Maintaining your outdoor power equipment is essential for ensuring its longevity and optimal performance. Whether you’re dealing with trimming tasks or tackling overgrown areas, understanding the nuances of your tools can greatly enhance your gardening experience. This section will delve into practical techniques for diagnosing issues and restoring functionality.

By familiarizing yourself with the various components and their interactions, you can confidently approach challenges that may arise during use. From identifying common malfunctions to executing straightforward solutions, the knowledge gained here will empower you to take charge of your equipment’s upkeep.

Equipped with the right information, you’ll be able to address potential problems before they escalate, saving both time and resources. Embracing these maintenance practices not only improves the efficiency of your tools but also fosters a deeper appreciation for your gardening endeavors.

Understanding Your Craftsman Weed Eater

Every user of outdoor maintenance equipment needs to grasp the fundamentals of their tools to ensure optimal performance and longevity. Knowing how to operate, maintain, and troubleshoot your device can significantly enhance your experience.

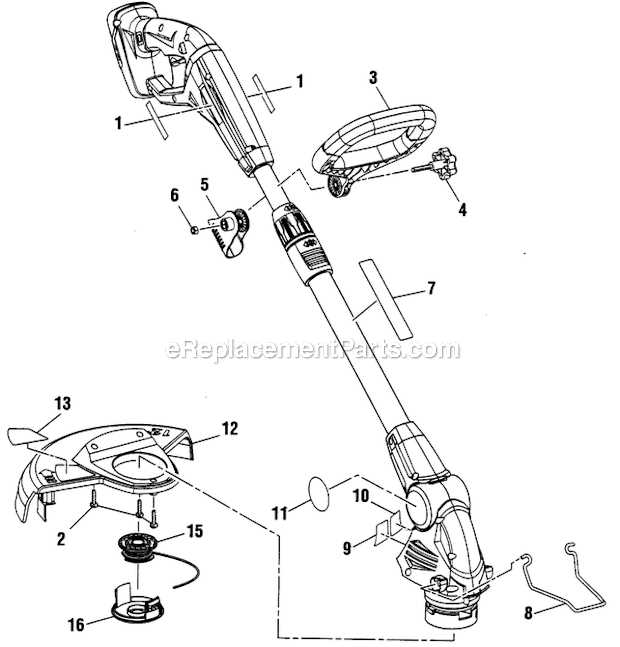

Familiarity with your tool’s components is crucial. Here are key elements to consider:

- Engine Type: Understanding the power source and its specifications can help you manage fuel requirements and performance expectations.

- Cutting Mechanism: Familiarizing yourself with how the cutting system functions is essential for efficient operation and maintenance.

- Safety Features: Always prioritize safety by recognizing and utilizing the built-in protective features of your equipment.

Regular upkeep can prevent common issues and prolong the life of your tool. Here are some maintenance tips:

- Regularly check and replace filters to ensure clean airflow.

- Inspect and sharpen cutting edges as needed for effective performance.

- Keep the exterior clean to prevent buildup that can lead to operational problems.

By comprehensively understanding your equipment and committing to its upkeep, you can achieve exceptional results and minimize the need for extensive troubleshooting.

Common Issues with Weed Eaters

Maintaining outdoor trimming equipment can often reveal several typical problems that users encounter. Recognizing these challenges can facilitate prompt solutions and enhance the lifespan of the device.

Starting Difficulties: One of the most frequent complaints involves trouble initiating the engine. This issue may stem from various sources, including stale fuel or a clogged air filter. Regular maintenance can help mitigate these complications.

Performance Drops: Users may notice a decline in cutting efficiency. This can result from dull blades or improper line feed. Ensuring that components are sharp and correctly adjusted is essential for optimal performance.

Excessive Vibration: Unusual vibrations during operation can indicate misalignment or wear in the motor. Addressing these concerns promptly can prevent further damage and ensure smoother functioning.

Fuel Leaks: Leaking fuel is a significant issue that not only affects performance but also poses safety risks. Checking the fuel lines and connections regularly can help prevent such incidents.

By staying aware of these common challenges and performing routine inspections, users can ensure their outdoor trimming tools remain efficient and reliable.

Essential Tools for Repair

When it comes to maintaining and fixing outdoor equipment, having the right instruments is crucial for achieving optimal performance. The appropriate tools not only simplify the process but also ensure that each task is completed with precision and efficiency.

One of the most fundamental items in any toolkit is a screwdriver set. These versatile implements come in various sizes and types, allowing you to tackle different screws with ease. Additionally, a wrench set is essential for loosening or tightening bolts, making it indispensable for any mechanical adjustments.

