Owning an all-terrain vehicle (ATV) can be an exhilarating experience, offering adventure and freedom on various terrains. However, to ensure optimal performance and longevity, regular maintenance and proper troubleshooting are crucial. This guide provides comprehensive insights into essential practices for keeping your vehicle in peak condition.

Understanding the mechanics and systems of your ATV is vital for any enthusiast. Whether it’s routine inspections or addressing specific issues, familiarity with the vehicle’s components can save time and money. In this section, we will delve into key procedures and tips that will empower you to take charge of your ATV’s upkeep.

From basic maintenance tasks to more complex repairs, being equipped with the right knowledge can enhance your riding experience. With an emphasis on practical advice and step-by-step instructions, this resource aims to facilitate a deeper understanding of your vehicle’s requirements. Prepare to unlock the potential of your ATV and enjoy the thrill of the ride with confidence.

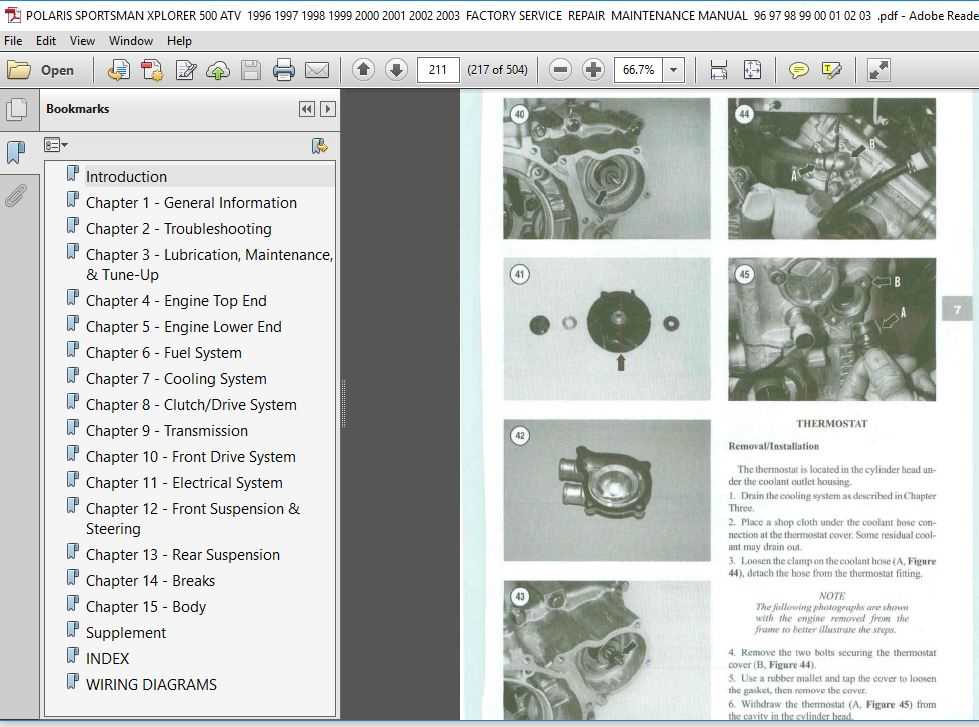

Essential Tools for Polaris Repair

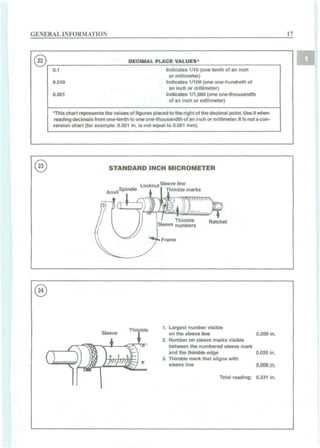

Having the right equipment is crucial when working on off-road vehicles. A well-equipped toolkit not only makes the task more efficient but also enhances the quality of the work performed. Understanding which instruments are necessary can save time and reduce frustration during maintenance or troubleshooting sessions.

Basic Toolkit Requirements

To start, a set of hand tools is essential. This includes various sizes of wrenches, sockets, and ratchets. These tools allow for easy access to different components and facilitate adjustments. Additionally, a quality screwdriver set with both flathead and Phillips heads is vital for handling screws and fasteners.

