The maintenance and troubleshooting of lawn machinery are essential for ensuring optimal performance and longevity. This guide aims to provide a comprehensive overview of common issues faced by operators and the appropriate solutions to address them. By following systematic approaches, users can effectively diagnose and rectify problems, leading to enhanced efficiency in their outdoor tasks.

In the realm of garden equipment, knowledge of mechanical components is crucial. Users will benefit from familiarizing themselves with various parts and their functions. This familiarity not only aids in identifying potential failures but also empowers individuals to take proactive steps in upkeep and management.

Furthermore, understanding the intricacies of the operating system will significantly enhance the user’s capability to maintain their equipment. Equipped with the right information, operators can confidently navigate challenges, ensuring that their machinery remains reliable and ready for any task. By following detailed guidance, one can ensure that their tools continue to perform at their best, ultimately saving time and resources.

Tuff Torq K46 Repair Overview

This section provides insights into the maintenance and troubleshooting of specific drive systems commonly found in various lawn care equipment. Understanding the components and their functions is crucial for effective service and longevity of the machinery.

Common Issues and Symptoms

- Loss of power or performance during operation

- Unusual noises indicating potential mechanical failure

- Inconsistent speed or difficulty in steering

- Fluid leaks from the unit

Basic Steps for Maintenance

- Inspect the system regularly for signs of wear and tear.

- Check fluid levels and replace fluids as necessary.

- Examine the belts and pulleys for damage or misalignment.

- Clean all accessible components to prevent debris buildup.

Common Issues and Symptoms

Understanding the typical problems that can arise in hydraulic drive systems is crucial for effective troubleshooting. Recognizing the signs early can help prevent further damage and ensure smooth operation.

Loss of Power

One of the primary indicators of a malfunction is a noticeable decline in power during operation. This can manifest as sluggish movement or an inability to engage properly. Regular checks can help identify if the fluid levels are adequate or if there are any blockages in the system.

Unusual Noises

Strange sounds such as grinding or whining can signal internal issues. These noises often indicate wear or damage within the components. Listening closely during use can provide insight into potential problems that require immediate attention.

Tools Required for Repairs

When addressing maintenance or troubleshooting tasks for machinery, having the right instruments on hand is essential for efficiency and effectiveness. The following section outlines the necessary equipment to ensure a smooth and successful process.

Essential Instruments

Begin with basic tools, including a set of wrenches and sockets. These will allow you to easily access and tighten various components. Additionally, a screwdriver set, particularly one with both flathead and Phillips options, is crucial for handling screws of different types. Consider including pliers for gripping and manipulating small parts.

Specialized Equipment

For more intricate tasks, specialized instruments such as torque wrenches can provide precise measurements necessary for proper assembly. An oil filter wrench is also recommended for those working with engine components. Finally, having a good-quality multimeter can help diagnose electrical issues effectively.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered in specific mechanical systems. By following these detailed instructions, you can effectively troubleshoot and resolve various malfunctions.

-

Preparation:

- Gather necessary tools, including wrenches, screwdrivers, and safety equipment.

- Ensure the work area is clean and well-lit to facilitate a safe environment.

- Consult any available documentation for insights on the assembly and components.

-

Disassembly:

- Carefully remove any protective covers or panels to access the internal mechanisms.

- Take notes or photos of the assembly to aid reassembly later.

- Detach components in a logical order, labeling parts as necessary.

-

Inspection:

- Examine all components for signs of wear, damage, or malfunction.

- Check seals, bearings, and moving parts for proper function and integrity.

- Identify any parts that may require replacement or repair.

-

Reassembly:

- Begin reattaching components in the reverse order of disassembly.

- Ensure all parts are securely fastened and aligned correctly.

- Double-check that all seals and gaskets are properly seated to prevent leaks.

-

Testing:

- Reconnect any necessary connections and restore power to the system.

- Conduct tests to ensure that everything operates as expected.

- Monitor for any unusual noises or behaviors during operation.

By adhering to these structured procedures, you can effectively maintain and restore the functionality of your mechanical system.

Understanding Hydraulic Systems

Hydraulic systems are vital mechanisms that utilize fluid under pressure to transmit energy and perform work. These systems are widely used across various applications, enabling efficient movement and control of machinery. Their fundamental operation relies on the principles of fluid mechanics, making them essential in both industrial and mobile equipment.

