Keeping your lawnmower in optimal condition can greatly enhance its performance and lifespan. Regular care and preventive measures not only ensure efficient operation but also help in avoiding common issues. This guide provides a clear, step-by-step approach for anyone looking to perform upkeep on their equipment confidently.

In the following sections, you will find practical advice for diagnosing and addressing frequent technical issues. From ensuring a smooth start to achieving a clean cut, each topic covers a range of useful tips that can be applied at home. Whether it’s routine checks or specific fixes, these methods can help extend the life of your machine while ensuring safety and reliability.

Designed for both beginners and experienced users, this resource aims to offer insights that simplify the maintenance process. With straightforward instructions and essential tips, you’ll find all you need to keep your lawn equipment in top shape, ready to tackle every mowing season.

Understanding Key Components and Mechanisms

Recognizing and understanding each part and its function is essential for maintaining a machine’s peak performance. By getting familiar with the various components, users can better address any issues that may arise and extend the device’s lifespan.

Core Structural Parts

- Engine: The powerhouse responsible for driving all mechanical processes. Familiarizing with its layout aids in identifying any unusual sounds or vibrations.

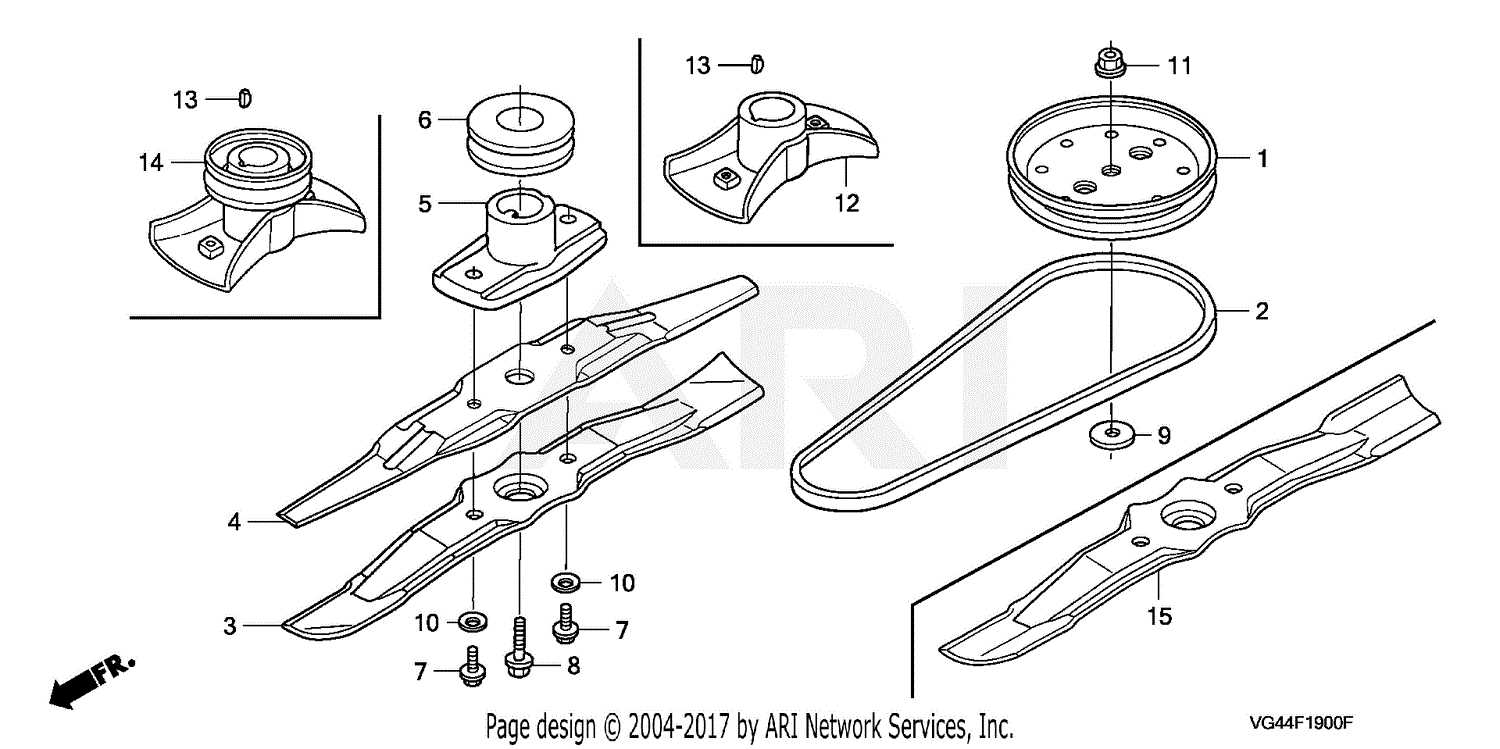

- Blade Assembly: Responsible for cutting efficiency, the blade’s condition significantly impacts overall operation. Regular inspection helps maintain cutting quality and safety.

- Fuel System: Includes the tank, lines, and filters. Understanding this system ensures optimal fuel flow and prevents clogging issues.

Operational Controls and Adjustments

- Throttle Control: Allows users to adjust engine speed according to different requirements. Proper usage helps manage fuel efficiency and control noise levels.

- Height Adjustment Lever: Enables setting the cutting height to match lawn conditions. Adjusting this ensures even, desirable grass length.

- Wheel Assembly: Influences maneuverability and stability. Regular checks can help avoid wear and ensure smooth navigation across various terrains.

Understanding these components and their roles empowers users to approach maintenance confidently, ensuring consistent and reliable operation.

