Maintaining the functionality of intricate timekeeping devices is essential for their longevity and performance. This section delves into the essential techniques and approaches for enhancing the inner workings of these delicate instruments. Understanding the components and their interplay is crucial for anyone looking to ensure optimal operation.

The art of revitalizing these mechanisms requires a blend of patience and precision. From identifying common issues to employing effective solutions, this guide provides insights into the processes involved. By mastering these skills, one can significantly prolong the lifespan of cherished timekeeping pieces.

In addition to addressing standard challenges, this resource emphasizes the importance of proper tools and methods. Each step outlined herein is designed to equip enthusiasts and practitioners with the knowledge needed to restore their treasured items to pristine condition. Through careful attention to detail, successful rejuvenation becomes an achievable goal.

This section aims to provide insight into the intricate mechanisms found in timekeeping devices. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring longevity and accuracy.

- Overview of Mechanisms

- Common Issues and Solutions

- Maintenance Tips for Longevity

Each mechanism comprises various elements that work together harmoniously. A deep dive into these parts can reveal how to identify and address frequent problems.

- Identify the Main Components

- Gear systems

- Pendulum functions

- Winding mechanisms

- Diagnosing Common Problems

- Inaccurate timekeeping

- Unresponsive features

- Physical damage

- Best Practices for Care

- Regular cleaning

- Proper storage techniques

- Periodic inspections

By comprehending the fundamental workings and applying consistent care, one can ensure that these devices continue to function smoothly over time.

Common Issues with Clock Mechanisms

Understanding typical problems that may arise in timekeeping devices is essential for effective troubleshooting. Various factors can lead to malfunction, often resulting in inaccurate timekeeping or complete failure. Recognizing these issues can help in implementing appropriate solutions.

- Power Source Failure: A depleted battery or faulty power connection can prevent the device from functioning properly.

- Misalignment: Components may shift over time, causing gears to misalign, which affects overall performance.

- Obstruction: Dust and debris can accumulate, hindering the movement of internal parts and leading to irregular operation.

- Wear and Tear: Continuous usage can result in deterioration of parts, particularly in mechanisms subjected to heavy use.

- Temperature Fluctuations: Extreme changes in temperature can cause expansion or contraction of materials, affecting precision.

Addressing these common concerns requires careful inspection and, when necessary, replacement of affected components. Regular maintenance can help prevent these issues from becoming significant problems in the long run.

