Effective maintenance of mechanical systems is crucial for ensuring longevity and optimal performance. Understanding the intricacies involved in servicing these devices can prevent unexpected breakdowns and enhance their operational efficiency. This section will provide essential insights into the methods and practices necessary for maintaining complex machinery.

Proper upkeep requires a systematic approach, including regular inspections and timely interventions. Familiarity with the components and their functions plays a significant role in diagnosing issues before they escalate. Adopting a proactive stance can save both time and resources, ultimately leading to a smoother operational workflow.

In the following sections, we will explore common challenges encountered during servicing, along with effective strategies to address them. This information aims to empower users with the knowledge needed to keep their equipment in top condition, minimizing downtime and enhancing reliability.

Regular upkeep is essential to ensure the longevity and efficiency of your equipment. By following systematic practices, you can minimize the risk of unexpected failures and enhance overall performance.

Routine Inspections

Conducting frequent evaluations allows for the early detection of potential issues. Focus on the following areas:

- Check for leaks and unusual noises.

- Inspect seals and connections for wear.

- Monitor performance metrics regularly.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is vital. Implement these steps:

- Clean components to remove debris and contaminants.

- Apply suitable lubricants to moving parts as recommended.

- Ensure drainage pathways are clear to prevent fluid buildup.

Replacement Parts and Compatibility

When dealing with maintenance tasks, understanding the availability and interchangeability of components is crucial. Ensuring that the right elements are utilized not only guarantees optimal functionality but also enhances the longevity of the device.

Several factors contribute to the selection of suitable parts:

- Specifications: Always refer to the technical details to match parts accurately.

- Brand Standards: Each manufacturer may have specific guidelines regarding the use of their components.

- Compatibility: Verify that the replacements fit seamlessly with the existing system.

Common replacement components include:

- Seals and gaskets for preventing leaks.

- Filters to ensure clean operation.

- Valves for controlling the flow.

- Housing parts to maintain structural integrity.

Consulting a parts catalog can provide insight into compatible options, ensuring reliable performance and efficiency. Regular updates to inventory are essential to keep track of new and obsolete components.

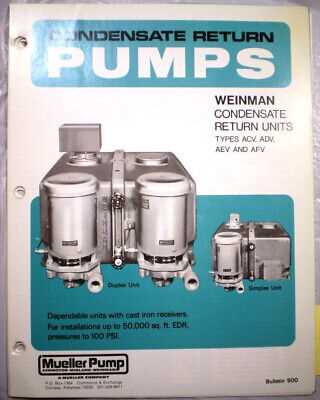

Best Practices for Pump Care

Maintaining optimal performance of your fluid handling equipment requires consistent attention and proper techniques. By implementing effective care strategies, users can extend the lifespan of their devices and ensure reliable operation over time.

Regular Inspections: Conduct frequent examinations to identify any signs of wear or damage. Check for leaks, unusual noises, and vibrations, which can indicate underlying issues.

Routine Cleaning: Keep all components clean and free of debris. Accumulated dirt can lead to inefficiencies and malfunctions. Utilize appropriate cleaning solutions to avoid damaging sensitive parts.

Monitor Performance: Pay close attention to operational metrics such as flow rates and pressure levels. Sudden changes may signal the need for further investigation or adjustments.

Lubrication: Ensure that moving parts are adequately lubricated according to the manufacturer’s specifications. Proper lubrication reduces friction and wear, promoting smoother operation.

Proper Storage: When not in use, store equipment in a dry, protected environment. This helps prevent corrosion and damage from environmental factors.

By adhering to these guidelines, users can promote the efficiency and longevity of their fluid handling systems, ensuring dependable performance in various applications.

Resources for Technical Support

Accessing reliable assistance is crucial when dealing with equipment issues. A variety of resources are available to provide guidance, ensuring that you can resolve problems efficiently and effectively. These resources can range from online forums and official websites to user manuals and professional services.

Online Communities

Participating in online forums and discussion groups can offer valuable insights from other users who have encountered similar challenges. Engaging with these communities allows for the exchange of troubleshooting tips and best practices.

Official Support Channels

Utilizing the official support channels of the manufacturer ensures that you receive accurate and up-to-date information. This includes accessing technical documentation, FAQs, and direct support from trained professionals who can assist with more complex issues.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting of equipment. Understanding these topics can enhance the longevity and functionality of your devices.

Below are some typical questions along with their answers:

- What are the signs that my device needs attention?

Look for unusual noises, leaks, or decreased performance as indicators that your unit may require servicing.

- How often should I perform maintenance?

Regular inspections and upkeep are recommended every few months, depending on usage.

- Can I fix issues on my own?

Many minor problems can be resolved with basic tools and knowledge. However, for complex issues, consulting a professional is advisable.

- What should I do if I encounter a persistent issue?

If problems persist despite attempts at resolution, it’s best to seek expert help to avoid further damage.

- Are there specific guidelines for cleaning?

Yes, follow manufacturer recommendations for cleaning to ensure safe and effective maintenance.