When it comes to ensuring optimal performance of essential equipment, understanding the intricacies of operation and potential issues is crucial. This section aims to provide a thorough overview of the processes involved in maintaining and restoring functionality to vital systems that contribute to comfort and efficiency.

Through a detailed examination of common challenges, this guide will equip you with the knowledge necessary to identify and resolve various faults. With an emphasis on practical solutions and preventative measures, you will be empowered to tackle complications confidently and effectively.

Whether you are an experienced technician or a novice seeking to enhance your skills, this resource will serve as a valuable tool in your journey. By familiarizing yourself with troubleshooting techniques and maintenance practices, you can ensure the longevity and reliability of your essential equipment.

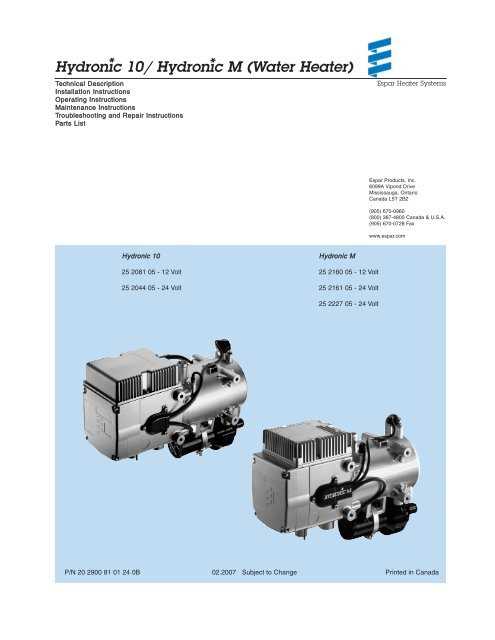

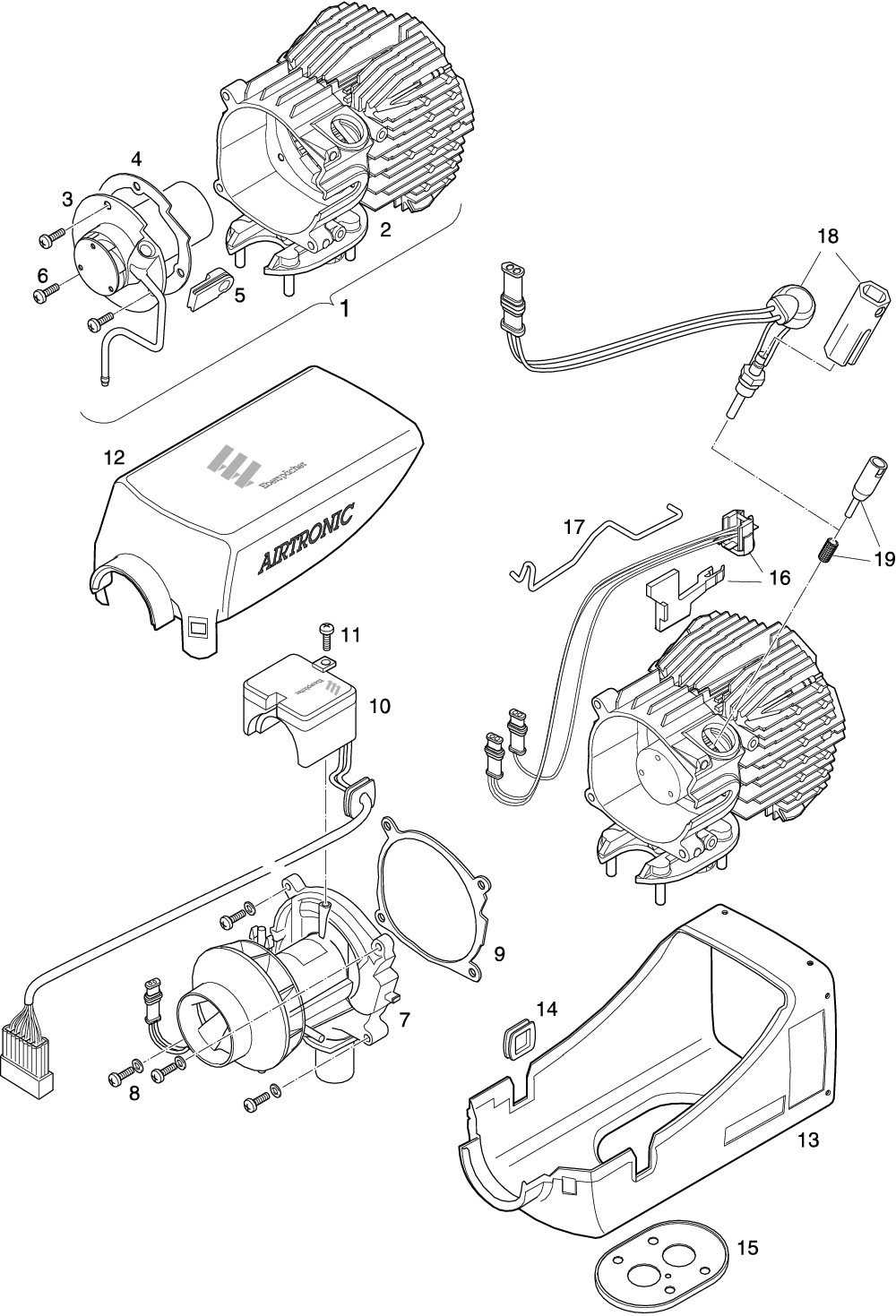

Understanding Espar Heaters

This section provides insights into a specific type of heating system designed for various applications, particularly in vehicles and outdoor environments. These systems are essential for maintaining a comfortable temperature, especially in cold conditions, and rely on efficient technology to deliver warmth effectively.

Key Features

Among the notable characteristics of these warming devices are their compact size and fuel efficiency. They are engineered to operate quietly and with minimal energy consumption, making them an ideal choice for individuals seeking reliable warmth without excessive noise or resource use. The systems can be powered by different types of fuel, which enhances their versatility in diverse settings.

Operational Principles