Specialized Equipment

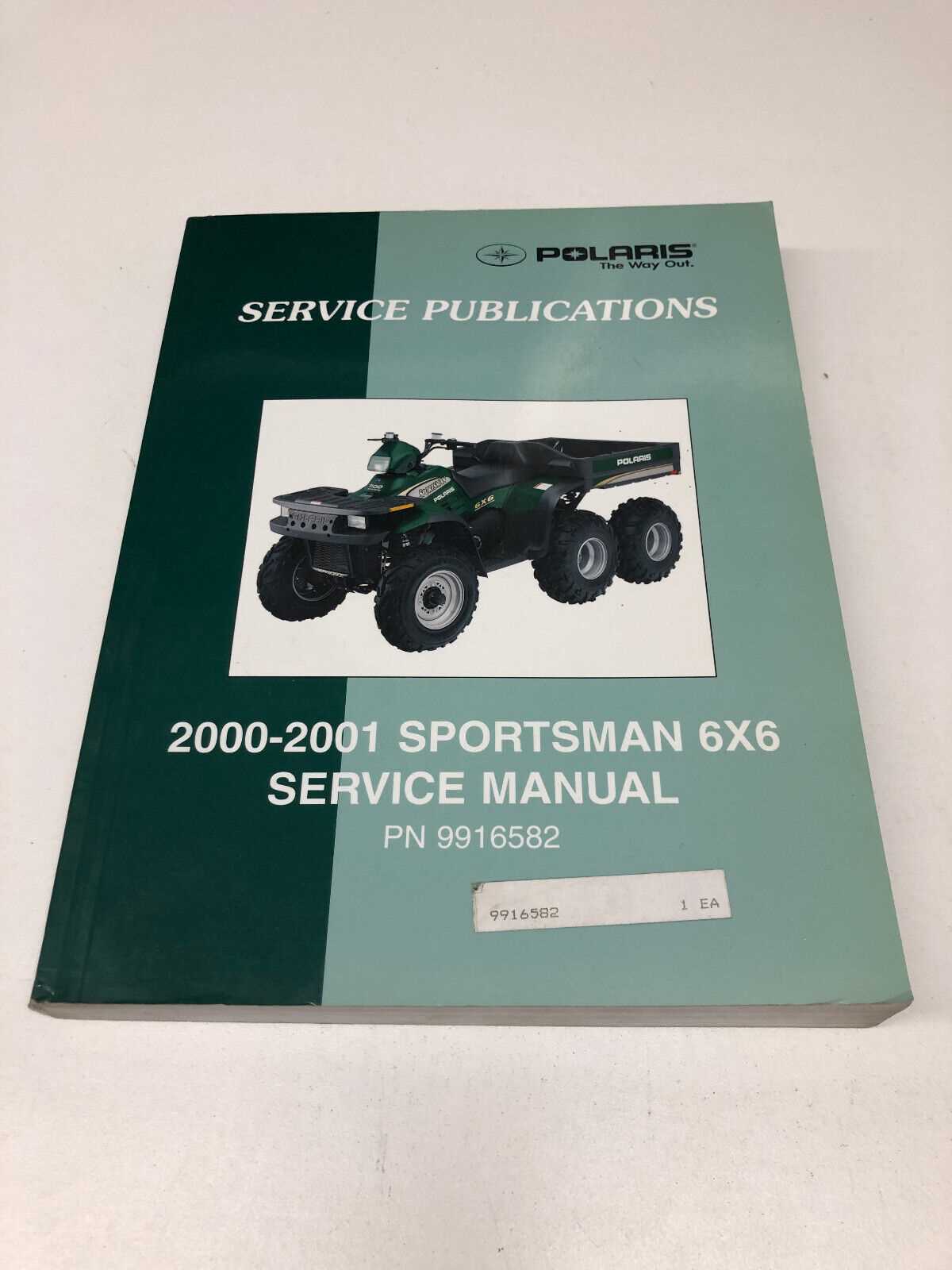

In addition to basic tools, having specialized gear can greatly improve the repair experience. A service manual is invaluable for understanding specific procedures and specifications. Furthermore, a torque wrench ensures that fasteners are tightened to the correct specifications, preventing potential damage. Finally, investing in a multimeter is essential for diagnosing electrical issues and ensuring all systems function properly.

