In the world of two-wheeled machines, understanding the intricacies of maintenance is essential for optimal performance and longevity. This section delves into the essential practices and knowledge needed to keep your ride in top shape, ensuring a smooth and enjoyable experience on the road or track.

Whether you are a seasoned enthusiast or a newcomer to the realm of motorcycling, having access to detailed information is invaluable. From troubleshooting common issues to conducting routine check-ups, this guide offers insights that cater to a wide range of needs and skill levels.

Proactive care not only enhances your vehicle’s reliability but also contributes to your safety. By familiarizing yourself with the key components and systems, you can identify potential problems before they escalate, ensuring a seamless journey every time you hit the throttle. Embrace the journey of knowledge as you empower yourself to tackle various maintenance tasks with confidence.

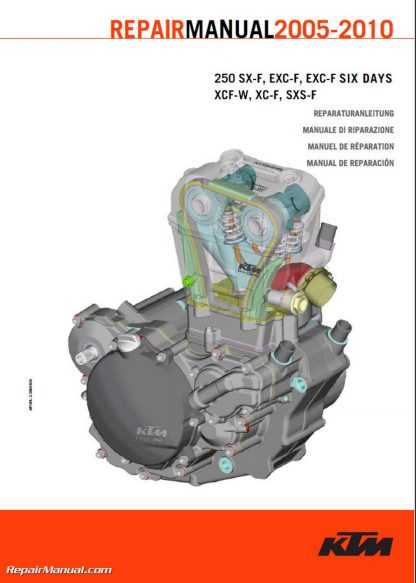

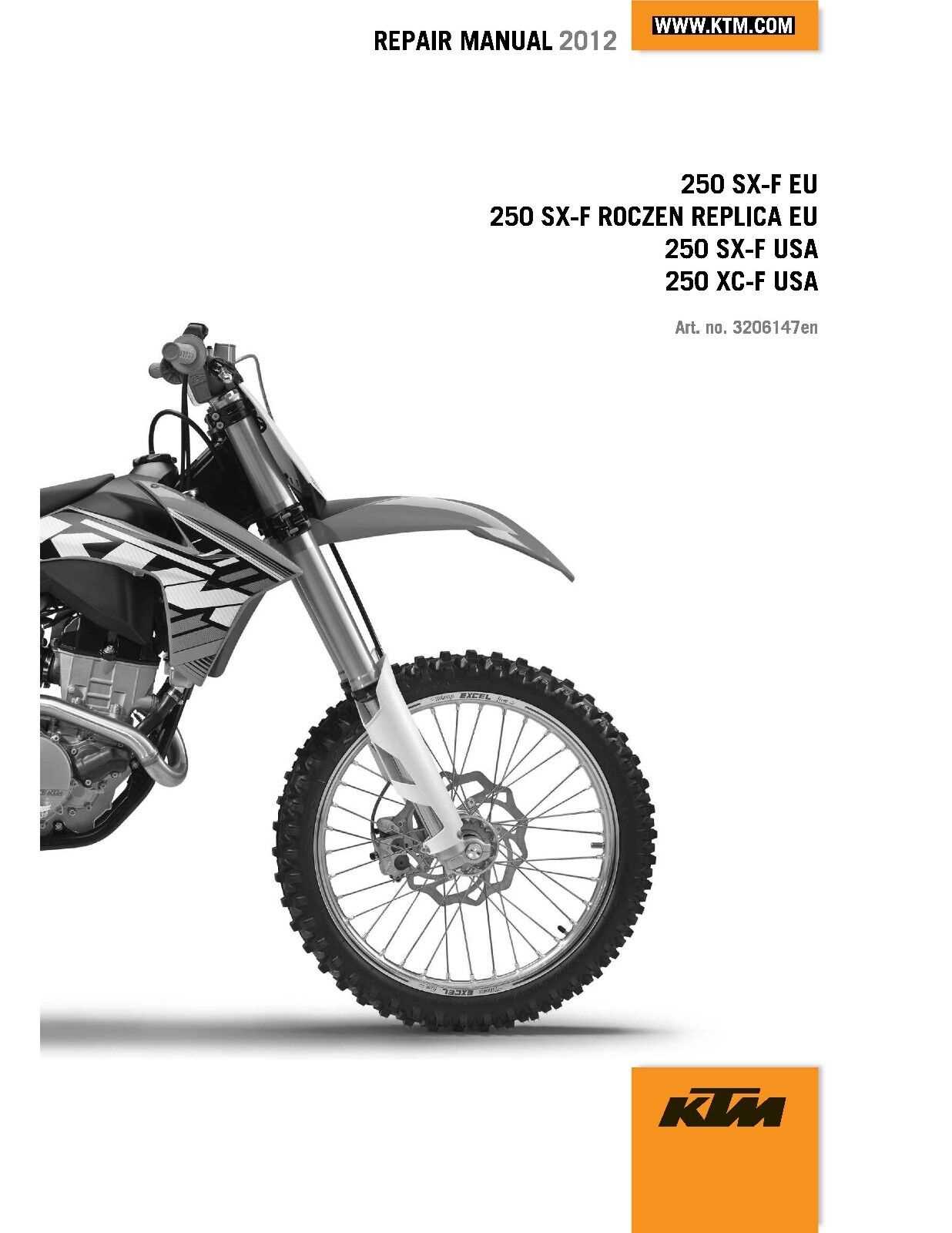

Overview of KTM 250SXF 2012

This section provides an in-depth examination of a specific model known for its exceptional performance in off-road racing. The vehicle is designed to deliver power, agility, and reliability, making it a favorite among competitive riders. Its engineering incorporates advanced technology, ensuring that it meets the demands of various terrains and conditions.

Key Features

- Lightweight frame for enhanced maneuverability

- Powerful engine with optimized torque delivery

- Advanced suspension system for superior handling

- High-performance braking system for improved safety

Performance and Handling

The model excels in various racing scenarios, offering a balance between speed and control. With a focus on rider feedback, the design promotes confidence in navigating challenging tracks.

- Responsive throttle for quick acceleration

- Stable chassis that adapts to rough terrain

- Customizable settings for individual rider preferences

Common Issues with KTM 250SXF

Motorcycles often encounter various challenges that can affect their performance and longevity. Identifying these issues early can save time and reduce repair costs. Below are some prevalent problems associated with this particular model.