The functioning of these systems typically involves a combustion process that generates heat, which is then circulated through the designated area. Advanced controls allow users to adjust settings according to their specific needs, ensuring a tailored experience. Understanding these operational principles is crucial for effective use and maintenance, ultimately leading to improved longevity and performance.

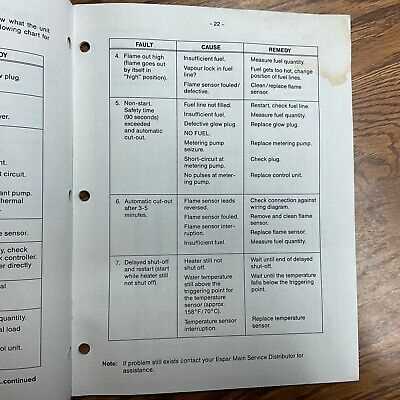

Common Issues with Espar Heaters

When it comes to vehicle heating systems, users often encounter a range of typical problems that can hinder performance and comfort. Understanding these common challenges is crucial for effective troubleshooting and maintaining optimal functionality.

| Issue | Description | Possible Solutions |

|---|---|---|

| No Ignition | The system fails to start, indicating an issue with the ignition process. | Check fuel supply, inspect electrical connections, and examine the glow plug. |

| Unusual Noises | Uncommon sounds during operation can signal mechanical problems. | Identify the source of the noise, check for loose components, and tighten any fittings. |

| Insufficient Heat | The output is lower than expected, affecting overall warmth. | Inspect the air intake and exhaust for blockages, and verify proper fuel flow. |

| Overheating | Excessive temperatures can lead to safety hazards and damage. | Check coolant levels, ensure the thermostat is functioning, and clean any debris around the unit. |

Essential Tools for Repairs

When tackling maintenance tasks, having the right instruments is crucial for achieving effective outcomes. A well-equipped toolkit not only facilitates the process but also ensures safety and efficiency during operations. Below are some fundamental items that can enhance your troubleshooting and service capabilities.