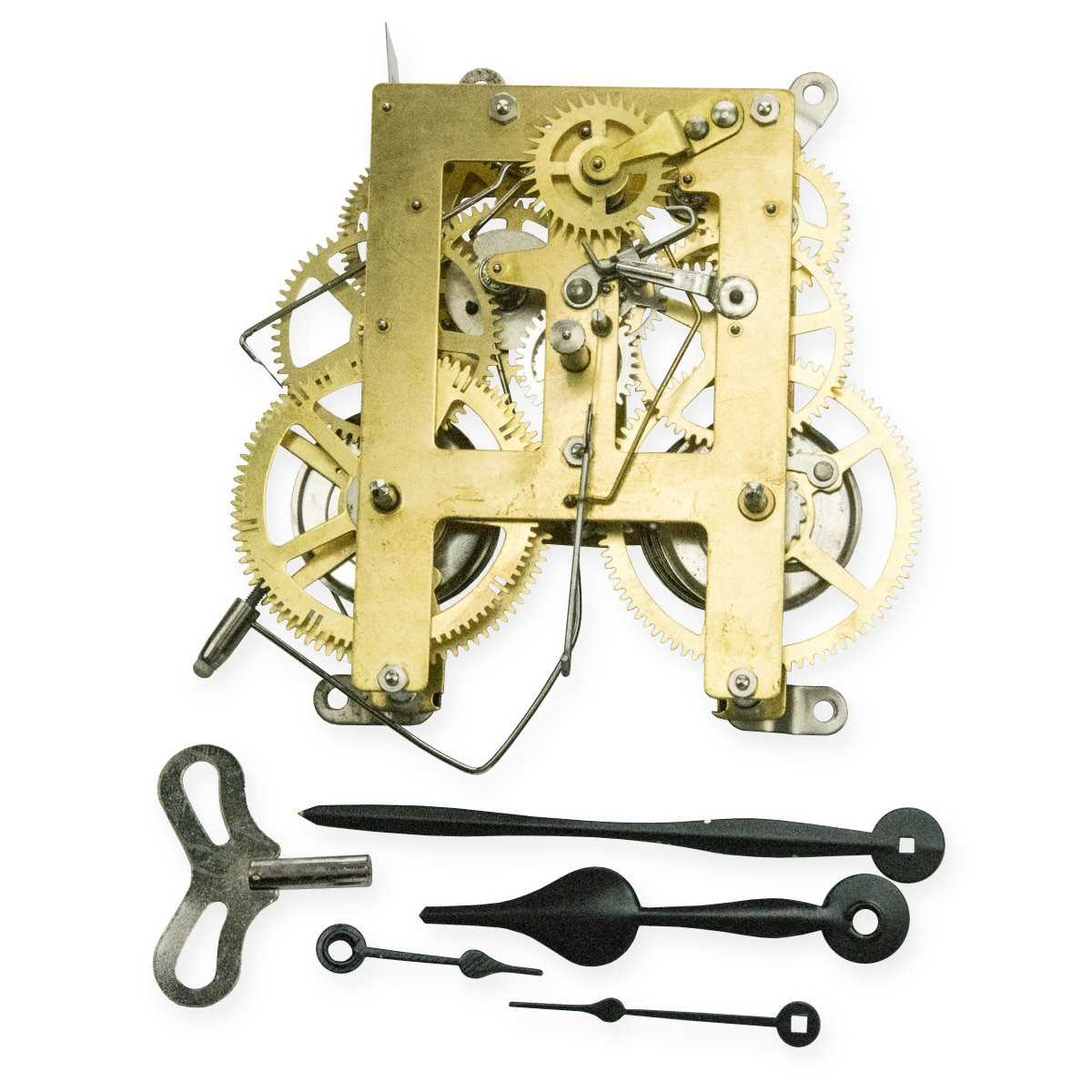

Essential Tools for Repairing Clocks

To successfully restore timekeeping devices, a variety of instruments is necessary. These tools enable enthusiasts and professionals alike to address issues effectively, ensuring that each component functions harmoniously. Understanding the importance of these instruments can significantly enhance the restoration process.

Basic Hand Tools

Every artisan should start with fundamental hand tools. A set of precision screwdrivers, pliers, and tweezers are indispensable for accessing and manipulating delicate parts. High-quality screwdrivers allow for accurate adjustments without damaging screws, while tweezers help in handling tiny components safely.

Measurement and Testing Instruments

In addition to hand tools, measurement devices play a crucial role in ensuring accuracy. A reliable caliper can measure small distances between components, while an oscillator assists in checking the timing accuracy. These tools help maintain the precision necessary for optimal functionality.

