When it comes to maintaining outdoor equipment, understanding the intricacies of their operation is essential for ensuring longevity and efficiency. This section aims to provide invaluable insights into the upkeep of portable devices designed for clearing debris, focusing on common issues and their solutions. Proper care not only enhances performance but also contributes to a safer working environment.

In any mechanical system, wear and tear can lead to performance degradation over time. Identifying symptoms of malfunction early can save time and resources, preventing more significant problems down the line. This guide outlines essential steps and considerations to help users navigate through common challenges encountered with these powerful tools.

Equipping oneself with the right knowledge is paramount. By understanding the operational principles and maintenance requirements, users can tackle difficulties with confidence. The following sections will delve into diagnostic techniques, routine servicing tasks, and troubleshooting strategies to empower users in their efforts to maintain optimal functionality.

Understanding Stihl Backpack Blowers

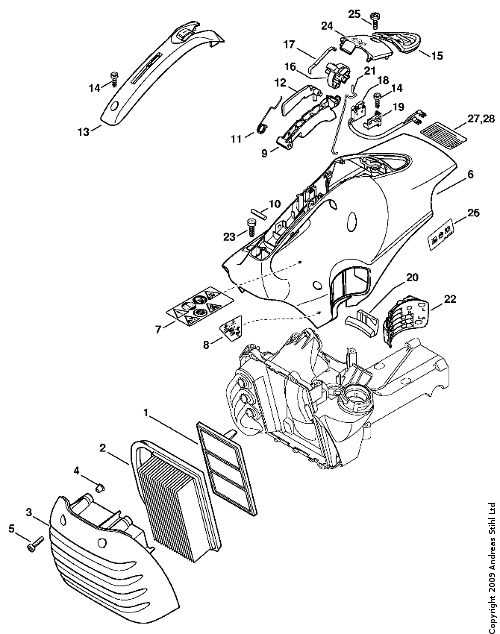

This section delves into the mechanics and features of portable outdoor equipment designed for efficient debris management. These powerful devices are engineered for ease of use, allowing individuals to maintain their outdoor spaces with minimal effort. Recognizing their capabilities and components can enhance the user experience and ensure optimal performance.

Key Features of Portable Outdoor Equipment

Modern machines in this category are equipped with advanced technologies that improve efficiency and comfort. Lightweight materials contribute to user convenience, while ergonomic designs reduce fatigue during extended use. Additionally, these devices often feature adjustable power settings, enabling users to customize performance based on specific tasks.

Maintenance and Care

Proper upkeep is crucial for longevity and effectiveness. Regular cleaning of air filters and fuel systems helps prevent issues, while periodic checks on the ignition and exhaust components ensure reliable operation. Understanding the importance of maintenance not only prolongs the life of the equipment but also enhances its overall performance.

Common Issues and Solutions

When using outdoor power equipment, it’s not uncommon to encounter certain challenges that can hinder performance. Understanding these typical problems and their respective solutions can help ensure optimal functionality and longevity of your device.

- Difficulty Starting:

- Check the fuel level and quality; stale fuel can cause starting issues.

- Inspect the spark plug for wear or carbon buildup; replacing it may resolve the problem.

- Ensure that the choke is set correctly for the starting conditions.

- Loss of Power:

- Examine the air filter for dirt and debris; cleaning or replacing it can improve airflow.

- Look for blockages in the exhaust system that may restrict performance.

- Check the fuel mixture; incorrect ratios can affect engine efficiency.

- Excessive Vibration:

- Inspect the mounting hardware and components for looseness; tighten as necessary.

- Examine the impeller for damage or imbalance; replacing it can help reduce vibration.

- Ensure that the device is on a stable surface when in use to minimize movement.

- Fuel Leaks:

- Check all fuel lines for cracks or damage; replacing worn lines can prevent leaks.

- Inspect the fuel tank for signs of wear; a damaged tank may need replacement.

- Ensure that all connections are tight and secure to prevent spills.

By addressing these common issues promptly, users can maintain their equipment in peak condition and avoid more significant repairs in the future.

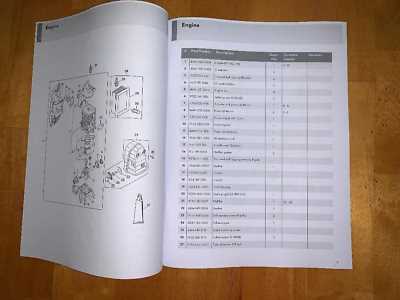

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right set of instruments is crucial. A well-equipped toolkit not only streamlines the process but also ensures that each task is completed efficiently and effectively. Understanding which items are essential can significantly enhance your ability to troubleshoot and resolve issues.

