The following section provides essential insights into the upkeep of a specific type of mechanical component. Understanding its intricacies is crucial for optimal performance and longevity. By following recommended practices, one can enhance the functionality and reliability of this vital system.

With a focus on practical advice, this guide aims to equip readers with the necessary knowledge to navigate common challenges. Detailed instructions and troubleshooting tips will empower individuals to address issues effectively, ensuring smooth operation and minimizing downtime.

Whether you are a novice or an experienced enthusiast, this comprehensive overview will serve as a valuable resource. Emphasizing simplicity and clarity, it offers step-by-step guidance to foster confidence in handling maintenance tasks.

Having the right equipment is crucial for effective maintenance and fixing tasks. A well-equipped workspace can significantly enhance the efficiency and quality of any technical endeavors. This section outlines fundamental implements necessary for carrying out various procedures, ensuring optimal performance and longevity of components.

Basic Equipment

The foundational tools encompass a variety of instruments that every technician should possess. These tools facilitate initial assessments and assist in executing routine tasks with precision.

| Tool | Purpose |

|---|---|

| Socket Set | Essential for loosening and tightening fasteners. |

| Wrench | Useful for gripping and turning nuts and bolts. |

| Screwdriver Set | Facilitates the removal and installation of screws. |

Specialized Instruments

Beyond basic implements, certain specialized tools are vital for more intricate tasks. These instruments allow for detailed work that requires a higher level of precision.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Multimeter | Measures voltage, current, and resistance for electrical diagnostics. |

| Diagnostic Scanner | Analyzes systems for faults and provides error codes. |

Step-by-Step Disassembly Process

This section outlines a systematic approach for taking apart the unit effectively. Understanding the order and techniques involved is crucial for ensuring all components are handled with care, minimizing the risk of damage during the process.

Preparation and Tools

Before beginning, gather all necessary tools and create a clean workspace. Essential instruments may include wrenches, screwdrivers, and pliers. Proper preparation facilitates a smooth disassembly process and helps keep track of small parts.

Disassembly Steps

Start by removing external covers and components, ensuring to note the placement of each part. Next, proceed to detach internal assemblies, following a logical sequence. Labeling and organizing each component can greatly assist in the reassembly phase. Always handle parts gently, avoiding excessive force to prevent damage.

Inspection Techniques for Components

Proper examination of various parts is essential for ensuring optimal performance and longevity. This section discusses effective methods for evaluating the integrity and functionality of critical elements, highlighting the importance of systematic approaches in the assessment process.

Visual Assessment

Conducting a thorough visual inspection is the first step in identifying potential issues. Look for signs of wear, corrosion, or damage. Utilizing good lighting can significantly enhance the visibility of any abnormalities. Make sure to document any findings for future reference.

Measurement and Testing

Utilizing specialized tools for measurement is crucial in evaluating component specifications. Techniques such as pressure testing and electrical resistance measurement can provide valuable insights into the performance levels of various parts. Regular testing ensures that any deviations from standard parameters are addressed promptly.

Replacing Worn-Out Parts

Ensuring optimal performance requires timely attention to components that show signs of wear. This section discusses the importance of identifying and substituting deteriorated elements, enhancing overall functionality and longevity.

Identifying Deteriorated Components

Recognizing which parts need replacement is crucial. Common indicators of wear include:

- Unusual noises during operation

- Decreased efficiency or performance

- Visible signs of damage or deterioration

- Fluid leaks in the vicinity of affected areas

Steps for Replacement

Follow these guidelines to successfully replace worn-out components:

- Gather necessary tools and replacement parts.

- Ensure the workspace is clean and organized.

- Carefully remove the damaged parts, taking note of their orientation.

- Install the new components, ensuring proper alignment and secure fittings.

- Test the system to confirm functionality and check for leaks.

Reassembly Best Practices

When undertaking the process of reassembling components, it is essential to adhere to certain guidelines that ensure optimal performance and longevity. Proper techniques can significantly influence the functionality of the assembly and help prevent potential issues down the line.

Preparation and Organization

Before starting, make sure to organize all parts and tools in a systematic manner. This preparation allows for efficient workflow and reduces the likelihood of losing critical elements. Utilizing labeled containers or magnetic trays can facilitate easy access to small components.

Sequential Assembly

Following a logical sequence during reassembly is crucial. Begin with the larger components and progressively move to the smaller ones. Always consult reliable references for torque specifications and assembly instructions. Applying the correct force prevents damage and ensures a tight fit.

Regular Inspections should be performed throughout the process. This approach allows for the identification of any inconsistencies or misalignments early on, ultimately saving time and resources.

By embracing these best practices, you can achieve a successful reassembly that enhances the reliability and efficiency of the overall system.

Tuning the Engine for Performance

Enhancing the performance of your power unit involves a range of modifications aimed at increasing efficiency and responsiveness. By focusing on various components and systems, you can achieve a noticeable improvement in overall output and driving experience.

One crucial aspect is adjusting the air intake and exhaust systems. Upgrading these elements can facilitate better airflow, allowing for a more efficient combustion process. Additionally, fine-tuning the fuel delivery system ensures that the right mixture reaches the combustion chambers, further optimizing performance.