Components of Hydraulic Systems

Every hydraulic system consists of several key components that work together to facilitate movement and power transmission. These elements include pumps, valves, actuators, and reservoirs. Understanding the role of each component is crucial for ensuring optimal performance and reliability.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure by moving fluid from the reservoir. |

| Valves | Control the flow and direction of hydraulic fluid. |

| Actuators | Convert hydraulic energy into mechanical motion. |

| Reservoir | Holds the hydraulic fluid and allows for expansion and cooling. |

Advantages of Hydraulic Systems

Hydraulic systems offer numerous benefits, including high power-to-weight ratios and precise control over movement. They can easily adapt to various loads and operate smoothly across a wide range of speeds. This flexibility makes them suitable for diverse applications, from construction equipment to agricultural machinery.

Replacing Key Components

Maintaining optimal performance in mechanical systems often necessitates the replacement of essential parts. This section outlines the process and considerations involved in substituting vital components to ensure longevity and functionality.

Before beginning the replacement process, it is crucial to identify the components that require attention. Common elements that may need to be replaced include:

- Drive belts

- Hydraulic seals

- Gear assemblies

- Control levers

- Fluid filters

To effectively carry out the replacement, follow these steps:

- Gather necessary tools and replacement parts.

- Ensure the machine is powered down and securely positioned.

- Carefully remove the old component, taking note of any specific connections or orientations.

- Install the new part, ensuring it fits snugly and aligns properly.

- Reconnect any cables or hoses as needed, verifying that all connections are secure.

- Test the system to confirm functionality after the replacement.

Regularly inspecting and replacing worn components is essential for maintaining the efficiency and reliability of the equipment. By following the outlined steps, you can ensure a successful replacement process.

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery requires consistent attention and proactive care. Regular upkeep not only enhances performance but also prevents costly repairs down the line. Here are some essential practices to maintain optimal functioning.

Regular Inspection

Conduct frequent checks on all components to identify wear or damage early. Look for signs of leaks, unusual noises, or decreased performance. Addressing issues promptly can prevent further complications and ensure smooth operation.

Proper Lubrication

Maintaining adequate lubrication is crucial for reducing friction and preventing overheating. Use the recommended lubricants and follow the guidelines for application. Frequent lubrication not only prolongs the life of moving parts but also enhances overall efficiency.

Diagnostic Techniques for Troubleshooting

Identifying issues in mechanical systems requires a systematic approach to uncover underlying problems. By employing effective diagnostic methods, one can efficiently determine the root cause of malfunctions, leading to appropriate solutions and enhanced performance.

Visual Inspection

A thorough visual assessment of components is essential. Look for signs of wear, damage, or misalignment. Check for any fluid leaks and ensure all connections are secure. This initial step can often reveal obvious faults that require immediate attention.

Performance Testing

Conducting performance evaluations helps in understanding how well the system operates under various conditions. Monitor operational parameters, such as speed and responsiveness, to identify discrepancies. Utilizing diagnostic tools can further assist in pinpointing specific areas that may be malfunctioning.

In summary, adopting these diagnostic techniques is crucial for effective troubleshooting. By combining visual inspections with performance assessments, you can systematically address issues and restore functionality.

Safety Precautions During Repairs

When undertaking maintenance tasks, prioritizing safety is essential to ensure both personal well-being and effective operation of the equipment. Following specific guidelines can prevent accidents and enhance the overall repair experience. Being aware of potential hazards and taking appropriate measures can lead to a more efficient and secure process.

Personal Protective Equipment

Utilizing the right personal protective gear is crucial. This includes wearing gloves to prevent injuries from sharp edges or harmful substances, as well as safety goggles to shield the eyes from debris. Additionally, sturdy footwear can protect against heavy objects that may fall during the procedure.

Work Environment Considerations

Maintaining a clean and organized workspace is vital. Ensure that the area is free from clutter and that tools are stored safely when not in use. Adequate lighting is also necessary to avoid missteps and ensure precise handling of components. Furthermore, working in a well-ventilated area can mitigate exposure to harmful fumes or dust.

FAQs About Tuff Torq K46

This section addresses common inquiries related to a specific hydraulic system used in various outdoor equipment. Understanding these questions can help users troubleshoot issues and enhance the longevity of their machinery.

Common Questions

- What symptoms indicate a malfunction in the hydraulic system?

- How often should the fluid be replaced for optimal performance?

- Are there specific tools required for maintenance tasks?

Maintenance Tips

- Regularly check fluid levels to ensure proper operation.

- Inspect hoses and connections for signs of wear or leakage.

- Clean any debris from the system to prevent clogging.