Socket Set: A comprehensive socket set is indispensable for loosening and tightening fasteners of various sizes. It allows for quick adjustments and ensures that components are securely fastened.

Multimeter: This versatile device is essential for measuring electrical properties such as voltage, current, and resistance. It helps diagnose issues related to the electrical system and ensures optimal functionality.

Wrenches: Both adjustable and fixed wrenches are vital for gripping and turning nuts and bolts. They provide leverage and precision, making it easier to work in tight spaces.

Screwdriver Set: A range of screwdrivers, including Phillips and flathead types, is necessary for accessing various components. This assortment allows for effective handling of screws without damaging them.

Pliers: A good pair of pliers can aid in gripping, twisting, and cutting wires or other materials. Needle-nose pliers are particularly useful for reaching into confined areas.

Safety Gear: Always prioritize safety by using protective eyewear, gloves, and masks. This equipment shields you from potential hazards and ensures a safer working environment.

Equipping yourself with these essential tools can significantly streamline the process of maintaining and optimizing performance. Being prepared not only enhances productivity but also contributes to a successful outcome in your tasks.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered with your heating system. Following a systematic method can help isolate problems and facilitate effective solutions, ensuring optimal performance and reliability.

| Issue | Symptoms | Possible Causes | Solutions |

|---|---|---|---|

| No operation | Device does not turn on | Power supply issue, faulty switch | Check power source, inspect switch functionality |

| Insufficient warmth | Low temperature output | Clogged lines, malfunctioning components | Clear blockages, test components |

| Unusual noises | Strange sounds during operation | Loose parts, mechanical wear | Tighten connections, replace worn parts |

| Odor emission | Unpleasant smells detected | Burnt materials, gas leaks | Inspect for leaks, clean unit thoroughly |

By systematically addressing each potential issue, you can enhance the efficiency and lifespan of your heating apparatus. Regular maintenance and prompt attention to problems are crucial for smooth operation.

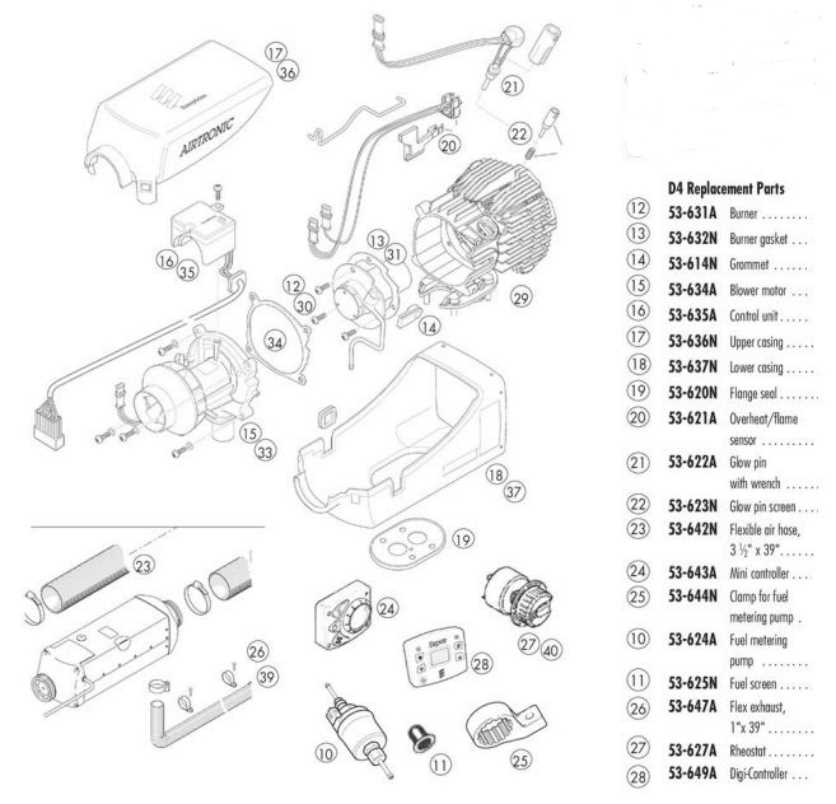

Replacing the Fuel Pump

Replacing a fuel delivery component is essential for maintaining optimal performance in your system. This process involves ensuring that the pump functions efficiently, allowing for smooth operation. A faulty unit can lead to various issues, so understanding the replacement steps is crucial.