Basic Hand Tools: A solid collection of hand tools is the foundation of any maintenance effort. Essential items include screwdrivers, wrenches, and pliers. These tools allow for easy disassembly and reassembly of various components, enabling access to internal parts that may require attention.

Specialized Equipment: Some tasks may necessitate specific tools designed for particular functions. For instance, a torque wrench is invaluable for ensuring that fasteners are tightened to the manufacturer’s specifications, while a multimeter can help diagnose electrical problems effectively.

Cleaning Supplies: Regular maintenance often involves cleaning to keep equipment in optimal condition. Brushes, solvents, and cloths are necessary to remove dirt, debris, and buildup that can affect performance. Keeping components clean is key to prolonging the lifespan of any device.

Protective Gear: Safety should always be a priority. Wearing gloves, goggles, and masks not only protects you during the maintenance process but also ensures that you can work confidently without risk of injury.

By equipping yourself with these fundamental tools and supplies, you can tackle a variety of tasks effectively, ensuring that your outdoor equipment remains in top shape for years to come.

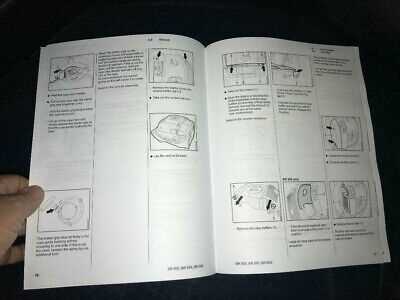

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. This guide outlines a systematic approach to maintaining your device, helping you identify key areas that require attention and providing clear instructions for each step.

-

Preparation: Before starting, gather all necessary tools and supplies, such as:

- Wrenches and screwdrivers

- Fuel and oil

- Cleaning cloths

- Protective gear

-

Inspection: Conduct a thorough examination of the equipment to identify any visible signs of wear or damage. Focus on:

- Hoses and connections

- Filters and screens

- Fuel tank and lines

-

Cleaning: Keep the machine clean for better performance. Follow these steps:

- Remove any debris from the exterior.

- Clean or replace air filters as needed.

- Flush the fuel system if required.

-

Lubrication: Regular lubrication is crucial for moving parts. Apply appropriate lubricants to:

- Bearings and pivots

- Cables and chains

-

Testing: After maintenance, perform a functionality check. Ensure:

- All components operate smoothly.

- There are no unusual noises or vibrations.

Following this maintenance guide will help enhance the efficiency and lifespan of your equipment, ensuring it operates at its best whenever you need it.

How to Troubleshoot Starting Problems

Encountering issues when attempting to ignite your equipment can be frustrating. Proper diagnostics can often identify the underlying causes of these starting difficulties. By systematically evaluating key components, you can determine whether the problem lies in fuel delivery, electrical systems, or other crucial areas.

Common Issues and Solutions

| Problem | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | No fuel | Check fuel level and refill if necessary. |

| Engine starts but stalls | Clogged fuel filter | Inspect and replace the fuel filter if needed. |

| Hard starting | Faulty spark plug | Examine the spark plug and replace it if worn. |

| Inconsistent starting | Dirty air filter | Clean or replace the air filter to ensure proper airflow. |

Step-by-Step Troubleshooting

Start by verifying that there is sufficient fuel and that it is fresh. Next, check the air intake system for blockages. Ensure that the ignition components are functioning correctly, as any malfunction here can prevent the engine from starting. If the equipment still does not start after these checks, it may be necessary to consult with a professional for further evaluation.

Replacing the Fuel Filter

Maintaining optimal performance of your equipment involves regular checks and replacements of vital components, one of which is the fuel filter. This small yet crucial part ensures that only clean fuel reaches the engine, preventing potential damage and inefficiencies. Understanding how to replace this component can lead to enhanced longevity and reliability of your machinery.

Tools and Materials Needed

Before beginning the replacement process, gather the necessary tools and materials. You will need:

- New fuel filter

- Screwdriver set

- Pliers

- Fuel line wrench (if applicable)

- Clean cloth

Steps to Replace the Fuel Filter

Follow these steps to successfully replace the fuel filter:

- Prepare the Equipment: Ensure the machine is turned off and cool. Disconnect the spark plug for safety.