Common Issues with This Lawnmower Model

This section provides an overview of frequent challenges owners encounter with this mower. Understanding these common issues can help users maintain their machine efficiently, ensuring smoother operation and extending its lifespan.

Engine Starting Troubles: A frequent issue is the difficulty in starting the engine, often due to fuel-related concerns. Regularly checking the fuel level, filter, and carburetor can prevent such starting problems.

Blade Performance: Reduced cutting performance may occur over time. To maintain optimal functionality, ensure blades are sharp and free from debris build-up.

Self-Propel Malfunctions: Users sometimes experience issues with the self-propel mechanism, particularly when the drive belt or transmission system requires adjustment or replacement. Inspecting these parts can often resolve propulsion concerns.

Uneven Cutting: Uneven or patchy cutting can result from wheel misalignment or issues with the height adjustment settings. Periodic adjustments can improve consistency and cutting precision.

By addressing these common concerns, owners can keep their mower performing effectively for longer periods and reduce the likelihood of more significant malfunctions.

Essential Tools for Repairs

To successfully tackle maintenance tasks, having the right set of tools at your disposal is crucial. Equipped with versatile and durable instruments, you can address a variety of mechanical challenges effectively. Below, you’ll find a list of recommended tools to make the job both efficient and thorough.

Basic Tool Kit

- Wrenches: Various sizes, including adjustable ones, help in loosening and tightening different nuts and bolts.

- Screwdrivers: A complete set with both flathead and Phillips types ensures you’re ready for all screw sizes.

- Pliers: These are essential for gripping, twisting, and cutting wires or cables, making them versatile for many tasks.

- Socket Set: A socket wrench set with an array of sizes will allow easy access to fasteners in tight spaces.

Advanced Tools for Specific Needs

- Torque Wrench: For precise tightening, this tool ensures bolts are secured with the correct force, avoiding damage from over-tightening.

- Multimeter: Ideal for diagnosing electrical issues, it measures voltage, current, and resistance, aiding in pinpointing electrical malfunctions.

