Proper upkeep of small engines is crucial for their longevity and optimal performance. This section focuses on the essential aspects of maintenance, offering valuable insights into troubleshooting common issues and implementing effective solutions. With a comprehensive approach, we aim to equip you with the knowledge needed to enhance your engine’s functionality.

Regular care not only improves efficiency but also prevents costly repairs in the future. By familiarizing yourself with basic operational principles, you can better understand how to identify problems early on. This proactive strategy will save time and resources, ensuring that your equipment runs smoothly.

In this guide, you will find detailed instructions and tips to help you navigate through various challenges. Whether you are a seasoned user or new to engine management, the information provided will assist you in maintaining your equipment effectively, ensuring a reliable and productive experience.

Kawasaki FC420V Repair Manual Overview

This section provides a comprehensive overview of the essential resources for maintaining and troubleshooting small engines. Proper guidance can ensure optimal performance and longevity of the equipment.

Key Features

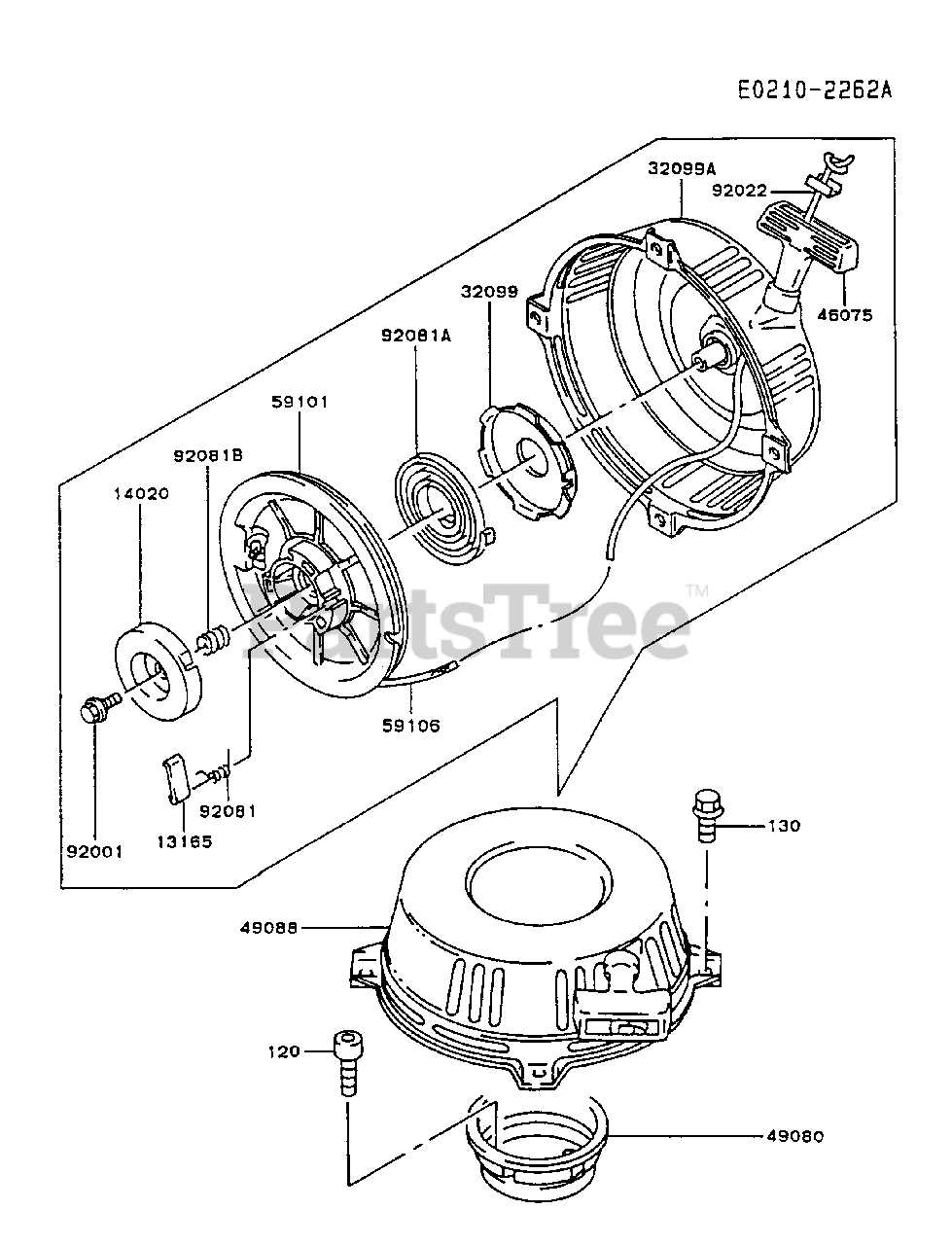

Users will benefit from detailed instructions, diagrams, and specifications that facilitate efficient service. Understanding these elements can greatly enhance repair capabilities.

Usage and Benefits

Following the outlined guidelines not only aids in repairs but also promotes safe operation. Familiarity with the content empowers users to tackle common issues independently.

| Feature | Description |

|---|---|

| Instructions | Step-by-step procedures for common tasks. |

| Diagrams | Visual aids for easier understanding of components. |

| Specifications | Detailed technical information for various parts. |

Common Issues with Kawasaki FC420V

This section highlights frequent problems encountered with a specific model of small engines, focusing on their causes and potential solutions. Understanding these challenges can aid in effective troubleshooting and maintenance.

Engine Not Starting

- Check the fuel supply: Ensure there is sufficient fuel and that it is fresh.

