Every vehicle enthusiast knows the frustration that comes with a malfunctioning opening mechanism. Issues can arise unexpectedly, disrupting daily routines and causing inconvenience. Understanding how to tackle these problems independently can save both time and money, transforming a seemingly daunting task into a manageable project.

In this guide, we will explore practical techniques to address common issues associated with the glass openings in vehicles. Whether it’s a minor glitch or a more persistent fault, having the right knowledge and tools can empower individuals to restore functionality effectively. By following step-by-step instructions, anyone can enhance their skills and gain confidence in handling such tasks.

From identifying the root cause of the malfunction to implementing suitable solutions, this article aims to provide a comprehensive overview. You’ll learn about essential tools, safety precautions, and troubleshooting methods that are essential for a successful fix. Get ready to embark on a journey of empowerment through hands-on problem-solving!

Understanding Manual Window Mechanisms

This section delves into the fundamental principles governing the operation of mechanical glazing systems found in vehicles. These systems are designed to provide a straightforward yet effective method for regulating the opening and closing of transparent barriers, allowing for ventilation and convenience. By exploring the various components and their interactions, one can gain insight into the reliability and functionality of these systems.

At the core of these mechanisms are a series of interconnected parts that work in unison. Each element plays a crucial role in ensuring smooth operation, while the absence of electronic components highlights the simplicity and durability of the design. Below is a table that outlines the key components involved in these systems:

| Component | Description |

|---|---|

| Handle | Leverage point used to initiate movement. |

| Regulator | Assembly that controls the up-and-down motion. |

| Track | Guides the movement along a designated path. |

| Gear System | Facilitates smooth transition and adjusts speed. |

| Glass | The transparent barrier that allows visibility. |

Understanding these components and their functions not only aids in recognizing potential issues but also enhances one’s ability to maintain and troubleshoot the system effectively. Familiarity with the mechanics involved can lead to improved performance and longevity of the installation.

Common Issues with Manual Windows

When dealing with the operation of certain vehicle openings, several recurring challenges may arise. These complications can impact functionality, leading to frustration for users. Understanding these problems is essential for effective troubleshooting and ensuring smooth operation.

Typical Problems Encountered

- Difficulty in Movement: Often, the mechanism may become sluggish or completely unresponsive.

- Obstruction: Debris or misalignment can prevent proper opening or closing.

- Wear and Tear: Over time, components may degrade, causing operational inefficiencies.

- Noise: Unusual sounds during operation can indicate internal issues needing attention.

Signs to Watch For

- Resistance when turning the handle.

- Partial opening or inability to close completely.

- Visible gaps or misalignment in the frame.

- Grinding or clicking noises during operation.

Addressing these issues promptly can help maintain functionality and prolong the life of the mechanisms involved.

Tools Needed for Window Repair

When tackling the restoration of your vehicle’s glass components, having the right equipment is crucial. This ensures that the process is not only efficient but also effective in achieving a flawless finish. Below is a list of essential instruments that will aid you in this endeavor.

| Tool | Description |

|---|---|

| Safety Gloves | Protects your hands from sharp edges and debris. |

| Plastic Trim Tool | Helps in removing panels without damaging the surrounding surfaces. |

| Wrench Set | Necessary for loosening and tightening bolts and screws. |

| Vacuum Cleaner | Clears away any glass fragments and dust from the area. |

| Adhesive Applicator | Used for applying bonding agents securely. |

| Glass Cutter | Essential for custom fitting or trimming glass. |

| Measuring Tape | Ensures accurate dimensions for fitting replacement parts. |

Step-by-Step Repair Process

This section outlines a systematic approach to restoring the functionality of your vehicle’s opening mechanism. By following these detailed instructions, you can address issues effectively and efficiently.

1. Gather Necessary Tools and Materials

Before starting, collect all required tools such as screwdrivers, pliers, and any replacement parts. Having everything on hand will streamline the process.

2. Prepare the Work Area

Ensure your workspace is clean and well-lit. This not only enhances safety but also allows for better visibility during the task.

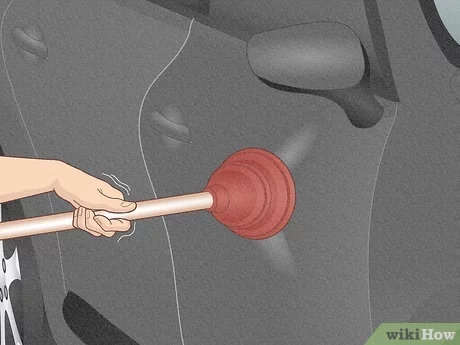

3. Remove the Inner Panel

Begin by carefully detaching the inner panel of the door. Use appropriate tools to avoid damaging any clips or fasteners, as these can be crucial for reassembly.

4. Inspect the Mechanism

Once the panel is removed, examine the mechanism closely. Look for any broken components or disconnections that may be causing the malfunction.

5. Replace Damaged Parts

If you identify any faulty parts, replace them with new ones. Ensure compatibility to maintain proper function.

6. Reassemble the Door

After making the necessary replacements, carefully reattach the inner panel. Ensure all clips and fasteners are secured tightly.

7. Test the Mechanism

Finally, test the functionality of the opening system. Make sure it operates smoothly and without any obstruction.

By adhering to these steps, you can restore the operational capability of the opening system, ensuring a seamless experience moving forward.

