Understanding the intricacies of automotive upkeep is essential for ensuring the longevity and performance of any vehicle. This section provides detailed insights into various procedures that enhance the functionality of your automobile. With the right knowledge, you can tackle common challenges and improve your driving experience.

Every car owner benefits from a systematic approach to maintenance, allowing for timely interventions and preventing potential issues. From routine checks to more complex procedures, knowing how to properly care for your vehicle is invaluable. This guide aims to equip you with the necessary information to navigate these tasks confidently.

Emphasizing the importance of regular assessments, this guide highlights critical areas to focus on for optimal vehicle operation. Whether you’re a seasoned enthusiast or a novice, the techniques outlined will help demystify the process and empower you to take charge of your automobile’s health.

This section provides a thorough overview of the essential aspects of maintaining and servicing a specific vehicle model. The guide will cover various elements including troubleshooting common issues, performing routine maintenance, and understanding technical specifications.

Key Features and Specifications

Understanding the main characteristics and specifications of the vehicle is crucial for effective upkeep. This includes engine details, performance metrics, and design elements that set this model apart.

Common Issues and Solutions

Identifying frequent problems that owners face can aid in proactive maintenance. This section will outline typical challenges and the best practices for resolving them.

| Issue | Solution |

|---|---|

| Engine Overheating | Check coolant levels and thermostat functionality. |

| Electrical Failures | Inspect battery connections and wiring for corrosion. |

| Brake Performance Issues | Examine brake pads and fluid levels. |

Essential Maintenance Procedures Overview

Proper upkeep of your vehicle is crucial for ensuring its longevity and optimal performance. Routine checks and essential tasks can help prevent larger issues, maintain safety, and enhance driving comfort.

The following are key procedures to consider for effective vehicle maintenance:

- Fluid Checks: Regularly inspect and top off vital fluids such as engine oil, coolant, transmission fluid, and brake fluid.

- Tire Care: Monitor tire pressure, tread depth, and overall condition. Rotate tires periodically to promote even wear.

- Brake System Inspection: Examine brake pads, rotors, and fluid levels to ensure responsive braking performance.

- Battery Maintenance: Check battery terminals for corrosion, and ensure secure connections. Replace the battery as needed.

- Filter Replacement: Change air and cabin filters to maintain air quality and engine efficiency.

- Light Checks: Verify that all exterior and interior lights are functioning properly for safety and visibility.

Adhering to these essential procedures will significantly contribute to the reliable operation of your vehicle and help avoid unexpected breakdowns.

Common Issues with Chrysler 300M

Owners of this particular vehicle model often encounter several recurring challenges that can affect performance and comfort. Understanding these common problems can help in timely identification and resolution, ensuring a smoother driving experience.

Frequent Problems

- Electrical system malfunctions, including issues with the battery and alternator.

- Suspension-related concerns, which can lead to a bumpy ride.

- Transmission difficulties, such as slipping or hesitation during gear changes.

Maintenance Tips

- Regularly inspect and replace the battery to prevent starting issues.

- Schedule routine suspension checks to maintain handling and comfort.

- Monitor transmission fluid levels and change them according to the manufacturer’s guidelines.

Step-by-Step Engine Diagnostics

This section provides a systematic approach to identifying and resolving engine issues. By following a structured method, you can pinpoint the source of performance problems and ensure the optimal functioning of your vehicle.

Begin with a thorough visual inspection of the engine compartment. Look for any signs of wear, leaks, or loose connections. Pay special attention to the condition of belts and hoses, as well as fluid levels.

Next, utilize diagnostic tools to retrieve any trouble codes from the onboard computer system. This information can guide you in understanding specific faults that may be affecting engine performance.

After retrieving codes, proceed to conduct a series of tests, including checking ignition timing, fuel pressure, and compression. Each of these tests provides critical data that can help isolate the root cause of any issues.

Finally, based on your findings, address any necessary repairs or adjustments. This may involve replacing faulty components, cleaning fuel injectors, or recalibrating sensors. Consistent monitoring and testing will ensure your engine operates smoothly and efficiently.

Transmission Troubleshooting Tips

Understanding the common issues related to vehicle transmission can greatly enhance your ability to identify problems and seek effective solutions. This section provides insights and advice for diagnosing and addressing transmission challenges that may arise during vehicle operation.

Identifying Symptoms

Recognizing the signs of transmission trouble is crucial for timely intervention. Look for unusual noises, slipping gears, or delayed engagement when shifting. Fluid leaks can also indicate potential problems, so regularly check under the vehicle for any signs of leakage.

Basic Diagnostic Steps

Begin troubleshooting by checking the transmission fluid level and condition. Low fluid levels can lead to inadequate lubrication and overheating. If the fluid appears burnt or has a dark color, it may need to be replaced. Additionally, inspecting the transmission filter for clogs can help improve overall performance.