Before you begin, gather the necessary tools and components. Follow these steps for a successful replacement:

| Step | Description |

|---|---|

| 1 | Disconnect the power supply to prevent any electrical hazards. |

| 2 | Remove the old fuel pump from its housing carefully. |

| 3 | Install the new pump, ensuring proper alignment and connection. |

| 4 | Reconnect the power supply and test the system for leaks. |

By following these steps diligently, you can ensure a seamless transition to a new fuel delivery component, enhancing the overall efficiency of your setup.

Cleaning the Combustion Chamber

Regular maintenance of the combustion chamber is essential for optimal performance and safety. Accumulated debris and residues can hinder efficiency and lead to potential issues. Proper cleaning techniques not only enhance functionality but also extend the lifespan of the unit.

Necessary Tools and Materials

- Protective gloves

- Safety goggles

- Soft brush or vacuum

- Clean cloth or rag

- Appropriate cleaning solution

Steps to Clean the Combustion Chamber

- Ensure the unit is turned off and completely cool before starting the cleaning process.

- Remove any access panels carefully to expose the combustion chamber.

- Use a soft brush or vacuum to eliminate loose debris and soot buildup.

- Wipe down the surfaces with a clean cloth dampened with an appropriate cleaning solution.

- Inspect for any signs of wear or damage while cleaning, addressing any issues as necessary.

- Reassemble the unit, ensuring all components are securely fastened.

Following these steps will help maintain the integrity of the system, ensuring it operates efficiently and safely.

Checking Electrical Connections

Ensuring the integrity of electrical links is crucial for optimal performance and safety. Faulty connections can lead to malfunctioning equipment or potential hazards. This section outlines the steps to effectively examine these crucial components.

- Begin by disconnecting the power supply to avoid any risk of electric shock.

- Inspect all visible connections for signs of wear or damage:

- Frayed wires

- Corrosion on terminals

- Loose fittings

- Set the device to the appropriate setting for resistance measurement.

- Touch the probes to the corresponding points in the circuit.

- Confirm that the reading falls within the expected range.

After completing these checks, restore the power supply and monitor the system for any irregular behavior. Regular inspections can prevent future issues and enhance overall reliability.

Adjusting the Thermostat Settings

Fine-tuning temperature controls is essential for optimal performance and energy efficiency. Proper adjustments can lead to a comfortable environment while minimizing energy consumption.

- Locate the temperature control unit, typically found on the front panel.

- Identify the current temperature setting and assess whether it aligns with your comfort needs.

- Turn the dial or press the buttons to increase or decrease the desired temperature.

- Monitor the system’s response to the new settings over a few hours.

Regular adjustments based on seasonal changes can enhance functionality and prolong the unit’s lifespan.

Inspecting the Exhaust System

Ensuring the proper functioning of the combustion byproducts pathway is crucial for both efficiency and safety. Regular examination of this system helps identify any issues that could lead to malfunctions or hazards. This section provides guidance on how to effectively assess the exhaust system’s components and their overall condition.

Begin by visually inspecting the exhaust pipes for any signs of wear or damage. Look for cracks, corrosion, or loose connections that might impede the flow of gases. Pay close attention to the junctions where components meet, as these areas are often prone to leaks.

| Component | Inspection Criteria | Common Issues |

|---|---|---|

| Exhaust Pipes | Check for cracks and rust | Corrosion, leaks |

| Joints | Ensure tight connections | Loose fittings, gaps |

| Muffler | Listen for unusual noises | Blockages, excessive noise |

| Exhaust Vent | Clear of obstructions | Debris, clogs |

After the visual inspection, conduct a functional test if possible. This may include checking for any unusual odors or sounds during operation. If any irregularities are detected, further investigation and maintenance may be necessary to ensure optimal performance and safety.

