When it comes to the longevity and optimal performance of outdoor equipment, understanding the intricacies of its upkeep is crucial. This guide aims to provide valuable insights into the necessary steps and techniques to ensure your machinery operates smoothly throughout its lifecycle. From routine checks to specific troubleshooting methods, a well-rounded approach can make all the difference in maintaining functionality.

Throughout this comprehensive resource, you will discover detailed instructions that cover various aspects of care and restoration. Each section is designed to empower users with knowledge, enabling them to tackle common issues effectively. By familiarizing yourself with the core components and their operations, you can confidently approach any maintenance tasks.

Whether you are a seasoned enthusiast or a newcomer, this guide offers essential information that can enhance your experience. Emphasizing practicality, it will help you develop a proactive mindset towards preserving your equipment. With the right tools and techniques at your disposal, you can ensure reliability and efficiency for many seasons to come.

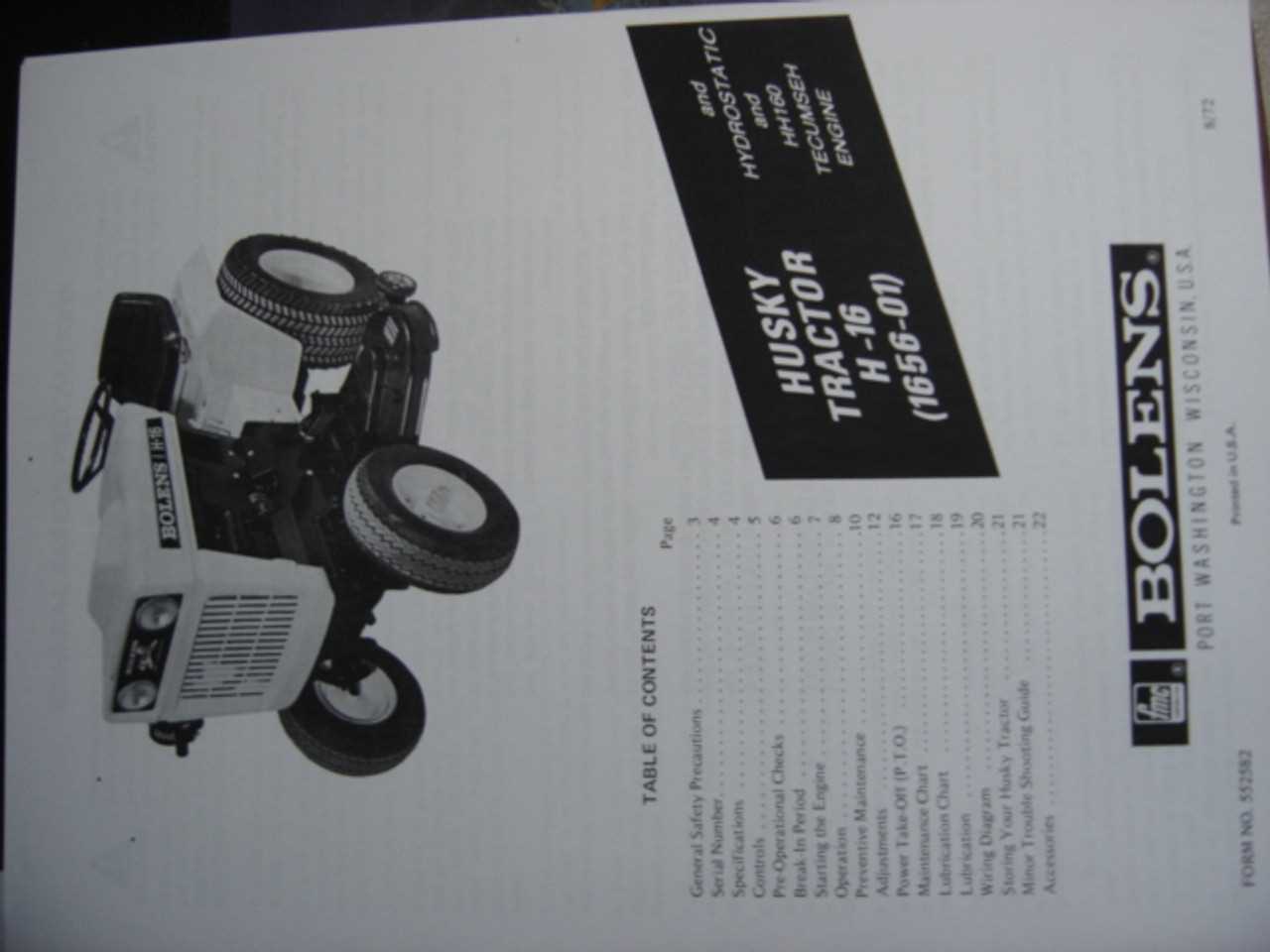

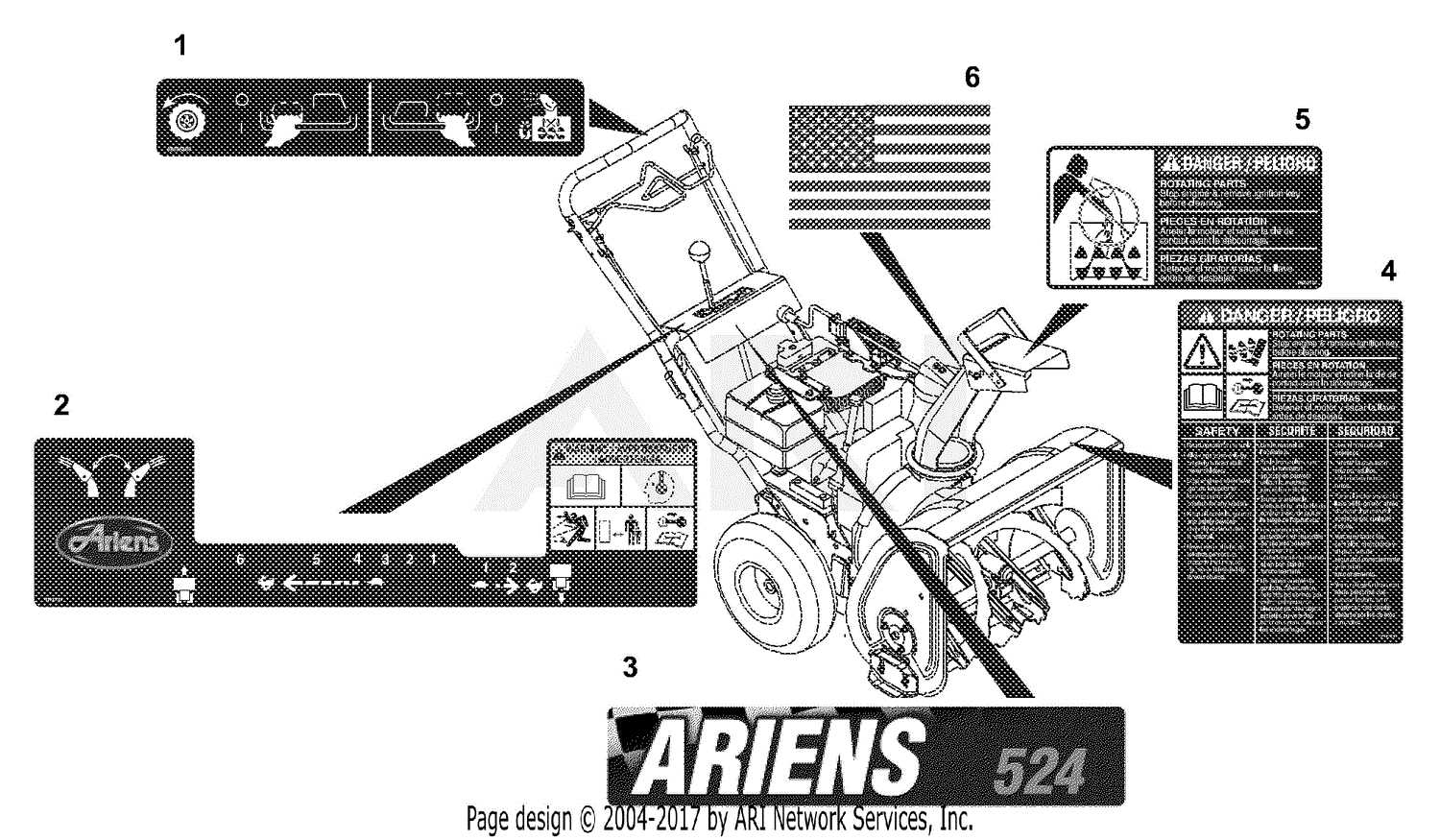

Ariens 932 Series Overview

This section provides a comprehensive insight into a specific line of outdoor power equipment known for its durability and efficiency. These machines are designed to tackle various tasks, making them a popular choice among homeowners and professionals alike. Understanding the features and capabilities of this equipment can significantly enhance user experience and performance.

