In the world of crafting, having a reliable device is essential for achieving the desired results. As time goes by, these intricate machines may encounter issues that can hinder performance. Understanding the complexities of their operation is key to keeping them in optimal condition.

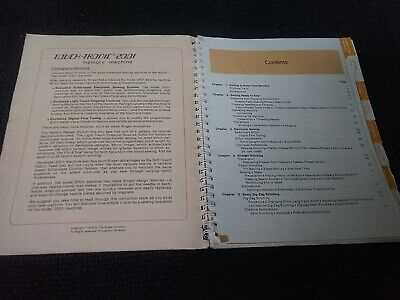

Within this resource, you will discover valuable insights into troubleshooting and maintaining your sewing apparatus. Whether you are a seasoned expert or a novice, the information provided will empower you to address common malfunctions effectively.

Each section is designed to equip you with the knowledge needed to navigate through potential challenges. With the right approach and techniques, restoring functionality can be a rewarding experience, allowing you to continue your creative projects without interruption.

Overview of the Model

This device represents a significant advancement in the realm of home stitching technology. Designed with precision and versatility in mind, it caters to a wide array of sewing tasks, making it an essential tool for both beginners and seasoned enthusiasts. Its user-friendly interface and comprehensive features allow for creative expression and professional-quality results.

Key Features

Among its standout attributes are a variety of built-in patterns and stitch options, enabling users to explore different styles with ease. The model is also equipped with an intuitive digital display, which enhances the sewing experience by providing clear instructions and settings. Furthermore, its robust construction ensures durability, making it suitable for extensive use.

Benefits of Use

Utilizing this machine not only streamlines the stitching process but also enhances efficiency. Its advanced functions promote precision, allowing for intricate designs that would be challenging to achieve manually. Additionally, the adaptability of the model means it can accommodate a wide range of fabrics, further expanding creative possibilities.

Common Issues with Singer Machines

When working with sewing devices, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems is essential for maintaining functionality and achieving optimal results in sewing projects.

Thread Bunching is a frequent occurrence that can lead to frustration. This issue often arises due to incorrect threading, poor-quality thread, or a misaligned bobbin. Ensuring that the thread is properly positioned and using quality materials can help mitigate this problem.

Skipped Stitches can be another major concern. This typically happens when the needle is dull, the wrong needle type is used, or the tension is improperly adjusted. Regular maintenance and selecting the appropriate needle for the fabric can reduce the likelihood of this issue.

Fabric Jamming is another common dilemma. It can occur when the fabric is pushed too forcefully into the machine or when there are issues with the feed dogs. Keeping the machine clean and ensuring that the fabric is fed smoothly can alleviate this problem.

Uneven Stitching can also present challenges. This may result from improper tension settings, a faulty needle, or variations in fabric thickness. Adjusting the tension and using the correct needle size for the fabric can improve stitching consistency.

By being aware of these typical complications, users can take proactive steps to address them and enhance their sewing experience.

Essential Tools for Repair

When it comes to maintaining and restoring intricate devices, having the right set of instruments is crucial. These tools not only facilitate the process but also ensure precision and efficiency in addressing various issues that may arise over time.

First and foremost, a good quality screwdriver set is indispensable. Different sizes and types, such as flathead and Phillips, allow for versatility in tackling screws of all kinds. Precision screwdrivers are particularly useful for small components, providing the necessary finesse to avoid damage.

A pair of needle-nose pliers is another essential item in any toolkit. Their ability to grip and manipulate small parts makes them ideal for intricate work. Additionally, wrenches are valuable for loosening and tightening nuts and bolts, ensuring that everything is securely fastened.

Furthermore, a reliable set of scissors can aid in cutting threads, fabric, or other materials with ease. For those dealing with electronic components, wire strippers are vital for safely exposing wires without causing harm to the surrounding elements.

Finally, don’t forget about a sturdy work surface. A well-organized area not only keeps tools handy but also provides a safe environment for assembling and disassembling components. With these basic yet essential instruments, anyone can tackle a wide range of tasks effectively.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing and resolving issues with your sewing device. Following these steps can help you identify the root cause of common problems and find effective solutions.

