Ensuring the smooth operation and longevity of a vehicle often depends on understanding its core systems and maintenance needs. This section provides a detailed breakdown of essential upkeep strategies, helping drivers keep their vehicles in optimal condition, even as they age. By following these structured guidelines, owners can tackle common issues confidently, reducing the likelihood of unexpected mechanical setbacks.

In addition to routine servicing tips, this guide explores specific aspects of vehicle functionality. Whether facing minor adjustments or more substantial work, these insights serve as a reliable reference, detailing important considerations for various system checks and component inspections. With clear explanations, this section aims to demystify the complexities of automotive care, making maintenance accessible and manageable for every owner.

For those navigating more advanced challenges, we also provide targeted advice on identifying and addressing particular system behaviors that may require extra attention. Utilizing this resource empowers owners to stay informed and proactive, fostering a sense of confidence and independence in vehicle

2007 Hyundai Sonata Repair Manual

In this section, you will find essential insights for maintaining and servicing this vehicle model, focusing on effective approaches and step-by-step procedures. Here, detailed explanations and organized instructions will guide you through the process of addressing various mechanical and electrical needs, ensuring smooth and reliable performance.

Routine Maintenance Checklist

Regular upkeep is crucial to ensure longevity and efficient operation. Below is a list of tasks that should be checked periodically to maintain optimal condition:

- Fluid levels: Keep an eye on oil, brake, and coolant levels to prevent overheating and ensure proper functioning of essential systems.

- Brakes: Inspect the condition of brake pads and rotors to ensure safe stopping power.

- Tires: Regularly check tire pressure and tread wear to maintain traction and reduce wear on the vehicle.

Troubleshooting Common Issues

This model may encounter common issues over time. Here are some frequent problems and possible solutions:

- Engine misfires: Check spark plugs and ignition coils; replacing these can improve engine performance and fuel efficiency.

- Transmission delays: Fluid replacement or adjustment may be necessary to address slipping or delayed gear shifts.

- Electrical system malfunctions: Inspect fuses and wiring connections, as these are often the sou