Key Features

Notable attributes of these models include robust engines that offer reliable performance under challenging conditions. Additionally, the innovative design ensures ease of use, with intuitive controls and adjustable settings that cater to different requirements. Maintenance is straightforward, allowing for longevity and sustained functionality, making these machines a valuable addition to any toolkit.

Applications and Benefits

These machines excel in a variety of applications, from snow removal to lawn care, showcasing versatility that meets diverse needs. Users appreciate the combination of power and efficiency, which translates to time-saving benefits. Investing in this equipment not only enhances productivity but also contributes to a well-maintained outdoor space.

Key Features of the Ariens 932

This section highlights the standout characteristics of a well-regarded snow-clearing machine designed for efficiency and durability. Users can expect a blend of power and functionality, making it suitable for various winter conditions.

One notable aspect is its robust engine, providing ample horsepower to tackle heavy snowfall. The advanced design ensures reliable performance even in the most challenging weather scenarios.

Equipped with multiple speed settings, this equipment allows for smooth operation, enabling users to adjust the pace according to their specific needs. The intuitive controls enhance usability, making it accessible for operators of all skill levels.

Additionally, the snow-throwing mechanism is engineered for optimal performance, ensuring effective snow displacement. The wide intake and adjustable chute facilitate efficient clearing of large areas without unnecessary effort.

Durability is another key feature, with high-quality materials used throughout the construction. This attention to detail results in a product that can withstand the rigors of regular use, providing long-lasting value to owners.

Finally, the ease of maintenance is a significant advantage, allowing for quick servicing to keep the machine in peak condition. This thoughtful design minimizes downtime, ensuring that it remains a reliable companion during the winter months.

Common Issues with Ariens 932

When it comes to outdoor equipment, certain recurring problems can affect performance and reliability. Understanding these common challenges can help users address issues promptly and maintain optimal functionality. Below are some typical concerns that operators may encounter with these machines.

One frequent issue involves the starting mechanism. Difficulty in ignition can stem from a range of factors, including fuel quality or battery condition. Ensuring that the battery is fully charged and that the fuel is fresh can often resolve these problems.

Another common complication is related to the drive system. Users may experience slippage or a complete lack of movement, which can usually be traced back to worn belts or improper tension. Regular inspection and maintenance of the drive components are essential to prevent these issues.

Additionally, performance can be hindered by clogged or damaged impellers. Debris buildup can significantly affect the efficiency of snow clearing, making it crucial to check for obstructions and clean the area regularly.

Lastly, issues with the controls, such as levers or switches not responding, can arise. This can often be attributed to wear and tear or electrical faults. Conducting routine checks on these components can help identify and rectify problems before they escalate.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing common issues associated with outdoor power equipment. By following these detailed instructions, users can effectively restore their machinery to optimal working condition. Each step is designed to be clear and accessible, ensuring that both novice and experienced individuals can successfully complete the tasks.

Identifying Common Issues

Before proceeding with any maintenance work, it’s crucial to pinpoint the specific problems affecting the equipment. Common symptoms may include poor performance, unusual noises, or difficulty starting. Understanding these signs will help in determining the appropriate course of action.