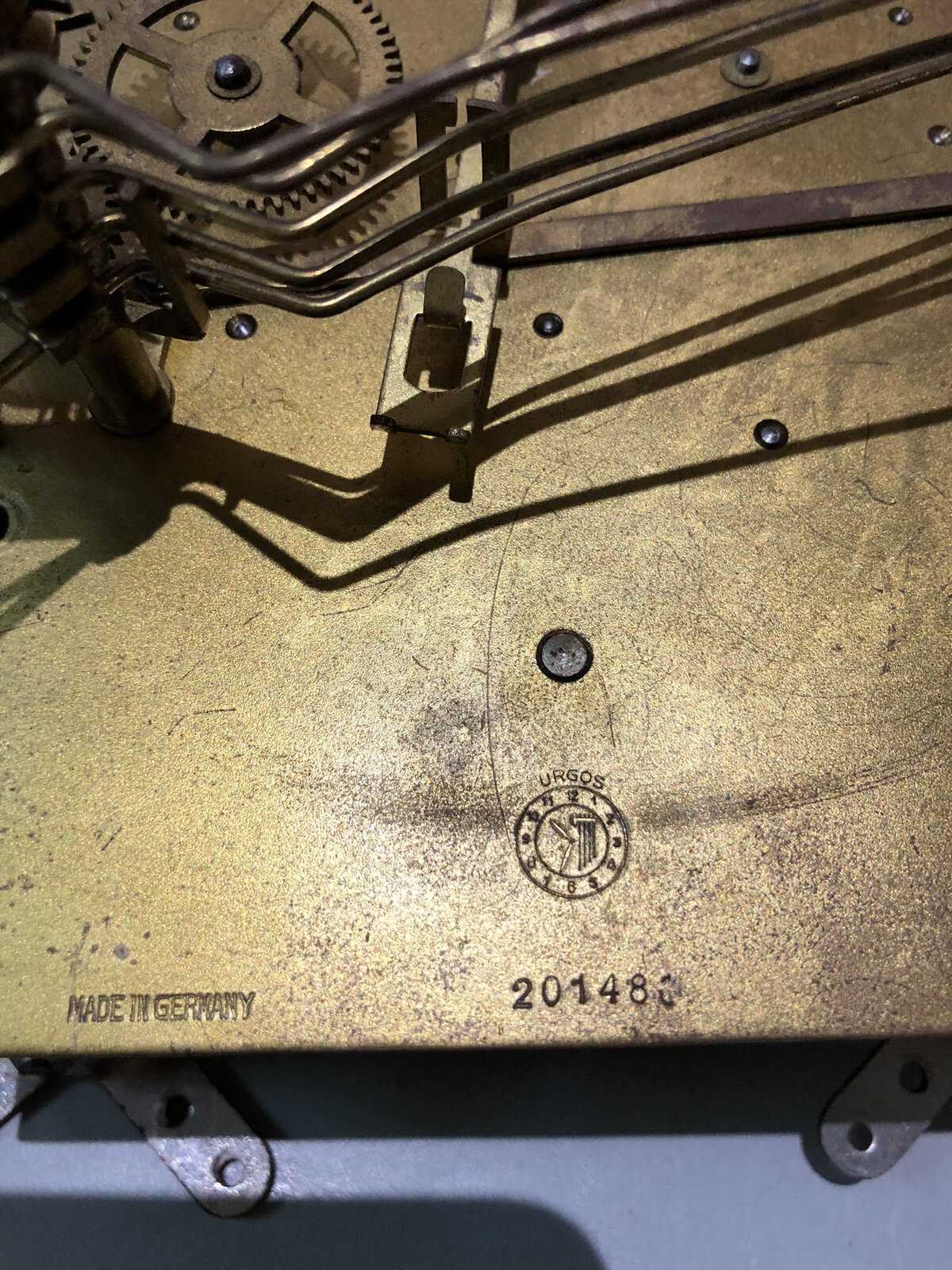

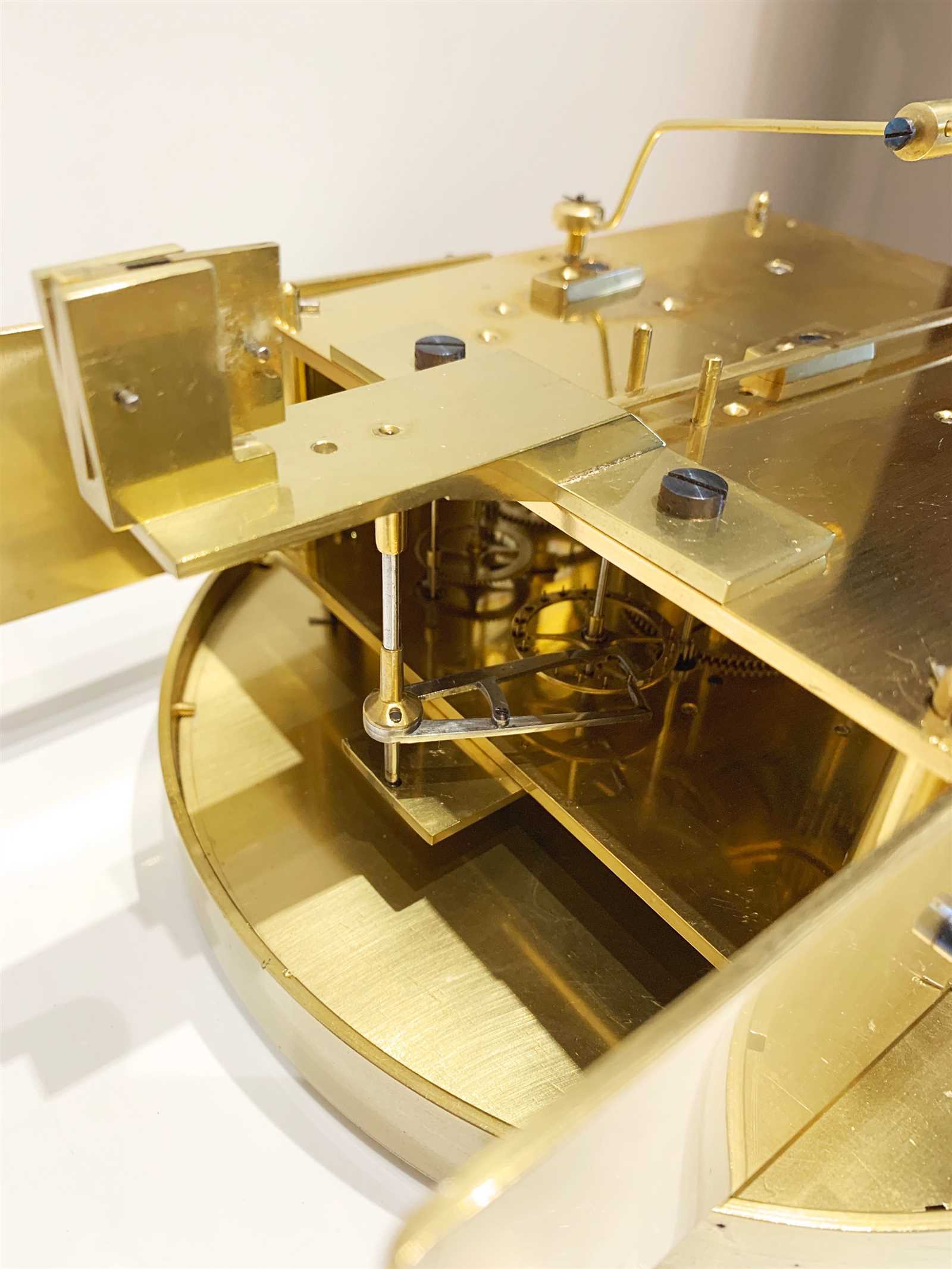

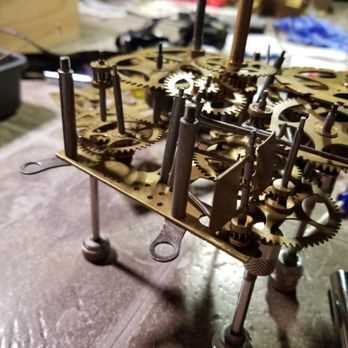

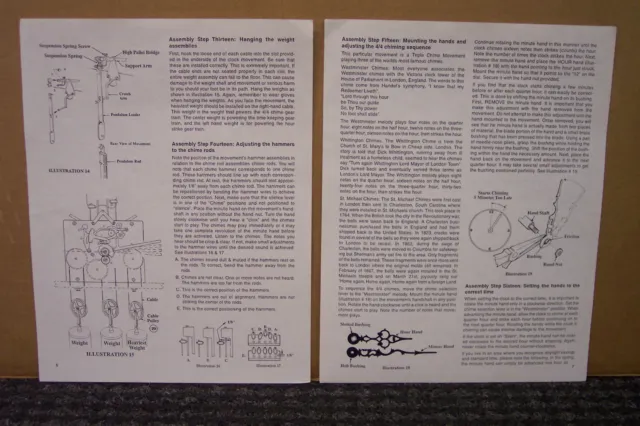

Disassembling the Urgos Movement

This section provides guidance on safely taking apart a timekeeping mechanism. Understanding the assembly’s intricacies is essential for effective maintenance and restoration.

Preparation Steps

- Gather necessary tools: small screwdrivers, tweezers, and a magnifying glass.

- Work in a well-lit area to avoid losing small components.

