Understanding the intricacies of automobile upkeep is essential for ensuring longevity and optimal performance. This section delves into the various aspects of vehicle care, focusing on troubleshooting common issues and implementing effective solutions. A well-maintained vehicle not only enhances safety but also improves driving efficiency.

Whether you are an experienced enthusiast or a novice, having access to detailed information can significantly simplify the process of maintaining your vehicle. This resource aims to provide you with valuable insights and step-by-step guidance on essential practices, from basic inspections to more complex procedures.

By familiarizing yourself with the inner workings of your vehicle, you empower yourself to tackle challenges confidently. Engaging in regular maintenance helps prevent potential breakdowns and costly repairs, making it a worthwhile investment of time and effort. This guide will equip you with the knowledge needed to ensure your automobile remains in top condition.

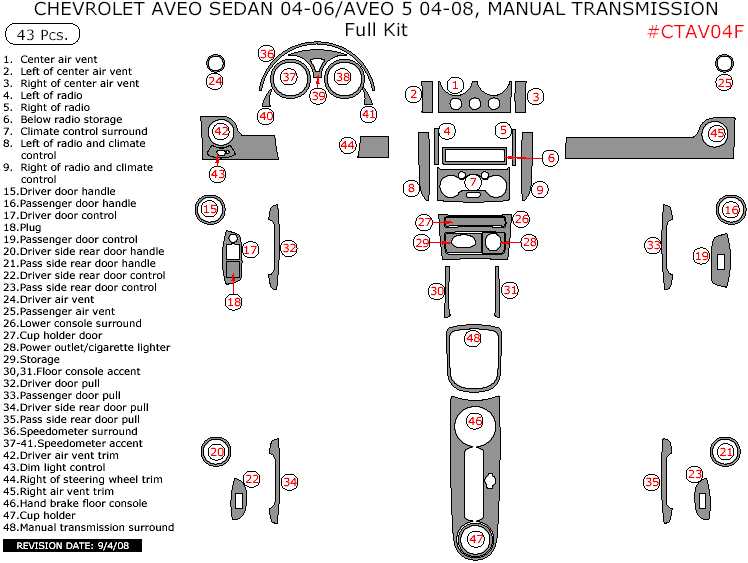

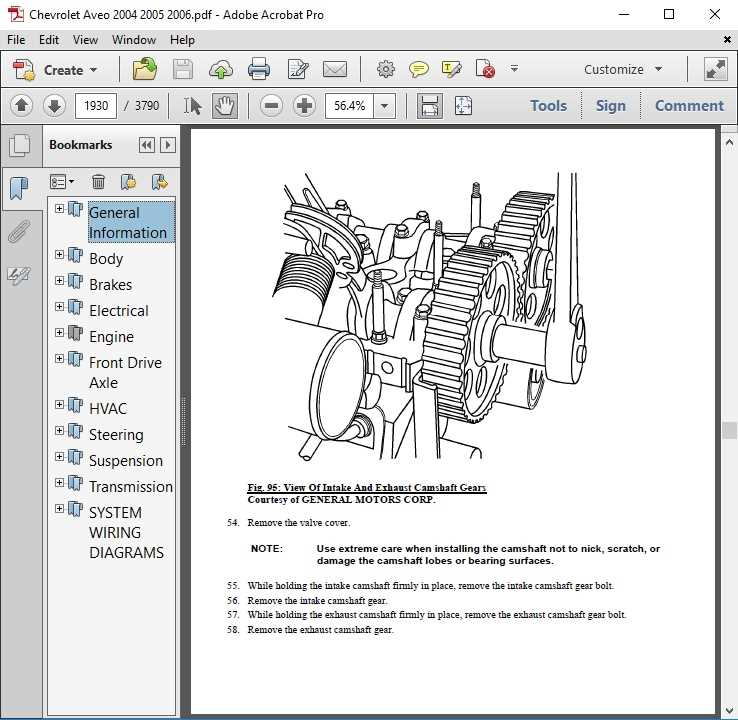

2006 Chevrolet Aveo Repair Manual Overview

This section provides a comprehensive insight into the guidelines for maintaining and servicing a compact vehicle model from the mid-2000s. It emphasizes the importance of regular upkeep to ensure optimal performance and longevity of the automobile.

