When it comes to maintaining your all-terrain vehicle, understanding its intricacies is essential for ensuring optimal performance. This section provides valuable insights and practical tips to help you navigate through the complexities of your machine. By familiarizing yourself with various components, you can enhance your riding experience and extend the lifespan of your vehicle.

Comprehensive knowledge of your ATV’s systems not only empowers you to address minor issues but also equips you with the skills needed for more significant challenges. Whether you’re performing routine checks or tackling unexpected problems, having a solid foundation in maintenance practices will serve you well. Emphasizing preventative measures can save you time and effort in the long run.

Equipped with the right information, you can approach repairs with confidence and a proactive mindset. Understanding the layout and function of each element allows for efficient troubleshooting and effective solutions. By delving into this guide, you’re taking the first step towards mastering the art of ATV care.

Overview of Polaris Scrambler 90

This section provides an insight into a compact off-road vehicle designed for younger riders and recreational enthusiasts. Known for its robust construction and reliable performance, this model combines agility with stability, making it a suitable choice for various terrains.

Design and Features

The vehicle showcases a sleek, ergonomic design that promotes ease of handling. With a lightweight frame and comfortable seating, it ensures a pleasant experience for the operator. Equipped with essential features such as a responsive throttle and dependable braking system, it enhances safety during rides.

Performance and Capabilities

This compact vehicle is powered by a dynamic engine that delivers impressive torque and acceleration. Its versatile suspension system allows for smooth navigation over bumps and rough surfaces, making it a great companion for outdoor adventures. Whether tackling trails or exploring open fields, this model excels in delivering an exhilarating experience.

Key Features and Specifications

This section highlights the essential characteristics and technical details of a versatile all-terrain vehicle, designed for performance and durability. Understanding these attributes is crucial for maintenance and enhancing the overall experience.

- Engine Type: Air-cooled single-cylinder engine

- Displacement: Approximately 90cc

- Transmission: Automatic with variable ratio

- Drive System: Chain drive for optimal power transfer

- Suspension:

- Front: Independent A-arm with adjustable shocks

- Rear: Mono-shock system for improved stability

- Brakes: Hydraulic front and rear disc brakes for enhanced stopping power

- Dimensions:

- Overall Length: 58 inches

- Overall Width: 36 inches

- Overall Height: 37 inches

- Fuel Capacity: 2.5 gallons for extended riding sessions

- Weight: Approximately 250 lbs for easy handling

Common Issues with the 2001 Model

This section addresses frequent challenges encountered in a specific all-terrain vehicle model. Understanding these common problems can help owners maintain optimal performance and enhance the longevity of their machines. Regular inspections and timely interventions are key to mitigating these issues.

Engine Performance Troubles

One prevalent concern involves engine efficiency, where riders may notice a decrease in power or irregular idling. These symptoms could stem from fuel delivery issues or air filter blockages, impacting overall operation. Regular maintenance of fuel lines and filters can significantly improve performance.

Electrical System Failures

Another frequent difficulty lies within the electrical components. Riders might experience issues with starting or intermittent electrical failures. These problems often relate to battery condition or faulty wiring. Ensuring connections are secure and the battery is adequately charged can prevent unexpected disruptions.

Effective Troubleshooting Techniques

When faced with mechanical challenges, adopting systematic methods can significantly enhance the problem-solving process. By approaching issues methodically, one can identify the root cause of malfunctions, ensuring more efficient repairs and maintenance.

Step-by-Step Approach

Utilizing a structured approach is essential. Here are some key steps to consider:

- Observation: Start by closely examining the situation. Note any unusual sounds, smells, or performance issues.

- Documentation: Keep a record of all findings. This can help track recurring problems and solutions.

- Isolation: Focus on one area at a time. Isolating components can help narrow down potential causes.

- Testing: Utilize basic tools to test individual parts. Checking electrical connections or fluid levels can reveal hidden issues.

Common Issues and Solutions

Being aware of frequent problems can aid in quicker diagnostics. Here are a few typical concerns:

- Starting Difficulties: Check the battery and ignition system for faults.

- Performance Drops: Inspect the fuel system for clogs or leaks.

- Electrical Failures: Examine wiring for damage or corrosion.

- Handling Problems: Assess tire pressure and suspension components for wear.

By applying these techniques, anyone can enhance their troubleshooting skills, leading to more effective resolutions and improved equipment longevity.

Maintenance Tips for Longevity

Ensuring the durability of your off-road vehicle requires consistent attention and care. Regular maintenance not only enhances performance but also extends the lifespan of essential components. By following a few straightforward practices, you can keep your machine running smoothly for years to come.

Routine Inspections: Conducting periodic checks of key systems is vital. Look for signs of wear or damage, paying special attention to the engine, brakes, and suspension. Early detection of issues can prevent costly repairs down the line.

Fluid Management: Maintaining proper fluid levels is crucial for optimal functionality. Regularly check and change the oil, coolant, and transmission fluids as specified in the guidelines. Clean fluids promote efficient operation and protect internal parts from unnecessary wear.

