Maintaining the efficiency of your fuel injection system is essential for optimal engine performance. This section provides insights into the various components and their functions, enabling you to address common issues effectively.

From troubleshooting to routine maintenance, knowing the inner workings of your system can save time and resources. Equipped with the right knowledge, you can enhance the lifespan of your equipment while ensuring smooth operation.

Familiarity with the intricacies of your system allows for informed decisions, whether it’s adjusting settings or identifying potential faults. By prioritizing this understanding, you pave the way for a more reliable and efficient experience.

This section addresses frequent problems encountered during operation and offers effective remedies to enhance functionality and reliability.

Understanding the typical challenges can facilitate timely interventions, ensuring optimal performance of your equipment. Below are some prevalent issues and their corresponding solutions:

| Issue | Solution |

|---|---|

| Poor fuel delivery | Check for blockages in the fuel line and replace filters as necessary. |

| Unstable operation | Inspect electrical connections and tighten loose components. |

| Inconsistent pressure readings | Calibrate the pressure gauge and ensure proper sealing of all connections. |

| Excessive noise | Examine moving parts for wear and lubricate accordingly. |

Tools Required for Repairs

When addressing maintenance tasks for your device, having the right equipment is essential for achieving effective results. Proper tools not only facilitate the process but also ensure that each component is handled with care and precision.

Essential instruments include wrenches, which are crucial for loosening or tightening various fittings. A set of screwdrivers with different head types is also vital, as they enable access to numerous screws that hold components in place. Additionally, pliers are invaluable for gripping, twisting, and cutting wires, allowing for versatile handling of different materials.

To enhance the effectiveness of your tasks, consider using a multimeter for electrical diagnostics, ensuring proper function of circuits and connections. Furthermore, having a workbench equipped with a magnetic tray can help keep small parts organized and within reach during your work.

Ultimately, assembling the right toolkit will greatly contribute to the efficiency and success of your maintenance efforts, enabling a smoother workflow and better outcomes.

Step-by-Step Repair Instructions

This section provides a detailed guide for addressing common issues encountered with the equipment. The following instructions aim to assist users in efficiently resolving problems through systematic steps, ensuring optimal performance and longevity of the device.

1. Identify the Issue: Begin by thoroughly examining the unit for any visible signs of malfunction. Pay attention to unusual noises, leaks, or irregular behavior that may indicate a specific fault.

2. Gather Necessary Tools: Collect all required tools and components before starting the troubleshooting process. This may include wrenches, screwdrivers, and replacement parts specific to the task at hand.

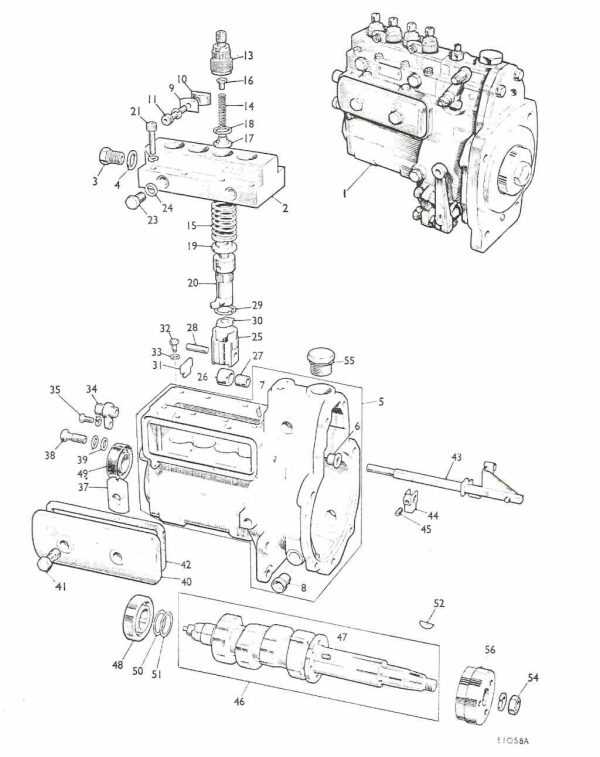

3. Disassemble the Device: Carefully take apart the necessary sections of the apparatus. Ensure you follow the proper sequence to avoid damage and keep track of all removed components.

4. Inspect Internal Parts: Examine the internal mechanisms for wear and tear. Look for damaged components or any debris that may impede functionality. Cleaning and replacing parts as needed is crucial at this stage.

5. Reassemble and Test: Once all repairs and maintenance are complete, reassemble the unit following the reverse order of disassembly. Conduct thorough testing to ensure everything operates smoothly and correctly.