- Lubricant: High-quality oils or sprays reduce friction and prevent wear on moving parts, ensuring smoother

Step-by-Step Maintenance Guide

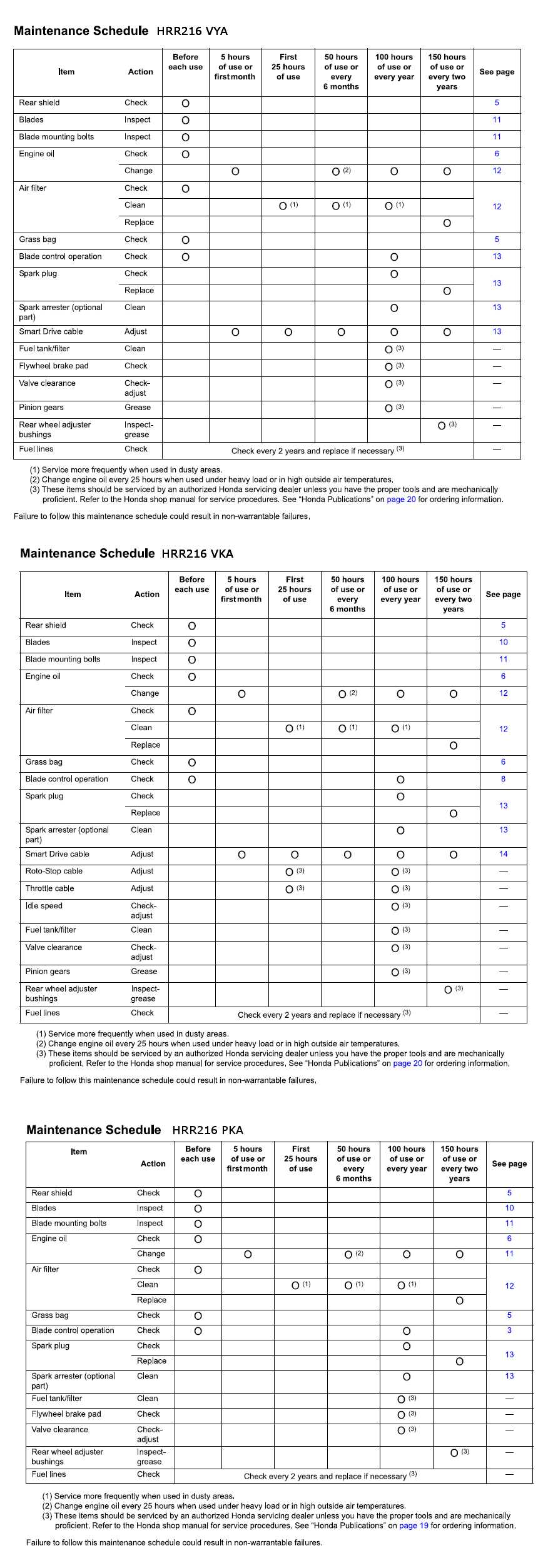

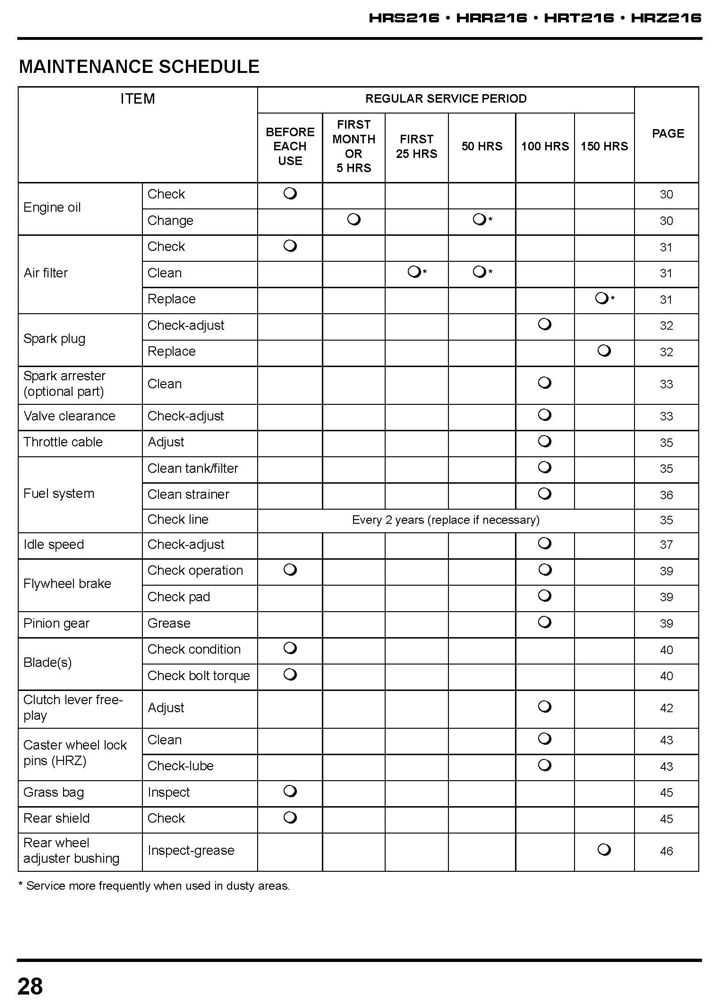

Regular upkeep of your equipment is essential for optimal performance and longevity. Following a consistent maintenance routine can prevent unexpected issues and ensure smooth operation over time.

- Check and Replace Oil: Frequently inspect the oil level and change it as recommended. This helps maintain engine efficiency and reduces friction.

- Air Filter Cleaning: Remove and clean the air filter regularly to keep debris from clogging the engine. Replace it if it shows signs of wear.

- Inspect and Sharpen Blades: Periodically check the condition of the blades. If they appear dull or chipped, sharpen or replace them to ensure clean cuts.

- Inspect Spark Plug: Examine the spark plug for any buildup or corrosion. Clean or replace it as needed to ensure easy starting and efficient fuel use.

- Clean the Deck: After each use, clear the deck of grass clippings and dirt buildup. A clean deck helps improve airflow and reduces strain on the machine.

Following these steps will keep your equipment running smoothly, helping it stay reliable and efficient for longer periods.