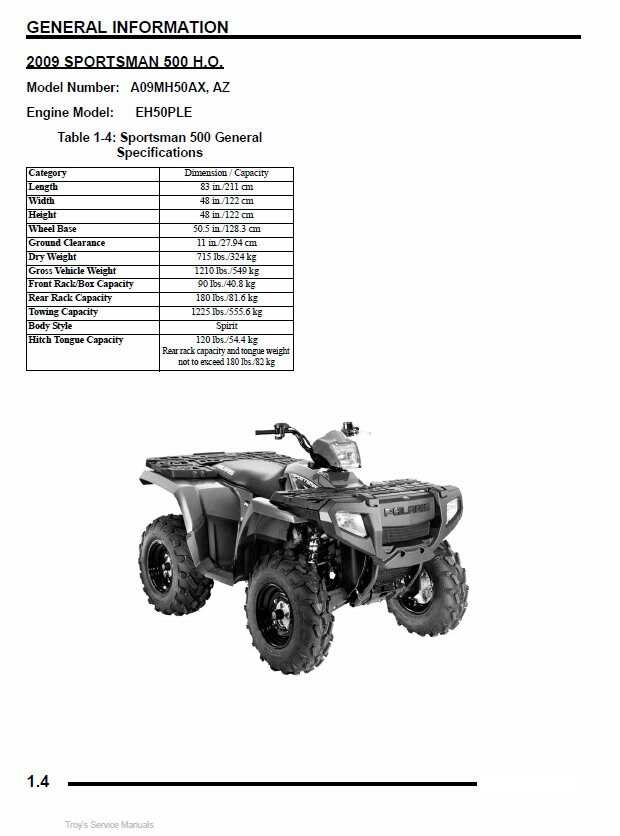

Understanding the Sportsman 500 Engine

The engine is the heart of any all-terrain vehicle, playing a crucial role in its overall performance and reliability. A deep comprehension of its components, functionality, and maintenance can significantly enhance your riding experience. This section delves into the essential aspects of the power unit, providing insights into its design and operation.

Key Components of the Power Unit

At the core of this mechanism lies a robust assembly, comprising various parts that work in unison. The cylinder, pistons, and crankshaft form the foundation of the internal workings, transforming fuel into kinetic energy. Understanding how these elements interact is vital for diagnosing issues and ensuring optimal functionality. Regular checks on the ignition system and fuel delivery are also crucial to maintain performance.

Maintenance Tips for Longevity

To ensure a prolonged lifespan of the engine, routine maintenance should be a priority. Regular oil changes, air filter replacements, and coolant checks are essential practices. Additionally, inspecting the belts and hoses for wear can prevent unexpected failures. Adhering to these maintenance routines not only enhances performance but also fosters a safe and enjoyable riding experience.

Common Issues with the 2001 Model

The vehicle in question has gained a reputation for certain recurring problems that owners frequently encounter. Understanding these issues can help in maintenance and ensure a smoother riding experience.

Electrical Problems

- Weak battery performance leading to starting difficulties.

- Frequent blown fuses that interrupt functionality.

- Malfunctioning ignition switches affecting overall operation.