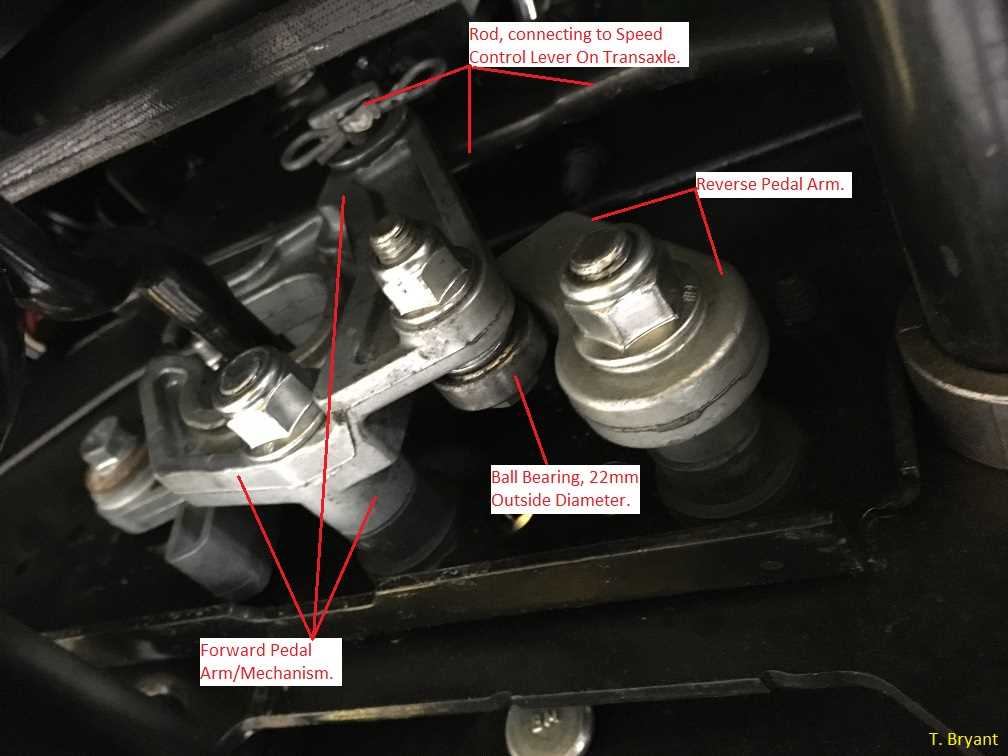

Parts Identification and Sourcing

Understanding the components of your equipment is essential for efficient maintenance and restoration. Proper identification of parts ensures that you can locate the necessary replacements quickly and accurately, minimizing downtime and enhancing performance. This section will guide you through the process of recognizing essential components and finding reliable sources for procurement.

Identifying Components

Begin by examining the machinery carefully, noting the various elements that may require attention. Use diagrams and manufacturer specifications to aid in identifying parts. Each component typically has a unique number or identifier, which is crucial for accurate sourcing. Additionally, familiarize yourself with the common wear items that often need replacing over time.

Finding Reliable Suppliers

Once you have identified the required components, the next step is sourcing them from trusted suppliers. Online marketplaces, local distributors, and specialty shops can provide the necessary parts. When selecting a supplier, consider factors such as pricing, shipping options, and customer reviews to ensure you receive quality products promptly.

Service Intervals and Recommendations

Regular maintenance is essential for ensuring optimal performance and longevity of your machinery. Adhering to recommended service intervals helps prevent unexpected failures and maintains operational efficiency. Proper upkeep not only extends the lifespan of components but also enhances overall functionality.

It is advisable to follow a systematic schedule for inspections and servicing. Typically, routine checks should be conducted every few months, depending on usage frequency and environmental conditions. Key areas to focus on include fluid levels, filter cleanliness, and general wear and tear on critical parts.

Additionally, consider performing a comprehensive evaluation annually. This allows for a thorough assessment of the entire system, ensuring that all components are functioning correctly. Keeping detailed records of maintenance activities can also provide insights into patterns that may require attention.

Using high-quality lubricants and replacement parts is crucial for maintaining optimal performance. Always consult the manufacturer’s specifications for recommended products and practices. By prioritizing these guidelines, you can enhance the reliability and efficiency of your equipment.

Upgrades and Performance Enhancements

Improving the efficiency and functionality of your equipment can significantly enhance its overall performance. Focusing on key areas such as power management, component quality, and operational precision can lead to noticeable gains in speed and reliability. Various modifications can be made to optimize performance, ensuring that your machinery operates at its best for longer periods.

Component Upgrades

Upgrading internal parts, such as gears and belts, can have a profound impact on performance. High-quality replacements not only improve durability but also enhance the efficiency of energy transfer. Consider integrating advanced materials or designs that offer greater strength and lighter weight, which can lead to better acceleration and reduced wear.

Performance Modifications

Incorporating modifications that improve airflow and cooling can greatly enhance functionality. Effective cooling systems prevent overheating, which is essential for maintaining optimal performance levels during extended use. Additionally, tuning the engine or adjusting fuel mixtures can result in better throttle response and increased power output, providing a noticeable improvement in overall operation.