In the world of outdoor power equipment, understanding the nuances of upkeep is essential for longevity and optimal performance. This section delves into various aspects of servicing and resolving common issues encountered with specific machinery. By familiarizing yourself with these concepts, you can enhance your operational efficiency and prolong the lifespan of your tools.

Regular maintenance not only ensures smooth functionality but also helps in identifying potential problems before they escalate. This proactive approach can save both time and resources in the long run. Whether you are a seasoned user or a novice, knowing the key components and their care is invaluable for anyone looking to keep their equipment in peak condition.

Furthermore, troubleshooting common challenges can empower users to tackle issues independently. Equipped with the right knowledge, you can confidently address minor setbacks and enjoy a seamless experience in your outdoor projects. Emphasizing proper techniques and safety measures will lead to more enjoyable and efficient work sessions.

Maintenance Overview

This section provides essential information on the upkeep and care of a specific power tool model, ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that may arise from neglect. Understanding the key aspects of care can significantly improve the tool’s reliability and functionality.

Routine Checks

Conducting periodic inspections is crucial for identifying wear and tear. Key components such as the air filter, spark plug, and fuel lines should be examined regularly. Cleaning or replacing these parts as needed helps maintain the equipment in peak condition.

Storage Practices

Proper storage is essential to protect the tool from environmental factors. After use, ensure it is cleaned thoroughly and stored in a dry place, away from moisture and direct sunlight. This practice extends the lifespan of the equipment and keeps it ready for the next operation.

Common Issues with Stihl 009

Understanding the frequent challenges encountered with this type of equipment can enhance performance and longevity. Users often face several typical problems that can impact functionality and efficiency.

Frequent Problems

- Difficulty starting the engine

- Inconsistent power output during operation

- Excessive smoke emission

- Fuel leakage from the tank or carburetor

Potential Solutions

- Check and replace the spark plug if necessary.

- Inspect the fuel lines for blockages or damage.

- Ensure the air filter is clean and unobstructed.

- Adjust the carburetor settings for optimal performance.

Tools Needed for Repairs

For effective maintenance and restoration of outdoor power equipment, having the right instruments is essential. The following tools are commonly required to ensure that the process is smooth and efficient.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws in various components. |

| File | Helps in smoothing rough edges and surfaces after adjustments. |

| Pliers | Useful for gripping and manipulating small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Safety Gear | Protective equipment like gloves and goggles to ensure personal safety during the work. |

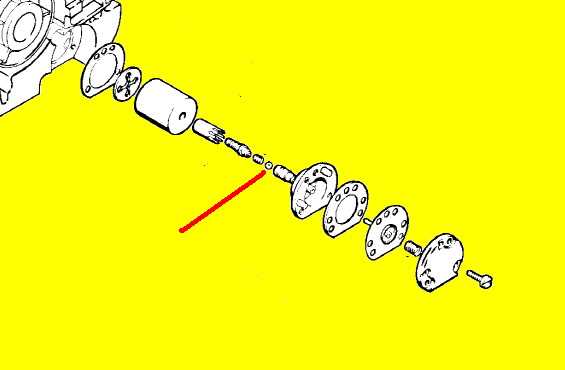

Step-by-Step Disassembly Process

This section outlines a detailed approach to dismantling a specific tool effectively. Understanding the procedure not only facilitates maintenance but also helps in diagnosing potential issues. Each stage of the disassembly is crucial for ensuring that all components are handled correctly and efficiently.

1. Prepare Your Workspace

Ensure that you have a clean and organized area for the disassembly. Gather all necessary tools, such as screwdrivers, wrenches, and pliers, to streamline the process.

2. Remove the Housing

Begin by loosening the screws securing the outer casing. Carefully lift off the housing to expose the internal components. Take note of the arrangement as it will assist in reassembly.

3. Disconnect the Fuel System

Next, detach any fuel lines connected to the device. Be cautious and ensure that no fuel spills, as this can pose safety hazards.

4. Take Off the Ignition Assembly

Unscrew and remove the ignition components. Ensure to document the placement of wires for easy reconnection later.

5. Remove the Cylinder Assembly

Carefully unscrew the cylinder from its base. Keep track of any gaskets or seals that may need replacement during reassembly.

6. Organize and Inspect Components

As each part is removed, organize them systematically. Inspect all components for wear and damage to determine if replacements are necessary.

7. Final Clean-Up

After disassembly, clean the workspace and tools to prepare for reassembly or further maintenance tasks.

Identifying Engine Problems

Recognizing issues within the power unit is crucial for maintaining optimal performance. Early detection can prevent further damage and ensure efficient operation. This section will explore common indicators of engine malfunctions and the steps to address them.

Common Symptoms of Engine Issues

- Unusual Noises: Listen for knocking, grinding, or popping sounds, which may indicate internal problems.

- Excessive Smoke: Observe the exhaust; colored smoke can signal burning oil or fuel issues.

- Difficulty Starting: Struggling to start the machine may point to fuel delivery or ignition failures.

- Loss of Power: A noticeable drop in performance can suggest various mechanical or fuel-related issues.

Steps to Diagnose Engine Problems

- Visual Inspection: Check for leaks, damaged parts, and loose connections.

- Test Fuel Quality: Ensure that the fuel used is fresh and suitable for the equipment.

- Check Air Filter: A clogged filter can restrict airflow, affecting engine efficiency.

- Evaluate Spark Plug Condition: Inspect for wear or fouling, which can lead to ignition problems.

Replacing Essential Components

Maintaining optimal performance of any tool often requires the periodic substitution of key parts. Understanding the process of component replacement is vital for ensuring longevity and efficiency. This section will guide you through essential steps to effectively swap out crucial elements of your device.