- Electrical Failures: Many riders report issues with the electrical system, including faulty wiring and battery problems. Regular checks can help avoid unexpected breakdowns.

- Overheating: Insufficient cooling can lead to overheating. Ensuring the coolant levels are appropriate and the radiator is clean can mitigate this risk.

- Clutch Problems: Slipping or grabbing of the clutch is a common complaint. Regular maintenance and proper adjustments are essential for optimal function.

- Suspension Issues: Riders often experience discomfort due to improper suspension settings. Regular tuning and inspections can enhance ride quality.

- Fuel System Troubles: Clogs in the fuel lines or issues with the injector can cause performance drops. Regular cleaning and checks can prevent these issues.

lessCopy code

Addressing these concerns promptly will not only enhance the riding experience but also prolong the lifespan of the motorcycle. Regular maintenance and awareness of potential problems are key to keeping your machine in top shape.

Tools Needed for Repairs

When maintaining and fixing your off-road machine, having the right tools is essential for efficient and effective work. Proper equipment not only speeds up the process but also ensures that tasks are completed safely and correctly. Below is a comprehensive list of essential items you will need for various maintenance tasks.

- Socket Set: A variety of sockets for different sizes of nuts and bolts.

- Wrenches: Adjustable and fixed wrenches for securing and loosening components.

- Screwdrivers: Flathead and Phillips screwdrivers in multiple sizes.

- Pliers: Needle-nose and slip-joint pliers for gripping and bending.

- Torque Wrench: To ensure proper tightening of fasteners.

In addition to the basic tools, some specialized equipment may also be beneficial:

- Chain Breaker: For adjusting or replacing the drive chain.

- Oil Filter Wrench: To remove and replace oil filters with ease.

- Stand: A sturdy platform for elevating the bike for maintenance.

- Feeler Gauges: To measure gap sizes for valve adjustments.

