For enthusiasts of all-terrain vehicles, understanding the intricacies of maintenance is crucial for ensuring optimal performance and longevity. Proper upkeep not only enhances the driving experience but also prevents costly repairs down the line. This guide aims to equip riders with essential knowledge and practical tips tailored to specific models, facilitating a smoother journey through the realm of vehicle care.

Maintaining a rugged machine requires attention to detail and a thorough grasp of its components. From engine checks to fluid replacements, each aspect plays a vital role in the overall functionality of the vehicle. Emphasizing preventive measures can significantly reduce the risk of breakdowns, allowing for more time spent enjoying the ride.

In this section, you will find a wealth of information designed to help both novice and seasoned riders navigate the complexities of vehicle upkeep. By delving into common issues, troubleshooting methods, and step-by-step instructions, you will be better prepared to tackle maintenance tasks with confidence and ease.

Understanding Honda Foreman 500 Overview

This section aims to provide a comprehensive understanding of a robust all-terrain vehicle designed for both recreational and work-related purposes. This machine is recognized for its durability, reliability, and versatility, making it a popular choice among enthusiasts and professionals alike. Knowing its fundamental characteristics and features can greatly enhance the experience of ownership and usage.

Key Features

The vehicle is equipped with a powerful engine, offering impressive performance across various terrains. Its four-wheel drive system ensures excellent traction, enabling smooth navigation through challenging landscapes. Additionally, the ergonomic design promotes comfort, making long rides less strenuous.

Maintenance Essentials

Regular upkeep is crucial to maintaining optimal performance and longevity. Understanding the basic components, such as the suspension, brakes, and electrical system, can empower users to perform routine checks effectively. Establishing a schedule for maintenance tasks not only prolongs the life of the machine but also enhances safety during operation.

Common Issues with Honda Foreman 500

Understanding the typical problems associated with all-terrain vehicles is crucial for any owner. These machines, while robust, can encounter various mechanical and electrical challenges over time. Identifying and addressing these issues promptly can ensure longevity and optimal performance.

One frequent concern is related to the electrical system, often manifesting as difficulty starting or intermittent power loss. Corroded connections or a failing battery can contribute significantly to these symptoms. Regular maintenance of electrical components can mitigate these risks.

Another common issue involves the transmission system. Owners may experience shifting difficulties or unusual noises while changing gears. These problems may stem from low fluid levels or worn components, making periodic checks essential to maintain smooth operation.

Additionally, suspension troubles are not uncommon. Excessive wear on shock absorbers can lead to a rough ride and compromised handling. Regular inspections can help identify signs of wear before they escalate into more severe problems.

Finally, overheating can be a significant concern, especially during extended use or in harsh conditions. Ensuring proper coolant levels and monitoring the radiator for clogs can help prevent this issue from affecting performance.

Tools Needed for Effective Repairs

When it comes to maintaining and fixing off-road vehicles, having the right equipment is essential for achieving optimal results. The right tools not only facilitate the process but also ensure safety and efficiency. Below is a comprehensive list of necessary instruments that can help in tackling various tasks.

- Basic Hand Tools:

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Socket set

- Specialized Equipment:

- Torque wrench

- Multimeter for electrical diagnostics

- Compression tester

- Safety Gear:

- Safety glasses

- Gloves

- Ear protection

- Maintenance Supplies:

- Oil and filters

- Grease

- Cleaning supplies (solvents and rags)

By equipping yourself with these essential tools, you can ensure that your vehicle remains in peak condition, ready for any adventure that lies ahead.

Step-by-Step Maintenance Guide

Proper upkeep is essential for maximizing the performance and longevity of your all-terrain vehicle. This guide provides a comprehensive approach to routine care, ensuring that your machine operates smoothly and efficiently. By following these steps, you can prevent common issues and enhance the overall riding experience.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace the engine oil and oil filter to keep the engine lubricated and running smoothly. |

| Air Filter Check | Every 50 hours | Inspect and clean the air filter to ensure optimal airflow and engine performance. |

| Tire Inspection | Before each ride | Check tire pressure and tread condition to maintain traction and stability. |

| Brake System Check | Every 100 hours | Examine brake pads and fluid levels to ensure responsive braking. |

| Belt Inspection | Every 200 hours | Inspect drive belts for wear and damage to prevent slippage and failure. |

By adhering to this maintenance schedule, you can safeguard your vehicle against unexpected breakdowns and enjoy a more reliable ride. Regular attention to these tasks will ultimately lead to a more enjoyable and trouble-free experience on the trails.