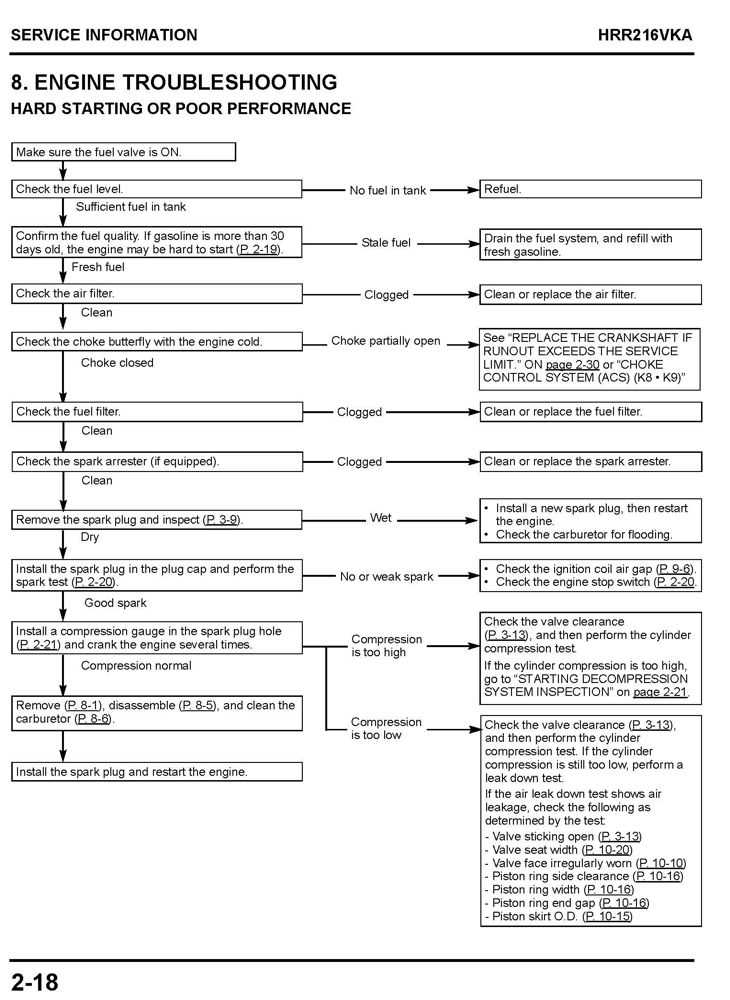

How to Diagnose Engine Problems

Understanding the root of engine issues can prevent minor malfunctions from turning into significant setbacks. With a few systematic checks, most common causes can be pinpointed effectively, allowing for timely maintenance and troubleshooting.

Step 1: Check the Fuel System

If the engine fails to start or runs inconsistently, begin with an inspection of the fuel system. Ensure that the fuel tank contains fresh fuel, as old or contaminated fuel can clog components and reduce efficiency. Verify that the fuel filter is clear, and check for any signs of leaks along the fuel line.

Step 2: Examine the Spark Plug

A worn or dirty spark plug can prevent the engine from starting or lead to intermittent performance. Remove the spark plug and inspect its condition. Clean any deposits from the electrode, and consider replacing the plug if it appears excessively worn. Reinstall and test the engine’s responsiveness.

Step 3: Assess the Air Filter

The air filter plays a vital role in maintaining airflow, and a clogged filter can cause the engine to run rough or lose power. Inspect the air filter and clean or replace it if it shows signs of dust buildup or damage. Proper airflow is essential for combustion efficiency.

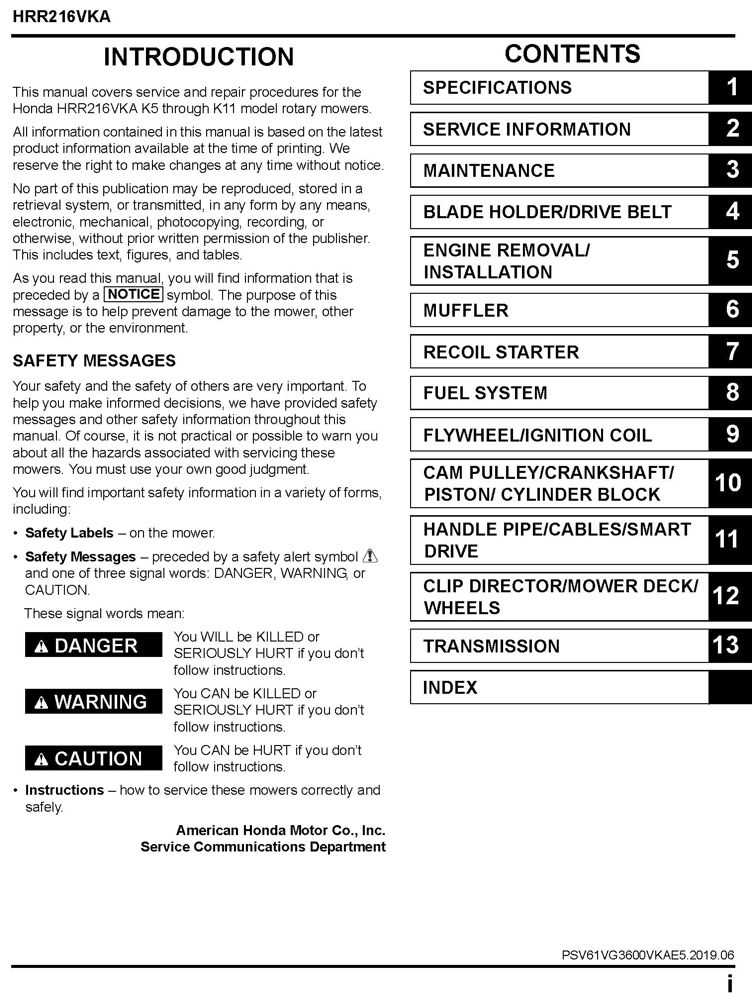

Step 4: Inspect the Carburetor

If the engine exhibits issues with idling or acceleration, the carburetor could be clogged. Use a carburetor cleaner to remove any residue from the jets and internal parts. Regular cleaning helps maintain a smooth engine performance and fuel delivery.