- Impact Driver: Useful for loosening stubborn screws and bolts.

Investing in quality tools will not only improve your repair experience but will also extend the lifespan of your machine. Make sure to keep your toolbox organized and regularly check the condition of your tools to ensure they are ready for any task.

Engine Maintenance Tips

Proper upkeep of the power unit is essential for optimal performance and longevity of your motorcycle. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Below are some essential practices to ensure your engine remains in top condition.

Regular Oil Changes

Changing the oil frequently is crucial for maintaining engine health. Oil lubricates moving parts, reducing friction and wear. Always refer to your vehicle’s specifications to determine the appropriate type and frequency of oil changes. Neglecting this step can lead to sludge buildup and potential engine failure.

Check and Clean Air Filters

A clean air filter is vital for optimal airflow and performance. Regularly inspect and replace or clean the air filter as needed. Clogged filters can restrict airflow, leading to decreased power and increased fuel consumption. Maintaining proper airflow ensures that your engine runs efficiently.

Suspension Setup Guidelines

Proper suspension tuning is crucial for enhancing performance, stability, and rider comfort on the track or trail. By adjusting various components, riders can optimize handling characteristics to suit their individual preferences and riding styles. This section outlines essential steps to achieve an ideal suspension setup.

Key Factors to Consider

- Rider Weight: Adjustments should be based on the total weight of the rider in gear. Spring rates are typically chosen according to this measurement.

- Riding Style: Different styles, such as aggressive cornering or casual cruising, require specific tuning for maximum effectiveness.

- Terrain Type: The type of surface being navigated–whether it’s rough, smooth, or mixed–will influence the setup.

Steps for Tuning Suspension

- Set Sag: Measure and adjust the sag to ensure proper weight distribution. This is essential for maintaining balance and responsiveness.

- Compression Damping: Adjust compression settings based on how the suspension reacts to bumps and obstacles. A stiffer setting may be beneficial for aggressive riding, while softer settings enhance comfort on smoother terrain.

- Rebound Damping: Fine-tune the rebound to control how quickly the suspension returns after compressing. Proper rebound is vital for maintaining traction and control.

- Test and Refine: After making adjustments, conduct test rides to evaluate the changes. Continue refining the setup based on feedback from the ride.

By methodically following these guidelines, riders can achieve an optimal suspension setup that maximizes performance and comfort, allowing for an enhanced riding experience.

Electrical System Troubleshooting

Diagnosing issues within the electrical components of a motorcycle can be challenging yet essential for optimal performance. Proper understanding of the wiring, connections, and circuitry is crucial for identifying problems that may affect ignition, lighting, or starting systems.

Begin with a systematic approach. Start by visually inspecting all wiring harnesses for signs of wear, corrosion, or damage. Ensure that all connectors are secure and free from dirt or moisture, as these factors can lead to electrical failures.

Check the battery first, as it serves as the primary power source. Measure the voltage to confirm it is within the recommended range. If the battery appears weak or shows signs of leakage, it may need to be replaced.

Next, test the fuses. A blown fuse can disrupt the entire electrical system. Replace any faulty fuses and retest the affected components. If the new fuse blows immediately, further investigation into the circuitry is necessary.

Utilize a multimeter to test continuity and voltage throughout the system. This tool allows for precise measurements and can help pinpoint issues in wiring or components such as relays and switches. Make sure to follow the circuit paths to identify any open circuits or shorts.

Finally, consult wiring diagrams specific to the model in question. These diagrams provide invaluable guidance for understanding how components are interconnected and can assist in tracking down elusive electrical issues.

Brake System Maintenance Steps

Ensuring the optimal performance of the braking mechanism is crucial for safety and functionality. Regular upkeep not only prolongs the life of the components but also enhances the overall riding experience. Below are essential steps to maintain the brake system effectively.

Inspection of Brake Components

Start by examining the brake pads for wear and tear. Replace them if they are worn down to the indicator line. Next, inspect the brake rotors for any signs of damage or warping. Clean the surfaces with a suitable solvent to remove debris and dust.