- Inspect the ignition system: Look for faulty spark plugs or ignition coils.

- Examine the battery: A weak or dead battery can prevent the engine from starting.

Overheating Issues

- Check the cooling system: Ensure that there are no blockages in the airflow.

- Inspect the oil level: Low oil can lead to excessive heat generation.

- Look for debris: Clear any dirt or obstructions that may hinder cooling.

By addressing these common concerns promptly, users can enhance the performance and longevity of their equipment.

Tools Needed for Effective Repairs

When addressing maintenance tasks for machinery, having the right tools is crucial for achieving optimal results. Proper instruments not only enhance efficiency but also ensure that the job is performed safely and accurately. Below is a list of essential items that can facilitate effective servicing of your equipment.

Essential Hand Tools

- Wrenches: Adjustable and fixed-size for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for handling various screws.

- Pliers: For gripping, twisting, and cutting wires or small components.

- Socket Set: Offers versatility for different sizes of nuts and bolts.

Power Tools for Enhanced Efficiency

- Drill: Useful for creating holes or driving screws with ease.

- Impact Wrench: Provides high torque for heavy-duty tasks.

- Grinder: Ideal for smoothing out surfaces or cutting through materials.

- Vacuum: Aids in keeping the workspace clean from debris.

Utilizing these tools can greatly improve the quality and speed of your maintenance tasks, allowing you to achieve professional results with confidence.

Step-by-Step Engine Disassembly Guide

This section provides a comprehensive approach to disassembling an engine systematically. Understanding the correct sequence and methods ensures that each component is handled with care, reducing the risk of damage and facilitating reassembly.

Tools Needed

- Socket set

- Screwdrivers

- Torque wrench

- Pliers

- Cleaning supplies

Disassembly Steps

- Preparation: Ensure the engine is cool and clean. Disconnect the battery to prevent electrical hazards.

- Remove External Components:

- Detach the air filter and housing.

- Take off the exhaust system.

- Unplug any electrical connectors.

- Drain Fluids: Empty the oil and fuel to avoid spills during disassembly.