The document serves as an essential resource for both novice and experienced mechanics, detailing various procedures, specifications, and troubleshooting techniques. Users will find detailed information on engine maintenance, transmission adjustments, and electrical system diagnostics.

Additionally, this resource highlights safety precautions and best practices, helping individuals navigate potential challenges during the maintenance process. By adhering to these recommendations, vehicle owners can enhance their driving experience and ensure reliability on the road.

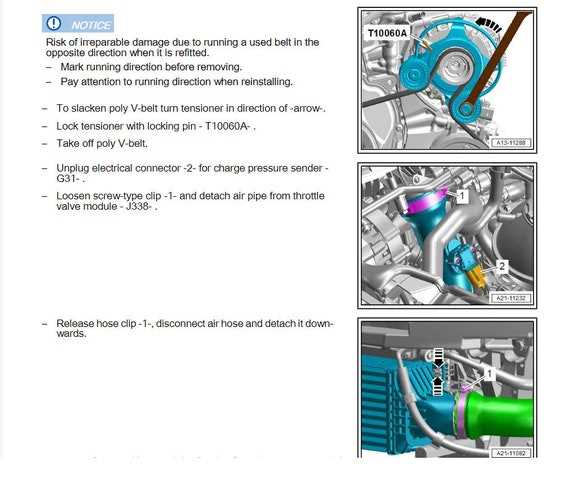

Essential Tools for Maintenance

Proper upkeep of a vehicle necessitates a selection of fundamental implements that ensure effective servicing and troubleshooting. Having the right tools on hand can significantly enhance the efficiency of maintenance tasks, making them simpler and more manageable.

Commonly used tools include wrenches, screwdrivers, and pliers, which serve a variety of functions during routine checks and repairs. Additionally, specialized equipment like torque wrenches and diagnostic devices can provide precision and help in identifying issues early on.

Investing in high-quality tools not only improves the maintenance experience but also contributes to the longevity and reliability of the vehicle. A well-equipped workshop fosters a proactive approach to care, ensuring that any necessary adjustments or repairs can be performed swiftly and accurately.

Understanding the Engine Specifications

This section delves into the fundamental aspects of engine characteristics that play a crucial role in vehicle performance and efficiency. A comprehensive understanding of these elements aids in optimizing functionality and ensuring longevity.

The powertrain typically comprises several key components, including displacement, horsepower, and torque ratings. These specifications serve as indicators of the engine’s capability and responsiveness, directly influencing acceleration and overall driving experience.

Moreover, fuel type and efficiency ratings are essential for assessing operational costs and environmental impact. By recognizing these specifications, owners can make informed decisions regarding maintenance and upgrades, ensuring the vehicle remains in peak condition.

Common Issues and Troubleshooting Tips

This section aims to highlight frequent challenges encountered with specific vehicle models and provides practical solutions for resolving them. Understanding these common issues can aid in efficient maintenance and enhance the overall driving experience.

Frequent Challenges

- Electrical System Failures

- Engine Performance Issues

- Transmission Difficulties

- Cooling System Malfunctions

- Suspension and Steering Concerns

Troubleshooting Suggestions

- Check the battery connections and fuses if electrical components are unresponsive.

- Monitor engine performance; irregularities may indicate fuel or air intake problems.

- Inspect fluid levels and leaks to address transmission-related concerns.

- Ensure the cooling system is functioning correctly by examining hoses and coolant levels.

- Assess suspension components for wear and tear to maintain proper handling.