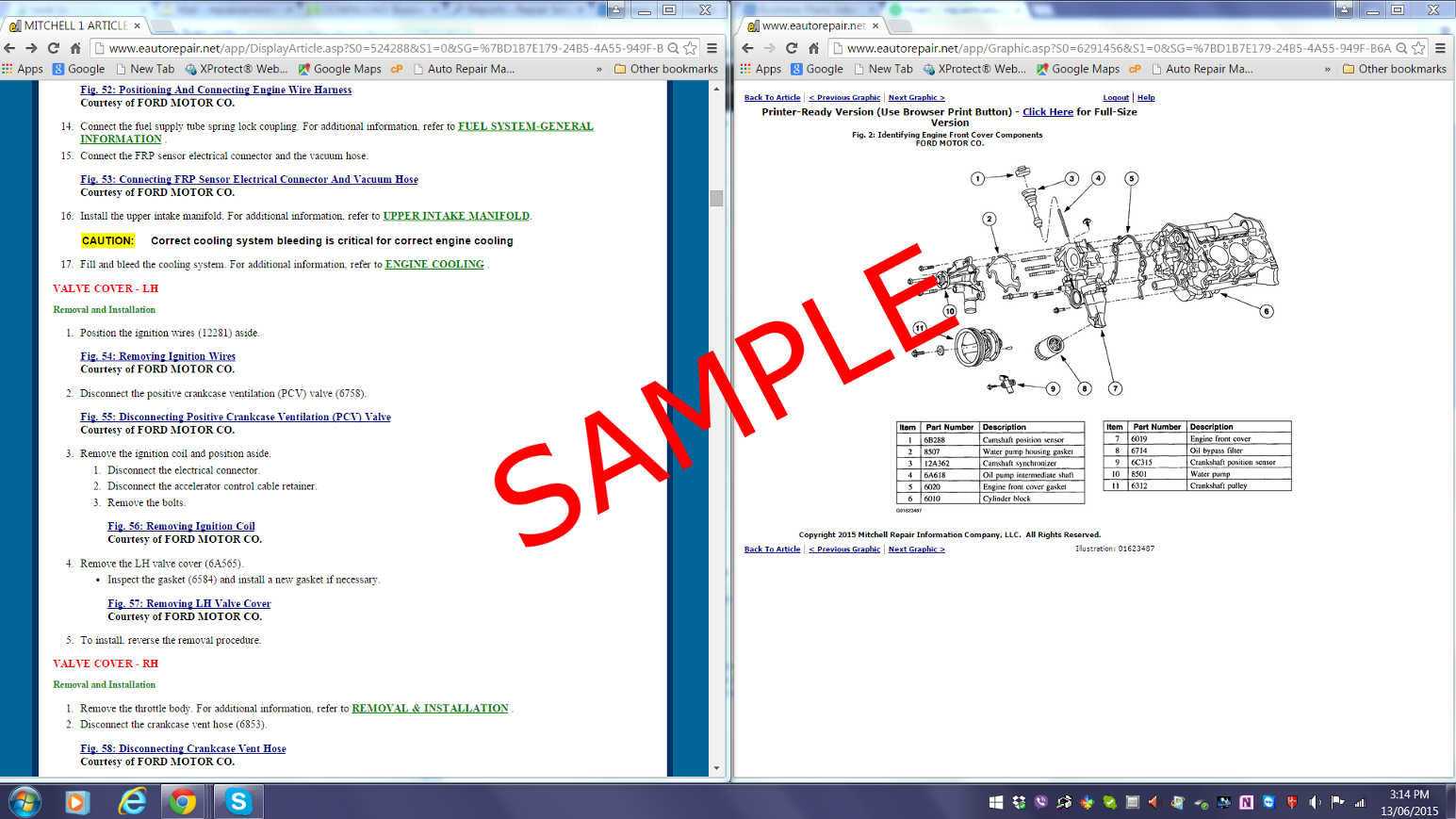

Engine Maintenance Essentials

Maintaining your engine’s health is crucial for achieving optimal performance and extending its lifespan. Proper upkeep ensures that each component functions smoothly, reducing wear and preventing potential issues from escalating into costly repairs. A well-maintained engine also contributes to better fuel efficiency, smoother operation, and reduced emissions, all of which enhance the overall driving experience.

Regular Oil Changes: Fresh oil is vital for lubricating engine parts, preventing friction, and reducing heat. Following a consistent schedule for oil changes is one of the most effective ways to keep your engine running smoothly. Make sure to choose high-quality oil and replace the oil filter to keep contaminants at bay.

Inspect and Replace Air Filters: Clean air is essential for combustion efficiency. A clogged air filter restricts airflow, leading to poor performance and increased fuel consumption. Regularly checking and replacing the air filter ensures that the engine breathes easily, allowing for optimal power output.

Transmission Troubleshooting and Solutions

Understanding how to identify and address transmission issues can help extend the life of your vehicle and ensure a smooth driving experience. Common transmission problems can range from unusual noises to difficulty shifting gears, and recognizing these symptoms early is key to effective maintenance. Regular inspections and timely repairs can prevent minor issues from becoming costly problems.

One of the first steps in diagnosing transmission concerns is checking the fluid level and quality. Low or degraded fluid can cause slipping, overheating, or delayed shifting. In many cases, topping up or replacing the fluid can resolve these issues. However, if the fluid level is correct and symptoms persist, further inspection of the transmission components may be necessary.

If unusual sounds such as grinding or whining are present, these could indicate wear on internal parts, requiring closer examination by a technician. Similarly, delayed engagement or hard shifts may signal that specific components, such as the clutch or solenoid, need attention or replacement. Regular servicing of the transmission system, including fluid flushes and inspections, is essential to prevent further wear.

While some transmission problems can be fixed with simple maintenance, others

Suspension System Overview

The suspension system plays a vital role in ensuring stability, control, and comfort during vehicle operation. Designed to absorb road imperfections and manage the force of impact, this system keeps the wheels connected to the road surface, enhancing grip and smoothness across various terrains. An effective suspension setup distributes weight evenly, which aids in handling and braking efficiency.

Components of the suspension include springs, dampers, and linkages, each with a distinct function to provide stability and reduce the effects of bumps or irregular surfaces. Springs bear the vehicle’s weight, while dampers, or shock absorbers, control oscillations, ensuring that the wheels remain grounded even on uneven roads. Linkages work together to maintain alignment, which is crucial for both safety and overall performance.

Understanding how these parts interact can aid in diagnosing issues related to handling, unusual noises, or uneven tire wear. Regular inspection and maintenance of suspension components contribute to the longevity and reliability of the entire system, ensuring a balanced and comfortable ride.