Tire Care: Tires are your vehicle’s primary contact with the ground. Ensure they are properly inflated and have sufficient tread. Rotate them regularly to promote even wear and extend their lifespan. Additionally, align the wheels to maintain stability and handling.

Storage Considerations: When not in use, store your vehicle in a cool, dry place. Use a cover to protect it from dust and moisture. If storing for an extended period, consider adding a fuel stabilizer to prevent degradation.

By incorporating these maintenance tips into your routine, you can enhance the reliability and longevity of your vehicle, ensuring enjoyable rides for many adventures ahead.

Essential Tools for Repairs

When it comes to maintaining and fixing your vehicle, having the right equipment can make all the difference. A well-equipped workspace not only enhances efficiency but also ensures safety during various tasks. This section outlines the fundamental instruments that every enthusiast should have on hand for effective upkeep and troubleshooting.

Basic Toolkit

A comprehensive toolkit is the foundation of any maintenance endeavor. Here are some indispensable items to consider:

| Tool | Purpose |

|---|---|

| Socket Set | Useful for loosening or tightening nuts and bolts. |

| Wrench Set | Ideal for gripping and turning fasteners. |

| Screwdriver Set | Essential for various screws found throughout the machine. |

| Pliers | Helpful for gripping and manipulating components. |

| Hammer | Used for driving or adjusting parts into place. |

Specialized Equipment

In addition to the basic tools, specialized instruments can be invaluable for specific tasks:

| Tool | Purpose |

|---|---|

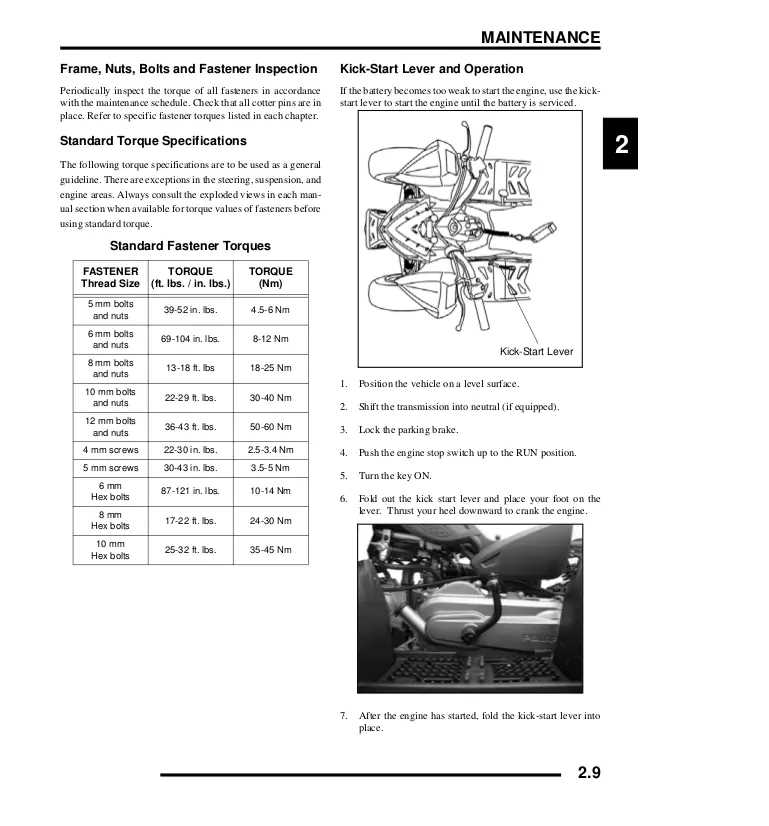

| Torque Wrench | Ensures fasteners are tightened to the correct specification. |

| Multimeter | Used for diagnosing electrical issues and measuring voltage. |

| Oil Filter Wrench | Facilitates the removal of oil filters during maintenance. |

| Brake Bleeder Kit | Essential for maintaining the braking system. |

| Fuel Pressure Gauge | Measures fuel system pressure for diagnostics. |

Step-by-Step Repair Processes

This section outlines a comprehensive approach to addressing various maintenance tasks for a specific all-terrain vehicle. By following these organized procedures, enthusiasts and mechanics can effectively diagnose issues and implement solutions, ensuring optimal performance and longevity of the machine.

Begin by gathering essential tools and materials. Having the right equipment on hand streamlines the process and enhances efficiency. Below is a table summarizing the necessary items:

| Tool/Material | Description |

|---|---|

| Socket Set | A variety of sockets for loosening and tightening bolts. |

| Screwdrivers | Flathead and Phillips for various screws. |

| Wrench Set | Different sizes for nuts and bolts. |

| Oil and Lubricants | Necessary for smooth operation of moving parts. |

| Safety Gear | Gloves and goggles to ensure personal safety. |

Next, establish a systematic approach to each task. Documenting observations and results during each stage is crucial for identifying patterns and areas that require attention. This method not only aids in problem-solving but also serves as a valuable reference for future projects.