- Organize a clean workspace to keep parts separated.

Disassembly Process

- Carefully remove the back cover using a screwdriver.

- Take out the battery and any additional elements with caution.

- Loosen screws that hold the main components in place.

- Gently detach each piece, noting their arrangement for reassembly.

Following these steps ensures a thorough and systematic disassembly, paving the way for effective restoration work.

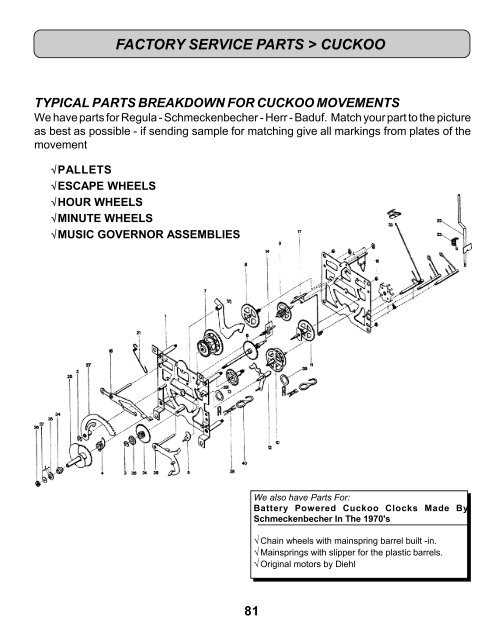