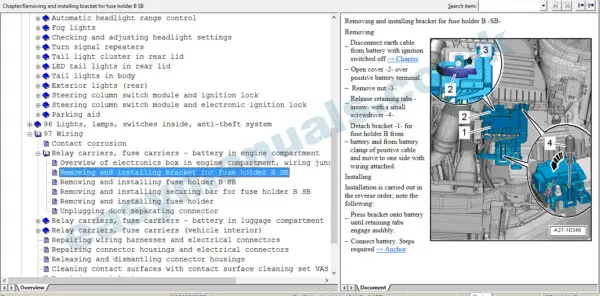

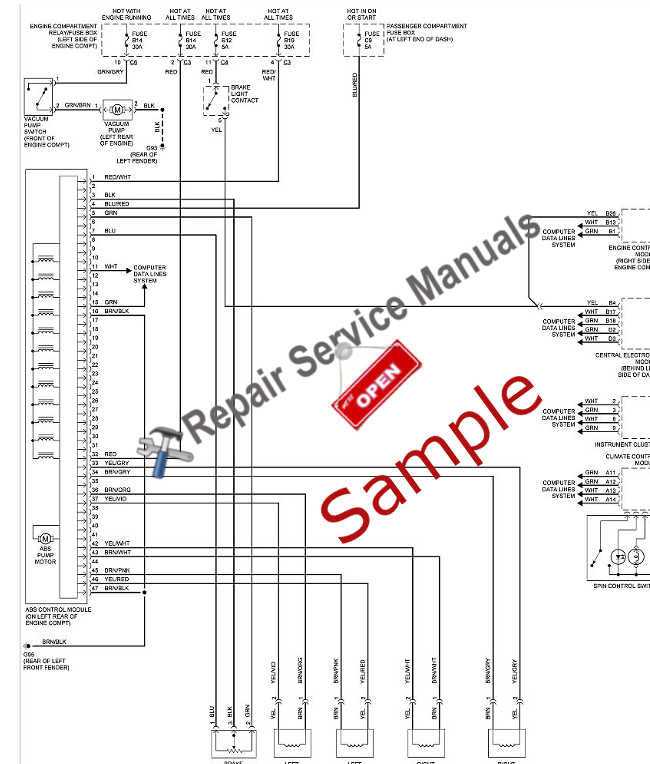

Electrical Wiring Basics

Understanding the essentials of automotive electrical wiring is key for maintaining vehicle functionality and safety. This section covers the core principles of connecting electrical components and the foundational practices needed to ensure consistent performance.

Common Types of Wires and Connectors

Different types of wires and connectors serve specific purposes within the electrical system. Each type must be selected carefully based on its intended function and current requirements to prevent issues.

- Primary Wires: Commonly used for general connections, these wires carry current between various components and are available in various gauges.

- Ground Wires: Grounding wires ensure safe operation by redirecting excess current to prevent overloads and short circuits.

- Battery Cables: Thick, high-capacity cables connecting the battery to the starter and electrical system, providing the necessary power for operation.

Basic Wiring Safety Tips

When working with wiring, it is crucial to follow safety practices to avoid damage to components or risk of injury.

- Disconnect Power: Always disconnect the vehicle’s power source before handling any wiring to reduce the risk of electric shock.

- Use Correct Tools: Specialized tools, like crimpers and wire strippers, ensure secure connections and help avoid damage to wires and connectors.

