When it comes to maintaining a high-performance outboard engine, having access to the right information is crucial. This section focuses on essential insights and techniques for ensuring optimal operation and longevity of your 60 HP marine engine. Whether you are an experienced technician or a novice enthusiast, understanding the intricacies of your motor can significantly enhance its performance.

Engaging in routine upkeep and troubleshooting can prevent minor issues from escalating into major repairs. By familiarizing yourself with common practices and guidelines, you can foster a deeper connection with your vessel and improve your boating experience. This resource aims to empower users with the knowledge necessary to tackle various challenges effectively.

Equipped with the right tools and insights, you will be well-prepared to address maintenance tasks confidently. This guide will provide detailed instructions on essential functions, from basic checks to more advanced procedures, ensuring that your engine remains reliable throughout its lifespan.

This section aims to provide a comprehensive understanding of a popular outboard engine, highlighting its features, performance, and specifications. This powerful marine engine is designed for efficiency and reliability, making it a preferred choice among boat enthusiasts.

Key characteristics include:

- Lightweight design for enhanced maneuverability.

- Fuel efficiency for extended journeys on the water.

- Robust construction to withstand various marine conditions.

- Easy maintenance access to simplify servicing.

Additionally, the following aspects contribute to its reputation:

- Performance: Offers impressive power output, suitable for a variety of watercraft.

- Technology: Equipped with advanced systems for optimal operation and control.

- Durability: Built with high-quality materials to endure harsh environments.

Understanding these features is crucial for users aiming to maximize the potential of their outboard engine.

Key Features and Specifications

This section outlines the notable attributes and technical details of the 60 hp engine, highlighting its design and operational capabilities. Understanding these features is essential for users to maximize performance and ensure optimal functionality.

- Engine Type: Four-cylinder configuration for enhanced power and efficiency.

- Fuel System: Electronic fuel injection for precise fuel delivery and improved fuel economy.

- Cooling System: Water-cooled design ensuring effective temperature regulation during operation.

- Ignition System: Advanced ignition technology for reliable starting and smooth performance.

The specifications provide a clear understanding of the engine’s capabilities:

- Power Output: 60 horsepower, delivering robust performance for various applications.

- Weight: Lightweight design for easy installation and better handling.

- Dimensions: Compact dimensions allowing for versatile mounting options.

- Fuel Capacity: Generous tank size to support extended operational periods without frequent refueling.

These features and specifications contribute to the overall efficiency and reliability of the engine, making it suitable for a range of marine activities.

Common Issues and Troubleshooting

This section focuses on prevalent challenges encountered with marine propulsion systems, emphasizing effective strategies for identifying and resolving them. Understanding these common problems can significantly enhance performance and longevity.

-

Starting Difficulties:

Common causes include:

- Insufficient fuel supply

- Weak battery or poor connections

- Faulty ignition system

-

Overheating:

This issue may arise from:

- Clogged cooling passages

- Defective water pump

- Low coolant levels

-

Unusual Noises:

Strange sounds can indicate:

- Loose or damaged components

- Excessive vibration

- Worn bearings

-

Fuel Leaks:

These may occur due to:

- Worn fuel lines

- Loose connections

- Faulty seals or gaskets

Proper maintenance and timely inspections can help mitigate these issues. Regular checks on the fuel system, cooling components, and electrical connections are essential to ensuring optimal operation.

Essential Tools for Repairs

When it comes to maintaining and fixing marine engines, having the right equipment is crucial. A well-equipped toolkit not only streamlines the process but also ensures that each task is completed efficiently and effectively. From basic hand tools to specialized instruments, understanding what to include in your collection can significantly impact the overall performance and longevity of your engine.

1. Wrenches: A variety of wrenches is necessary for loosening and tightening bolts and nuts. Adjustable and socket wrenches are particularly useful for working in tight spaces, while a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications.

2. Screwdrivers: A set of flathead and Phillips screwdrivers in various sizes is essential for removing and securing screws throughout the engine assembly. Consider magnetic screwdrivers for added convenience.