Step-by-Step Guide for Oil Change

Changing the lubricant in your vehicle is a crucial maintenance task that ensures optimal engine performance. This guide provides a comprehensive overview of the process, helping you maintain your engine’s health and extend its lifespan.

Necessary Tools and Materials

Before starting, gather the following items:

- New lubricant

- Oil filter

- Wrench set

- Oil catch pan

- Funnel

- Rags or paper towels

Procedure Overview

Follow these steps to successfully change the lubricant:

| Step | Action |

|---|---|

| 1 | Warm up the engine to thin the lubricant, then turn it off. |

| 2 | Place the catch pan under the engine and remove the drain plug to let the old lubricant flow out. |

| 3 | Replace the drain plug once all the old lubricant has drained. |

| 4 | Remove the old oil filter using the wrench, and install the new filter. |

| 5 | Pour the new lubricant through the funnel into the engine. |

| 6 | Start the engine and let it run for a few minutes, checking for leaks. |

| 7 | Turn off the engine and check the lubricant level with the dipstick, adding more if necessary. |

Regularly changing the lubricant will significantly contribute to the longevity and efficiency of your vehicle’s engine. Follow these steps diligently to ensure a successful maintenance task.

Brake System Inspection and Repair

The braking system is a crucial component of any vehicle, ensuring safe and reliable stopping performance. Regular assessment and maintenance of this system are essential for optimal functionality. This section outlines key procedures and considerations for inspecting and servicing the braking components effectively.

Inspection Procedures

Begin by visually examining the brake pads and rotors for signs of wear and damage. Check for uneven wear patterns, which may indicate issues with alignment or suspension components. Additionally, inspect the brake fluid level and quality, as contaminated or low fluid can impair braking efficiency.

Service Recommendations

If any components show significant wear or damage, replacement is necessary. Ensure that new parts meet manufacturer specifications for compatibility and performance. After installation, conduct a thorough test of the braking system to confirm that it operates smoothly and effectively, providing the necessary stopping power.

Transmission Service Procedures Explained

Understanding the intricacies of transmission maintenance is essential for ensuring optimal vehicle performance. This section delves into the various steps involved in servicing the transmission system, emphasizing the importance of regular inspections and timely interventions.

Fluid Checks are the foundation of transmission upkeep. Regularly inspecting fluid levels and quality can prevent significant issues. It is crucial to ensure that the fluid is clean and at the correct level to facilitate smooth operation.

Filter Replacement is another vital task. Over time, the transmission filter can become clogged with debris, leading to potential damage. Replacing the filter at recommended intervals can enhance performance and prolong the lifespan of the transmission.

Seal and Gasket Inspections are essential to identify leaks. These components can degrade over time, resulting in fluid loss. Promptly addressing any leaks can prevent more extensive repairs and ensure the transmission operates efficiently.

System Diagnostics are crucial for identifying underlying issues. Utilizing specialized equipment can help detect problems before they escalate, allowing for proactive measures to be taken.