- Secure Connections Properly: Ensure that all connections are tight and insula

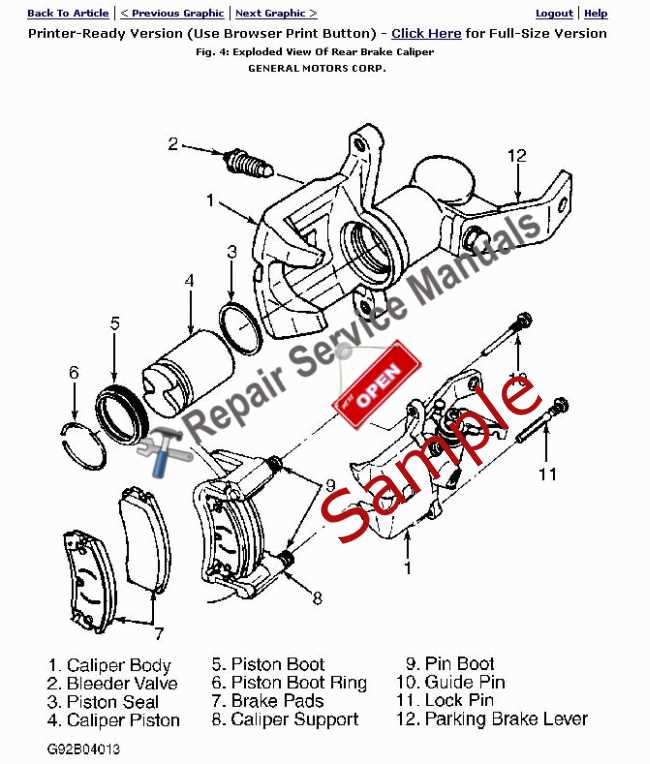

Brake System Inspection Guide

Ensuring the optimal performance of the braking mechanism is crucial for vehicle safety. Regular assessment of this system not only enhances performance but also prolongs the lifespan of various components. This guide outlines essential steps for conducting a thorough examination of the braking apparatus.

1. Visual Inspection: Begin by examining the brake pads, rotors, and calipers for signs of wear and damage. Look for uneven wear patterns, cracks, or excessive rust. Ensure that all components are securely fastened and free from leaks.

2. Brake Fluid Check: Inspect the brake fluid reservoir for appropriate levels and clarity. Contaminated or low fluid can affect braking efficiency. If necessary, replace the fluid to maintain optimal function.

3. Performance Test: Conduct a test drive to evaluate braking response. Listen for unusual noises such as squeaking or grinding, which may indicate worn pads. Pay attention to the pedal feel; it should be firm and responsive, with no excessive travel.

4. Component Functionality: Check the operation of the brake lights and anti-lock braking system (ABS). Ensure all sensors are functioning correctly and that there are no warning lights on the dashboard.

Regular maintenance and inspection of the braking system are essential for safe driving. By following these guidelines, you can identify potential issues early and ensure reliable operation.

Cooling System Repairs

The cooling system is a crucial component that maintains optimal engine temperature, preventing overheating and ensuring efficient operation. When issues arise within this system, timely attention is essential to avoid more severe damage. This section outlines common problems and the necessary steps to address them effectively.

Common Issues

- Leaking coolant

- Overheating engine

- Faulty thermostat

- Clogged radiator

Repair Steps

- Inspect the coolant level and top up if necessary, using the appropriate fluid.

- Check for leaks in hoses, connections, and the radiator. Replace any damaged components.

- Test the thermostat by removing it and placing it in boiling water. If it does not open, replace it.

- Flush the radiator to remove any blockages that may hinder fluid flow.

- Ensure that the radiator fan operates correctly, as it plays a vital role in regulating temperature.

By following these guidelines, vehicle owners can maintain their cooling system’s efficiency, ensuring longevity and reliability.

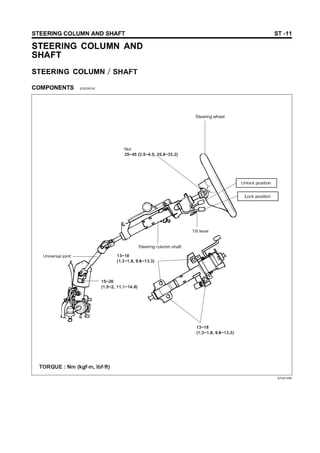

Steering Mechanism Adjustments

The steering system is a critical component that ensures precise handling and maneuverability of the vehicle. Proper alignment and adjustments are essential for maintaining optimal performance and safety. This section outlines the necessary procedures to fine-tune the steering apparatus, enhancing responsiveness and driving comfort.

Alignment Procedures

To achieve accurate alignment, it is important to check the angles of the wheels. This involves measuring the camber, caster, and toe settings, which affect how the wheels interact with the road surface. Using specialized equipment, adjustments can be made to ensure that all parameters fall within the manufacturer’s specifications. Regularly inspecting these angles can prevent uneven tire wear and improve handling.

Power Steering System Checks

The power assistance feature in the steering system should also be assessed for proper functionality. Ensure that the fluid level is adequate and that there are no leaks in the system. Listening for unusual noises during operation can indicate potential issues that may require further investigation. Regular maintenance of the power steering system is crucial for effortless steering and overall vehicle control.