-

Check the Power Source:

- Ensure the machine is plugged in securely.

- Examine the power cord for any visible damage.

- Test the outlet with another device to confirm it is functioning.

-

Inspect the Threading:

- Confirm the upper thread is properly threaded through the machine.

- Check the bobbin placement and ensure it is correctly wound.

- Look for tangles or knots in the thread.

-

Examine the Stitching:

- Test different stitch settings to see if the problem persists.

- Check for uneven stitches and adjust tension if necessary.

- Ensure the needle is appropriate for the fabric being used.

-

Assess for Blockages:

- Inspect the feed dogs for lint or debris.

- Check the area around the needle and presser foot for obstructions.

- Clean any dust accumulation that might impede movement.

-

Review the User Settings:

- Reset any custom settings to their factory defaults.

- Consult the display for any error messages that may indicate issues.

- Adjust the speed settings if the machine is operating too quickly or slowly.

By following these steps, you can systematically narrow down the issues and implement appropriate fixes, ensuring optimal performance of your sewing apparatus.

Replacing Worn Parts Effectively

Maintaining optimal performance in any mechanical device often hinges on timely and efficient replacement of degraded components. Recognizing when a part has lost its functionality is crucial for ensuring longevity and reliable operation. This section explores effective strategies for identifying and substituting worn elements to enhance overall device performance.

Identifying Worn Components

Before replacing any parts, it is essential to accurately determine which components are in need of attention. Consider the following signs of wear:

- Unusual noises during operation.

- Visible signs of damage, such as cracks or fraying.

- Decreased performance or efficiency.

- Inconsistent operation or failure to perform tasks.

Regular inspections can help catch issues early, preventing further damage and more costly repairs.

Steps for Effective Replacement

Once worn parts have been identified, follow these steps for a successful replacement:

- Gather necessary tools and replacement components.

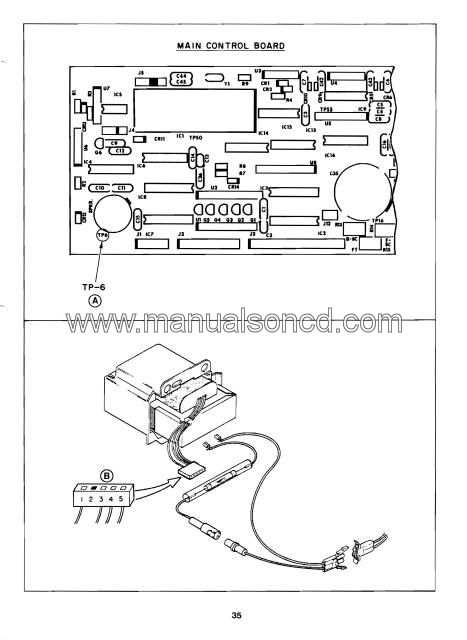

- Carefully disassemble the affected area, taking note of how parts are arranged.

- Remove the damaged components, ensuring to avoid additional strain on surrounding parts.

- Install the new parts, following the original arrangement closely.

- Reassemble the device and conduct thorough testing to confirm proper functionality.

By adhering to these guidelines, you can ensure that your equipment remains in peak condition, allowing for seamless operation and extended lifespan.

Maintaining Your Sewing Machine

Proper upkeep of your stitching device is essential for ensuring its longevity and optimal performance. Regular maintenance not only helps in avoiding costly repairs but also enhances the quality of your sewing projects. By following a few simple practices, you can keep your machine running smoothly and efficiently.

Essential Maintenance Tasks

- Cleaning: Remove lint and dust from the feed dogs, bobbin area, and needle plate. Use a soft brush or a vacuum designed for sewing machines.

- Oiling: Lubricate the designated parts as per the manufacturer’s guidelines to reduce friction and wear.

- Needle Replacement: Change the needle regularly to prevent fabric snagging and ensure clean stitches.