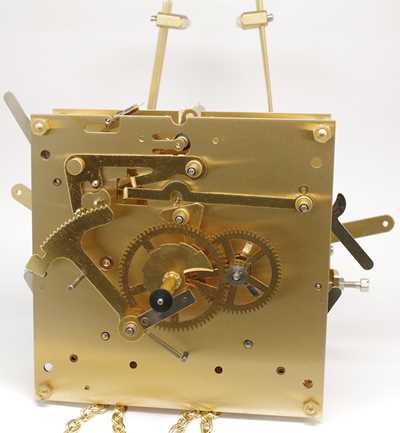

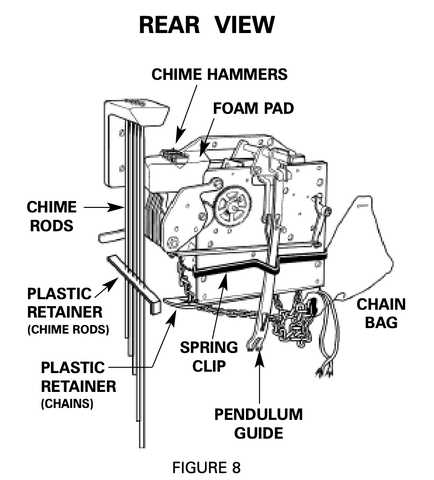

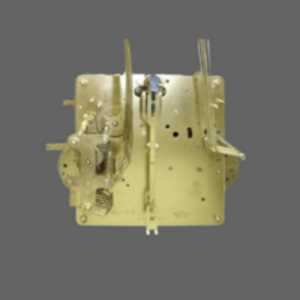

Identifying Movement Parts and Functions

Understanding the components and their roles is crucial for anyone involved in the restoration or maintenance of timekeeping devices. Each part plays a specific role in ensuring accurate time display and reliable operation. By familiarizing oneself with these elements, one can more effectively diagnose issues and perform necessary adjustments.