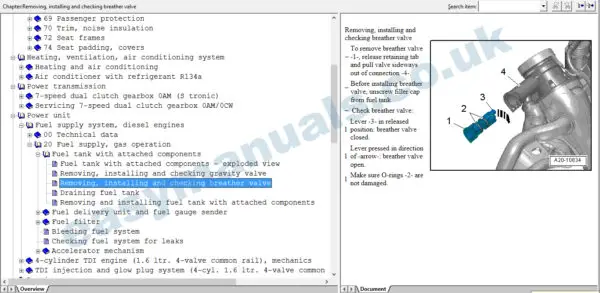

Fuel System Servicing Tips

Proper maintenance of the fuel system is essential for optimal engine performance and longevity. Regularly addressing potential issues can help prevent costly repairs and ensure efficient operation. Below are some valuable suggestions for maintaining this critical component of your vehicle.

Regular Inspections

Conducting routine checks of the fuel system can identify early signs of wear or damage. Look for any leaks, cracks, or signs of corrosion on fuel lines and connectors. Inspect the fuel filter periodically to ensure it is not clogged, as a clean filter promotes better fuel flow and engine efficiency.

Quality Fuel and Additives

Using high-quality fuel and reputable fuel additives can significantly impact the performance of your engine. Consider using fuel stabilizers to prevent degradation during long periods of inactivity. Additionally, incorporating a fuel injector cleaner can help maintain clean injectors, enhancing fuel atomization and combustion efficiency.

In conclusion, consistent attention to the fuel system through inspections and quality fuel choices can lead to improved vehicle performance and reliability.

Exhaust System Maintenance

Proper upkeep of the exhaust system is essential for ensuring optimal vehicle performance and compliance with emissions regulations. Regular inspections and timely repairs can prevent costly damage and improve fuel efficiency. This section outlines the key aspects of maintaining this crucial component of your vehicle.

Inspection Procedures

Routine examination of the exhaust system helps identify potential issues before they escalate. Check for visible signs of wear, such as rust, holes, or loose connections. Additionally, listen for unusual noises that may indicate exhaust leaks, which can affect engine performance and lead to harmful emissions.

Common Maintenance Practices

Regular maintenance tasks include replacing worn-out gaskets and seals, tightening loose connections, and cleaning the exhaust pipes to prevent buildup. Keeping the exhaust system free from obstructions enhances airflow and efficiency. Following the manufacturer’s guidelines for replacement intervals can help ensure longevity.

Maintenance Task Frequency Visual Inspection Every 6 months Gasket Replacement As needed Exhaust Pipe Cleaning Annually Professional Inspection Every 2 years Body Repair and Care Techniques