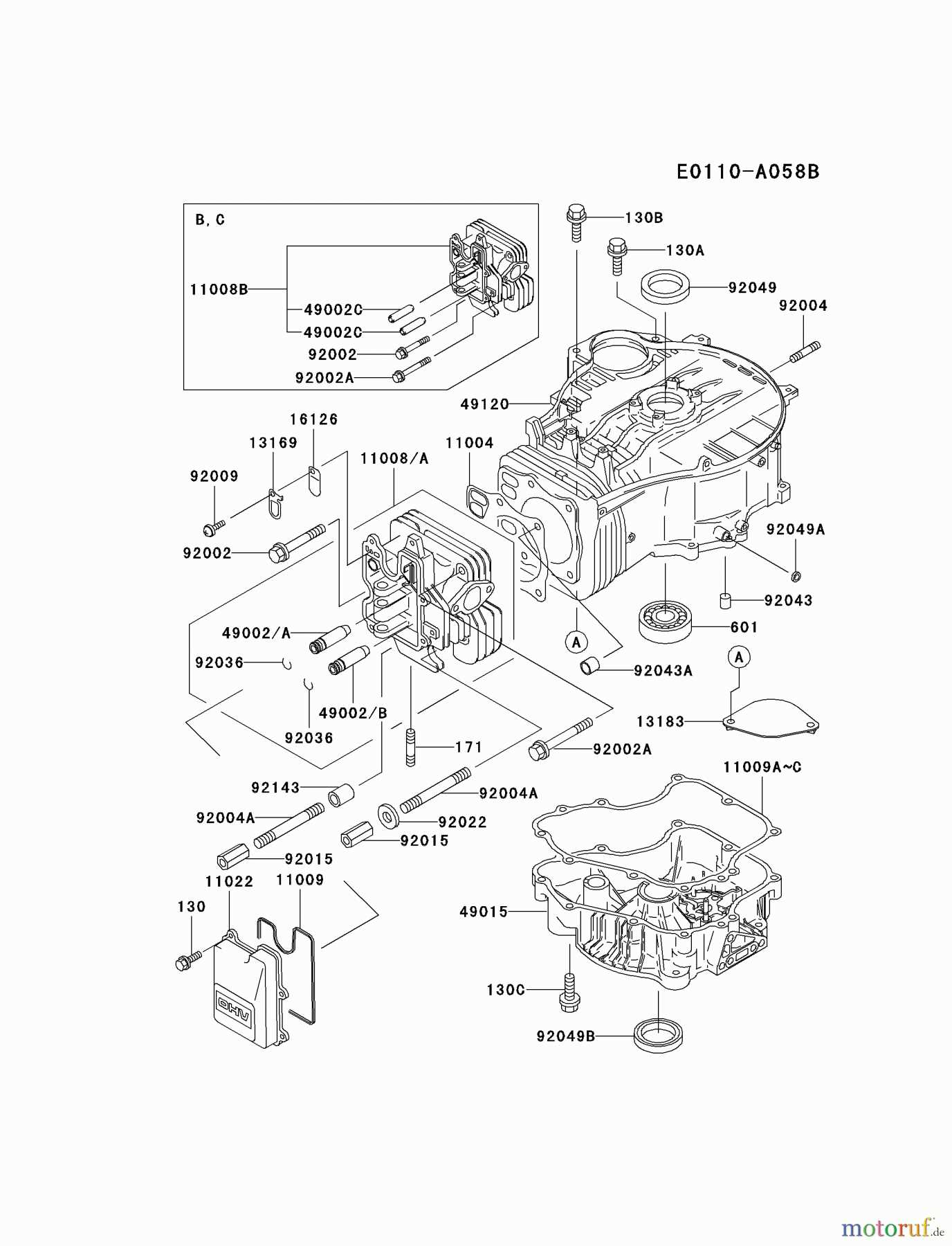

- Remove the Cylinder Head: Unfasten the bolts in a crisscross pattern to prevent warping.

- Detach the Cylinder: Carefully lift the cylinder from the crankcase after removing the necessary bolts.

- Extract the Crankshaft: Unscrew any retaining bolts and gently remove the crankshaft.

- Inspect Components: As each part is removed, check for wear or damage, and clean them as needed.

Following these steps will ensure a smooth disassembly process, laying the groundwork for effective maintenance or repair tasks.

Reassembling the Kawasaki FC420V Engine

Reassembling an engine requires careful attention to detail and a methodical approach. This process is crucial to ensure that all components fit together seamlessly and function as intended. Following specific guidelines will help you achieve optimal performance and longevity for the engine.