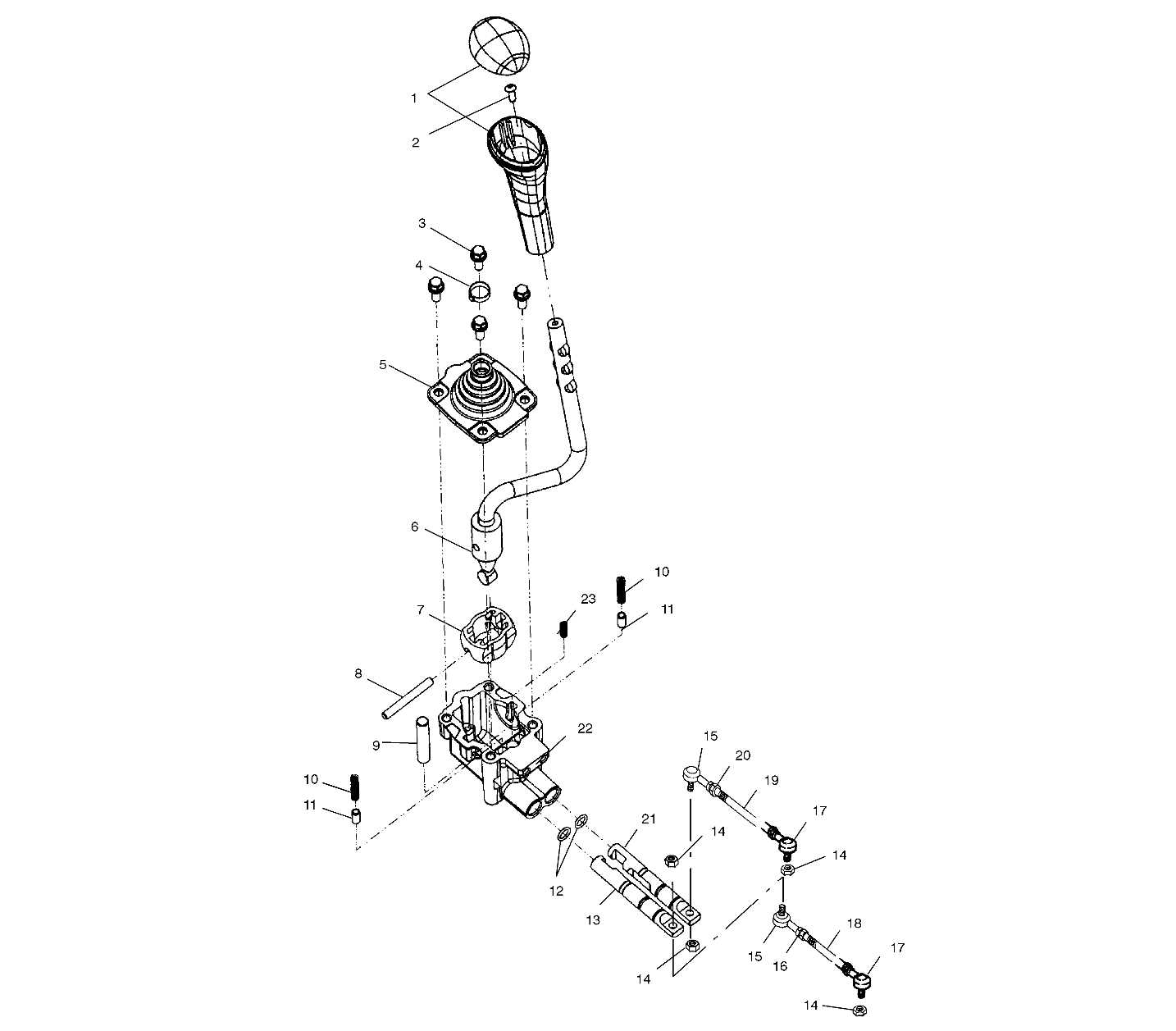

Mechanical Concerns

- Transmission slipping or improper shifting between gears.

- Suspension components wearing out prematurely, impacting ride quality.

- Engine overheating due to cooling system inefficiencies.

Awareness of these common issues can aid in troubleshooting and maintaining the longevity of the vehicle, ensuring a better experience on the trails.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of your off-road vehicle. This section outlines a series of systematic tasks designed to keep your machine in peak condition. Following these procedures will help prevent issues and enhance your riding experience.

1. Engine Oil Change: Begin by warming up the engine to thin the oil for easier drainage. Use an appropriate oil filter wrench to remove the old filter, then drain the oil completely. Replace it with high-quality oil, ensuring the correct level is maintained.

2. Air Filter Inspection: Remove the air filter cover and take out the filter. Check for dirt and debris. If it appears dirty, clean it with compressed air or replace it as necessary to ensure proper airflow.

3. Tire Maintenance: Inspect tire pressure using a gauge, ensuring it aligns with manufacturer specifications. Look for any signs of wear or damage. Rotate the tires if necessary, and replace any that are excessively worn.

4. Brake System Check: Examine the brake fluid level and inspect the pads for wear. Replace any worn components to maintain optimal stopping power. Ensure the brake lines are free from leaks.

5. Battery Care: Check the battery terminals for corrosion and clean them if needed. Ensure the battery is securely mounted and test its charge. Replace the battery if it shows signs of weakness.