3. Pliers: These tools are indispensable for gripping, twisting, and cutting wires or components. Needle-nose pliers are especially valuable for reaching confined areas.

4. Multimeter: This device is essential for diagnosing electrical issues. A multimeter allows you to measure voltage, current, and resistance, helping to identify problems within the electrical system.

5. Oil Filter Wrench: This specialized tool makes changing the oil filter more manageable, preventing damage to the filter and ensuring a secure fit during reinstallation.

6. Cleaning Supplies: Keeping your engine clean is vital for its performance. Use brushes, rags, and appropriate solvents to remove grime and debris from engine surfaces.

7. Safety Equipment: Protecting yourself during maintenance activities is paramount. Always wear safety glasses and gloves to guard against injuries from sharp objects and chemicals.

Having these essential tools on hand will not only enhance your maintenance experience but also contribute to the reliability and performance of your marine engine. A well-prepared approach can lead to successful troubleshooting and long-lasting functionality.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your outboard engine. Regular upkeep not only enhances efficiency but also helps in early identification of potential issues. Following a structured maintenance schedule is crucial for any boating enthusiast.

Essential Maintenance Tasks

- Check the oil level and condition regularly.

- Inspect the fuel system for leaks or blockages.

- Clean or replace the air filter as needed.

- Examine the propeller for damage and ensure it is securely attached.

- Flush the cooling system after each use, especially in saltwater.

- Inspect the electrical connections and battery condition.

Seasonal Maintenance Checklist

- Change the engine oil and filter.

- Replace the spark plugs to ensure efficient ignition.

- Lubricate all moving parts as per the manufacturer’s recommendations.

- Test the fuel system and replace any old fuel.

- Inspect the hull and transom for signs of wear or damage.

- Check safety equipment and emergency supplies before heading out.

Replacing Engine Parts Effectively

Maintaining optimal performance and reliability in marine engines often requires the timely replacement of specific components. This process is crucial to ensure longevity and efficient operation. Understanding the steps and best practices involved can greatly enhance the success of these undertakings.

Before initiating the replacement procedure, it is essential to gather all necessary tools and components. This preparation minimizes downtime and facilitates a smoother workflow. Carefully consult the specifications of the engine to ensure that the parts being installed are compatible and meet the required standards.

When removing old components, take note of their arrangement and connections. Documenting this can provide valuable guidance during reassembly. Utilize appropriate methods to detach each part, ensuring that no damage occurs to surrounding elements or the engine itself.

Once the old components are removed, clean the area thoroughly to prevent contamination. This step is vital for ensuring a proper fit and function of the new parts. Apply lubrication as necessary to enhance performance and reduce wear during operation.

As you install the new components, follow the manufacturer’s guidelines closely. Proper torque specifications and installation techniques should be adhered to, as this ensures that parts function together seamlessly. Regularly inspecting the work done will help identify any potential issues early on.

Finally, once the installation is complete, perform a comprehensive check of the entire system. Testing the engine under various conditions will confirm that all replacements were successful and that everything operates as intended. Regular maintenance checks will also help sustain the performance achieved through these updates.

Fuel System Care and Optimization

Maintaining and enhancing the performance of the fuel delivery system is crucial for ensuring efficiency and longevity. Proper care not only prevents potential issues but also maximizes power output and reduces fuel consumption. This section delves into essential practices for keeping the fuel system in optimal condition.

Regular Inspections: Conduct frequent examinations of the fuel components, including lines, filters, and injectors. Look for any signs of wear, leaks, or clogs that could hinder performance.

Filter Replacement: Replacing fuel filters at recommended intervals is vital. A clean filter ensures that contaminants do not enter the engine, which can lead to significant damage over time.

Fuel Quality: Always use high-quality fuel that meets the manufacturer’s specifications. Poor-quality fuel can introduce impurities that can cause blockages and affect combustion efficiency.

Stabilizers and Additives: Utilize fuel stabilizers and additives to enhance the quality of the fuel, especially if the engine is not in regular use. These products can help prevent oxidation and keep the fuel system clean.