- Access the Fuel Filter: Locate the fuel filter; it is usually found along the fuel line or inside the fuel tank.

- Remove the Old Filter: Using pliers, gently squeeze the clips securing the filter. Carefully pull it from the line, taking care not to damage surrounding components.

- Install the New Filter: Position the new filter in the same orientation as the old one. Secure it with the clips to ensure a tight fit.

- Reconnect and Test: Reattach any disconnected parts and the spark plug. Start the machine to check for proper function and ensure there are no leaks.

Regular replacement of the fuel filter is essential for maintaining efficiency. This simple task can prevent costly repairs down the line, ensuring your equipment runs smoothly for years to come.

Cleaning the Air Filter Effectively

Maintaining optimal performance of outdoor equipment requires regular upkeep, and one of the most crucial components to care for is the air filter. A clean air filter ensures that the engine receives an adequate supply of clean air, which is essential for efficient combustion and overall functionality. Neglecting this task can lead to decreased performance and increased fuel consumption.

Steps to Clean the Air Filter:

Begin by removing the filter from its housing. This usually involves loosening a few screws or clips. Once detached, gently tap the filter against a hard surface to dislodge any loose debris. For deeper cleaning, consider using a soft brush or compressed air to eliminate trapped particles without damaging the filter material.

If the filter is heavily soiled, it may require washing. Use warm, soapy water and a gentle scrubbing motion. After rinsing thoroughly, allow the filter to dry completely before reinstallation. This step is crucial, as moisture can affect the performance of the engine.

Reinstallation and Final Check:

Once the filter is dry, carefully place it back into its designated slot, ensuring it fits securely. Check for any gaps or misalignments that could allow unfiltered air to enter the engine. Regularly inspect the filter during routine maintenance to ensure longevity and optimal performance of your equipment.

Fixing Ignition System Failures

Addressing issues within the ignition framework is crucial for restoring optimal functionality to your equipment. Understanding the common pitfalls and their solutions can significantly enhance performance and reliability. This guide outlines key troubleshooting steps to rectify ignition-related problems.

Common Symptoms of Ignition Problems

- Engine fails to start

- Intermittent starting issues

- Engine misfires during operation

- Stalling or rough idling

Troubleshooting Steps

- Check Spark Plug:

- Remove the spark plug and inspect for wear or damage.

- Ensure proper gap settings are maintained.

- Replace if necessary.

- Inspect Ignition Coil:

- Examine for cracks or signs of corrosion.

- Test with a multimeter to ensure it’s functioning within specifications.

- Replace if faulty.

- Examine Wiring Connections:

- Look for loose or frayed wires.

- Ensure all connections are secure and free of rust.

- Fuel Quality Check:

- Verify that the fuel is fresh and free from contaminants.

- Replace old fuel to ensure optimal ignition.

Following these steps will help identify and resolve ignition system failures, ensuring reliable performance in your equipment.

Identifying and Resolving Performance Issues

Understanding how to diagnose and fix efficiency problems is crucial for maintaining optimal functionality. Various symptoms may indicate underlying issues that can be addressed to restore performance. This section provides insights into common challenges and effective solutions to enhance operational capability.

Common Symptoms and Their Causes

Several indicators can help identify performance-related issues. Recognizing these signs is the first step in troubleshooting effectively.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Reduced Airflow | Clogged air filter | Clean or replace the filter |

| Hard Starting | Old fuel or spark plug issue | Replace fuel and inspect spark plug |

| Unusual Noises | Loose components or debris | Tighten parts and clear obstructions |

| Inconsistent Performance | Fuel mixture problems | Check and adjust fuel mixture |

Steps for Resolution

Once the symptoms and potential causes are identified, follow these systematic steps to rectify the issues. Regular maintenance and prompt attention to problems will significantly improve longevity and performance.

When to Seek Professional Help

Understanding when to consult an expert can save time, effort, and potentially costly mistakes. While some issues may seem manageable, there are situations where professional intervention is essential for safety and efficiency.

Complex Issues

If you encounter intricate problems that require specialized knowledge, it’s wise to reach out for assistance. Symptoms such as unusual noises, inconsistent performance, or smoke emission often indicate deeper mechanical failures that demand an experienced technician’s assessment.

Safety Concerns

Safety should always be a priority. If you feel uncertain about handling repairs or notice hazards such as leaks or electrical issues, seeking help is crucial. Professionals can ensure that your equipment is functioning safely and effectively, preventing accidents and further damage.