Ensuring the optimal functionality of your automated swimming area maintenance device is essential for keeping your aquatic environment in pristine condition. This guide aims to provide valuable insights into the upkeep and troubleshooting of such equipment, allowing users to maximize efficiency and extend its lifespan. By following the recommended procedures, you can tackle common issues and maintain peak performance.

The importance of regular checks and preventative measures cannot be overstated. By understanding how to identify and resolve potential complications, users can effectively manage their devices, ensuring that they continue to operate smoothly. This section will delve into various aspects of the maintenance process, offering practical advice and step-by-step guidance.

As you navigate through the specifics of maintenance, keep in mind that familiarity with your equipment’s components and functions will significantly enhance your ability to address issues as they arise. Empowering yourself with this knowledge will not only lead to more efficient troubleshooting but also enhance your overall experience with your cleaning apparatus.

This section outlines a comprehensive guide focusing on various aspects related to the maintenance and troubleshooting of automatic aquatic maintenance devices. Understanding these systems is crucial for ensuring optimal performance and longevity. Below is a structured plan featuring distinct topics that will provide valuable insights into their functionality and upkeep.

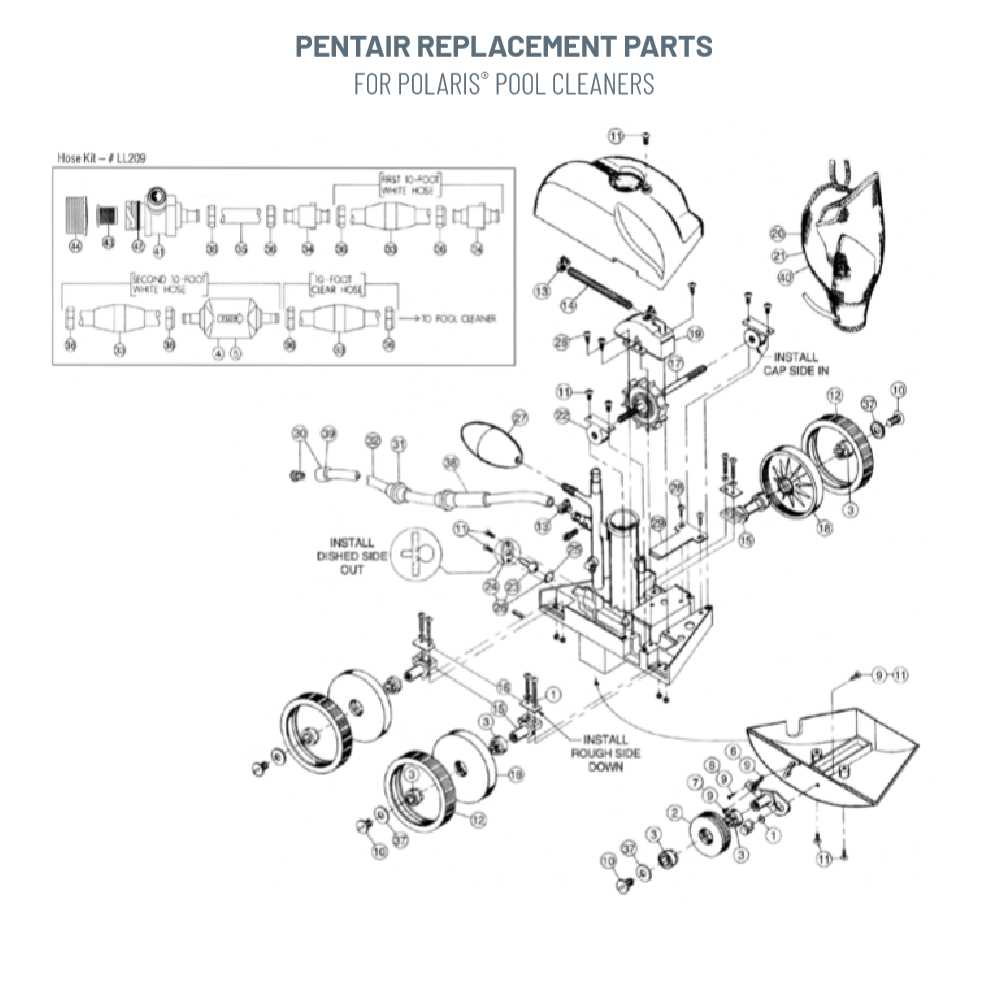

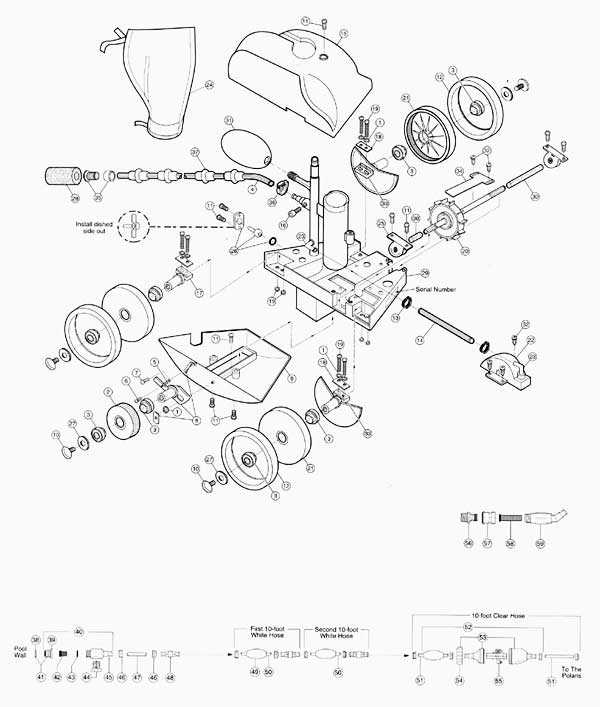

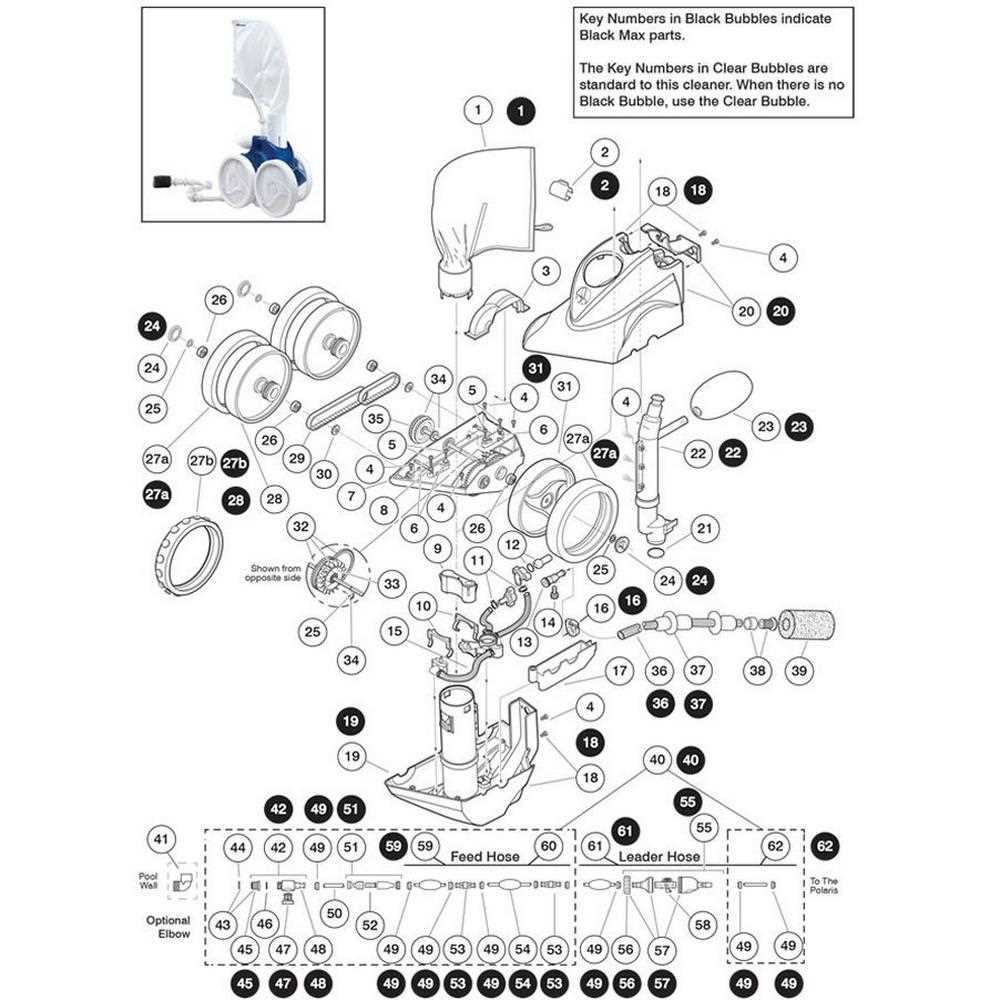

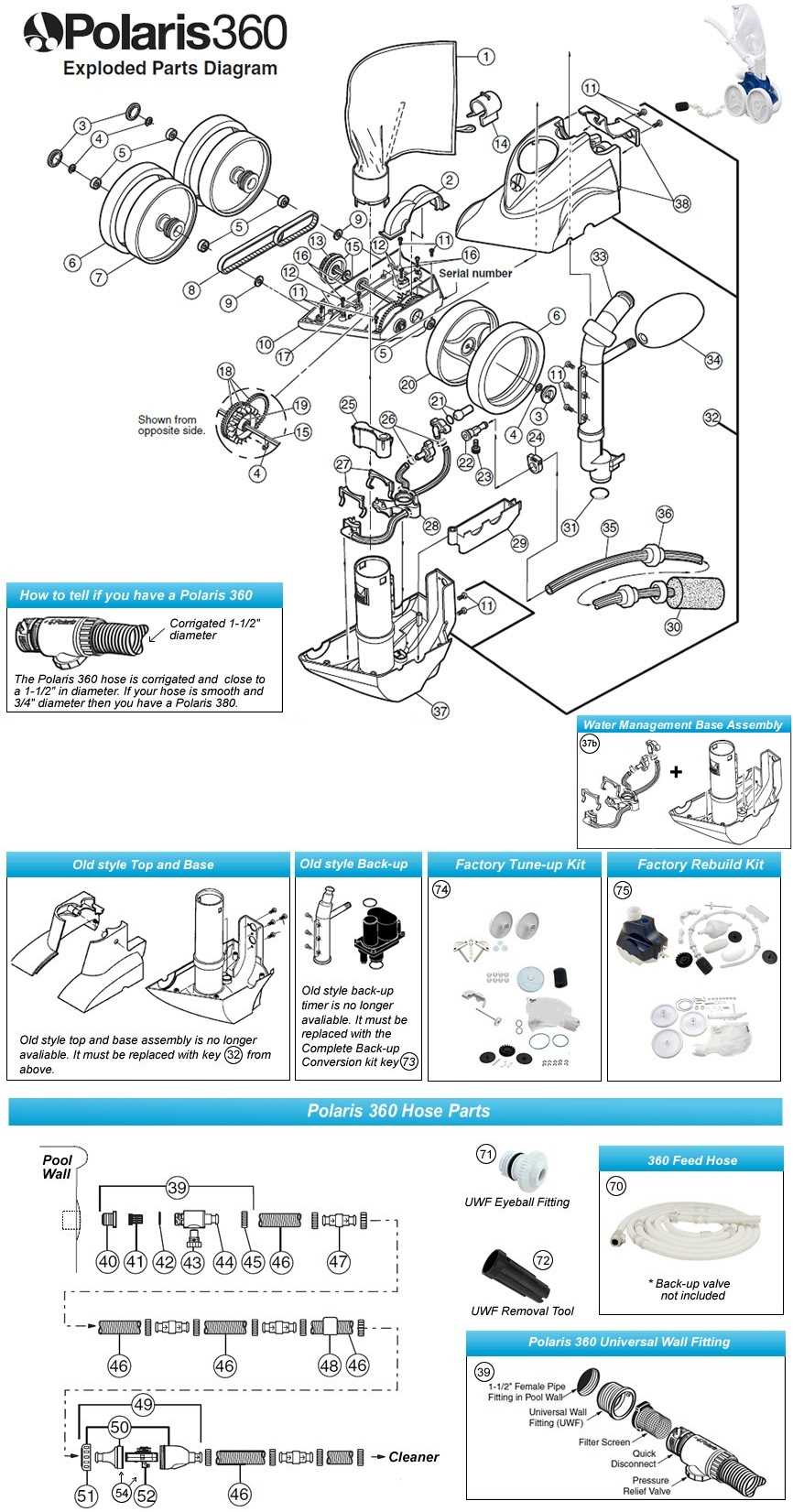

- Basics of Automatic Aquatic Maintenance Devices

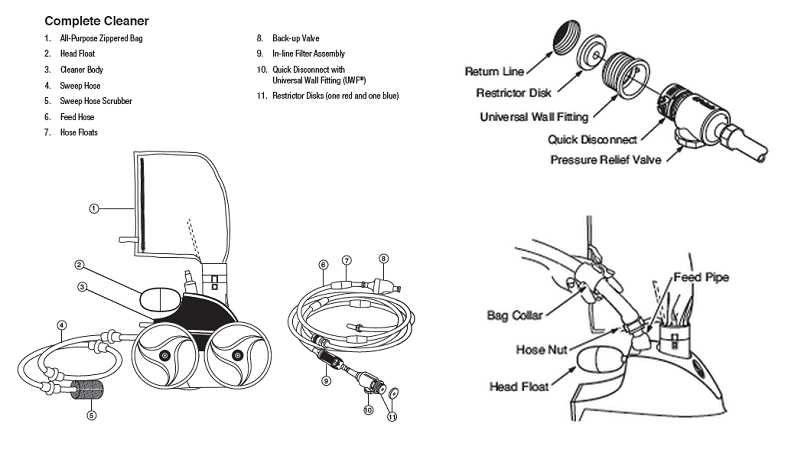

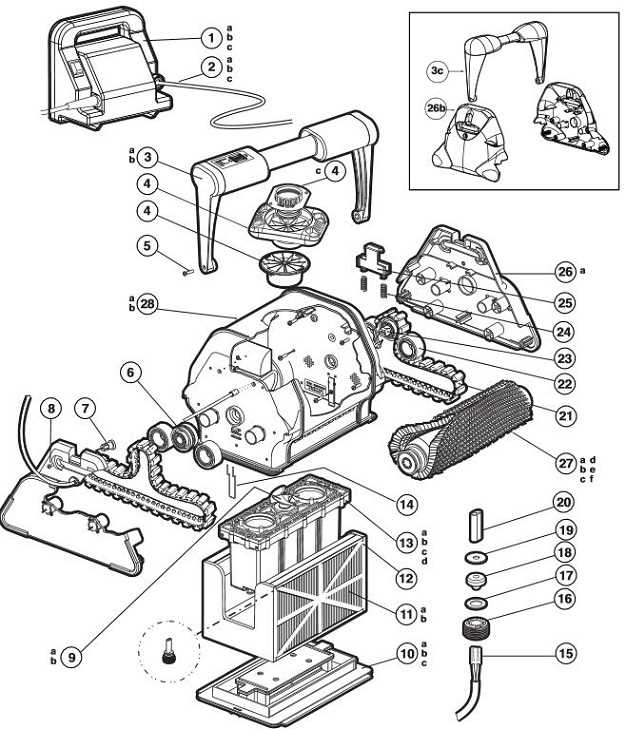

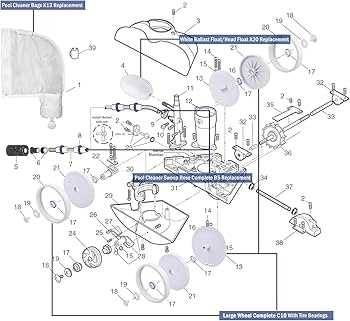

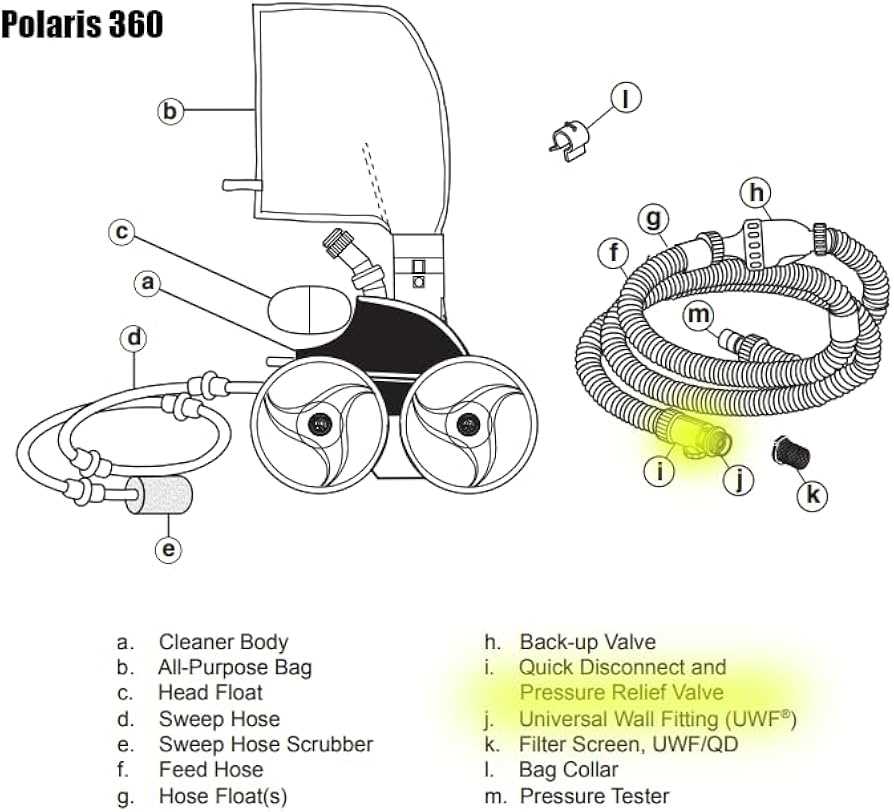

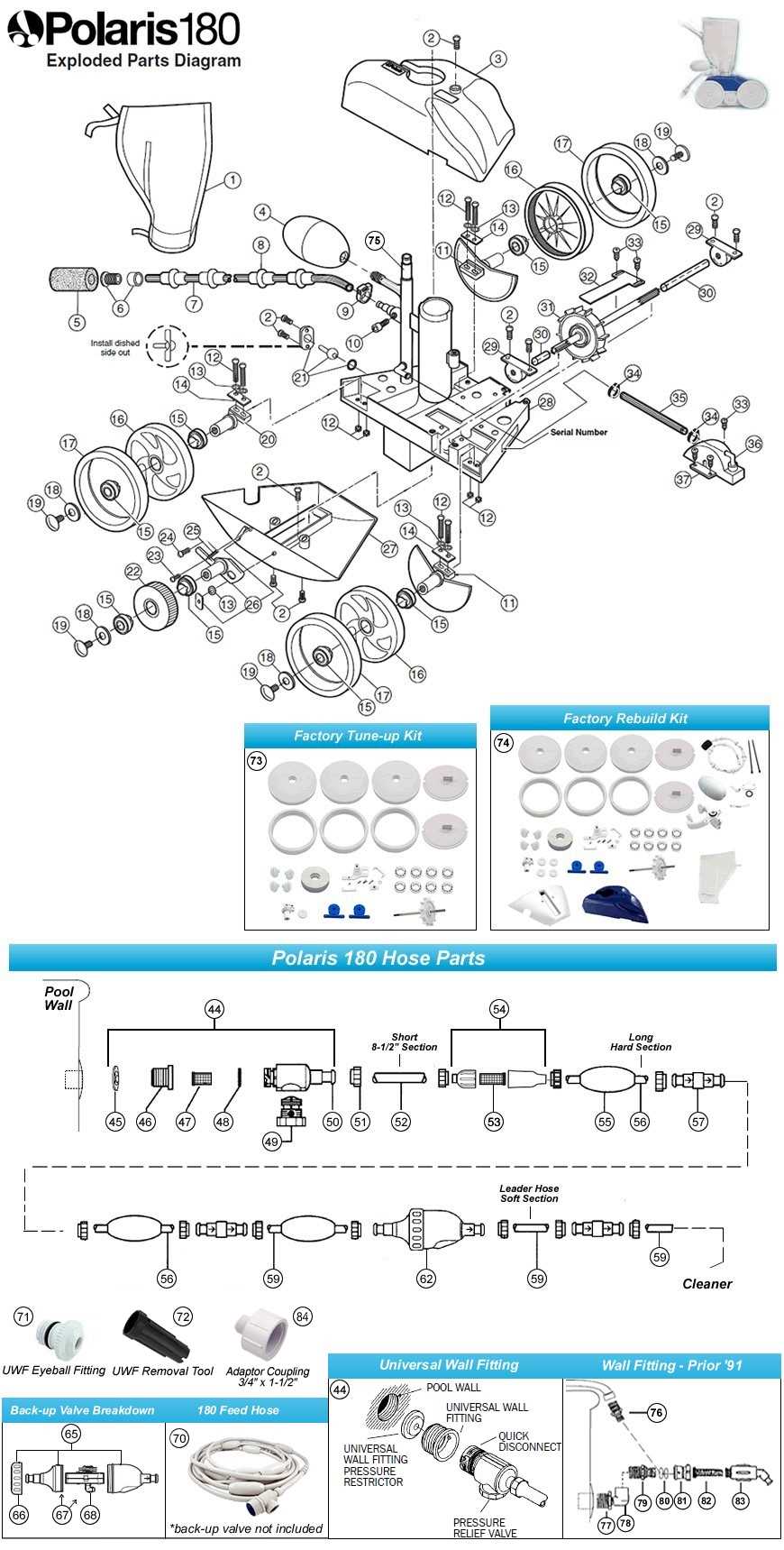

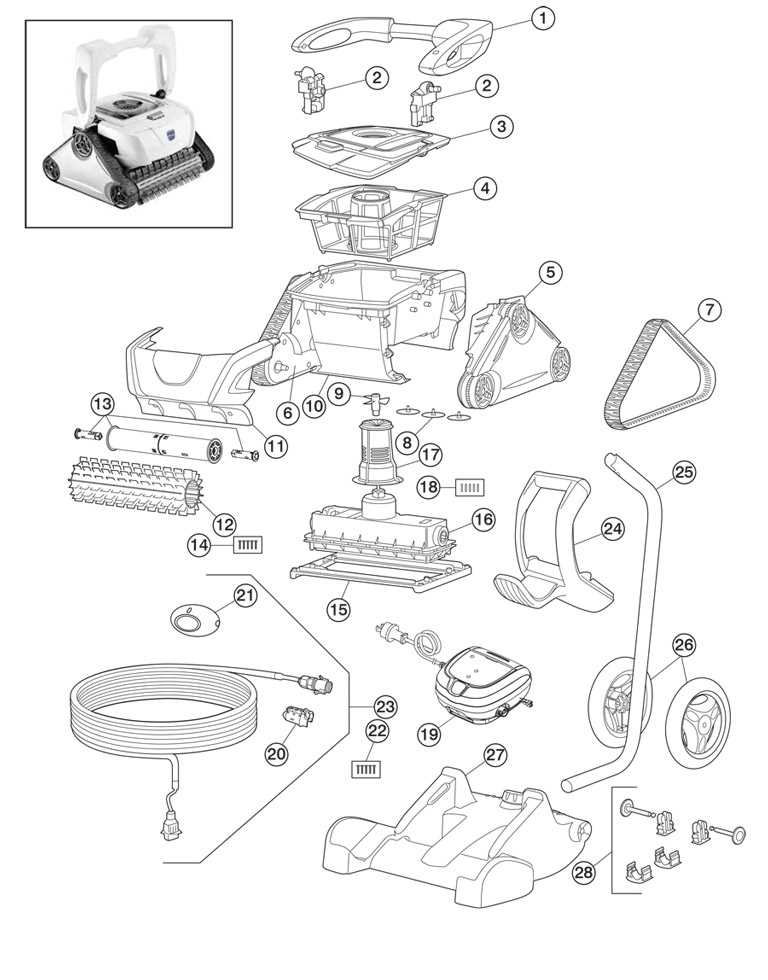

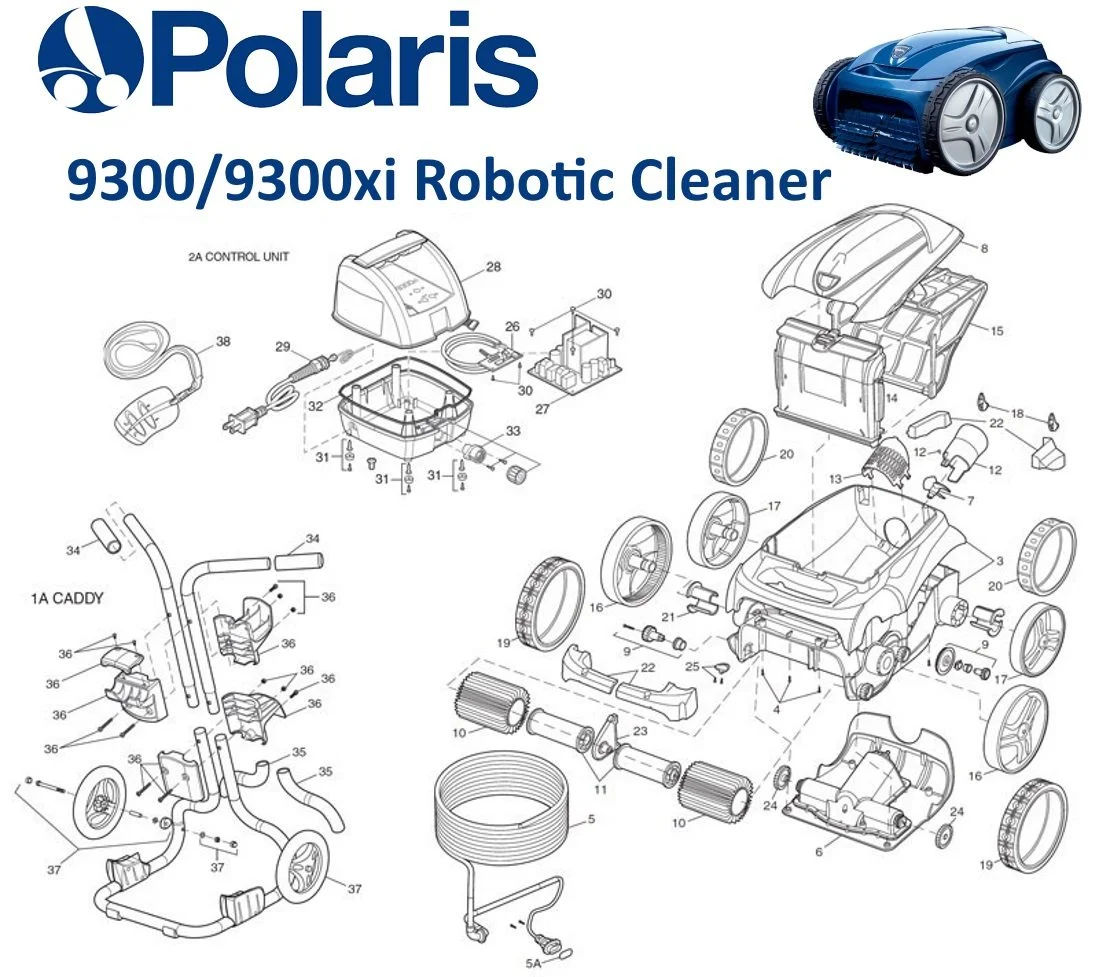

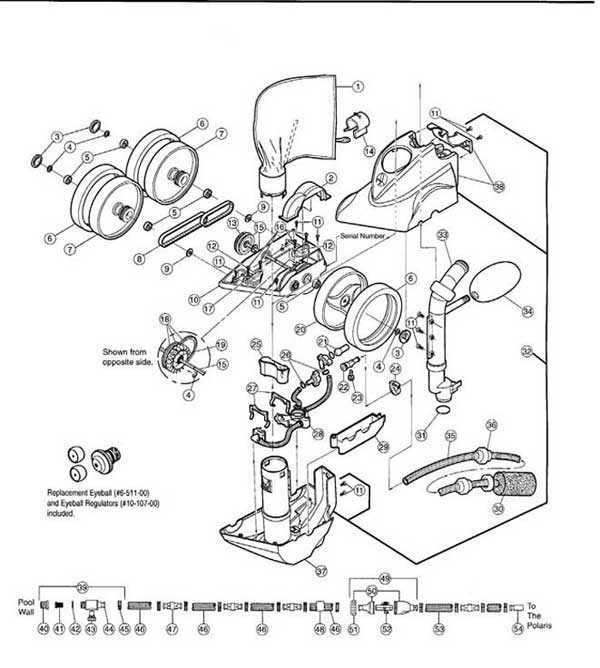

An overview of the essential components and how they contribute to efficient operation.

- Common Issues and Their Symptoms