Engine Troubleshooting Techniques

When facing performance issues with an engine, employing systematic troubleshooting techniques can help identify and resolve problems effectively. This process involves a methodical examination of various components to determine the root cause of malfunctions.

Here are some essential steps to follow during the troubleshooting process:

- Gather Information:

- Note any unusual sounds or vibrations.

- Record symptoms like loss of power or difficulty starting.

- Check for warning lights on the dashboard.

- Inspect Visual Cues:

- Examine fluid levels and leaks.

- Look for damaged wires or connectors.

- Check for signs of wear on belts and hoses.

- Conduct Diagnostic Tests:

- Use a multimeter to test electrical systems.

- Perform compression tests to assess cylinder health.

- Run an OBD-II scan for error codes.

- Review Maintenance History:

- Check for recent service records.

- Determine if recommended maintenance was performed.

- Identify patterns of recurring issues.

By following these techniques, you can systematically address engine problems and restore optimal performance. Proper analysis not only resolves current issues but also helps prevent future complications.

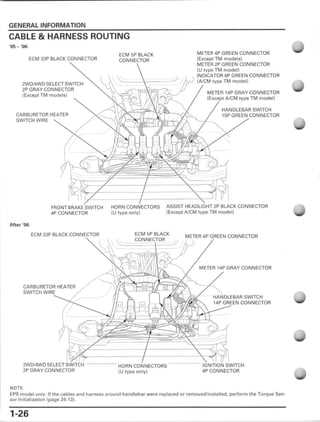

Electrical System Diagnostics Explained

The diagnosis of electrical systems is crucial for maintaining the performance and reliability of any vehicle. Understanding how to identify issues within the electrical circuitry can save time and resources while ensuring that the machinery operates smoothly. This section delves into the key concepts and methods for effectively diagnosing electrical problems.

Common Electrical Issues

Electrical systems often face a variety of challenges. Some prevalent problems include faulty wiring, blown fuses, and malfunctioning components. Recognizing symptoms such as flickering lights or inconsistent power delivery is essential for pinpointing the source of the issue. Regular inspections can help detect these common faults before they escalate into more significant concerns.

Diagnostic Techniques

To effectively diagnose electrical faults, several techniques can be employed. Multimeters are invaluable tools that allow technicians to measure voltage, current, and resistance within circuits. Additionally, circuit testers can quickly identify breaks or shorts in wiring. By systematically checking each component and connection, a clearer picture of the system’s health can be obtained, facilitating timely repairs.

Transmission Repair Tips and Tricks

Maintaining the functionality of your vehicle’s gearbox is crucial for optimal performance. Whether you’re dealing with a slipping issue or unusual noises, understanding the intricacies of transmission components can lead to effective solutions. This guide offers practical advice to help troubleshoot common problems and perform maintenance tasks efficiently.

Common Issues and Their Solutions

Identifying problems early can save time and resources. Below is a table highlighting frequent transmission issues along with suggested fixes.

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Slipping Gears | Low fluid levels, worn clutch | Check fluid levels, inspect clutch for wear |

| Noisy Operation | Worn bearings, insufficient lubrication | Replace bearings, ensure proper fluid levels |

| Difficulty Shifting | Clutch cable issues, hydraulic problems | Adjust or replace clutch cable, inspect hydraulic system |

Maintenance Best Practices

Regular upkeep can significantly extend the lifespan of transmission components. Here are some best practices to consider:

- Change transmission fluid as recommended by the manufacturer.

- Inspect and replace filters periodically to ensure clean fluid circulation.

- Monitor for leaks and address them promptly to avoid fluid loss.

Brake System Inspection and Fixes

Regular assessment of the braking mechanism is crucial for ensuring safety and performance. This section outlines essential steps for inspecting the components, identifying potential issues, and executing necessary repairs. A well-maintained braking system enhances overall vehicle control and extends the lifespan of its parts.