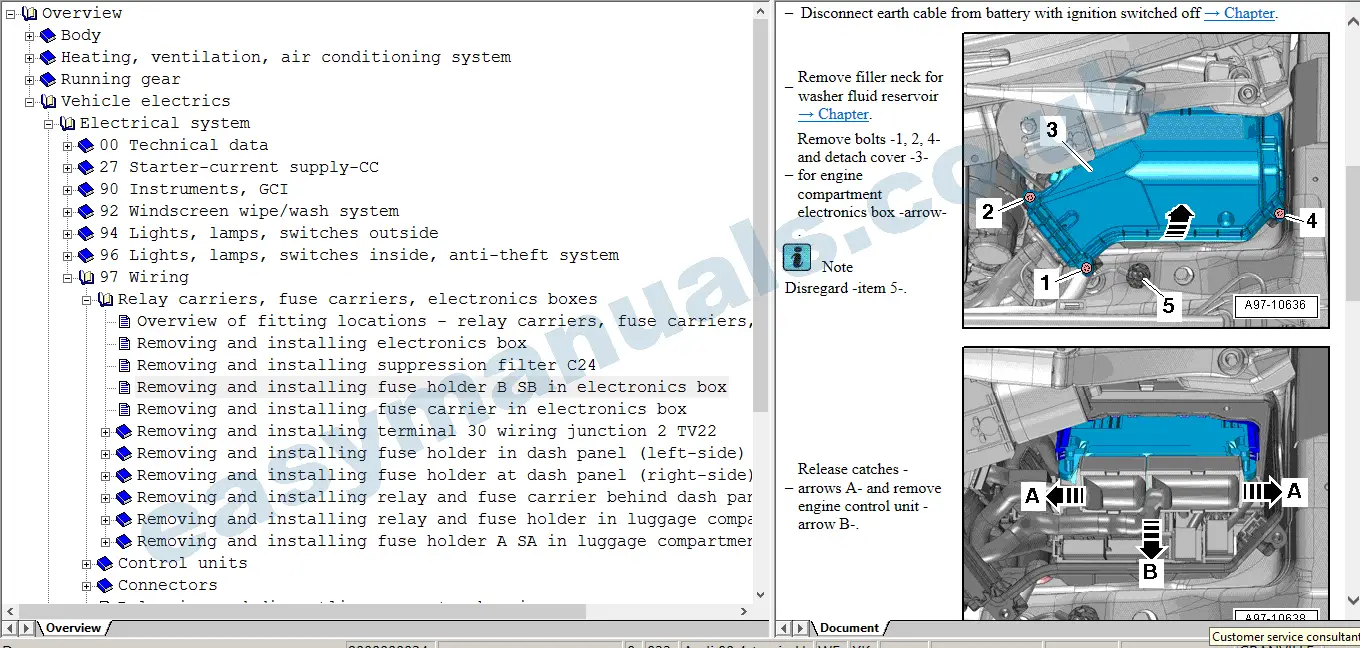

Electrical System Diagnostics Techniques

Understanding the intricacies of an automobile’s electrical network is crucial for effective troubleshooting. This segment outlines various strategies and methodologies that can be employed to identify and resolve electrical issues within a vehicle. Mastering these techniques not only enhances diagnostic accuracy but also ensures the longevity and reliability of the electrical components.

To initiate the diagnostic process, a thorough inspection of the wiring and connectors is essential. Look for signs of wear, corrosion, or loose connections that may impede electrical flow. Using a multimeter can provide valuable insights, allowing technicians to measure voltage, current, and resistance levels across various components.

Furthermore, utilizing specialized diagnostic tools can streamline the identification of faults. Scan tools can communicate with the vehicle’s onboard computer, revealing error codes that pinpoint specific malfunctions. This data serves as a foundation for further investigation and corrective action.

Another effective approach involves testing individual components such as relays, fuses, and sensors. By isolating each part, technicians can determine their operational status and functionality. This methodical examination aids in identifying faulty elements that may compromise the overall performance of the electrical system.

Lastly, it is essential to maintain comprehensive records of diagnostic procedures and findings. Documenting each step not only facilitates better understanding but also assists in future troubleshooting efforts, ultimately leading to more efficient repairs and enhanced vehicle performance.

Cooling System Maintenance Strategies

Maintaining the efficiency of the cooling system is crucial for the longevity and performance of any vehicle. Regular checks and proper care can prevent overheating and ensure optimal functionality. This section outlines effective methods to keep the cooling system in top condition.

Regular Inspections

Routine examinations of the cooling system components can identify potential issues before they escalate. Inspect hoses, clamps, and connections for wear and tear. Look for leaks or cracks, and ensure that all parts are securely attached.