Brake System Inspection and Repair

The braking mechanism is a critical component of any vehicle, ensuring safety and control during operation. Regular examination and maintenance are essential to identify potential issues and ensure optimal performance. This section outlines key steps for evaluating and servicing the brake system, focusing on common components and troubleshooting techniques.

Key Components to Inspect

When assessing the braking system, it’s important to pay attention to the following parts:

| Component | Inspection Points |

|---|---|

| Brake Pads | Check for wear and thickness; replace if below specifications. |

| Brake Rotors | Examine for scoring, warping, and thickness; ensure they meet manufacturer’s guidelines. |

| Brake Lines | Look for leaks, cracks, or corrosion; ensure connections are secure. |

Common Issues and Solutions

Identifying common problems can save time and enhance safety. Here are frequent issues and their resolutions:

- Squeaking Noise: Often indicates worn brake pads; replacement is advised.

- Vibrations During Braking: May suggest warped rotors; resurfacing or replacing is necessary.

- Soft Brake Pedal: Could be a sign of air in the brake lines; bleeding the system will help restore firmness.

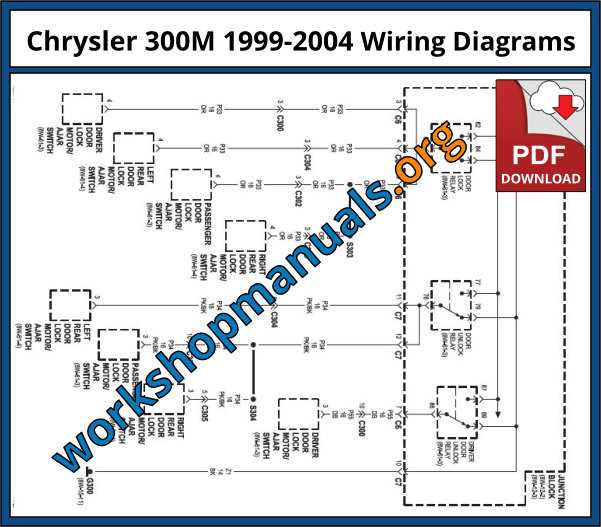

Electrical System Troubleshooting Guide

The electrical system is crucial for the proper functioning of any vehicle. Identifying and resolving issues within this system can prevent more severe complications and ensure reliable performance. This guide provides a structured approach to diagnosing common electrical problems.

Step 1: Inspect the Battery

Begin by examining the battery connections for corrosion or looseness. A well-maintained battery is essential for the entire electrical system. Check the voltage using a multimeter; it should typically read around 12.6 volts when fully charged.

Step 2: Check Fuses and Relays

Next, inspect the fuses and relays in the fuse box. A blown fuse can interrupt power to critical components. Replace any faulty fuses and test the relays to ensure they are functioning correctly.

Step 3: Examine Wiring and Connectors

Thoroughly inspect the wiring harness and connectors for signs of wear, fraying, or damage. Secure connections are vital for the proper flow of electricity. Look for any exposed wires that could cause short circuits.

Step 4: Test Components

For components like the alternator and starter motor, use a multimeter to check for proper voltage and functionality. If these components are not working as intended, they may need replacement or repair.

By following these steps systematically, you can effectively troubleshoot and resolve electrical issues, ensuring the vehicle operates smoothly and efficiently.

Cooling System Maintenance Essentials

The efficiency of an engine heavily relies on the proper functioning of its temperature regulation system. Regular upkeep of this system ensures optimal performance and prolongs the lifespan of various components. Understanding the key aspects of maintaining this system is vital for any vehicle owner.

Routine Inspections should be conducted to check for leaks, corrosion, or any wear and tear. Keeping an eye on the coolant level is crucial; it should be within the recommended range to avoid overheating.

Fluid Quality is equally important. The coolant should be replaced periodically to prevent sludge buildup and to maintain its effectiveness in regulating temperature. It’s essential to use the correct type of fluid that meets the manufacturer’s specifications.

System Flushing is recommended to remove any contaminants that can hinder performance. This process involves draining the old fluid and replacing it with fresh coolant, ensuring the system operates efficiently.

Lastly, thermostat and radiator checks are necessary to ensure that these components are functioning correctly. A faulty thermostat can lead to incorrect temperature readings, while a malfunctioning radiator can cause severe overheating issues.

Suspension and Steering Repairs Explained

Maintaining the integrity of the suspension and steering systems is crucial for optimal vehicle performance. These components ensure a smooth ride, enhance handling, and provide stability. Regular attention to these areas can prevent more significant issues and improve overall driving safety.