Inspection Steps

- Check brake fluid level and condition.

- Inspect brake pads for wear and damage.

- Examine rotors for scoring or warping.

- Assess calipers for leaks or sticking.

- Review brake lines for any signs of wear or corrosion.

Common Fixes

- Replace worn brake pads to maintain effective stopping power.

- Resurface or replace damaged rotors to prevent vibrations.

- Fix or replace leaking calipers to restore functionality.

- Flush and replace brake fluid to ensure optimal performance.

- Repair or replace worn brake lines to avoid potential failures.

Conducting these inspections and fixes periodically will ensure a reliable braking experience and enhance safety on the road.

Suspension and Steering Adjustments

Proper calibration of the suspension and steering systems is crucial for achieving optimal performance and comfort during operation. These components not only enhance handling but also contribute significantly to safety and stability on various terrains. Adjusting these systems according to specific requirements can lead to a smoother ride and improved vehicle responsiveness.

Suspension System Tuning

Adjusting the suspension involves fine-tuning the springs and dampers to match the weight distribution and intended use. A well-tuned suspension helps absorb shocks from rough surfaces while maintaining control. Below are key specifications for suspension settings:

| Component | Adjustment Type | Recommended Range |

|---|---|---|

| Front Spring Preload | Increase/Decrease | 0.5 – 1.5 inches |

| Rear Shock Compression | Adjust | 10 – 15 clicks |

| Rear Shock Rebound | Adjust | 10 – 15 clicks |

Steering System Calibration

The steering mechanism requires regular checks and adjustments to ensure precise handling. Misalignment can lead to uneven tire wear and compromised control. Below are important adjustment guidelines:

| Component | Adjustment Type | Recommended Value |

|---|---|---|

| Toe Angle | Align | 0 – 1/8 inch (inward) |

| Caster Angle | Set | 3 – 5 degrees |

| Camber Angle | Adjust | 0 – 1 degree (negative) |

Exhaust System Maintenance Guidelines

Regular upkeep of the exhaust system is crucial for optimal performance and longevity of your vehicle. Ensuring that this component is in top condition helps maintain engine efficiency and reduces harmful emissions. Adopting a proactive approach to maintenance can prevent costly repairs and improve overall functionality.

Inspection: Periodically examine the exhaust system for any signs of damage, such as rust, cracks, or loose fittings. A thorough visual check can help identify potential issues before they escalate into significant problems.

Cleaning: Accumulation of debris and carbon buildup can hinder performance. Use appropriate cleaning agents to remove deposits, ensuring all sections, including the muffler and pipes, are free from obstructions. Regular cleaning will also extend the life of the system.

Sealing: Check for any leaks around joints and connections. A compromised seal can lead to decreased efficiency and increased noise. If leaks are detected, reseal or replace gaskets as necessary to maintain optimal function.

Component Replacement: Be vigilant about replacing worn or damaged parts. Components such as catalytic converters and mufflers play a vital role in emission control and sound management. Timely replacements can help avoid further complications.

Professional Servicing: When in doubt, consult a professional mechanic for comprehensive inspections and servicing. Expert evaluation can uncover underlying issues that may not be apparent during a basic inspection.

By adhering to these guidelines, you can ensure that your exhaust system operates efficiently, contributing to the overall performance and reliability of your vehicle.

