Engines are vital components of various machinery, requiring proper attention for optimal performance. Understanding the intricacies of these machines enhances not only their longevity but also their efficiency. This guide aims to provide essential insights into troubleshooting and upkeep procedures, ensuring smooth operation over time.

With an array of common issues that can arise, having a resource that outlines diagnostic steps and solutions is invaluable. From addressing minor faults to undertaking more significant interventions, familiarity with specific aspects of engine care can prevent costly repairs and downtime. By following systematic approaches, users can confidently tackle challenges that may surface.

Additionally, gaining knowledge about various components and their functions can demystify the maintenance process. This empowers individuals to make informed decisions and take proactive measures in caring for their engines. Whether you’re a novice or an experienced enthusiast, this comprehensive resource is designed to equip you with the necessary tools for successful engine management.

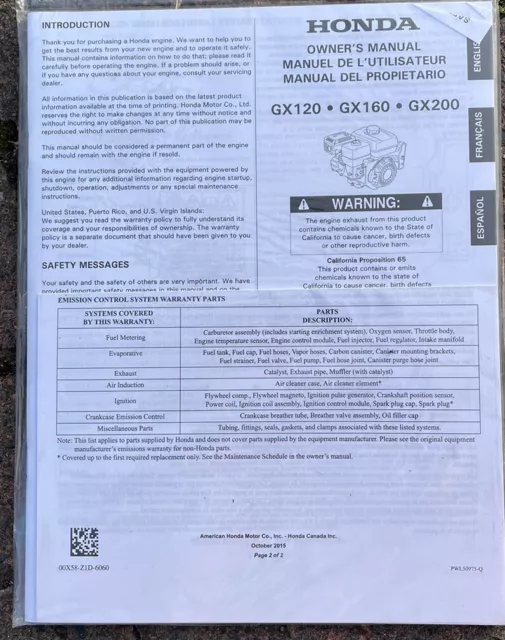

Overview of Honda GX200 Engine

This section provides a comprehensive insight into a widely utilized power unit known for its reliability and performance. Its design is suited for various applications, making it a preferred choice for many users.

The engine features a range of characteristics that contribute to its efficiency:

- Single-cylinder, four-stroke design

- Horizontal shaft for versatile mounting options

- Air-cooled system ensuring optimal temperature regulation

- Compact and lightweight structure for easy transportation

Common applications include:

- Generators

- Pressure washers

- Lawn equipment

- Construction machinery

Regular maintenance is essential for sustaining optimal performance and longevity. Key maintenance tasks include:

- Changing the oil

- Inspecting the air filter

- Checking spark plug condition

- Monitoring fuel quality

Understanding the features and maintenance requirements of this power unit will enhance its lifespan and reliability in various tasks.

Common Issues and Troubleshooting Tips

When dealing with small engine problems, it’s essential to identify frequent complications and apply effective solutions. This section focuses on typical malfunctions and provides guidance for diagnosing and fixing these issues efficiently.

Engine Won’t Start

If the engine fails to ignite, check the fuel supply, ensuring it’s fresh and reaches the carburetor. Inspect the spark plug for wear or damage; replacing it may resolve ignition issues. Additionally, ensure the choke is in the correct position for starting.

Overheating

Overheating can be caused by insufficient airflow or a clogged cooling system. Clean the cooling fins and check the air intake for debris. Ensure that the oil level is adequate, as low oil can lead to increased friction and heat.

Regular maintenance is crucial to prolong the life of the engine and minimize the likelihood of these issues. Stay proactive by conducting routine inspections and servicing as needed.

Maintenance Guidelines for Longevity

Regular upkeep is essential for ensuring the extended life of any engine. By following a few fundamental practices, users can enhance performance and reduce the likelihood of issues over time. Adopting a proactive approach not only preserves functionality but also maximizes efficiency.

Routine Checks

- Inspect the air filter regularly; clean or replace as necessary to ensure optimal airflow.

- Check oil levels frequently and change the oil at recommended intervals to maintain lubrication.

- Examine spark plugs for wear and replace them to ensure reliable ignition.

Seasonal Care

- Before long periods of inactivity, drain fuel to prevent residue buildup.

- Store the engine in a dry, cool place to protect against corrosion.

- Run the engine periodically to keep components lubricated and functioning smoothly.

Parts Replacement and Compatibility

Maintaining and enhancing engine performance often involves understanding the nuances of component substitution and the interrelationships between various parts. Selecting the right replacements ensures optimal functionality and longevity, while compatibility among components is crucial for seamless integration.

Identifying Suitable Components is the first step in the replacement process. It is essential to refer to specifications and consult trusted sources to guarantee that the selected items align with the engine’s design and requirements. Considerations should include dimensions, materials, and operational characteristics.

Ensuring Compatibility among different parts can prevent potential issues. Not all components are interchangeable; hence, verifying their fit and performance with existing systems is vital. Utilizing original specifications or verified aftermarket alternatives can provide a reliable path to successful integration.

In summary, a thorough understanding of component replacement and the significance of compatibility can enhance overall performance and reliability, allowing for effective upkeep of the engine’s functionality.

Step-by-Step Repair Procedures

This section outlines a systematic approach to fixing common issues in small engines, providing a clear path to restore functionality. By following these detailed instructions, even those with limited experience can tackle maintenance tasks effectively.

Initial Assessment

Begin by evaluating the engine to identify symptoms of malfunction. Look for signs such as unusual noises, lack of power, or difficulty starting. Document these observations to guide your troubleshooting process.

Disassembly and Inspection

Carefully disassemble the engine components, paying attention to the order of removal to ensure easy reassembly. Inspect each part for wear or damage, particularly the spark plug and fuel lines. Replace any faulty components as necessary, ensuring that replacements match the specifications for optimal performance.