Main Components

The key elements of a timekeeping device typically include the following:

| Part Name | Function |

|---|---|

| Gear Train | Transmits power and regulates speed. |

| Escapement | Controls the release of energy in a controlled manner. |

| Balance Wheel | Maintains a consistent oscillation to ensure timekeeping accuracy. |

| Dials and Hands | Indicates the time visually. |

Recognizing Common Issues

Familiarity with these parts allows for the identification of common malfunctions. Problems may arise from wear and tear, misalignment, or inadequate lubrication. Recognizing these signs early can prevent further complications and facilitate smoother restoration processes.

Cleaning Techniques for Clock Movements

Maintaining precision instruments requires meticulous attention to cleanliness. Regularly removing dust and grime can enhance functionality and prolong the lifespan of intricate mechanisms. Here are some effective strategies to ensure thorough cleaning.

- Disassembly: Carefully take apart the components to access hard-to-reach areas. This step is crucial for a deep clean.

- Brush Cleaning: Use soft brushes to gently remove dust from surfaces. Avoid using stiff bristles that could scratch delicate parts.

- Ultrasonic Cleaning: Consider utilizing an ultrasonic cleaner for a thorough wash. This method uses high-frequency sound waves to dislodge debris.

- Cleaning Solutions: Employ appropriate cleaning solutions designed for delicate mechanisms. Ensure they are non-corrosive and safe for all materials.

After cleaning, reassemble the components carefully, ensuring everything is positioned correctly. Regular maintenance can significantly improve performance and reliability.

Lubrication Guidelines for Longevity

Proper maintenance of timekeeping mechanisms is essential for ensuring their durability and optimal performance. Regular application of appropriate lubricants helps reduce friction, minimize wear, and enhance the overall efficiency of the internal components.

To achieve the best results, consider the following recommendations:

- Choose high-quality lubricants specifically designed for precision instruments.

- Apply lubricant sparingly to avoid excess buildup that could lead to obstructions.

- Ensure that all moving parts are clean and free from old lubricant before application.

Routine inspections should be performed to assess the condition of the lubricated areas. If any signs of degradation are noticed, it may be necessary to clean and reapply the lubricant. Following these guidelines will contribute significantly to the longevity and reliability of the mechanism.