Periodic Cleaning: Regularly clean the fuel injectors and other components to remove any built-up deposits. This can help maintain efficient fuel flow and optimal engine performance.

Storage Practices: When storing the vessel for extended periods, ensure that the fuel system is properly prepared. Consider draining the fuel system or adding stabilizers to prevent degradation and clogging.

By implementing these strategies, owners can ensure their fuel delivery system operates efficiently, contributing to overall engine health and performance.

Electrical Components and Diagnostics

This section focuses on the essential electrical elements within marine propulsion systems, emphasizing the importance of proper functioning and effective troubleshooting techniques. Understanding these components can significantly enhance performance and reliability, ensuring optimal operation on the water.

Key Electrical Components

Several critical components work together to create a reliable electrical system. Each part plays a vital role in maintaining functionality and safety. Here are the main elements:

| Component | Function |

|---|---|

| Battery | Supplies electrical energy for starting and powering components. |

| Alternator | Generates electricity to recharge the battery and power electrical systems. |

| Wiring Harness | Connects all electrical components and ensures proper signal transmission. |

| Fuse | Protects the electrical system from overloads and shorts. |

| Ignition System | Controls the spark timing and delivers the necessary voltage for combustion. |

Diagnostic Procedures

To ensure all electrical components function correctly, a systematic approach to diagnostics is crucial. Regular inspections and testing can help identify issues before they escalate. Here are some basic procedures:

- Visual inspection of wiring and connections for signs of wear or damage.

- Using a multimeter to check voltage levels and continuity.

- Testing battery condition and charge levels.

- Monitoring performance of the alternator and ignition components.

Cooling System Functionality

The efficiency and longevity of any marine engine significantly depend on the effectiveness of its cooling mechanism. This system plays a crucial role in regulating the engine temperature, ensuring optimal performance during operation. By maintaining a stable temperature, it prevents overheating and potential damage, contributing to the overall health of the motor.

In essence, the cooling apparatus operates by circulating a fluid, typically water, around the engine components. This fluid absorbs heat generated during the combustion process and dissipates it into the surrounding environment. A well-designed system will ensure a continuous flow of this cooling medium, allowing for consistent temperature management even under demanding conditions.

Moreover, various components such as pumps, thermostats, and heat exchangers work in harmony to enhance the system’s efficiency. The pump initiates the circulation of the coolant, while the thermostat regulates the temperature by adjusting the flow based on the engine’s needs. Additionally, heat exchangers play a vital role in transferring heat away from critical engine parts, ensuring that the entire unit operates within safe temperature ranges.

Regular maintenance of the cooling system is essential for preventing blockages and ensuring proper fluid levels. Neglecting this aspect can lead to inefficiencies and, ultimately, significant engine failures. Therefore, understanding the functionality of the cooling apparatus is fundamental for any operator aiming to maximize the performance and durability of their vessel’s engine.

Understanding the Gearbox Mechanics

The gearbox is a crucial component in any marine propulsion system, responsible for translating engine power into rotational force that drives the propeller. A thorough understanding of its mechanics is essential for effective operation and maintenance. This section explores the fundamental aspects of gearbox functionality and the key elements involved in its performance.

Key Components of the Gearbox

- Gears: The heart of the gearbox, these components interlock to transmit power efficiently.

- Shafts: They transfer the rotational force from the engine to the gears and ultimately to the propeller.

- Bearings: Essential for reducing friction and supporting the rotating parts.

- Seals: Prevent leaks and keep contaminants out of the gearbox.

Operating Principles

The gearbox operates by engaging different gear ratios, allowing for optimal performance at various speeds and loads. By adjusting the connection between the engine and the propeller, the system can enhance efficiency and power delivery. Understanding these principles aids in diagnosing issues and improving the overall functionality of the vessel.

- Engagement of gears alters the output speed and torque.

- Proper lubrication is vital for smooth operation and longevity.