6. Document the Process: Finally, keep a record of the steps taken and any changes made during the procedure. This documentation will be valuable for future reference and for anyone else who may need guidance.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of machinery. Implementing a systematic approach can help identify potential issues before they escalate, minimizing downtime and repair costs. Below are some valuable practices to consider for effective maintenance.

Routine Inspections

Conducting frequent assessments of equipment allows for early detection of wear and tear. Check key components and systems to ensure everything is functioning properly.

Lubrication and Cleaning

Maintaining cleanliness and appropriate lubrication is crucial. This reduces friction, prevents rust, and ensures smooth operation.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for signs of damage or leaks. |

| Lubrication | Monthly | Use recommended lubricants for best results. |

| Cleaning | Bi-monthly | Remove debris and dirt to enhance efficiency. |

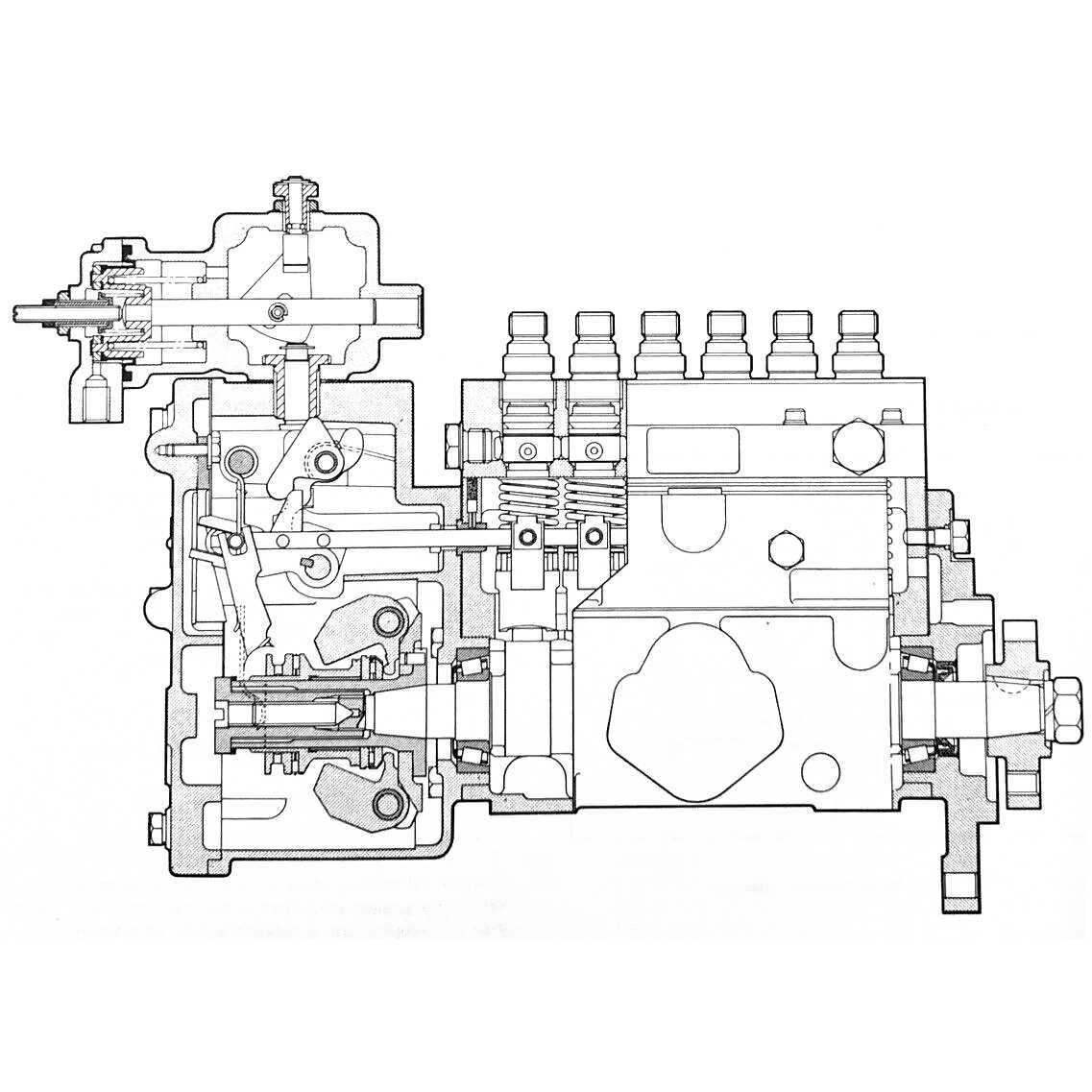

Understanding the Fuel System

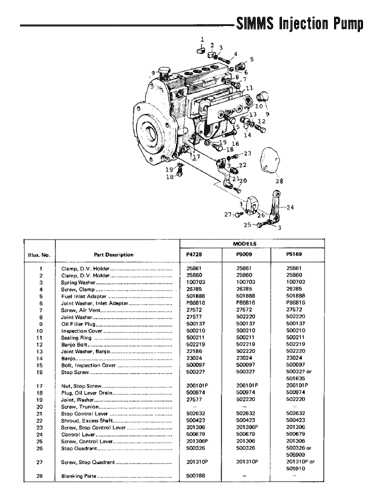

The fuel system plays a crucial role in the overall functionality of an engine. It is responsible for delivering the necessary energy source to ensure optimal performance and efficiency. A comprehensive understanding of this system is essential for effective troubleshooting and maintenance.

Key components of the fuel system include:

- Fuel Tank: Stores the fuel required for operation.

- Fuel Pump: Responsible for transferring fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to protect engine components.

- Injectors: Deliver precise amounts of fuel into the combustion chamber.

- Fuel Lines: Transport fuel between different components of the system.

Proper maintenance of each component is vital to prevent issues such as blockages or leaks, which can lead to decreased efficiency and performance. Regular inspections and timely replacements can significantly enhance the longevity and reliability of the entire system.

Diagnosing Electrical Problems

Identifying issues within electrical systems is crucial for ensuring optimal performance. A systematic approach can help isolate faults, leading to effective solutions. Understanding common symptoms can significantly ease the diagnostic process.

- Check for visible damage to wiring and connectors.

- Inspect the fuse box for blown fuses or tripped circuit breakers.

- Utilize a multimeter to measure voltage and continuity.

- Examine ground connections for corrosion or looseness.

Once initial checks are complete, proceed with more detailed evaluations:

- Monitor voltage at various points within the circuit.

- Test individual components for functionality.

- Verify that all connections are secure and free of corrosion.

By following these steps, you can systematically pinpoint electrical faults and facilitate timely repairs.