Another vital component is a spark plug socket, which is specifically designed for accessing and replacing spark plugs, a common area that requires attention. A fuel line cutter can also be beneficial for quick and clean modifications, while a cleaning kit helps maintain the overall functionality of the equipment.

Finally, don’t overlook the importance of safety gear, such as gloves and goggles. Protecting yourself while working is paramount, ensuring a safe and effective working environment.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor tools. This guide provides a comprehensive approach to maintaining your equipment, allowing you to enjoy efficient operation for years to come.

Essential Preparations

Before beginning any maintenance tasks, gather necessary tools and supplies. A clean workspace will make the process smoother. Ensure you have access to safety gear, such as gloves and goggles, to protect yourself during the procedure.

Routine Checks

Start with a visual inspection of your device. Look for signs of wear, loose components, or accumulated debris. Pay close attention to the air filter, fuel lines, and spark plug. Cleaning or replacing these parts regularly can significantly enhance performance. Additionally, ensure that all fasteners are tightened to prevent operational issues.

Replacing the String Trimmer Head

Maintaining a grass cutting tool is essential for ensuring its longevity and performance. One common task is swapping out the cutting head, which can become worn or damaged over time. This section will guide you through the necessary steps to successfully replace this component, ensuring your device operates efficiently once again.

To begin, gather the required tools and safety gear. You will need a suitable replacement head, a wrench, and protective gloves. First, ensure the device is turned off and disconnected from any power source. This is crucial for your safety during the replacement process.

Next, locate the securing mechanism of the current head. Depending on the model, this may involve unscrewing or unclipping it. Carefully remove the old head, taking note of how it is attached, as this will aid in installing the new one. Once removed, position the new head in place and secure it according to the manufacturer’s guidelines. Double-check that everything is tightly fastened to avoid any issues during operation.

After installation, perform a quick test run to ensure the new head is functioning correctly. If you notice any unusual sounds or movements, recheck your work. Regular maintenance and timely replacements will keep your grass trimming tool in peak condition for years to come.

Troubleshooting Engine Performance Problems

Engine issues can lead to unsatisfactory performance, affecting efficiency and reliability. Identifying and addressing these problems is essential for optimal functionality. Common symptoms may include stalling, reduced power, or difficulty starting. Understanding the root causes can help in effectively resolving these concerns.

- Check Fuel Quality: Ensure the fuel is fresh and free from contaminants. Old or contaminated fuel can cause starting issues and poor performance.

- Inspect Air Filter: A clogged air filter restricts airflow, leading to poor combustion. Clean or replace it if necessary.

- Examine Spark Plug: A faulty spark plug can hinder ignition. Inspect for wear and replace it if needed.

- Assess Carburetor: If the engine is running lean or rich, the carburetor may need adjustment or cleaning to ensure proper fuel delivery.

- Look for Leaks: Check for any fuel or air leaks in the system that could affect performance.

By systematically evaluating these areas, one can often pinpoint the issue and restore the engine’s performance. Regular maintenance can also prevent many common problems.

Cleaning and Replacing Air Filters

Maintaining optimal performance in outdoor power equipment requires regular attention to various components. One crucial element that often gets overlooked is the air filtration system. A clean air filter ensures that the engine receives an adequate supply of air, which is essential for efficient combustion and overall functionality.

Importance of Clean Air Filters

Over time, air filters can accumulate dust, debris, and other particles, leading to reduced airflow. This blockage can result in poor engine performance, increased fuel consumption, and even potential damage to the machine. Regular cleaning or replacement of the air filter is vital to prevent these issues and prolong the lifespan of your equipment.

Steps to Clean or Replace

To maintain your device, start by removing the air filter cover, which usually requires a screwdriver. Take out the filter gently, ensuring not to damage any surrounding parts. If the filter is reusable, clean it with compressed air or wash it with soap and water, allowing it to dry completely before reinserting. If the filter is worn or damaged, it’s advisable to replace it with a new one. Always consult the specific guidelines for your model to ensure proper installation.

Adjusting Carburetor Settings

Proper calibration of the fuel delivery mechanism is essential for optimal performance. Ensuring the correct mixture of air and fuel allows for efficient operation and prolongs the lifespan of the equipment. Fine-tuning these settings can help resolve issues related to starting, idling, and overall functionality.