Identifying Necessary Parts

Before proceeding with replacements, it is important to accurately identify which components need attention. Commonly replaced parts include filters, spark plugs, and drive mechanisms. Assessing the condition of these elements will help in determining the necessary actions.

Gathering Tools

Having the right tools on hand is essential for a smooth replacement process. Standard tools may include wrenches, screwdrivers, and pliers. Ensuring you have everything ready will save time and minimize frustration during the task.

Step-by-Step Replacement

Once you have identified the components to be replaced and gathered your tools, follow a methodical approach. Start by carefully removing the defective part, ensuring not to damage surrounding elements. Next, install the new component, making sure it is secured properly. Finally, conduct a brief test to confirm functionality.

Regular Maintenance

Incorporating regular checks and timely replacements into your maintenance routine will help avoid potential issues down the line. Keeping track of part conditions and service intervals ensures that your equipment remains reliable and effective.

Reassembling the Chainsaw

Reassembling a cutting tool requires careful attention to detail and a systematic approach. This process ensures that all components are correctly aligned and function efficiently, leading to optimal performance.

To begin the reassembly, follow these steps:

- Gather all parts: Make sure you have all necessary components, including the body, engine, chain, and protective casing.

- Inspect components: Check each part for wear or damage, ensuring they are in good condition before assembly.

- Attach the engine: Secure the engine to the main body using appropriate fasteners, ensuring a tight fit.

- Install the chain: Carefully place the chain around the guide bar, making sure it is properly tensioned.

- Secure the casing: Attach the protective casing, ensuring all screws are tightened to avoid any loosening during use.

Finally, conduct a thorough inspection of the assembled tool to ensure all parts are securely fastened and functioning correctly before testing its operation.

Adjusting Carburetor Settings

Proper calibration of fuel delivery mechanisms is essential for optimal engine performance. Fine-tuning these settings ensures efficient operation, reduced emissions, and enhanced power output. This section provides insights into how to adjust the necessary components effectively.

Understanding the Components

The primary elements involved in fuel regulation include the idle speed screw, the mixture adjustment, and the throttle response. Familiarizing yourself with these components allows for a more precise adjustment process, contributing to improved functionality.

Steps for Calibration

Begin by ensuring the engine is warm for accurate readings. Adjust the idle speed screw until the engine runs smoothly at idle without stalling. Next, modify the mixture adjustment screw gradually, observing engine performance for optimal running conditions. A well-tuned engine will respond quickly to throttle inputs, indicating successful calibration.

Safety Precautions During Repair

Ensuring a safe environment is crucial when conducting maintenance on any equipment. Proper precautions not only protect the individual performing the tasks but also enhance the longevity and performance of the machine. Understanding and implementing safety measures can prevent accidents and ensure a smooth workflow.

Personal Protective Equipment

Before starting any service work, it is essential to equip oneself with appropriate protective gear. This includes gloves to guard against sharp edges and safety goggles to protect the eyes from debris. Wearing ear protection can also be beneficial, especially during noisy operations.

Work Area Preparation

Creating a clean and organized workspace is vital. Ensure that the area is well-lit and free from clutter. Remove any unnecessary items that could pose a tripping hazard. Additionally, having a first aid kit nearby can be a lifesaver in case of unexpected incidents.

Recommended Lubricants and Oils

Choosing the right lubricants and oils is essential for the optimal performance and longevity of your equipment. Proper maintenance relies heavily on the quality of these substances, as they ensure smooth operation and reduce wear on moving parts.

Types of Lubricants

There are various types of lubricants available, each designed for specific applications. For chain saws, a high-quality bar and chain oil is crucial. This type of lubricant helps to minimize friction, providing a protective barrier against wear while enhancing cutting efficiency.

Oil Specifications

When selecting oils, it is important to consider viscosity and composition. Synthetic oils often offer better protection and performance under extreme conditions compared to conventional oils. Always refer to manufacturer guidelines for the best practices regarding oil selection and application.

Troubleshooting Electrical Issues

Electrical complications can significantly impact the performance of various equipment. Identifying and addressing these problems is essential for ensuring optimal operation. This section aims to provide guidance on diagnosing and resolving common electrical challenges encountered in machinery.

| Issue | Possible Causes | Solutions |

|---|---|---|

| No Power | Disconnected battery, faulty wiring | Check connections and replace damaged wires |

| Intermittent Operation | Loose connections, corroded terminals | Tighten connections and clean terminals |

| Blown Fuse | Short circuit, overload | Inspect for shorts and replace fuse |

| Inconsistent Voltage | Defective voltage regulator, worn components | Test and replace faulty parts |

Cleaning the Air Filter

Maintaining the airflow within your equipment is crucial for optimal performance. Regularly inspecting and cleaning the air filter ensures that the engine receives a sufficient amount of clean air, which is essential for its efficient operation.

Steps for Cleaning

Begin by removing the air filter from its housing. Gently tap it to remove loose dirt and debris. For a more thorough clean, wash the filter with warm, soapy water, then rinse it well and allow it to dry completely before reinstallation.

Importance of Regular Maintenance

Regular cleaning of the air filter helps prevent engine wear and prolongs the lifespan of your equipment. By ensuring that the filter is free of obstructions, you enhance the overall efficiency and reliability of the engine.

When to Seek Professional Help

There are instances when attempting to fix issues with your equipment might not be the best course of action. Understanding the signs that indicate a need for expert assistance can save time and prevent further complications.

- If the problem persists after basic troubleshooting efforts.

- When you encounter unfamiliar or complex issues that require specialized knowledge.

- If there are signs of significant damage or wear that could affect performance.

- When safety concerns arise, such as potential hazards during operation.

- If you lack the necessary tools or resources to address the problem effectively.

In these cases, consulting with a qualified technician can ensure proper diagnosis and repair, ultimately prolonging the lifespan of your machinery.