Common Issues and Symptoms

Various problems can arise within the suspension and steering assemblies. Symptoms such as unusual noises, excessive bouncing, or steering difficulty may indicate underlying issues. Inspecting components like shock absorbers, struts, and tie rods regularly can help identify potential concerns early.

Repair Techniques

When addressing faults in these systems, a systematic approach is essential. Replacing worn-out parts, adjusting alignment, and ensuring proper fluid levels are standard procedures. Utilizing quality components and following manufacturer guidelines during repairs can greatly extend the lifespan of the suspension and steering systems.

Interior Component Restoration Techniques

Restoring interior components can significantly enhance the overall aesthetic and functionality of a vehicle. This process involves various methods tailored to address wear and tear, while also improving the visual appeal of surfaces and materials. Proper techniques not only rejuvenate the space but can also increase the value of the automobile.

One effective approach is deep cleaning fabrics and upholstery. Utilizing specialized cleaners designed for specific materials can remove stains and restore color vibrancy. For leather surfaces, conditioning treatments help to retain suppleness and prevent cracking.

Additionally, attention to detail is crucial when dealing with plastic and vinyl elements. Applying heat to minor scratches can help to smoothen surfaces, while appropriate polishing compounds can bring back the original shine. Regular maintenance, such as applying protectants, can further prolong the lifespan of these components.

For wooden trims, sanding and refinishing can revitalize the look, restoring its natural grain and gloss. Employing the right finishes will ensure durability and a pleasing appearance.

Overall, employing these restoration techniques fosters a comfortable and appealing interior, making each journey more enjoyable.

Exterior Body Repair Instructions

This section provides essential guidelines for addressing damage to the outer structure of your vehicle. Proper handling of such issues is crucial for maintaining the aesthetic and functional aspects of the automobile.

Before beginning any work, ensure you have the necessary tools and materials:

- Safety goggles

- Gloves

- Body filler

- Sandpaper (various grits)

- Primer and paint

- Sealant

Follow these steps for effective repair:

- Assess the extent of the damage. Identify areas that require filling, sanding, or repainting.

- Clean the affected area thoroughly to remove dirt and debris.

- If there are dents, use a puller or hammer to reshape the metal as needed.

- Apply body filler to fill in any imperfections, smoothing it out with a spatula.

- Once dry, sand the area to achieve a flat surface that blends with the surrounding body.

- Prime the surface to prepare it for painting. Allow adequate drying time.

- Finally, apply paint in layers, allowing each layer to dry before adding the next. Seal the edges for a finished look.

Regular maintenance and prompt attention to bodywork can prolong the lifespan of your vehicle’s exterior.

Fluid Replacement Procedures Explained

Maintaining optimal performance in any vehicle requires regular attention to various fluid levels. This section provides a comprehensive overview of the necessary steps for fluid changes, ensuring that your automobile operates smoothly and efficiently. Proper fluid management not only enhances performance but also extends the lifespan of essential components.

Understanding the Importance of Fluid Changes

Regularly scheduled fluid changes are crucial for the health of your vehicle. Over time, fluids can become contaminated or lose their effectiveness, leading to potential issues. For instance, engine oil can degrade, impacting lubrication, while coolant can lose its protective properties. Addressing these changes proactively helps prevent costly repairs down the line.

Step-by-Step Replacement Process

The process of fluid replacement typically involves a few straightforward steps. Begin by identifying the type of fluid that requires changing, such as engine oil, transmission fluid, or brake fluid. Next, gather the necessary tools and materials, including a drain pan, funnel, and the appropriate replacement fluid. Once equipped, follow these steps:

- Drain the old fluid: Locate the drain plug and carefully remove it to allow the old fluid to exit into the drain pan.

- Replace filters: If applicable, change any filters that may be present, ensuring optimal flow and function.

- Add new fluid: Use a funnel to pour in the new fluid, ensuring it meets the specifications required for your vehicle.

- Check levels: After adding the new fluid, check the levels to ensure they meet the recommended standards.

By following these guidelines, you can maintain the efficiency and reliability of your vehicle, ensuring a safer and more enjoyable driving experience.

Safety Features and Adjustments

This section discusses essential protective elements and necessary modifications to ensure optimal vehicle performance. Understanding these components is crucial for enhancing safety and comfort during operation.

Key Protective Elements

The vehicle is equipped with various safety mechanisms designed to shield occupants in the event of a collision. These include advanced airbag systems, reinforced structural integrity, and anti-lock braking capabilities. Each feature plays a vital role in mitigating potential injuries and maintaining control during emergency situations.

Adjustment Procedures

Regular adjustments and inspections of safety features are imperative for maintaining their effectiveness. It is recommended to periodically check the airbag system status, inspect brake functionality, and assess tire pressure to ensure all components are functioning correctly. Proper maintenance not only enhances safety but also contributes to overall driving experience.