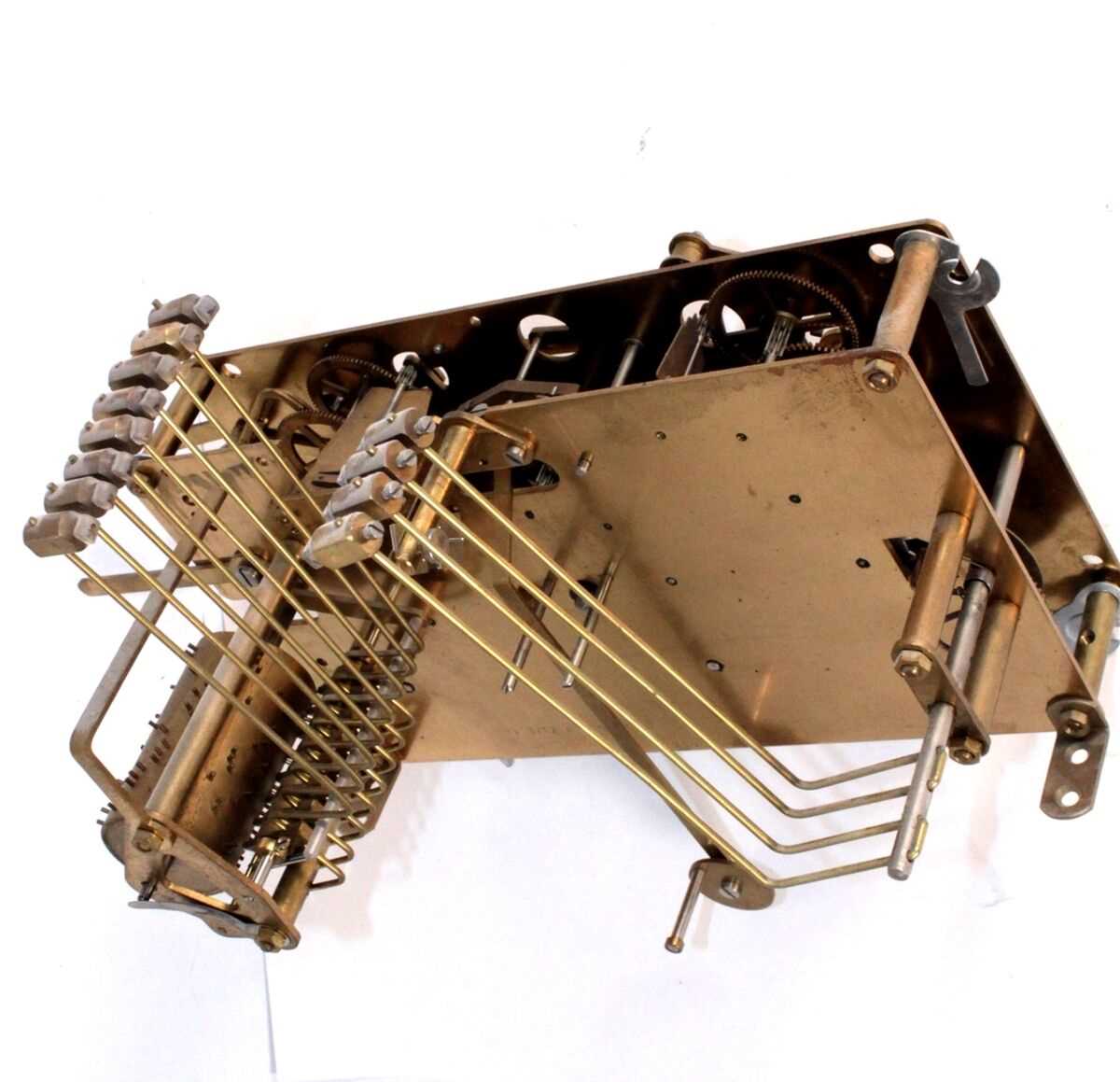

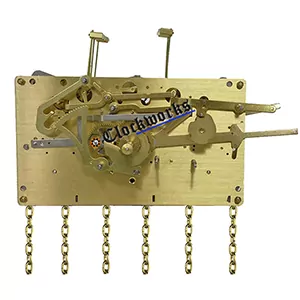

Reassembling the Urgos Clock Movement

Reconstructing a timekeeping device requires precision and attention to detail. The process involves carefully placing each component back into its rightful position, ensuring proper alignment for optimal functionality.

Follow these steps to successfully complete the assembly:

- Start by gathering all parts and tools needed for the task.

- Refer to the exploded view of the assembly for guidance on the order of reassembly.

- Begin with the base component and securely position it on a flat surface.

- Install the central gear, ensuring it is oriented correctly for smooth operation.

- Attach the surrounding elements, checking that each part fits snugly without excessive force.

- Connect the power source, verifying that all connections are secure and insulated.

- Perform a final inspection to ensure no parts are loose and everything is aligned.