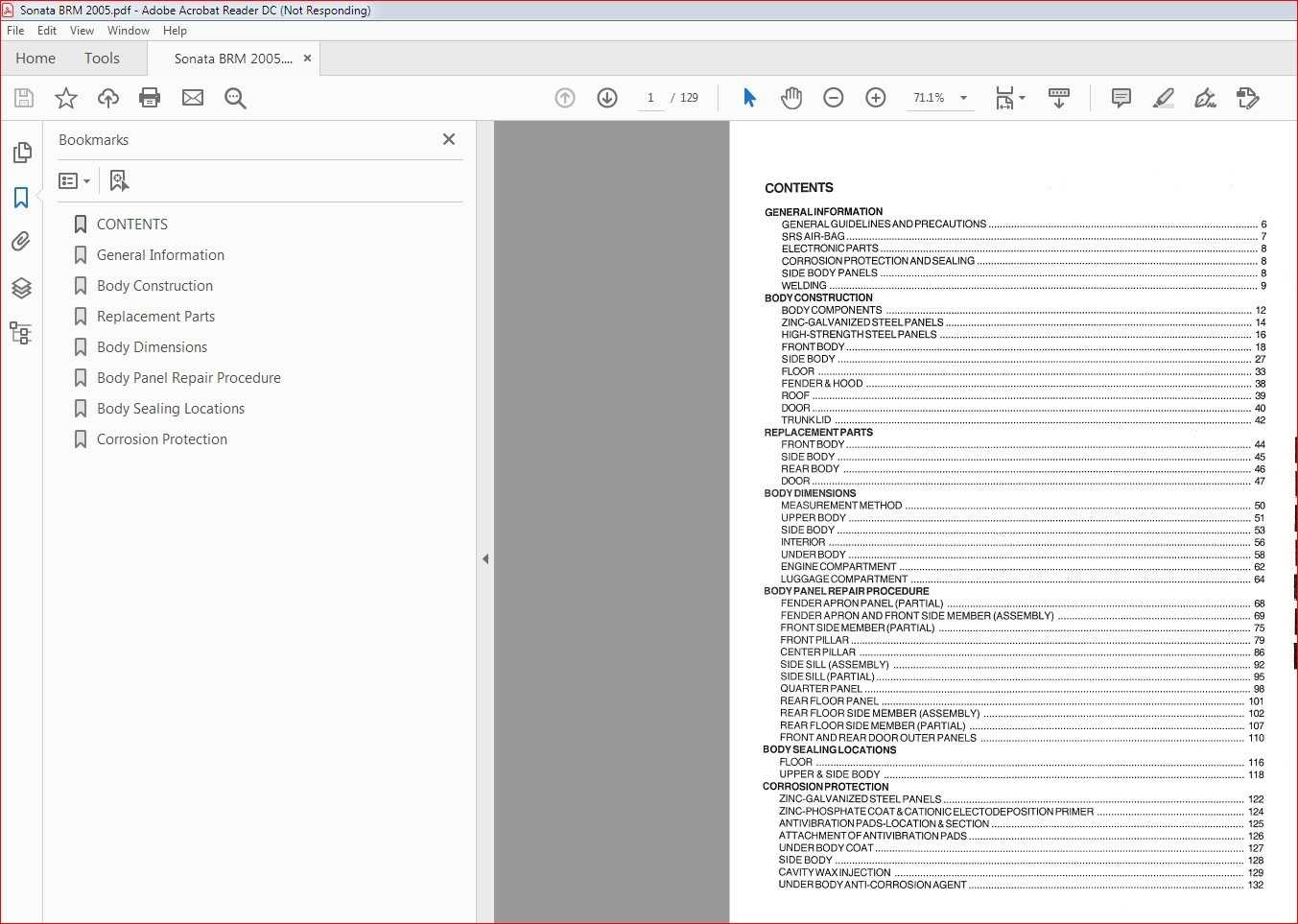

Maintaining the exterior of a vehicle is crucial for both aesthetics and longevity. Proper methods for addressing damage and preserving the surface can significantly enhance the overall appearance and functionality of the automobile. This section delves into effective approaches to ensure the body remains in optimal condition.

Assessing Damage: The first step in any restoration process is a thorough evaluation of the affected areas. Identifying dents, scratches, or corrosion is essential for determining the best course of action. Visual inspections, combined with touch tests, can help pinpoint imperfections that require attention.

Surface Preparation: Before any treatment, it is vital to prepare the surface adequately. This includes cleaning the area with a suitable detergent to remove dirt and grease. Following this, sanding the damaged regions ensures proper adhesion of repair materials. Use fine-grit sandpaper to smooth out rough edges and create a uniform surface.

Applying Treatments: Depending on the type and extent of damage, various techniques may be employed. For minor dents, methods such as suction cups or specialized tools can restore the shape without extensive work. For scratches, touch-up paint or clear coat can effectively mask imperfections. In cases of rust, a rust converter or primer should be applied before repainting to prevent further deterioration.

Finishing Touches: Once repairs are complete, the final step is polishing the surface to restore its shine. A high-quality polish can enhance the vehicle’s appearance, making it look like new. Regular waxing after repairs helps protect the finish from environmental factors, prolonging the life of the restoration.

By following these techniques, vehicle owners can ensure their automobiles remain in excellent condition, enhancing both appearance and value.

Diagnostic Tools and Techniques

Effective troubleshooting of automotive issues relies heavily on the right equipment and methodologies. Utilizing appropriate diagnostic instruments can significantly enhance the process of identifying and resolving problems in vehicles. These tools not only streamline the assessment but also contribute to accurate and efficient repairs.

Electronic Diagnostic Equipment plays a crucial role in modern automotive diagnostics. Such tools can interface with a vehicle’s onboard computer system to retrieve error codes and performance data. This data helps technicians pinpoint malfunctions and understand the vehicle’s health status. Code readers and scan tools are essential for this purpose, providing insights into potential issues that may not be visible during a visual inspection.

In addition to electronic tools, traditional diagnostic methods remain valuable. Techniques such as visual inspections, listening for unusual sounds, and checking fluid levels are fundamental in the initial stages of troubleshooting. By combining both modern technology and tried-and-true methods, technicians can develop a comprehensive understanding of the vehicle’s condition.

Finally, keeping up with advancements in diagnostic technology is vital. As vehicles evolve, so do the tools required to maintain them. Staying informed about the latest techniques and equipment ensures that technicians can effectively address any challenges that arise, providing reliable solutions for vehicle owners.