Safety Precautions During Repair

Ensuring a safe environment while addressing issues is crucial for both personal safety and the successful completion of the task. Being aware of potential hazards and taking appropriate measures can prevent accidents and injuries.

Essential Safety Gear

- Wear safety goggles to protect your eyes from debris.

- Use gloves to shield your hands from sharp edges.

- Consider a dust mask if working with materials that create airborne particles.

Workspace Considerations

- Ensure your area is well-lit to clearly see all components.

- Keep the workspace tidy to avoid tripping hazards.

- Have first aid supplies readily accessible in case of minor injuries.

By following these guidelines, you can significantly reduce risks and enhance your efficiency during the task.

Identifying the Problem Area

Understanding the source of an issue is crucial for effective resolution. This involves carefully examining the mechanism and components involved, ensuring that all potential trouble spots are considered. By systematically narrowing down the possibilities, one can pinpoint the exact area requiring attention.

Common Indicators of Malfunction

Look for signs such as unusual noises, slow movement, or misalignment. These symptoms often suggest where the complication lies. Pay attention to any changes in performance, as they can provide valuable clues.

Visual Inspection Techniques

A thorough visual check can reveal obvious wear or damage. Inspect the joints, seals, and tracks to determine if anything appears out of place. Documenting any findings can help streamline the troubleshooting process.

Replacing Broken Components

When dealing with damaged parts in vehicles, the replacement process is crucial for restoring functionality and ensuring safety. Understanding the various components involved is essential for effective substitution. This section will outline the necessary steps and considerations for replacing these elements efficiently.

| Component | Symptoms of Damage | Replacement Steps |

|---|---|---|

| Regulator | Difficulty in movement, strange noises | 1. Remove the panel 2. Disconnect the old regulator 3. Install the new regulator |

| Motor | Inconsistent operation, complete failure | 1. Disconnect the power source 2. Unscrew the motor 3. Attach the new motor |

| Track | Misalignment, unusual gaps | 1. Assess the track condition 2. Remove damaged sections 3. Install the replacement track |

Following these guidelines will facilitate a smooth replacement process, enhancing the overall performance and durability of the system.

Lubricating Window Mechanisms

Ensuring the smooth operation of components involved in raising and lowering panes is essential for maintaining overall functionality. Proper lubrication minimizes friction, preventing wear and tear, and enhances performance. Regular attention to these mechanisms can lead to improved longevity and reliability.

The process involves identifying key points where lubrication is necessary, typically around gears, tracks, and pivot points. Utilizing the right type of lubricant is crucial; options range from silicone sprays to lithium greases, each offering unique benefits depending on the environment and materials involved.

Before applying any substance, it’s advisable to clean the surfaces to remove dirt and debris. This helps achieve a more effective application and ensures that the lubricant can penetrate properly. A small amount is usually sufficient; excessive application can attract dirt and lead to buildup, counteracting the intended benefits.

After lubrication, testing the mechanisms by operating them a few times ensures everything is functioning smoothly. If any resistance or noise persists, further investigation may be required to address underlying issues. Regular maintenance of these components not only enhances functionality but also contributes to a more enjoyable experience overall.

Testing Functionality After Repair

Once the restoration process is complete, it’s crucial to ensure that the mechanism operates smoothly and effectively. This stage involves a series of evaluations designed to confirm that all components are functioning as intended, providing a reliable and seamless experience.

Begin by checking the movement: Engage the mechanism and observe its operation. It should glide effortlessly without any unusual noises or resistance. If any obstruction is detected, further adjustments may be necessary.

Next, assess the responsiveness: Ensure that controls react promptly to commands. Delays or failures in response can indicate underlying issues that need addressing. A quick test will help identify any anomalies.

Finally, inspect the alignment: Verify that all parts are correctly positioned and secure. Misalignment can lead to premature wear or malfunction, compromising the effectiveness of the entire assembly. Proper alignment ensures durability and optimal performance.

Conducting these tests thoroughly will help guarantee that the mechanism operates reliably, providing peace of mind and functionality for the user.

Preventative Maintenance Tips

Regular upkeep is essential to extend the lifespan and functionality of essential components. By following a few straightforward practices, you can minimize the likelihood of issues arising and ensure smoother operations over time.

Routine Checks

- Inspect the mechanisms regularly for signs of wear or damage.

- Ensure that all moving parts are properly lubricated to prevent friction.

- Monitor seals and gaskets for deterioration or leaks.

Environmental Considerations

- Avoid exposing components to extreme weather conditions when possible.

- Keep areas clean to prevent debris buildup that can impede functionality.

- Utilize protective covers if the vehicle will be parked for an extended period.

When to Seek Professional Help

Understanding when to turn to experts can save time, money, and frustration. While some issues may seem manageable, others require specialized knowledge and tools to ensure safety and effectiveness. Recognizing the signs that indicate the need for assistance is crucial for maintaining functionality and preventing further complications.

Signs That Indicate Professional Assistance

Look for persistent difficulties that do not resolve with basic troubleshooting. Unusual noises, failure to operate smoothly, or misalignment can signal underlying problems. If you encounter any of these symptoms consistently, it’s advisable to consult a skilled technician.

The Complexity of the Issue

If the task at hand involves intricate components or advanced mechanisms, seeking professional guidance is often the best choice. An expert possesses the necessary experience and tools to address complex situations effectively, ensuring a reliable outcome without risking additional damage.