- Regular inspection of components helps in early identification of potential problems.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Following specific guidelines can help create a secure environment for both the technician and the equipment. Prioritizing safety measures protects individuals and ensures the longevity and efficiency of the machinery.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the work area is well-lit and free of clutter to reduce the risk of slips, trips, and falls.

- Disconnect the power source before beginning any disassembly or maintenance tasks.

- Utilize tools and equipment that are in good condition and suitable for the task at hand.

- Keep a first-aid kit nearby and be aware of emergency procedures in case of accidents.

Adhering to these safety practices not only minimizes potential hazards but also fosters a culture of responsibility and awareness among technicians. Proper precautions contribute significantly to the overall efficiency of maintenance efforts.

Resources for Further Assistance

When facing challenges with your outboard engine, having access to reliable resources can make a significant difference. Whether you’re a novice or an experienced technician, various materials and support systems are available to enhance your understanding and facilitate effective troubleshooting.

Online Forums and Communities

Engaging with online communities dedicated to marine engines can provide valuable insights and firsthand experiences from fellow enthusiasts and professionals. Websites such as forums and social media groups allow you to pose questions, share knowledge, and learn from others who have encountered similar issues. These platforms often have extensive archives of discussions that can serve as a valuable reference.

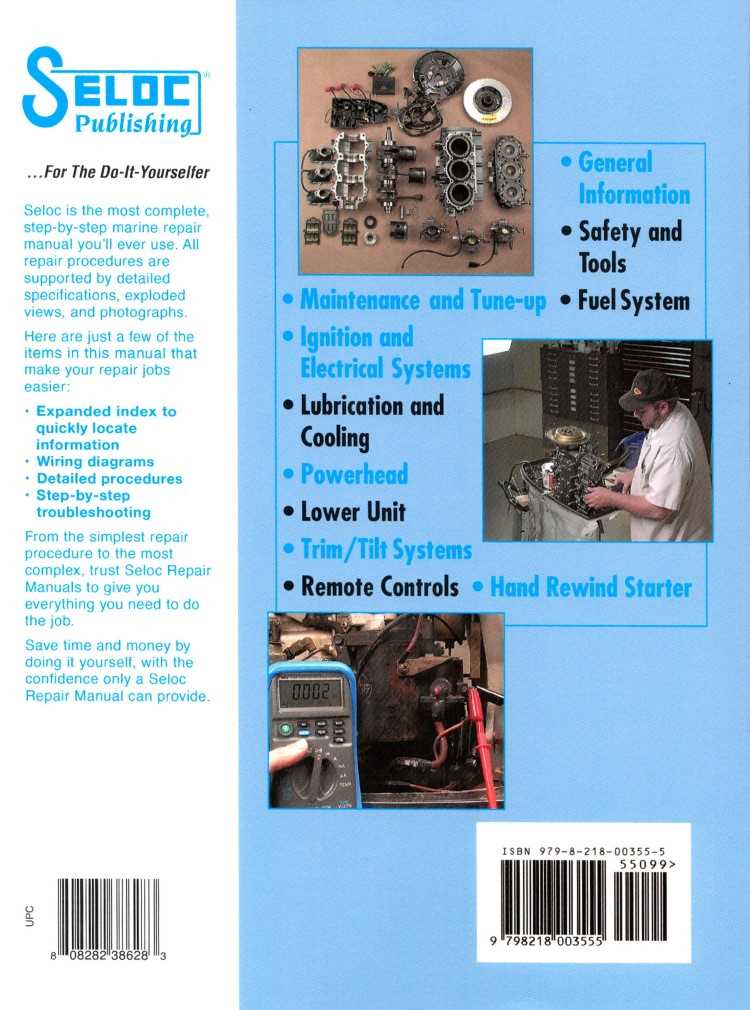

Technical Publications and Guides

Comprehensive literature, including technical books and guides, offers in-depth information on various aspects of engine operation and maintenance. Many publishers provide manuals tailored to specific models, covering everything from basic functionality to advanced diagnostics. Additionally, manufacturers often publish bulletins and updates that can keep you informed about best practices and new developments in the field.