Fluid Maintenance

Check the brake fluid level in the reservoir. If it appears low, top it up with the appropriate type of fluid as specified by the manufacturer. Additionally, consider flushing the system periodically to remove old fluid, which can absorb moisture over time and affect performance.

Regular Oil Change Procedures

Maintaining optimal engine performance requires routine oil changes, an essential task for preserving the longevity and efficiency of your machine. Regularly refreshing the lubricant not only ensures smooth operation but also helps to prevent wear and tear on internal components.

To perform an oil change, begin by warming up the engine briefly. This helps to thin the oil, allowing for a more thorough drainage. Next, securely position the vehicle on a stable surface and gather the necessary tools, including an oil catch pan, wrench, and fresh lubricant. Once prepared, remove the drain plug and allow the old oil to flow completely into the pan.

After draining, replace the drain plug securely and proceed to remove the old oil filter, if applicable. Install a new filter, applying a thin layer of fresh oil to the gasket to ensure a proper seal. Finally, refill the engine with the appropriate amount of new oil, checking the dipstick to confirm the correct level.

After the procedure, start the engine and let it run for a few moments to circulate the new oil, then check for any leaks around the filter and drain plug. Regularly monitoring the oil level and quality will help maintain optimal performance and extend the life of your machine.

Frame Inspection and Repair

Ensuring the integrity of the chassis is essential for optimal performance and rider safety. Regular assessments of the frame can identify wear and damage that may compromise the bike’s handling and stability. Addressing these issues promptly can prolong the lifespan of the motorcycle and enhance the riding experience.

Visual Inspection

Begin with a thorough visual examination of the frame for any signs of cracks, bends, or corrosion. Pay close attention to high-stress areas such as the mounting points and joints. Look for any surface imperfections that might indicate underlying problems. Additionally, check for any loose bolts or fasteners that could lead to structural weaknesses.

Structural Integrity Assessment

After the visual check, perform a more detailed assessment. Utilize a straight edge to verify alignment and identify any misalignment issues. If any structural concerns are detected, it may be necessary to engage a professional for specialized techniques such as welding or frame straightening. Maintaining the frame’s integrity is crucial for safe and reliable operation on various terrains.

Upgrading Performance Parts

Enhancing the performance of your motorcycle can significantly improve your riding experience, offering better acceleration, handling, and overall responsiveness. This section explores various components that can be upgraded to unlock the full potential of your machine.

Key Areas for Improvement

- Engine Modifications: Upgrading the engine can lead to increased horsepower and torque. Consider options such as high-performance pistons, camshafts, and exhaust systems.

- Suspension Upgrades: Improved suspension can enhance stability and comfort. Investing in adjustable forks and rear shocks can provide better control over rough terrains.

- Braking System: Better stopping power is essential for safety. Upgrading to high-performance brake pads and rotors can enhance your braking efficiency.

- Fuel System Enhancements: Optimizing the fuel system with a larger throttle body or upgraded injectors can improve air-fuel mixture, resulting in better performance.

Installation Tips

- Research compatible parts that fit your specific model to avoid compatibility issues.

- Consider professional installation if you are not experienced with motorcycle mechanics.

- Test your motorcycle after each upgrade to assess performance improvements and ensure everything is functioning correctly.

Finding Replacement Parts Efficiently

Locating components for your motorcycle can often be a daunting task, but with the right approach, you can streamline the process. Understanding where to search and what resources are available can save you both time and money, ensuring your bike stays in optimal condition without unnecessary delays.

Utilizing Online Resources

The internet is a treasure trove of information when it comes to sourcing motorcycle parts. Websites specializing in motorcycle components often provide extensive catalogs, allowing you to filter by brand, model, and type of part. Additionally, forums and social media groups dedicated to biking enthusiasts can offer insights and recommendations from experienced riders who have faced similar challenges.

Local Dealerships and Salvage Yards

Your local dealership can be an excellent resource for genuine parts, especially if you’re seeking items that are hard to find elsewhere. They often have access to the latest inventory and can provide expert advice. Conversely, salvage yards can be a cost-effective option for used parts, allowing you to find quality components at reduced prices while also supporting sustainability in the biking community.