Tools Required for Effective Repairs

Proper maintenance and restoration tasks necessitate a variety of specialized instruments. These essential items ensure efficiency and precision, allowing for thorough examinations and effective adjustments. Having the right tools at hand simplifies processes, minimizes errors, and enhances the overall quality of the work.

Commonly needed implements include wrenches, screwdrivers, and pliers, each serving a distinct purpose in disassembly and assembly. Measurement devices, such as calipers and gauges, aid in verifying specifications and tolerances, ensuring that components fit correctly. Additionally, a comprehensive toolkit often features cleaning supplies and lubricants, vital for maintaining optimal functionality and preventing wear.

For more intricate tasks, diagnostic equipment becomes indispensable. Multimeters and compression testers provide critical insights into performance issues, guiding technicians in pinpointing faults accurately. Investing in high-quality tools not only facilitates smoother operations but also extends the lifespan of the machinery.

Understanding Engine Components and Functions

The operation of a combustion engine relies on a variety of interconnected elements that work together to convert fuel into mechanical energy. Each component plays a specific role in ensuring efficient performance and longevity, contributing to the overall functionality of the system.

At the heart of the engine lies the cylinder, where the fuel-air mixture ignites, generating the force necessary for movement. Surrounding this core are several essential parts, including the piston, which moves up and down to compress the mixture, and the crankshaft, which transforms this linear motion into rotational energy.

The ignition system is crucial for initiating combustion. It includes components like the spark plug, which creates a spark to ignite the mixture at the right moment. Meanwhile, the fuel system ensures a steady supply of gasoline or diesel, facilitating consistent operation.

Additionally, the cooling system prevents overheating by circulating coolant around the engine, while the lubrication system reduces friction between moving parts, promoting durability. Understanding these key components and their functions is vital for anyone looking to maintain or troubleshoot their machinery effectively.

Fuel System Care and Cleaning

Maintaining the fuel delivery mechanism is essential for optimal engine performance and longevity. Regular attention to this area can prevent common issues such as clogs, leaks, and inefficient combustion. Proper upkeep ensures that the system functions smoothly, allowing for better power output and fuel efficiency.

To begin, always use clean and high-quality fuel to reduce contaminants entering the system. Periodically inspect the fuel filter for debris and replace it as necessary to ensure unobstructed flow. Cleaning the carburetor and related components is crucial; this can be done by removing deposits that accumulate over time. A gentle soak in a suitable cleaning solution can help eliminate stubborn residues.

Additionally, check the fuel lines for any signs of wear or leakage. Replace any damaged sections to maintain integrity within the system. Using fuel stabilizers during prolonged periods of inactivity can prevent the degradation of fuel, ensuring readiness when the engine is needed again. Consistent monitoring and cleaning will greatly enhance reliability and performance.

Electrical System Diagnosis Techniques

Assessing the functionality of an electrical system is crucial for ensuring optimal performance. This section outlines effective methods for evaluating components, identifying issues, and ensuring reliable operation.

Utilizing systematic approaches can lead to more efficient troubleshooting. The following techniques can be employed:

- Visual Inspection: Examine wiring, connectors, and components for signs of wear, corrosion, or damage.

- Multimeter Testing: Use a multimeter to measure voltage, current, and resistance, helping pinpoint faults in circuits.

- Continuity Testing: Check for complete electrical paths to confirm connections are intact.

- Component Testing: Isolate and test individual parts to determine their operational status.

- Load Testing: Assess how the system performs under varying loads to identify potential failures.

Implementing these techniques will assist in diagnosing electrical issues effectively and ensuring a system’s longevity and reliability.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on machinery is paramount. Adhering to specific guidelines can prevent accidents and promote a secure working environment. Understanding and implementing these measures will not only protect the individual but also enhance the longevity of the equipment being serviced.

Personal Protective Equipment

Wearing appropriate protective gear is essential during maintenance tasks. This includes items such as gloves, goggles, and ear protection, which can significantly reduce the risk of injury. Always ensure that your clothing is fitted properly to avoid entanglement in moving parts.

Workspace Safety

Maintaining a clean and organized workspace can help minimize hazards. Ensure that tools and materials are stored properly and that the area is well-lit. Avoid clutter, and keep flammable materials away from the worksite to reduce the risk of fire.

| Safety Measure | Description |

|---|---|

| Protective Gear | Wear gloves, goggles, and appropriate clothing to minimize injury risk. |

| Tool Maintenance | Ensure all tools are in good condition and suitable for the task at hand. |

| Fire Safety | Keep flammable substances away from the workspace and have a fire extinguisher nearby. |

Service Schedule for Optimal Performance

Maintaining optimal efficiency and longevity of small engines requires a systematic approach to upkeep. Adhering to a well-structured timeline for service tasks ensures that performance remains consistent and issues are identified early.

Below are key tasks that should be incorporated into the service schedule:

- Oil Change: Regularly replacing the lubrication fluid is crucial. Aim to change it every 20-50 operating hours, or at least once a season.

- Air Filter Maintenance: Inspect the air filtration system frequently. Clean or replace the filter every 25 hours of use to ensure proper airflow and efficiency.

- Spark Plug Inspection: Check the ignition component every 50 hours. Replace it if there are signs of wear or carbon buildup to maintain reliable starting and smooth operation.

- Fuel System Cleaning: Ensure the fuel delivery system remains unobstructed. Flush the system at least once a year to prevent clogs and maintain performance.

- Valve Clearance Check: Periodically verify the spacing of the valve assembly, typically every 100 hours, to ensure optimal engine timing and efficiency.

Following this service schedule not only enhances performance but also extends the lifespan of the equipment, making it a worthwhile investment for any user.