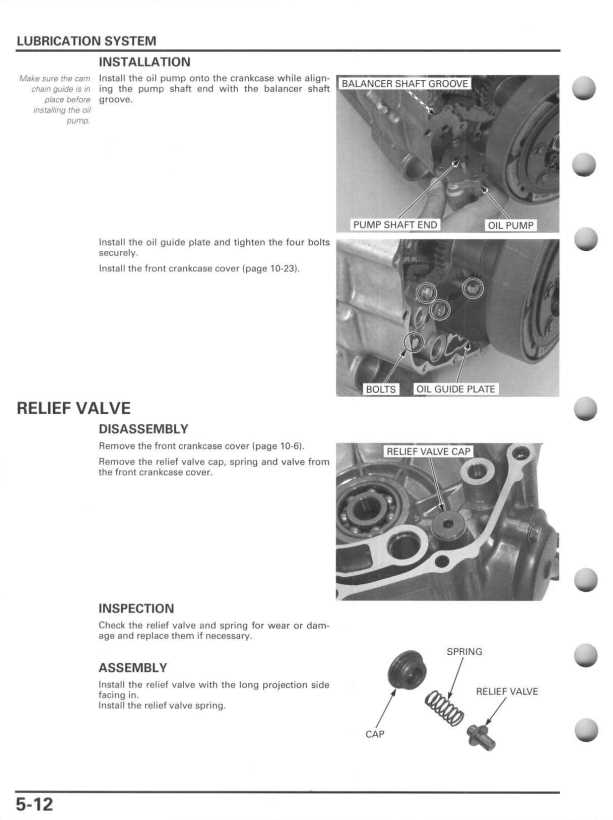

Fuel System Cleaning Procedures

Maintaining the integrity of the fuel delivery system is crucial for optimal engine performance. Over time, deposits and contaminants can accumulate, leading to decreased efficiency and potential damage. This section outlines the essential steps for effectively cleaning the fuel system, ensuring that the vehicle runs smoothly and reliably.

Preparation Steps

Before commencing the cleaning process, it is important to gather the necessary tools and materials. Ensure you have a fuel system cleaner, safety goggles, gloves, and a clean workspace. Always disconnect the battery to prevent any electrical hazards. Additionally, consult the vehicle’s specifications for any specific guidelines related to the fuel system components.

Cleaning Procedure

Start by removing the fuel filter and inspecting it for debris. A clogged filter can significantly hinder fuel flow. Next, introduce the cleaning solution into the fuel tank or directly into the fuel line, depending on the product’s instructions. Allow the cleaner to circulate through the system as recommended, typically involving engine operation for a specific duration. Finally, replace the fuel filter and any other components removed during the process. After reassembly, run the engine to ensure everything is functioning correctly.

How to Replace Key Components

Replacing essential parts in your all-terrain vehicle is a crucial skill that ensures optimal performance and longevity. Whether you’re facing issues with the engine, suspension, or electrical system, understanding the steps to efficiently swap out components can save you time and money. This guide will walk you through the fundamental procedures necessary for a successful replacement.

Engine Component Replacement

When addressing problems within the engine, it is vital to follow a systematic approach. Start by disconnecting the battery to ensure safety. Then, identify the specific component that needs replacement, such as the spark plug or air filter. For instance, when replacing a spark plug, remove the ignition wire carefully, unscrew the old plug, and replace it with a new one. Make sure to tighten it properly but avoid over-torquing, which can cause damage.

Suspension System Overhaul

Upgrading or replacing parts of the suspension system can significantly improve ride quality and handling. Begin by lifting the vehicle and securing it on jack stands. Inspect the shock absorbers and springs for wear. To replace a shock absorber, unbolt the old unit from the frame and lower control arm, then position the new shock in place and secure it with bolts. Always ensure that all fasteners are tightened to the manufacturer’s specifications for safety.

Emphasizing regular maintenance and timely replacements will not only enhance performance but also extend the life of your vehicle. Always consult your service documentation for specific guidelines and torque specifications.

When to Seek Professional Help

Understanding the limits of your abilities is crucial when dealing with mechanical issues. While many problems can be addressed through basic troubleshooting and maintenance, certain situations demand the expertise of a qualified technician. Knowing when to reach out for professional assistance can save time, money, and ensure safety.

Signs That Indicate Professional Assistance is Needed

- Persistent Issues: If a problem recurs despite your attempts to fix it, it may be time to consult an expert.

- Complex Repairs: Tasks requiring specialized tools or knowledge are often best left to professionals.

- Safety Concerns: If you encounter any electrical problems or fuel leaks, immediate professional help is necessary.

- Warranty Considerations: Attempting DIY repairs on a vehicle under warranty can void coverage, making professional help the safer choice.

Benefits of Consulting a Professional

- Expert Knowledge: Professionals possess extensive training and experience in handling intricate repairs.

- Time Efficiency: Skilled technicians can often diagnose and resolve issues more quickly than an inexperienced individual.

- Access to Specialized Tools: Professionals have access to equipment that may not be available for general use.

- Peace of Mind: Knowing that a qualified individual is handling repairs can alleviate stress and concerns about safety.