Diagnosing Air Supply Problems

Ensuring proper airflow is crucial for optimal performance in any system that relies on combustion. Inadequate air supply can lead to inefficiency, poor operation, and even potential damage. Identifying and addressing issues in the air delivery system is essential for maintaining functionality and safety.

Common Symptoms of Airflow Issues

Several indicators may suggest a disruption in the air supply. Recognizing these signs early can help prevent further complications:

- Unusual noises during operation

- Inconsistent or diminished output

- Excessive emissions or smoke

- Unresponsive controls or irregular cycling

Steps to Diagnose Air Supply Problems

To effectively pinpoint the source of airflow issues, follow these steps:

- Inspect air intake and exhaust pathways for blockages or obstructions.

- Check all filters for dirt and debris, ensuring they are clean and properly installed.

- Examine connections and hoses for wear, leaks, or damage.

- Verify that fans and blowers are functioning correctly and free from debris.

- Assess overall system configuration to ensure it meets specifications for optimal airflow.

By systematically evaluating these elements, you can identify and resolve air supply problems, leading to improved system performance and longevity.

Maintaining Optimal Performance

To ensure efficient operation and longevity of your heating system, regular upkeep is essential. Proper maintenance not only enhances functionality but also reduces the risk of unexpected failures, ensuring that the unit operates at peak efficiency throughout its lifespan.

Begin by routinely checking all components for any signs of wear or damage. This includes inspecting connections and ensuring that any filters or vents are clean and unobstructed. Keeping these elements in good condition allows for better airflow and heat distribution.

Additionally, it is important to follow the manufacturer’s guidelines regarding service intervals. Schedule periodic checks by a qualified technician who can perform more in-depth inspections and address any potential issues that may arise. Consistent professional servicing can identify problems before they escalate, ultimately saving time and money.

Finally, maintaining a clean environment around the unit is crucial. Remove any debris or obstructions from the vicinity, which could impede operation. By implementing these practices, you can promote a reliable performance and extend the life of your heating equipment.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Proper preparation and adherence to guidelines can significantly mitigate risks associated with working on heating systems.

First and foremost, always disconnect the power source before beginning any work. This simple step can help avoid electric shocks or unintended activation of the unit. Additionally, make sure to allow sufficient time for any residual heat to dissipate, especially if the device was recently in use.

Using the right tools is essential for safe handling and efficient performance. Ensure that all equipment is in good condition and suitable for the specific tasks at hand. Wearing appropriate personal protective equipment, such as gloves and goggles, can further safeguard against potential hazards.

It’s also important to work in a well-ventilated area to minimize exposure to harmful fumes and ensure adequate airflow. If any signs of leakage or damage are present, it is advisable to consult a professional to address these issues safely.

Lastly, keeping a first aid kit readily accessible can be beneficial in case of minor injuries. Staying alert and focused during the process will enhance overall safety and efficiency.

When to Seek Professional Help

Identifying when to call in an expert can be crucial for ensuring the longevity and efficiency of your equipment. While many issues can be resolved with basic troubleshooting, certain signs indicate that professional intervention is necessary. Understanding these indicators can save you time and prevent further complications.

Signs You Need an Expert

- Persistent Malfunctions: If the unit continues to malfunction despite your attempts to address the problem, it may be time to consult a technician.

- Strange Noises or Odors: Unusual sounds or smells can signal serious issues that require specialized knowledge to diagnose and repair.

- Warning Indicators: If any warning lights or error codes appear, seeking professional assistance is advisable to avoid potential hazards.

- Increased Energy Bills: A sudden rise in energy costs can indicate inefficiency that a professional can help rectify.

Benefits of Professional Assistance

- Expertise: Professionals possess the training and experience to handle complex issues safely and effectively.

- Time-Saving: Engaging an expert can often lead to faster resolutions compared to trial-and-error attempts.

- Warranty Protection: Professional servicing may be required to maintain warranty validity for your device.