Fluid Quality and Levels

Monitoring the coolant levels and its quality is essential. Replace the coolant according to the manufacturer’s recommendations. Regular flushing of the system helps remove debris and prevent corrosion, maintaining the effectiveness of the coolant.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and clamps | Every 6 months | Look for signs of wear or leaks |

| Check coolant level | Monthly | Top up if necessary |

| Flush cooling system | Every 2 years | Remove old coolant and debris |

| Inspect radiator | Every 6 months | Ensure no blockages |

Suspension and Steering Adjustments

This section focuses on optimizing the vehicle’s suspension and steering systems to ensure a smooth and stable driving experience. Proper adjustments can enhance handling, comfort, and safety, contributing to overall performance.

Regular inspection and maintenance of suspension components are essential for optimal functionality. This includes checking the alignment, balancing, and condition of various parts.

| Component | Adjustment Procedure | Tools Required |

|---|---|---|

| Wheel Alignment | Adjust camber, caster, and toe settings as per manufacturer specifications. | Alignment tool, wrenches |

| Shock Absorbers | Inspect for wear and adjust damping settings if applicable. | Wrench set, shock absorber tool |

| Steering Rack | Check for play and adjust tension to eliminate excessive movement. | Sockets, torque wrench |

Maintaining proper suspension and steering settings is vital for vehicle control and stability. Regular checks and timely adjustments can prevent larger issues and enhance the driving experience.

Bodywork and Paint Repair Basics

Understanding the fundamentals of bodywork and paint restoration is essential for maintaining the appearance and longevity of any vehicle. This section delves into the critical aspects of addressing exterior damage, ensuring that the vehicle not only looks its best but also retains its value over time.

Common Types of Damage

Exterior surfaces can suffer from various forms of harm, including dents, scratches, and corrosion. Recognizing these issues early can help in implementing effective solutions. Dents may result from minor collisions or environmental factors, while scratches often arise from careless handling or abrasive materials. Rust, on the other hand, can compromise structural integrity if not addressed promptly.

Preparation and Application Techniques

Proper preparation is key to achieving a flawless finish. This involves cleaning the affected area, sanding it down to create a smooth surface, and applying appropriate primers before painting. When applying paint, technique plays a crucial role in achieving an even coat. Utilizing spray techniques can help in distributing the paint uniformly, minimizing the appearance of imperfections.

Safety Features and Enhancements

This section focuses on the various protective mechanisms and upgrades designed to enhance occupant safety in vehicles. Understanding these features is crucial for ensuring a secure driving experience, whether during routine commutes or long journeys.

Key Safety Mechanisms

Modern automobiles are equipped with numerous safety systems aimed at preventing accidents and minimizing injuries. These include structural elements that absorb impact, advanced braking systems, and electronic stability controls that assist drivers in maintaining control during adverse conditions.

Additional Enhancements

In addition to basic safety features, various enhancements can further improve vehicle protection. Optional features may include advanced airbag systems, traction control, and collision avoidance technologies that actively work to prevent potential incidents.

| Feature | Description |

|---|---|

| Airbags | Deploy in the event of a collision to cushion occupants. |

| ABS | Prevents wheel lock-up during hard braking, maintaining steering control. |

| ESC | Helps maintain vehicle stability by reducing skidding. |

| Traction Control | Minimizes wheel spin during acceleration on slippery surfaces. |

| Collision Avoidance | Uses sensors to detect potential collisions and can apply brakes automatically. |

Regular Inspection Checklist for Longevity

Conducting routine assessments is essential for enhancing the lifespan of your vehicle. By adhering to a systematic approach, owners can identify potential issues before they escalate, ensuring a smooth and reliable driving experience.

| Inspection Area | Frequency | Key Actions |

|---|---|---|

| Fluid Levels | Monthly | Check and top off oil, coolant, brake fluid, and transmission fluid. |

| Tires | Monthly | Inspect tire pressure, tread depth, and overall condition. |

| Brakes | Every 6 months | Examine pads, rotors, and brake fluid level. |

| Battery | Every 6 months | Check connections, clean terminals, and test charge. |

| Lights | Monthly | Verify all headlights, taillights, and turn signals are functioning. |