- Threading Check: Ensure that the threading is correct and that the tension is properly adjusted for different fabrics.

Storage Tips

- Cover the machine with a protective cover when not in use to prevent dust accumulation.

- Store in a stable, temperature-controlled environment to avoid damage from humidity or extreme temperatures.

- Keep accessories organized in a designated space to ensure everything is easily accessible.

Adjusting Tension for Optimal Performance

Achieving the right level of tension is crucial for enhancing the functionality of your sewing machine. Proper tension ensures that threads interlock correctly, which results in even stitches and prevents common issues like puckering or thread breakage. This section will guide you through the steps to adjust the tension effectively, allowing you to maximize your sewing experience.

Understanding Tension Settings

Tension settings control how tightly the threads are held during stitching. Each fabric type may require different adjustments. Here are some key points to consider:

- Lightweight fabrics generally need less tension.

- Heavy materials may require a tighter setting for balanced stitching.

- Threads of varying thickness can affect the desired tension.

Steps to Adjust Tension

- Start by selecting the appropriate needle and thread for your project.

- Test the tension on a scrap piece of fabric similar to your project.

- Observe the stitch quality; adjust the tension dial as needed.

- Repeat the test until the stitches are uniform and secure.

- Make final adjustments based on your specific fabric and thread combination.

By taking the time to fine-tune the tension, you can significantly improve your sewing outcomes and enjoy a smoother, more efficient crafting process.

Understanding the Machine’s Features

Exploring the various capabilities of this device reveals its multifaceted design, tailored for both novices and experienced users. Familiarity with its components can significantly enhance the user experience, making tasks easier and more efficient. Each feature is crafted to streamline processes and provide versatility, enabling a wide range of applications.

Core Functionalities

The machine boasts a selection of essential functions that cater to diverse needs. From automatic settings to customizable options, users can easily navigate through different modes. These functionalities not only simplify operations but also ensure precision in every task. Mastery of these features can greatly improve productivity and creativity.

Innovative Technology

Incorporating advanced technology, this equipment offers intelligent solutions for modern crafting. Features such as built-in patterns and adaptive adjustments reflect a commitment to innovation. Users can enjoy seamless integration of traditional techniques with contemporary enhancements, ultimately elevating the quality of their projects.

Frequently Asked Repair Questions

This section addresses common inquiries regarding maintenance and troubleshooting for a popular sewing machine model. Whether you’re experiencing issues or simply looking for guidance, this resource aims to provide clear and helpful answers to your concerns.

Common Issues and Solutions

Many users report problems with thread tension and skipping stitches. Adjusting the tension dial is often the first step in resolving these issues. Additionally, ensure that the needle is appropriate for the fabric type and that it is properly inserted. Regularly cleaning the feed dogs and bobbin area can prevent various operational problems.

Maintenance Tips

To extend the lifespan of your device, regular upkeep is essential. It’s recommended to oil moving parts as per the manufacturer’s guidelines and to replace the needle after several uses. Keeping the machine covered when not in use can also protect it from dust and debris, ensuring optimal performance.

Resources for Further Assistance

When encountering challenges with your sewing machine, it’s essential to access reliable resources that can provide guidance and support. Whether you’re looking for troubleshooting tips, detailed instructions, or community advice, various avenues are available to help you resolve issues effectively.

Here are some valuable resources you can explore:

| Resource Type | Description | Link |

|---|---|---|

| Official Website | Visit the manufacturer’s site for product-specific information, FAQs, and updates. | Manufacturer’s Official Site |

| User Forums | Join online communities where enthusiasts share experiences and solutions. | Sewing Community Forum |

| Video Tutorials | Watch instructional videos that demonstrate common repairs and maintenance techniques. | YouTube Sewing Tutorials |

| Local Repair Shops | Find nearby professionals who can assist with more complex issues and servicing. | Local Repair Directory |

Utilizing these resources can enhance your knowledge and improve your experience with your sewing machine. Don’t hesitate to reach out for help when needed; a wealth of information is just a click away!