Following these organized steps will promote a thorough understanding of the vehicle’s components and contribute to more effective maintenance practices. Engaging with the machinery in this manner fosters a deeper connection and appreciation for the craft of upkeep.

Electrical System Troubleshooting Guide

This section offers essential guidance for diagnosing and addressing issues related to the electrical components of your vehicle. Understanding the electrical system is crucial for ensuring optimal performance and reliability. With a systematic approach, you can identify common problems and implement effective solutions.

Common Issues to Look For

- Battery failures

- Faulty wiring connections

- Malfunctioning switches

- Inoperative lights and indicators

- Defective fuses

Troubleshooting Steps

- Check the battery voltage with a multimeter.

- Inspect wiring for signs of wear, damage, or corrosion.

- Test switches to ensure they are functioning correctly.

- Examine bulbs and connectors for faults.

- Replace any blown fuses and test the circuit again.

By following these steps, you can effectively troubleshoot and resolve electrical issues, ensuring your vehicle operates smoothly and efficiently.

Engine Performance Enhancements

Improving the performance of a small all-terrain vehicle engine can significantly enhance its responsiveness and overall driving experience. Various modifications and upgrades can lead to better power output, improved throttle response, and increased efficiency. This section explores several methods to achieve these enhancements, focusing on practical applications that can be implemented with minimal effort.

One of the most effective ways to boost engine performance is through the optimization of airflow. This can be achieved by upgrading the intake and exhaust systems. Enhanced airflow allows the engine to breathe better, leading to improved combustion efficiency. The table below summarizes key components that can be modified for optimal performance:

| Component | Description |

|---|---|

| Air Filter | Installing a high-flow air filter to increase the amount of clean air entering the engine. |

| Exhaust System | Replacing the stock exhaust with a performance-oriented system to reduce back pressure. |

| Carburetor Jetting | Adjusting the carburetor jets to ensure optimal fuel-air mixture for enhanced performance. |

Additionally, engine tuning plays a critical role in achieving desired performance levels. Fine-tuning ignition timing and fuel delivery can lead to better engine responsiveness. Implementing these enhancements can transform a standard engine into a more dynamic and enjoyable driving machine.

Upgrading Tires and Suspension

Enhancing the performance of your off-road vehicle can significantly improve your riding experience. One of the most impactful modifications involves upgrading the tires and suspension system. This not only boosts traction and handling but also contributes to a smoother ride over various terrains.

Choosing the Right Tires

Selecting appropriate tires is crucial for optimizing grip and stability. Consider the following factors when making your choice:

- Tread Pattern: Look for aggressive patterns that provide better traction on loose surfaces.

- Size: Larger tires can enhance ground clearance and improve off-road capability.

- Material: Durable materials can withstand rough conditions and reduce the risk of punctures.

Enhancing Suspension Performance

Improving the suspension system can lead to better handling and comfort. Here are some options to consider:

- Adjustable Shocks: These allow you to customize the ride stiffness based on your preferences and terrain.

- Upgraded Springs: Stronger springs can provide additional support for heavier loads or rougher terrain.

- Lift Kits: Installing a lift kit can increase ground clearance and enhance approach and departure angles.

Investing in quality tires and a robust suspension system is essential for maximizing performance and ensuring a thrilling and safe ride.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to ensure a secure working environment. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding area from potential hazards.

Before beginning any tasks, familiarize yourself with the specific requirements and guidelines associated with the project. This helps in anticipating any risks and preparing adequately. Here are some vital safety measures to consider:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear suitable protective gear such as gloves, goggles, and steel-toed boots to minimize the risk of injury. |

| Workspace Organization | Keep the work area tidy and free from clutter to prevent accidents. Ensure tools and materials are stored properly. |

| Electrical Safety | Disconnect power sources before starting work on electrical components to avoid shocks or short circuits. |

| Manual Handling | Use correct lifting techniques to avoid strain or injury when moving heavy parts. |

| Fire Safety | Have a fire extinguisher accessible and be aware of flammable materials in the area. |

Adhering to these guidelines can significantly reduce the likelihood of accidents and injuries during maintenance activities. Always stay alert and prepared, and if unsure about any process, seek assistance or consult relevant resources.

Finding Replacement Parts Easily

Locating the right components for your vehicle can sometimes feel overwhelming, but it doesn’t have to be. With the right approach and resources, you can quickly identify the necessary pieces to keep your machine running smoothly. Understanding where to search and what to look for can save you time and ensure you have the best quality parts available.

Utilizing Online Resources

The internet offers a wealth of information and resources for sourcing components. Numerous websites specialize in aftermarket and OEM parts, allowing you to compare prices and availability. Online forums and communities can also provide valuable insights from fellow enthusiasts who have faced similar challenges.

Local Dealerships and Auto Parts Stores

Visiting nearby dealerships or auto parts stores can be beneficial as well. Many establishments carry a range of components or can order them for you. Building a relationship with local suppliers may also grant you access to exclusive deals and promotions. Don’t hesitate to ask for recommendations to ensure you’re getting reliable options.