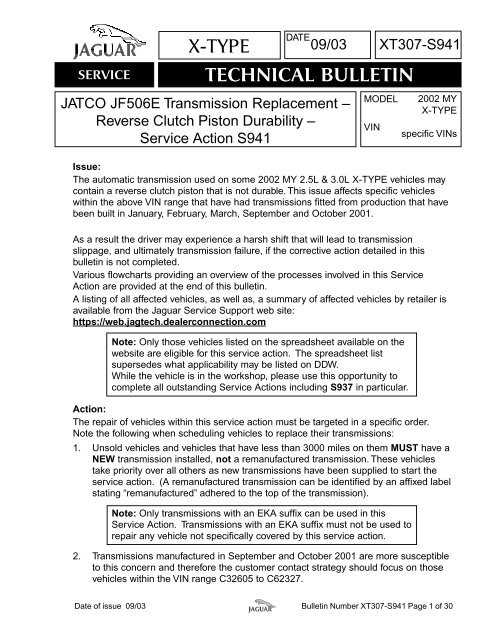

Transmission Problems and Solutions

The smooth functioning of a vehicle’s gear system is vital for optimal performance. However, various issues can arise, leading to complications in shifting and overall operation. Understanding these problems and their respective remedies is crucial for maintaining efficiency and safety on the road.

Common Issues

- Slipping Gears: This occurs when the transmission unexpectedly shifts out of gear, leading to a lack of power.

- Delayed Engagement: A noticeable delay when shifting from park to drive or reverse can indicate internal issues.

- Fluid Leaks: Low fluid levels can cause overheating and affect overall transmission function.

- Unusual Noises: Grinding, whining, or clunking sounds can signal mechanical failures within the system.

Solutions and Maintenance Tips

- Regular Fluid Checks: Ensure fluid levels are adequate and that the fluid is clean, replacing it as needed.

- Address Leaks Promptly: Inspect and repair any leaks to prevent further damage.

- Software Updates: For modern systems, ensure that the transmission control module has the latest software updates installed.

- Professional Diagnosis: Seek expert assistance if problems persist, as specialized tools may be required for accurate assessment.

Braking System Inspection Procedures

The braking mechanism is a critical component for ensuring safe operation of a vehicle. Regular examination of this system is essential to identify any wear or malfunction that may compromise performance. By following systematic inspection steps, one can ensure optimal functionality and safety while driving.

Visual Inspection

Commence the evaluation by conducting a thorough visual check of the braking components. Look for any signs of fluid leakage, damaged hoses, or corrosion on metal parts. Examine the brake pads for thickness; insufficient material may indicate the need for replacement. Additionally, inspect the rotors for any visible cracks or warping that could affect braking efficiency.

Functional Testing

After completing the visual assessment, proceed with functional tests to evaluate the responsiveness of the braking system. Press the brake pedal firmly and check for any unusual sounds or vibrations. Ensure that the pedal feels firm and does not sink to the floor, which could signal air in the lines or a leak in the hydraulic system. Pay attention to the vehicle’s stopping distance; any increase in this distance may necessitate further examination of the entire assembly.