A detailed look at frequent problems users may encounter and the signs that indicate malfunction.

- Tools Required for Basic Upkeep

A list of necessary tools and equipment that can assist in routine maintenance tasks.

- Step-by-Step Troubleshooting Process

A systematic approach to diagnosing and resolving common issues.

- Cleaning and Maintenance Tips

Best practices for keeping the system in optimal working condition.

- Understanding the Cleaning Cycle

A breakdown of the operational cycle and its significance for performance efficiency.

- Replacing Wearable Components

Guidelines for identifying and changing parts that are prone to wear over time.

- Advanced Repair Techniques

In-depth methods for users comfortable with more complex repairs.

- Seasonal Preparation and Storage

Advice on how to prepare the system for seasonal changes and proper storage techniques.

- Frequently Asked Questions

A collection of common inquiries and expert responses to clarify user concerns.

- When to Seek Professional Assistance

Indicators that may suggest the need for expert intervention to resolve issues.

Common Issues with Pool Cleaners

Regular maintenance of aquatic maintenance devices is crucial to ensure their efficiency and longevity. Various challenges may arise during their operation, affecting their performance. Understanding these common issues can help users troubleshoot and maintain their equipment effectively.

Frequent Problems Encountered

- Inconsistent Movement: Devices may struggle to move or navigate properly, often due to debris blockage or faulty components.

- Poor Cleaning Performance: Inadequate suction or coverage can result from worn brushes or filters that need replacement.

- Unusual Noises: Strange sounds during operation may indicate mechanical issues, such as loose parts or damaged gears.

- Power Failures: Intermittent power loss can stem from electrical issues, including frayed cords or faulty connections.

Troubleshooting Tips

- Inspect and clear any blockages in hoses or intake areas.

- Regularly clean or replace filters and brushes to maintain optimal performance.

- Examine electrical connections and ensure all components are securely attached.

- Listen for unusual sounds and take note of any patterns to identify specific issues.

Tools Needed for Repairs

Having the right equipment is essential for maintaining and fixing various aquatic maintenance devices. Proper tools can significantly ease the troubleshooting process and enhance efficiency during any restoration tasks. Understanding what items are required will help ensure a smoother experience when addressing issues.

Basic instruments include screwdrivers, pliers, and wrenches, which are fundamental for disassembling components. Additionally, a multimeter is useful for diagnosing electrical faults, while lubricants can aid in the smooth operation of moving parts. For more complex tasks, specialized tools may be necessary to access hard-to-reach areas or perform specific functions effectively.