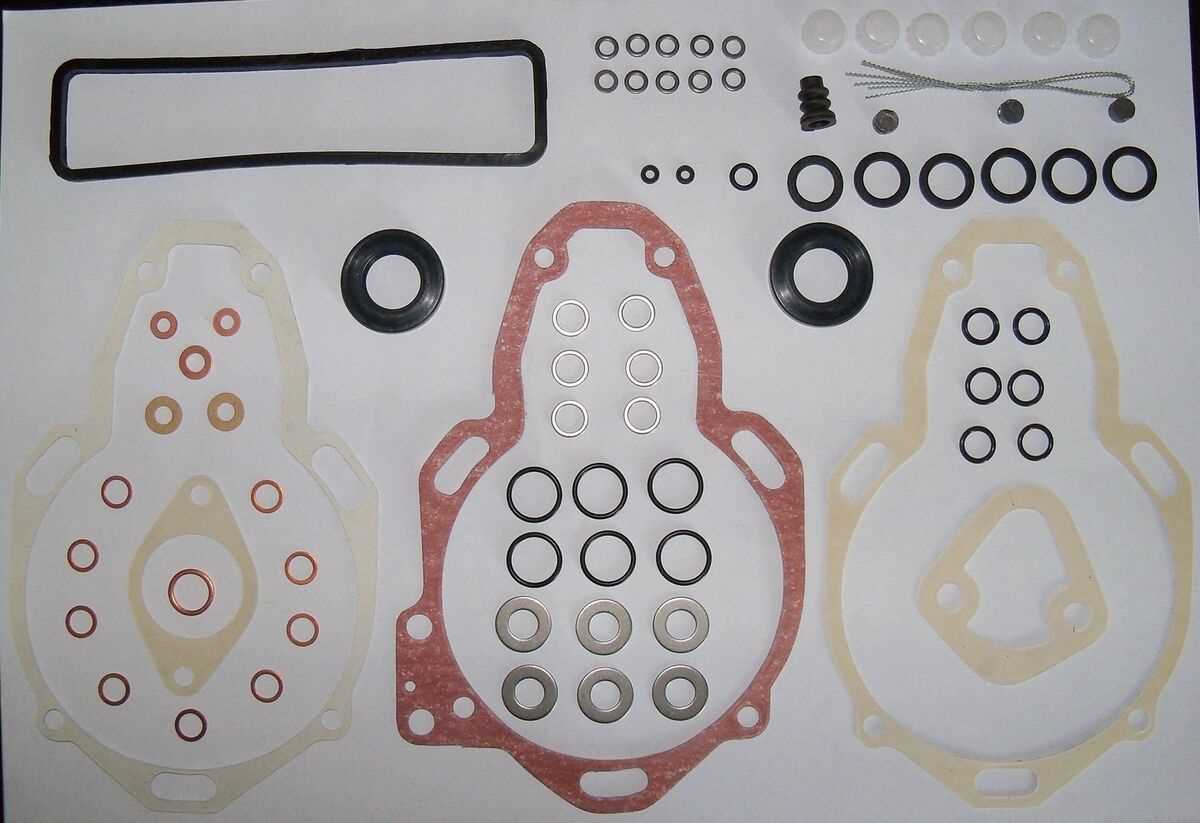

Replacing Key Components

When maintaining a fuel injection system, it is essential to address the replacement of vital parts to ensure optimal performance and reliability. This process involves identifying the components that may wear over time and replacing them with high-quality alternatives to restore functionality.

| Component | Symptoms of Wear | Replacement Tips |

|---|---|---|

| Fuel Pump | Decreased fuel pressure, engine stalling | Check electrical connections; ensure proper mounting. |

| Injector Nozzle | Uneven engine performance, increased emissions | Clean thoroughly or replace if damaged; use OEM parts. |

| Filter | Blocked fuel flow, reduced efficiency | Replace regularly as part of routine maintenance. |

By following the guidelines for component replacement, operators can effectively enhance the system’s efficiency and longevity. Prioritizing these updates not only improves performance but also prevents future complications, ensuring a smoother operation.

Testing Performance After Repairs

Evaluating functionality following maintenance is crucial to ensure optimal operation. This process helps identify any remaining issues and confirms that all components are working harmoniously. Conducting thorough assessments can prevent future complications and enhance reliability.

Initial Checks: Start by inspecting the system for visible signs of malfunction. Look for leaks, unusual noises, or inconsistent behavior that could indicate underlying problems. Addressing these observations early on is essential.

Performance Tests: Implement standardized tests to measure efficiency. This may involve monitoring output levels, fuel consumption, and response times under various operating conditions. Consistency in results is key to determining whether the system meets expected standards.

Data Analysis: Compile and analyze the data collected from tests. Compare the results against baseline measurements taken before any work was performed. This comparison will highlight any improvements or persisting deficiencies that need attention.