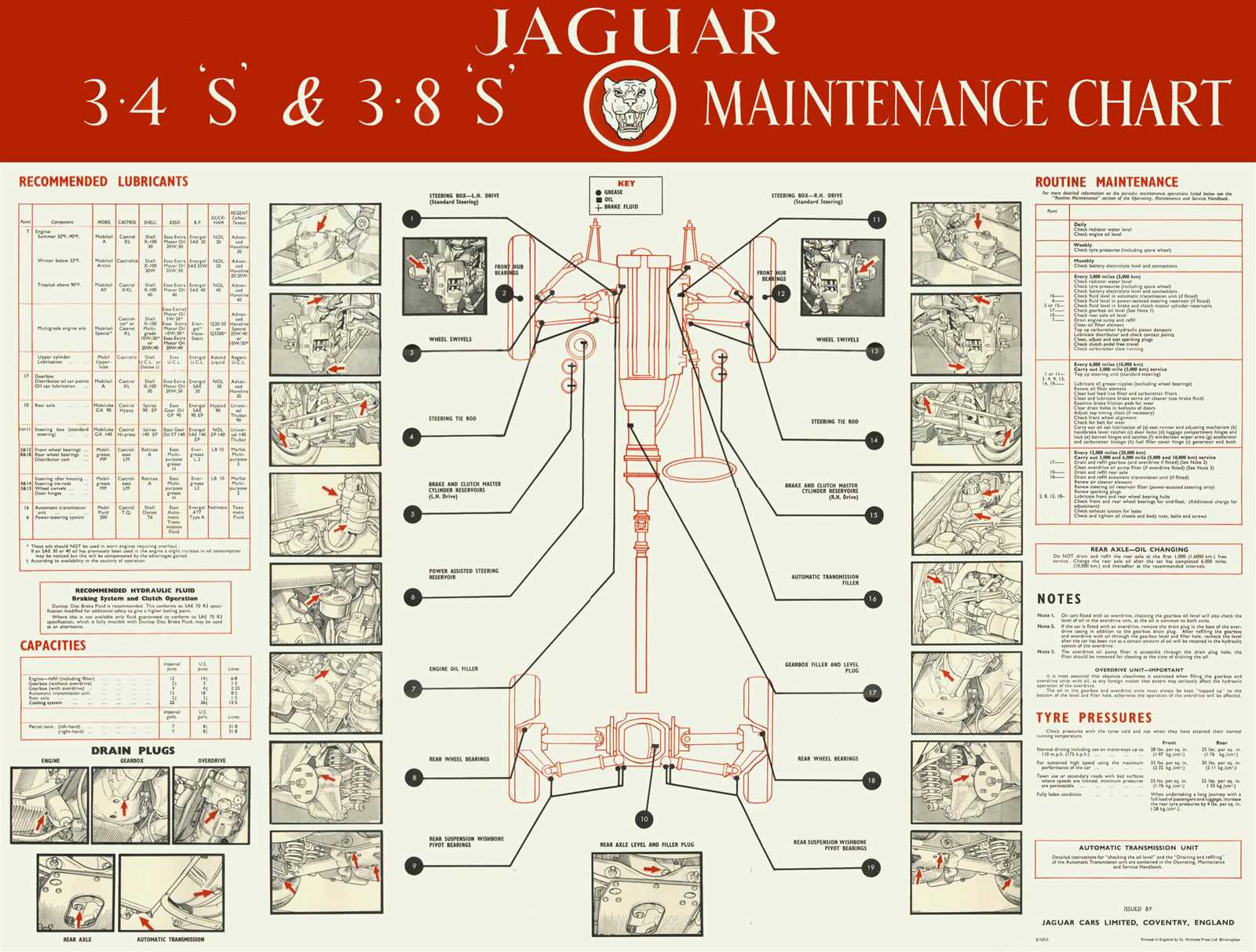

Suspension and Steering Maintenance

Proper upkeep of the suspension and steering systems is essential for a smooth and safe driving experience. Regular inspections and timely adjustments can prevent wear and enhance overall performance. This section covers the key aspects of maintaining these critical components.

To ensure optimal functionality, consider the following maintenance tasks:

- Inspect Suspension Components: Check for signs of damage, such as cracks, rust, or wear on parts like control arms, bushings, and shocks.

- Examine Steering Linkage: Look for any loose connections or excessive play in the steering system to maintain precise handling.

- Monitor Fluid Levels: Regularly check power steering fluid levels and replace any contaminated fluid to ensure smooth operation.

- Alignment Checks: Schedule routine wheel alignments to prevent uneven tire wear and improve handling characteristics.

In addition to these tasks, it’s advisable to:

- Perform visual inspections of tires for proper inflation and tread depth.

- Listen for unusual noises while turning or driving over bumps, which may indicate underlying issues.

- Consult with a qualified technician if any problems are detected during inspections.

Maintaining the suspension and steering systems not only enhances the vehicle’s comfort but also ensures safety on the road. Adhering to a regular maintenance schedule will extend the lifespan of these components and improve driving dynamics.

Bodywork Repairs and Painting Tips

Addressing exterior damage and refreshing surfaces can significantly enhance the overall appearance and longevity of your vehicle. Whether it involves fixing minor dents, scratches, or applying a fresh coat of paint, mastering these techniques will not only save costs but also improve your automotive skills.

Here are some essential tips for tackling bodywork issues effectively:

- Assess the Damage: Before starting any project, evaluate the extent of the damage. This helps in determining the necessary tools and materials.

- Gather Tools and Materials: Commonly needed items include sandpaper, body filler, primer, paint, and clear coat. Ensure you have everything within reach.

- Surface Preparation: Clean the area thoroughly to remove dirt and grease. Use sandpaper to smooth out rough edges around the damaged area.

- Applying Body Filler: For dents or scratches, mix and apply body filler. Once dry, sand it down to achieve a smooth finish.

- Priming: Apply a primer to the repaired area to help the paint adhere better and create a uniform surface.

- Painting: Use high-quality paint for the best results. Apply multiple thin coats, allowing adequate drying time between each.

- Finishing Touches: After the paint dries, apply a clear coat for protection. This step enhances the shine and durability of the finish.

By following these steps, you can achieve professional-looking results while enhancing the aesthetic appeal of your vehicle.

Replacing Parts: What You Need

When it comes to maintaining a vehicle, understanding the essentials for swapping out components is crucial. Proper preparation not only ensures smooth operation but also prolongs the lifespan of your automobile. Familiarizing yourself with the necessary tools and parts will streamline the process and enhance overall efficiency.

Essential Tools for Component Replacement

Before diving into the task of component swapping, gather a few fundamental tools. A quality set of wrenches and sockets, along with screwdrivers of various sizes, will cover most basic needs. Additionally, having pliers, a torque wrench, and a jack stands will provide the support required for safe and effective replacements. Investing in a repair kit can also save time and effort.

Identifying Quality Components

When selecting new parts, prioritize quality over cost. Authentic or high-quality aftermarket components can significantly impact the performance of your vehicle. Researching compatibility and reading reviews will help in making informed decisions. Ensure that any part you choose meets the specifications necessary for optimal functionality.

Safety Precautions During Repairs

When undertaking maintenance tasks on your vehicle, ensuring a secure environment is essential. Proper precautions not only protect you but also enhance the efficiency of the work being performed. A careful approach can prevent accidents and damage to components, ultimately leading to a smoother process and better results.

Protective Gear

Wearing the appropriate protective equipment is vital. This includes items such as gloves, goggles, and sturdy footwear. Gloves shield your hands from sharp edges and harmful substances, while goggles prevent debris from causing eye injuries. Additionally, durable shoes can protect your feet from heavy tools and falling parts.

Workspace Organization

Maintaining an organized workspace significantly reduces the risk of mishaps. Ensure that all tools and materials are within easy reach and that the area is free from clutter. A tidy environment allows for better focus and minimizes the likelihood of slipping or tripping. Always dispose of waste materials appropriately to keep the area safe.