Step 1: Prepare Your Workspace

Before starting the reassembly, ensure that your workspace is clean and organized. Gather all necessary tools and components, making sure that everything is within reach. This will streamline the process and reduce the likelihood of losing parts.

Step 2: Align the Components

Begin by aligning the key components, such as the crankshaft, pistons, and cylinder head. Ensure that all gaskets are in place and free of any damage. A proper fit is essential for preventing leaks and ensuring efficient operation.

Step 3: Torque Specifications

Follow the manufacturer’s torque specifications for each bolt. Use a calibrated torque wrench to apply the correct amount of pressure. Over-tightening or under-tightening can lead to mechanical failure or improper sealing.

Step 4: Final Checks

Once everything is in place, conduct a thorough inspection. Check for any loose parts and ensure that all connections are secure. Performing a final check helps prevent issues during operation.

By adhering to these steps, you can successfully reassemble the engine, setting the foundation for reliable performance in the future.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. By following a few simple yet effective practices, you can significantly extend its lifespan and maintain optimal functionality. Regular attention to maintenance tasks can prevent costly repairs and enhance overall efficiency.

Regular Inspection

Frequent checks on various components can help identify potential issues before they escalate. Look for signs of wear, such as unusual noises, vibrations, or leaks. Addressing these concerns early can save time and money in the long run.

Cleaning and Lubrication

Keeping the machinery clean is crucial for smooth operation. Remove any dirt or debris that may accumulate, especially around moving parts. Additionally, applying appropriate lubricants to essential areas will reduce friction and prevent overheating, ensuring that the equipment runs efficiently for years to come.

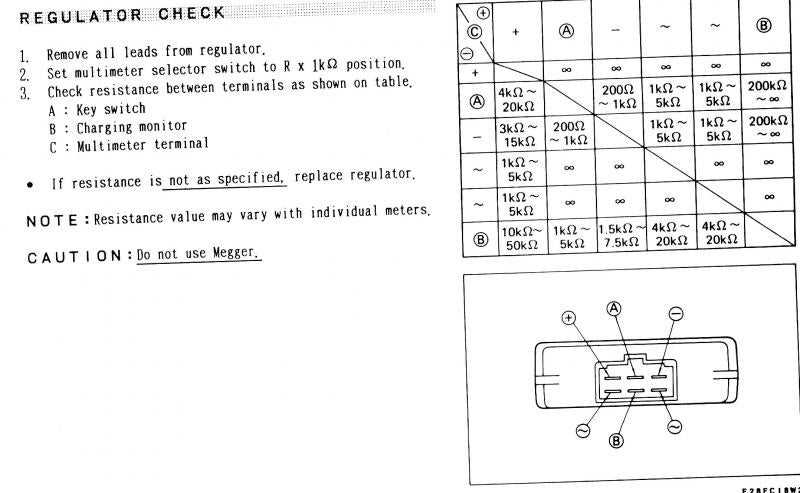

Understanding Electrical System Diagnostics

Diagnosing electrical systems is a crucial aspect of maintaining machinery. It involves identifying issues within the circuitry that can affect overall performance and efficiency. A systematic approach to troubleshooting can help pinpoint faults and enhance reliability.

Key Components of Electrical Diagnostics

To effectively diagnose electrical systems, one must understand the main components, including the battery, alternator, and wiring harness. Each element plays a vital role in the system’s operation. Regular checks of these parts can prevent potential failures.

Common Diagnostic Techniques

Several techniques are employed in diagnostics, such as using multimeters to measure voltage and continuity. This practice helps to identify shorts or open circuits, ensuring the electrical flow is uninterrupted. Additionally, visual inspections of connections and wiring can reveal wear or damage that may not be evident through testing alone.

Importance of Regular Maintenance

Regular maintenance is essential for the longevity of electrical systems. Scheduled inspections allow for early detection of issues, reducing the risk of unexpected breakdowns. Proper upkeep can save time and costs associated with major repairs, ensuring optimal functionality.

Fuel System Troubleshooting Techniques

Effective diagnosis of fuel system issues is essential for ensuring optimal performance of small engines. This section outlines various methods to identify and resolve common problems associated with fuel delivery and efficiency.