Step 5: Verify Compression

Low compression can lead to hard starts or weak power output. Use a compression gauge to measure the engine’s compression level. If the reading is below the manufacturer’s recommended range, internal wear may be present, indicating a need for more detailed mechanical assessment.

By following these steps, many engine problems can be identified early, helping maintain optimal operation and prolonging engine life. For complex issues, however, seeking professional assistance is advisable.

Replacing the Blades Effectively

Changing the cutting elements is crucial for maintaining optimal performance and ensuring a clean cut in your equipment. Regularly replacing dull blades not only enhances efficiency but also prolongs the lifespan of the device. This section outlines the steps for executing this task effectively, ensuring that your machine operates at its best.

To begin the process, it is essential to gather the necessary tools and follow safety precautions. Always disconnect the power source before starting any maintenance work. The following table provides a list of required tools and materials:

Tool/Material Purpose Wrench For loosening and tightening bolts Replacement Blades New cutting elements Screwdriver For removing any cover plates Protective Gloves To ensure safety while handling sharp components After gathering the tools, proceed to remove the old blades carefully. Make sure to follow the manufacturer’s guidelines for blade removal and installation. Once the new blades are in place, check for secure fittings to prevent any operational issues during use.

Cleaning and Caring for the Deck

Maintaining the integrity and cleanliness of your equipment’s deck is essential for optimal performance and longevity. Regular upkeep not only enhances the appearance but also prevents potential damage that can arise from neglect.

Here are some effective steps to ensure your deck remains in top condition:

- Remove Debris: After each use, clear the deck of grass clippings, leaves, and other debris. This prevents buildup that can lead to rust or corrosion.

- Wash the Surface: Use a mild detergent mixed with water and a soft brush to scrub the deck. Avoid harsh chemicals that could damage the finish.

- Dry Thoroughly: After washing, ensure that the deck is completely dry. This minimizes the risk of moisture-related issues.

- Inspect for Damage: Regularly check for any cracks, dents, or signs of wear. Addressing these issues promptly can prevent further damage.

- Apply Protective Coating: Consider applying a protective wax or sealant to enhance durability and resist corrosion.

By following these simple care practices, you can significantly extend the life of your deck and maintain its functionality throughout its use.

Adjusting the Cutting Height

Modifying the height of the cutting blades is essential for achieving the desired grass length and overall lawn health. This adjustment allows you to tailor the mower’s performance to various grass types and seasonal conditions, ensuring optimal results.

To effectively change the cutting height, follow these steps:

Step Description 1 Locate the height adjustment lever or knob, usually found on the mower’s chassis. 2 Decide on the preferred cutting height based on your lawn’s requirements. 3 Adjust the lever or knob to raise or lower the cutting blades accordingly. 4 Ensure both sides of the mower are set to the same height for an even cut. 5 Test the mower on a small patch of grass to confirm the new height is suitable. Regularly checking and adjusting the cutting height will contribute to a healthier and more attractive lawn.

Battery and Fuel System Checks

Ensuring the optimal performance of your equipment requires regular assessments of the energy source and the fuel mechanism. These evaluations are crucial for identifying potential issues that could hinder functionality and efficiency.

Battery Inspection: Start by examining the battery for any signs of corrosion or damage. Clean the terminals gently with a wire brush to prevent poor connections. Additionally, check the voltage using a multimeter to confirm that it meets the recommended specifications.