6. Chain and Sprocket Maintenance: Inspect the drive chain for tension and lubrication. Clean any debris, then apply chain lubricant to enhance performance and reduce wear.

Following these steps regularly will not only extend the life of your vehicle but also ensure a safer and more enjoyable ride. Always consult the specific guidelines provided by the manufacturer for precise details and specifications.

Electrical System Troubleshooting Guide

This section aims to provide a comprehensive approach to diagnosing and resolving issues within the electrical framework of your vehicle. Understanding the intricacies of the electrical components is essential for effective troubleshooting and maintenance. By following the outlined steps, you can identify problems ranging from minor glitches to significant malfunctions.

Initial Checks: Begin with a visual inspection of the wiring harness, connectors, and electrical components. Look for signs of wear, corrosion, or loose connections that could disrupt the flow of electricity. Ensure the battery is charged and terminals are secure. A simple multimeter can be invaluable for measuring voltage and continuity.

Testing Components: Isolate individual parts of the electrical system, such as switches, relays, and fuses. Testing these components separately can help pinpoint the source of the issue. If a fuse is blown, replace it and determine the underlying cause of the failure.

Voltage Drop Analysis: Conduct a voltage drop test to identify poor connections or excessive resistance in the circuit. This method involves measuring the voltage at various points in the system while it is under load. Significant drops can indicate areas needing attention.

Grounding Issues: Check all grounding points to ensure they are clean and secure. Poor grounding can lead to a variety of electrical problems, including intermittent issues and erratic behavior of components. A good ground is crucial for the system’s overall performance.

Consulting Diagrams: Utilize wiring diagrams and schematics for reference. These visual aids can help clarify how components are interconnected, making it easier to identify potential issues within the circuit.

Documentation: Keep detailed records of any issues encountered and the steps taken to resolve them. This information can be helpful for future troubleshooting and maintenance tasks.

By methodically following these troubleshooting techniques, you can effectively address electrical system issues, ensuring optimal performance and reliability for your vehicle.

Replacing Tires and Suspension Parts

Maintaining optimal performance and safety of your vehicle requires regular attention to its tires and suspension components. This section focuses on the essential procedures for replacing these critical elements, ensuring a smoother ride and enhanced handling capabilities. Proper maintenance not only extends the lifespan of your vehicle but also improves overall driving experience.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. Here’s a quick reference table:

| Tool/Material | Description |

|---|---|

| Jack | Used to lift the vehicle for tire access. |

| Jack Stands | Ensures stability when the vehicle is raised. |

| Lug Wrench | For removing and tightening wheel nuts. |

| Socket Set | Required for suspension component bolts. |

| New Tires | To replace the old, worn-out tires. |

| Suspension Parts | New components for any damaged or worn sections. |

Step-by-Step Replacement Process

Follow these steps to ensure a successful replacement:

- Begin by securing the vehicle on a flat surface and engaging the parking brake.

- Use the jack to lift the vehicle, then place jack stands underneath for safety.

- Remove the wheel by loosening the lug nuts with the wrench.

- Inspect the suspension components; if damaged, use the socket set to detach and replace them.

- Mount the new tire, tightening the lug nuts in a crisscross pattern to ensure even pressure.

- Lower the vehicle and remove the jack stands.

- Check the alignment and ensure all components are secure before taking the vehicle on a test drive.

How to Change the Oil Properly

Maintaining the proper lubrication of your vehicle’s engine is crucial for its longevity and performance. Regular oil changes ensure that harmful contaminants are removed and that the engine operates smoothly. This guide outlines the steps to effectively replace the oil, providing a seamless experience for both novice and experienced individuals.

What You’ll Need

- New oil

- Oil filter

- Oil catch pan

- Wrench set

- Funnel

- Clean rags

Step-by-Step Procedure

- Prepare Your Vehicle: Ensure the vehicle is on a flat surface and turn off the engine. Allow it to cool down before starting the process.

- Locate the Drain Plug: Find the oil drain plug beneath the engine. Place the oil catch pan underneath it.

- Drain the Old Oil: Use a wrench to remove the drain plug. Allow the old oil to fully drain into the pan. Be cautious, as the oil may still be warm.

- Replace the Oil Filter: Locate the oil filter and use an oil filter wrench to remove it. Apply a small amount of new oil to the gasket of the new filter and install it securely.