Once the assembly is complete, conduct a brief test to confirm that the device operates as intended. Make any necessary adjustments to guarantee accurate performance.

Testing Your Clock for Accuracy

Ensuring that your timekeeping device operates with precision is essential for maintaining its functionality and reliability. This process involves a systematic approach to check its performance against a known standard. Regular assessments can help identify any discrepancies that may affect time measurement.

Understanding Time Standards

To effectively evaluate the accuracy of your timepiece, it is crucial to have a reliable reference. The most commonly used standard is the atomic clock, which provides the most precise time measurement available. Comparing your device against this benchmark will give you an accurate picture of its performance.

Conducting the Test

Begin by synchronizing your device with the reference time. Observe the performance over a set period, typically 24 hours. Note any variations in timekeeping. If the timepiece consistently runs fast or slow, adjustments may be necessary to enhance its accuracy. Regular testing will help maintain its reliability over time.

Adjusting the Timekeeping Mechanism

Ensuring accurate timekeeping is crucial for any timepiece. This section outlines essential steps to fine-tune the timing aspect, enhancing reliability and performance. By making necessary adjustments, one can achieve optimal accuracy, allowing the instrument to maintain precise time intervals.

Understanding the Adjustment Process

The adjustment process begins by identifying the current timekeeping status. Observing the deviation over a specified period provides insights into whether the timing is fast or slow. Once the issue is recognized, adjustments can be made to correct the discrepancies effectively.

Making Precise Adjustments

To modify the timing, locate the regulating mechanism, which typically involves a small lever or screw. Turning this component in one direction will increase speed, while turning it in the opposite direction will decrease it. Patience is key; make small adjustments and monitor the results over several days to ensure the desired accuracy is achieved.

Troubleshooting Common Clock Problems

Addressing typical issues with timekeeping devices can enhance their performance and longevity. Recognizing common faults allows for effective diagnosis and resolution, ensuring accurate time display and functionality.

Here are some prevalent concerns and their potential solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Device not functioning | Power source issues | Check batteries or power supply connection |

| Inaccurate timekeeping | Wear or misalignment | Realign gears or replace worn components |

| Unusual noises | Dust or debris buildup | Clean internal parts and lubricate as necessary |

| Hands not moving | Jammed mechanism | Inspect for blockages and clear obstructions |

Preventive Maintenance for Clock Movements

Regular upkeep is essential for ensuring the longevity and accuracy of timekeeping devices. Implementing a routine maintenance schedule can significantly reduce the likelihood of malfunctions and extend the lifespan of the internal mechanisms.

Key Steps for Effective Upkeep

- Cleanliness: Keep the exterior surfaces free from dust and grime to prevent contamination.

- Lubrication: Apply appropriate oils to the moving parts to minimize friction and wear.

- Inspection: Regularly check components for signs of wear or damage, replacing any that show significant deterioration.

- Stability: Ensure that the device is positioned on a stable surface to avoid misalignment.

Recommended Maintenance Frequency

- Daily: Wipe the exterior with a soft cloth to remove dust.

- Monthly: Inspect for visible signs of wear and apply lubricant where necessary.

- Yearly: Conduct a thorough examination and professional servicing to ensure all parts function correctly.

When to Seek Professional Help

Understanding when to consult an expert is crucial for maintaining the functionality of your timepiece. While many issues can be resolved independently, certain situations require specialized knowledge and skills to ensure proper restoration.

Signs That Indicate a Need for Expertise

- Persistent inaccuracies in timekeeping despite adjustments.

- Unusual noises or irregular movements from the mechanism.

- Visible damage to components such as gears or springs.

- Corrosion or moisture inside the casing.

Benefits of Professional Assistance

- Access to specialized tools and techniques.

- Expertise in diagnosing complex issues that may not be apparent.

- Assurance of quality and longevity of repairs.

- Preservation of historical or sentimental value of the timepiece.