Understanding the Adjustments

Adjustments typically involve manipulating three main screws: the idle, low-speed, and high-speed settings. Each screw plays a crucial role in controlling the flow of fuel and air, impacting the engine’s efficiency at various RPMs.

| Adjustment Type | Description | Effect on Performance |

|---|---|---|

| Idle Adjustment | Regulates the fuel flow at rest. | Ensures smooth starting and stable idle. |

| Low-Speed Adjustment | Affects fuel mixture at low RPMs. | Enhances performance during light tasks. |

| High-Speed Adjustment | Controls fuel flow at maximum RPMs. | Improves power and efficiency during heavy usage. |

Steps for Calibration

Begin by locating the adjustment screws on the fuel delivery unit. Start with the idle setting, turning the screw clockwise or counterclockwise to achieve a stable idle. Next, proceed to the low-speed adjustment, ensuring the engine runs smoothly under minimal load. Finally, adjust the high-speed setting for optimal performance during demanding operations. Regular checks and adjustments will help maintain efficiency and prevent operational issues.

Repairing Fuel Line Issues

Addressing problems with the fuel delivery system is essential for optimal performance. When the flow of fuel is obstructed or compromised, it can lead to inefficient operation or complete failure to start. This section outlines the common issues that may arise and offers solutions to restore functionality.

Identifying Common Symptoms

Typical indicators of fuel line complications include difficulty starting the engine, sputtering during operation, or a noticeable drop in power. Additionally, you may observe fuel leaks or smell gasoline, which can signal a breach in the line. Recognizing these signs early can prevent further damage and ensure a smoother resolution.

Steps for Troubleshooting

To begin addressing these challenges, first inspect the entire fuel delivery pathway for cracks or blockages. Clear any obstructions using compressed air or by gently shaking the line. If you notice any physical damage, consider replacing the affected section. Always ensure that connections are tight and free of debris. Finally, after making adjustments, run a test to verify that fuel flows properly and the engine operates smoothly.

Safety Precautions During Repairs

Ensuring personal safety while conducting maintenance tasks is crucial. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Awareness of potential hazards and appropriate preventive measures is essential for a smooth working experience.

- Always wear protective gear, including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling fumes and dust.

- Disconnect the power source before starting any maintenance work.

- Keep the workspace organized and free of clutter to prevent trips and falls.

Furthermore, ensure that tools are in good condition and suitable for the task. Regular inspections and maintenance of equipment can enhance safety and efficiency.

- Follow the manufacturer’s guidelines for specific procedures.

- Store hazardous materials securely and out of reach of children.

- Be aware of your surroundings and avoid distractions while working.

By implementing these safety measures, you can create a safer environment, minimizing the likelihood of mishaps during maintenance activities.

Tips for Extending Lifespan

Maintaining the longevity of your outdoor power equipment involves several key practices. By adopting these strategies, you can ensure optimal performance and minimize the need for frequent repairs.

- Regular Cleaning: After each use, remove dirt and debris from the machine. Pay special attention to the air filter and cooling vents to prevent overheating.

- Fuel Quality: Use fresh, high-quality fuel to avoid engine issues. Old or contaminated fuel can lead to poor performance and potential damage.

- Scheduled Maintenance: Follow a consistent maintenance schedule. Check spark plugs, filters, and other components regularly to identify and address wear before it escalates.

- Proper Storage: Store your equipment in a dry, sheltered location to protect it from the elements. Consider using a cover to keep dust and moisture at bay.

- Use the Right Tools: Utilize the appropriate attachments and accessories for your tasks. This ensures efficient operation and reduces strain on the machine.

Implementing these practices will enhance the reliability and lifespan of your outdoor tools, making them a valuable part of your gardening routine for years to come.

Finding Replacement Parts Easily

Locating suitable components for your gardening equipment can often be a daunting task. However, with the right approach, you can streamline the process and ensure that you have access to all necessary parts quickly and efficiently.

Start by consulting reputable online retailers that specialize in garden tools and accessories. These platforms often provide comprehensive catalogs, allowing you to search by model or part number. Additionally, customer reviews can guide you in choosing high-quality replacements.

Another effective strategy is to join online forums or social media groups dedicated to gardening enthusiasts. Engaging with a community can offer valuable insights and recommendations for sourcing components that may not be readily available through traditional retailers.

Don’t overlook local hardware stores or specialty shops. They may stock essential items or be able to order them for you. Establishing a relationship with knowledgeable staff can lead to personalized assistance and advice tailored to your specific needs.

Lastly, always keep your equipment’s documentation handy. Having the original specifications at your fingertips will help you identify the exact components you need, reducing the chances of purchasing incorrect items.