Understanding the symptoms can help narrow down potential issues. Here are some typical signs indicating fuel system malfunctions:

| Symptom | Possible Causes |

|---|---|

| Engine won’t start | Empty fuel tank, clogged fuel line, or faulty fuel pump |

| Poor acceleration | Contaminated fuel, air leaks, or dirty fuel filter |

| Rough idling | Dirty carburetor, incorrect fuel mixture, or vacuum leaks |

| Engine misfires | Clogged injectors, low fuel pressure, or air-fuel mixture issues |

Begin troubleshooting by checking the fuel level and ensuring it is free of contaminants. Inspect fuel lines for leaks or blockages and verify that the fuel filter is clean. If the engine is equipped with a carburetor, a thorough cleaning may be necessary to remove buildup. For fuel injection systems, ensure that the injectors are functioning correctly and that there is adequate fuel pressure.

By systematically addressing these components, most fuel-related issues can be identified and resolved, leading to improved engine performance.

Identifying and Fixing Mechanical Failures

Recognizing and addressing mechanical issues is essential for maintaining the performance and longevity of any engine. Regular inspections can help pinpoint potential problems before they escalate into significant failures, ensuring optimal operation.

Common Signs of Mechanical Problems

- Unusual noises such as grinding or knocking

- Decreased power output or sluggish performance

- Inconsistent operation or stalling

- Visible leaks or fluid stains

Troubleshooting Steps

- Conduct a visual inspection of the engine components.

- Listen for abnormal sounds during operation.

- Check fluid levels and inspect for leaks.

- Test the system’s performance under load conditions.

- Consult the specifications to verify all components are functioning correctly.

By systematically identifying symptoms and following troubleshooting procedures, one can effectively address mechanical issues, restoring the equipment to its optimal performance level.

Recommended Replacement Parts and Accessories

Ensuring optimal performance of your equipment often requires the use of specific components and enhancements. This section outlines the essential replacement parts and accessories that can help maintain efficiency and extend the lifespan of your machinery.

Essential Replacement Parts

- Air Filters: Crucial for maintaining airflow and engine efficiency.

- Oil Filters: Vital for preventing contaminants from damaging engine components.

- Spark Plugs: Essential for reliable ignition and optimal engine performance.

- Batteries: Important for consistent power supply and starting capability.

- Belts and Hoses: Necessary for smooth operation and preventing leaks.

Recommended Accessories

- Protective Covers: Help safeguard your equipment from environmental factors.

- Fuel Stabilizers: Enhance fuel longevity and prevent degradation.

- Cleaning Kits: Ensure that all components remain free from debris and buildup.

- Storage Solutions: Keep parts organized and easily accessible for maintenance.

Safety Precautions During Repairs

Ensuring safety is paramount when working on mechanical devices. Taking appropriate precautions not only protects the individual but also preserves the equipment’s integrity. Adhering to safety guidelines minimizes the risk of accidents and promotes a secure working environment.

General Guidelines

- Wear suitable personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep a first aid kit nearby for any unexpected incidents.

- Ensure that all tools are in good condition and appropriate for the task.

Before Starting the Work

- Disconnect the power source to prevent accidental starts.

- Review the instructions thoroughly to understand the steps involved.

- Clear the workspace of unnecessary items to reduce clutter.

- Inform others in the vicinity about the ongoing work for their awareness.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and troubleshooting. Understanding typical issues can help users resolve problems efficiently and enhance the longevity of their equipment.

- What are the signs that maintenance is needed?

- Unusual noises during operation

- Decreased performance or efficiency

- Visible leaks or fluid loss

- How often should maintenance be performed?

- Every 25 hours of operation for routine checks

- Seasonal inspections before heavy usage

- Can I perform maintenance myself?

- Yes, many tasks can be done by the user

- Refer to guidelines for basic procedures

- When should I consult a professional?

- For complex issues beyond basic maintenance

- When replacement parts are required

- What tools are necessary for maintenance?

- Basic hand tools like wrenches and screwdrivers

- Specific tools as indicated in the guidelines