Lastly, keeping safety gear such as gloves and goggles on hand is advisable to protect against potential hazards during maintenance. By equipping yourself with the appropriate tools, you will be better prepared to tackle any challenges that arise during the upkeep of these devices.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your automatic cleaning device. Following this structured method will help ensure that you address the problems effectively, restoring optimal performance.

-

Identify the Issue:

Begin by observing the device during operation to pinpoint the problem. Common issues may include:

- Lack of movement

- Inconsistent cleaning

- Strange noises

-

Gather Necessary Tools:

Before starting, collect the tools you will need for the process:

- Screwdriver set

- Replacement parts

- Cleaning brushes

-

Disassemble the Unit:

Carefully take apart the device according to the user instructions. Keep track of all components to facilitate reassembly.

-

Inspect Components:

Check for wear and tear on essential parts. Look for:

- Cracks or breaks

- Blockages in hoses

- Damaged seals

-

Replace Faulty Parts:

If any components are damaged or worn out, replace them with compatible parts. Ensure that all replacements meet the original specifications.

-

Reassemble the Device:

Carefully put all parts back together. Make sure everything is securely fastened to avoid future issues.

-

Test the Functionality:

After reassembly, run the device to confirm that it operates correctly. Observe for any signs of malfunction.

By following these steps, you can effectively address most common issues and keep your automatic cleaning unit in top condition.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your aquatic maintenance device. Regular care not only enhances performance but also prevents premature wear and tear, allowing for a more efficient and effective cleaning process. By adhering to a few straightforward practices, you can significantly extend the life of your equipment.

First, make it a habit to inspect and clean the unit frequently. Debris accumulation can hinder functionality and lead to mechanical issues. After each use, remove any large particles or obstructions from the filtration system to maintain optimal performance. Additionally, rinsing the device with fresh water helps eliminate residual chemicals and prevent corrosion.

Furthermore, check the moving parts and hoses for signs of damage or wear. Replace any frayed or cracked components promptly to avoid further complications. Regular lubrication of mechanical joints will also ensure smooth operation, reducing the strain on the motor and prolonging its effectiveness.

Lastly, store the unit in a dry, shaded area when not in use. Protecting it from harsh weather conditions and direct sunlight will minimize deterioration and help maintain its structural integrity. By implementing these simple maintenance practices, you can enjoy a more reliable and efficient cleaning solution for years to come.

Troubleshooting Performance Problems

Addressing issues related to efficiency is essential for maintaining optimal functionality in your aquatic maintenance device. Various factors can contribute to subpar performance, and identifying these elements will enhance the overall effectiveness of the unit.

Common Issues to Consider

- Blockages in the filtration system

- Improper alignment or positioning

- Worn or damaged components

- Insufficient water flow or pressure

Steps to Diagnose Issues

- Check for obstructions in the intake and exhaust areas.

- Ensure the device is correctly oriented within the water.

- Inspect all moving parts for wear and tear.

- Measure the water pressure to confirm it meets operational standards.

By systematically evaluating these aspects, you can effectively pinpoint and resolve performance-related challenges, ensuring that your device operates at its best.

Replacing Worn Out Parts

Maintaining the efficiency of your device involves periodically replacing components that have deteriorated over time. Regular inspection and timely replacements can prevent further damage and ensure optimal performance. Understanding which parts require attention is crucial for effective maintenance.

Identifying Damaged Components

To keep your equipment functioning smoothly, it’s essential to recognize signs of wear and tear. Look for cracks, tears, or any noticeable deterioration in components. Regular checks will help you spot potential issues before they lead to significant problems.

Replacement Process

Once you identify worn parts, proceed with caution during the replacement process. First, ensure the device is powered off and disconnected from any source. Carefully remove the damaged component and replace it with a new one, ensuring a secure fit. Following the manufacturer’s guidelines will aid in achieving the best results.

Cleaning and Care Instructions

Regular maintenance and proper care significantly extend the life of any device used in water environments. By following a few essential steps, you ensure its efficiency and reliability, helping it perform optimally over time. This guide provides straightforward instructions on how to keep every component in excellent condition.

Routine Rinsing

After each use, rinse all parts thoroughly with fresh water to remove any accumulated debris and impurities. This helps prevent build-up that can hinder performance. Be sure to inspect smaller components for any signs of wear or trapped material, which should be cleaned promptly.

Monthly Deep Clean

In addition to routine rinsing, a more thorough cleaning should be conducted monthly. Disassemble the main sections carefully and clean them individually, paying attention to the filters and moving parts that may accumulate dirt. Use a soft brush to scrub delicate parts, avoiding any harsh chemicals that could degrade the materials.

| Part | Cleaning Frequency | Instructions |

|---|---|---|

| Outer Casing | After Each Use | Rinse with water, dry with a soft cloth. |

| Filters |