Final Assessment: After conducting tests and analyzing results, make informed decisions regarding any further actions. Continuous monitoring can ensure sustained performance and identify potential issues before they escalate.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and troubleshooting of a specific fuel system component. Here, you will find answers to frequently encountered issues, ensuring efficient operation and longevity.

What are the signs that my unit needs attention?

Common indicators include irregular performance, unusual noises, or leaks. Monitoring these symptoms can help prevent further complications.

How can I maintain optimal performance?

Regular inspections and timely replacements of worn parts are essential. Ensuring cleanliness and proper calibration can enhance functionality significantly.

Where can I find replacement components?

Replacement parts can typically be sourced from authorized dealers or reputable online retailers specializing in automotive equipment.

Is professional assistance necessary for all issues?

While some problems may be resolved with basic tools and knowledge, consulting a qualified technician is advisable for complex repairs to ensure safety and reliability.

Resources for Further Assistance

For individuals seeking additional support and information regarding their equipment, a variety of resources are available. These can enhance understanding and facilitate troubleshooting when encountering issues. Engaging with expert communities and utilizing comprehensive guides can significantly improve the experience of managing and maintaining your device.

Online Forums and Communities

Participating in online platforms dedicated to enthusiasts and professionals alike can provide valuable insights. Users can share experiences, ask questions, and access a wealth of knowledge from those who have faced similar challenges.

Technical Documentation and Guides

Accessing detailed documents and user-oriented guides can be instrumental in comprehending the functionalities of your device. These materials often include troubleshooting tips, maintenance procedures, and configuration advice, allowing users to effectively resolve issues independently.

| Resource Type | Description | Access Link |

|---|---|---|

| Forums | Community-driven discussions and advice. | Visit Forum |

| Guides | Step-by-step instructions and technical documentation. | Access Guides |

| Support Services | Professional assistance and troubleshooting. | Contact Support |