- Reattach the Drain Plug: Once the oil has drained, replace the drain plug and tighten it properly.

- Add New Oil: Using a funnel, pour the new oil into the engine through the designated opening. Refer to your vehicle’s specifications for the correct oil type and amount.

- Check Oil Level: After adding oil, wait a few moments and then check the level using the dipstick. Add more oil if necessary.

- Dispose of Old Oil: Ensure that you dispose of the used oil and filter properly at a designated recycling center.

By following these straightforward steps, you can ensure your engine remains in top condition and performs optimally for years to come.

Upgrading Components for Better Performance

Enhancing the capabilities of your all-terrain vehicle involves a strategic approach to component upgrades. By focusing on key areas, enthusiasts can significantly improve handling, speed, and overall efficiency. This section delves into essential upgrades that can elevate your riding experience.

Engine Enhancements: Boosting engine performance is paramount. Consider upgrading the air intake system and exhaust for better airflow, which can lead to increased horsepower. Additionally, a performance chip can optimize fuel delivery, further enhancing acceleration and throttle response.

Suspension Upgrades: Improving the suspension system is crucial for better handling and comfort on rugged terrain. Installing high-quality shocks and springs can provide superior damping and stability. Adjustability features allow riders to tailor the setup to their preferences and riding conditions.

Tires and Wheels: Selecting the right tires can dramatically impact traction and control. Opt for all-terrain tires that offer a balance between off-road capability and on-road performance. Upgrading to lightweight alloy wheels can reduce unsprung weight, contributing to improved maneuverability.

Braking System: An efficient braking system is vital for safety and performance. Upgrading to larger rotors and high-performance pads can enhance stopping power. Consider stainless steel brake lines for improved pedal feel and responsiveness.

Electrical and Lighting: Enhanced lighting systems not only improve visibility but also add a modern touch. Upgrading to LED lights can provide brighter illumination while being energy efficient. Additionally, adding auxiliary power outlets allows for charging devices or powering accessories during your adventures.

By systematically upgrading these components, you can unlock the full potential of your vehicle, ensuring an exhilarating and safe ride in various terrains.

Safety Tips During Repairs

Engaging in maintenance tasks requires a proactive approach to safety. Ensuring a secure environment not only protects the individual performing the work but also safeguards the equipment and surrounding area. Implementing a few essential precautions can prevent accidents and enhance overall efficiency during the process.

Personal Protective Equipment

Wearing appropriate personal protective gear is vital. This includes gloves, goggles, and sturdy footwear. Such equipment shields against potential hazards, such as flying debris or sharp edges. Additionally, consider using ear protection if working with loud machinery. Always prioritize your well-being by staying vigilant and attentive to your surroundings.

Workspace Organization

An organized workspace is crucial for maintaining focus and preventing mishaps. Keep tools and materials neatly arranged and within easy reach. A clutter-free area minimizes the risk of tripping or losing important items. Moreover, ensure adequate lighting to illuminate your tasks, as visibility plays a key role in avoiding mistakes and accidents.

Finding OEM and Aftermarket Parts

Locating the right components for your all-terrain vehicle can greatly influence its performance and longevity. Understanding the differences between original equipment manufacturer (OEM) parts and aftermarket alternatives is essential for making informed decisions. Each option has its own benefits and drawbacks, which can impact both functionality and cost.

OEM parts are produced by the original manufacturer and designed specifically for your vehicle. They ensure a perfect fit and often come with warranties. However, they may be more expensive. Here are some tips for sourcing OEM components:

- Visit authorized dealers or service centers for authentic replacements.

- Check online OEM parts catalogs for availability and pricing.

- Look for factory specifications to ensure compatibility.

Aftermarket parts, on the other hand, are made by third-party companies and can offer a wider range of options at varying price points. They may not always match the quality of OEM parts but can provide excellent alternatives. Consider the following when searching for aftermarket options:

- Research reputable brands known for quality and durability.

- Read customer reviews to gauge performance and reliability.

- Compare prices across multiple retailers to find the best deals.

Ultimately, choosing between OEM and aftermarket parts depends on your specific needs, budget, and the intended use of your vehicle. Careful consideration will ensure you make the best choice for maintaining optimal performance.