Fuel System Evaluation: Inspect the fuel lines and filter for blockages or leaks. Ensure that the fuel is clean and fresh, as stale fuel can lead to operational problems. It is also important to verify that the carburetor is free of debris and functioning properly to maintain optimal fuel delivery.

By performing these checks regularly, you can prolong the lifespan of your equipment and ensure reliable performance.

Tips for Winter Storage

Proper winter storage is essential for maintaining the longevity and performance of your equipment. By taking a few simple steps, you can ensure that it remains in excellent condition during the colder months. This section outlines effective strategies to prepare your machine for storage, safeguarding it from potential damage caused by harsh winter weather.

Preparation Steps

Before storing your equipment, follow these important steps to ensure its protection:

Step Description Clean Thoroughly Remove any dirt, grass, or debris from the surface to prevent corrosion and damage. Drain Fluids Empty the fuel tank and oil reservoir to avoid leaks and deterioration during storage. Check Battery Disconnect and store the battery in a cool, dry place to prolong its lifespan. Cover the Equipment Use a breathable cover to protect from dust and moisture while allowing air circulation. Maintenance Tips

Consider these additional maintenance tips to enhance the condition of your equipment:

- Inspect all parts regularly for wear and tear.

- Lubricate moving components to prevent rust and ensure smooth operation.

- Store in a sheltered area to protect against extreme weather conditions.

Upgrading Your HRR216 Features

Enhancing your lawn mower can significantly improve its performance and efficiency. Whether you aim to boost cutting capabilities or add new functionalities, there are several ways to modernize your equipment for a more effective mowing experience.

One popular upgrade is to install a high-performance blade. A sharper and more efficient blade can provide a cleaner cut, ensuring your lawn stays healthy and vibrant. Additionally, consider integrating a mulching kit. This accessory allows the mower to finely chop grass clippings, returning nutrients to the soil and reducing the need for additional fertilizers.

Another valuable enhancement is adding a bagging system. This feature collects grass clippings, minimizing cleanup time and helping maintain a tidy yard. Furthermore, upgrading the engine or adding a throttle control can enhance power and fuel efficiency, providing you with better performance during extended use.

Lastly, think about integrating smart technology. Features like a lawn monitoring system can help you keep track of mowing schedules and grass health, making maintenance more manageable and efficient.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks. Proper precautions not only protect the individual performing the tasks but also enhance the effectiveness of the procedures being executed. This section outlines essential safety measures to keep in mind during such activities.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Keep all tools and materials organized to prevent accidents and improve efficiency.

- Disconnect the power source before starting any work to eliminate the risk of electric shock.

- Follow the manufacturer’s guidelines for safe handling and usage of specific components.

Being aware of your surroundings is essential. Maintain a clutter-free area, and ensure that emergency exits are easily accessible. Regularly inspect tools and equipment for any signs of damage before use.

Additionally, familiarize yourself with basic first aid procedures. In case of an emergency, knowing how to respond can significantly mitigate risks and injuries. Always have a first aid kit on hand and ensure that it is stocked and ready for use.

Finding Genuine Honda Parts

When it comes to maintaining and enhancing the performance of your equipment, sourcing authentic components is essential. Genuine parts not only ensure compatibility but also contribute to the longevity and efficiency of the machine. This section will guide you through the process of locating these high-quality components.

Why Choose Authentic Components?

Using original parts has numerous advantages:

- Quality Assurance: Genuine components are manufactured to the highest standards, ensuring durability.

- Perfect Fit: They are designed specifically for your equipment, reducing the risk of malfunction.

- Warranty Protection: Many manufacturers offer warranties on their parts, providing peace of mind.

Where to Find Genuine Parts

Here are several reliable sources to consider:

- Authorized Dealers: These are the best places to find authentic components, as they are directly connected to the manufacturer.

- Official Websites: Many manufacturers have online stores where you can browse and purchase parts directly.

- Reputable Retailers: Look for retailers with a good reputation that specialize in quality components.

- Online Marketplaces: Be cautious, but many platforms offer genuine parts. Check reviews and seller ratings.