Moreover, recalibrating the ignition timing can significantly impact how effectively the unit operates under different conditions. A precise adjustment helps in maximizing power while maintaining fuel efficiency. Implementing these modifications requires careful planning and consideration of the specific characteristics of your setup.

Ultimately, engaging in performance tuning is not just about enhancing power; it’s about creating a balanced and responsive setup that caters to your driving preferences. With the right approach, you can unlock the full potential of your power unit and enjoy an elevated driving experience.

Maintenance Tips for Longevity

To ensure the extended life of your vehicle’s power source, regular upkeep and attention to detail are crucial. By following a few essential practices, you can significantly enhance performance and durability over time.

Regular Fluid Checks: Keeping an eye on the various fluids is vital. Regularly inspect oil, coolant, and transmission fluid levels. This helps maintain optimal functioning and prevents potential damage.

Scheduled Servicing: Adhering to a structured maintenance schedule is important. Routine inspections by a qualified technician can identify issues early, allowing for timely interventions before they escalate.

Quality Components: When replacing parts, always opt for high-quality components. Using inferior materials can compromise the overall performance and longevity, leading to frequent repairs.

Driving Habits: Adopt smooth driving techniques. Rapid acceleration and abrupt braking can strain the internal systems, causing premature wear. Gentle handling promotes better efficiency and reduces unnecessary stress.

Temperature Control: Monitor operating temperatures carefully. Overheating can cause severe damage. Ensure that the cooling system is functioning effectively, and address any signs of overheating promptly.

Implementing these strategies will foster reliability and prolong the lifespan of your vehicle’s vital systems, ultimately saving time and resources in the long run.

Common Modifications and Upgrades

Enhancing performance and efficiency often involves various tweaks and improvements. Enthusiasts frequently explore options that boost power output, improve handling, or increase overall reliability. Below are some popular modifications that can transform a standard configuration into a more dynamic setup.

Performance Enhancements

- Upgrading the exhaust system can lead to better airflow and increased horsepower.

- Installing a high-performance air intake allows for improved combustion efficiency.

- Tuning the fuel management system optimizes fuel delivery for enhanced responsiveness.

Suspension and Handling Improvements

- Replacing stock shock absorbers with adjustable options improves ride quality and handling.

- Upgrading sway bars helps reduce body roll during cornering.

- Installing performance tires enhances grip and stability on various surfaces.

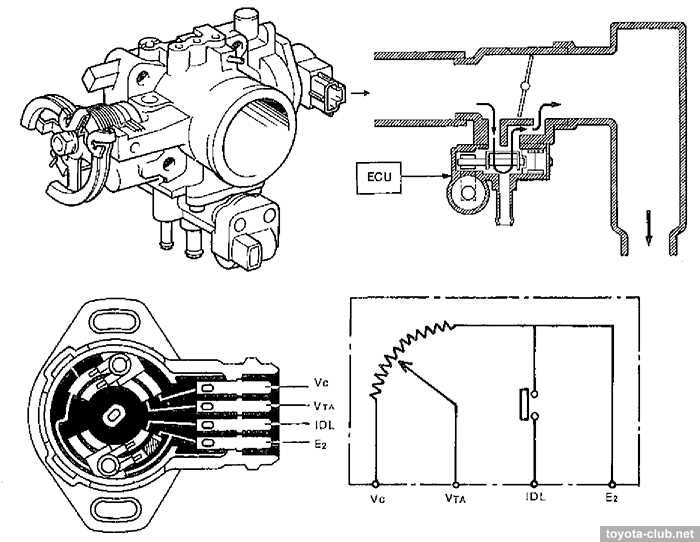

Diagnosing Electrical Problems

Identifying issues related to the electrical system can often be a complex process. Understanding the various components involved is essential for effective troubleshooting. This section aims to guide you through the methods and techniques needed to pinpoint electrical malfunctions.

Common Symptoms to Look For

Pay attention to unusual signs that may indicate an electrical fault. Common symptoms include dimming lights, unexpected shut-offs, or erratic behavior of various systems. Observing these indicators can help narrow down the potential causes.

Testing and Troubleshooting Techniques

Utilizing diagnostic tools is crucial for evaluating electrical components. A multimeter can be invaluable for measuring voltage, current, and resistance. By systematically testing individual parts, you can isolate the problem area and take appropriate action to restore functionality.

Resources for Further Assistance

For those seeking additional guidance and support in their automotive endeavors, a variety of valuable resources are available. These tools can enhance understanding and facilitate effective troubleshooting, ensuring that any challenges can be addressed efficiently.

Online Forums and Communities

Participating in online platforms dedicated to automotive discussions can provide insights from experienced individuals. These communities often share tips, troubleshooting advice, and personal experiences, making them an excellent source for collective knowledge.

Technical Documentation and Guides

Accessing comprehensive literature that covers various aspects of vehicle maintenance can be incredibly beneficial. These documents typically include detailed information on components, systems, and procedures, serving as essential references for those looking to deepen their knowledge and skills.