Procedure Overview

The following table outlines the essential steps to address typical challenges encountered during maintenance:

| Step | Description |

|---|---|

| 1 | Inspect the equipment for visible signs of wear or damage. |

| 2 | Check fuel levels and ensure proper fuel quality. |

| 3 | Examine and clean air filters to improve airflow. |

| 4 | Inspect spark plugs for signs of wear and replace if necessary. |

| 5 | Lubricate moving parts according to the manufacturer’s specifications. |

| 6 | Test the equipment after performing maintenance to ensure proper function. |

Maintenance Tips for Longevity

Ensuring the durability of outdoor equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and extend the lifespan of your machinery. Regular maintenance not only helps in preventing unexpected breakdowns but also optimizes functionality for seasonal tasks.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris from the exterior and engine components to prevent rust and deterioration. |

| Oil Changes | Change the oil at recommended intervals to keep the engine running smoothly and efficiently. |

| Check Belts and Cables | Inspect belts for wear and tear, and replace any frayed or damaged parts to ensure safe operation. |

| Sharpen Blades | Keep cutting edges sharp to improve performance and reduce strain on the engine during operation. |

| Fuel Maintenance | Use fresh fuel and consider adding stabilizers to prevent degradation during storage. |

Implementing these simple yet effective practices will not only enhance the reliability of your equipment but also ensure that it remains in optimal condition for many years to come.

Tools Required for Repairs

When maintaining and fixing outdoor power equipment, having the right instruments is crucial for achieving optimal results. A well-equipped toolbox not only simplifies the process but also enhances efficiency and safety. Below is a comprehensive list of essential items that will assist in troubleshooting and resolving common issues.

Wrenches and Sockets: A set of wrenches and sockets in various sizes is necessary for loosening and tightening bolts and nuts. Ensure you have both metric and standard options to accommodate different fasteners.

Screwdrivers: A variety of screwdrivers, including flathead and Phillips types, are indispensable for accessing and securing components. Having multiple sizes on hand will make it easier to tackle various screws.

Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires. They provide better control when handling small parts or performing detailed tasks.

Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening and ensuring safety during operation.

Cleaning Supplies: Brushes, rags, and cleaning solutions are essential for keeping parts free from dirt and debris. Regular maintenance helps prolong the life of the equipment.

Safety Gear: Protective eyewear, gloves, and ear protection should always be worn to safeguard against potential hazards during maintenance activities.

Equipping yourself with these tools will greatly enhance your ability to conduct effective maintenance and address any problems that may arise, ultimately contributing to the longevity and performance of your equipment.

Understanding the Engine Components

Grasping the fundamentals of engine parts is essential for anyone looking to enhance performance or troubleshoot issues. Each component plays a vital role in the overall functionality and efficiency of the machinery. By familiarizing yourself with these elements, you can make informed decisions regarding maintenance and repairs.

Key components of an engine include:

- Cylinder: The space where combustion occurs, driving the engine’s pistons.

- Piston: Moves up and down within the cylinder, converting fuel into mechanical energy.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion.

- Valves: Control the intake of air and fuel, as well as the exhaust of combustion gases.

- Camshaft: Operates the valves, synchronizing their movement with the pistons.

Understanding these components will allow you to better assess engine performance and identify potential areas for improvement or issues that may arise during operation.

Additionally, familiarity with the supporting systems is crucial:

- Fuel System: Delivers the necessary fuel to the engine for combustion.

- Ignition System: Initiates the combustion process by igniting the fuel-air mixture.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Lubrication System: Reduces friction between moving parts and prevents wear.

By understanding both the primary components and their supporting systems, you can ensure your engine runs smoothly and efficiently.

Electrical System Troubleshooting Guide

This section provides essential insights into diagnosing and resolving common electrical issues that may arise in outdoor power equipment. By following systematic steps, users can efficiently identify faults within the electrical components, ensuring optimal performance and reliability.

Common Electrical Issues

Several problems may affect the functionality of the electrical system. Below are some frequently encountered issues along with their potential causes:

| Issue | Possible Causes |

|---|---|

| Engine Won’t Start | Defective battery, faulty ignition switch, loose wiring connections |

| Intermittent Power Loss | Corroded terminals, damaged wiring, failing electrical components |

| Lights Flickering | Loose connections, inadequate voltage, faulty bulbs |

Troubleshooting Steps

To effectively address electrical problems, follow these steps:

- Inspect battery connections for corrosion and tightness.

- Test the voltage output with a multimeter.

- Examine wiring for damage or wear.

- Check switches and relays for functionality.

- Replace any defective components as needed.

Implementing these troubleshooting techniques can help restore the equipment to optimal working condition.

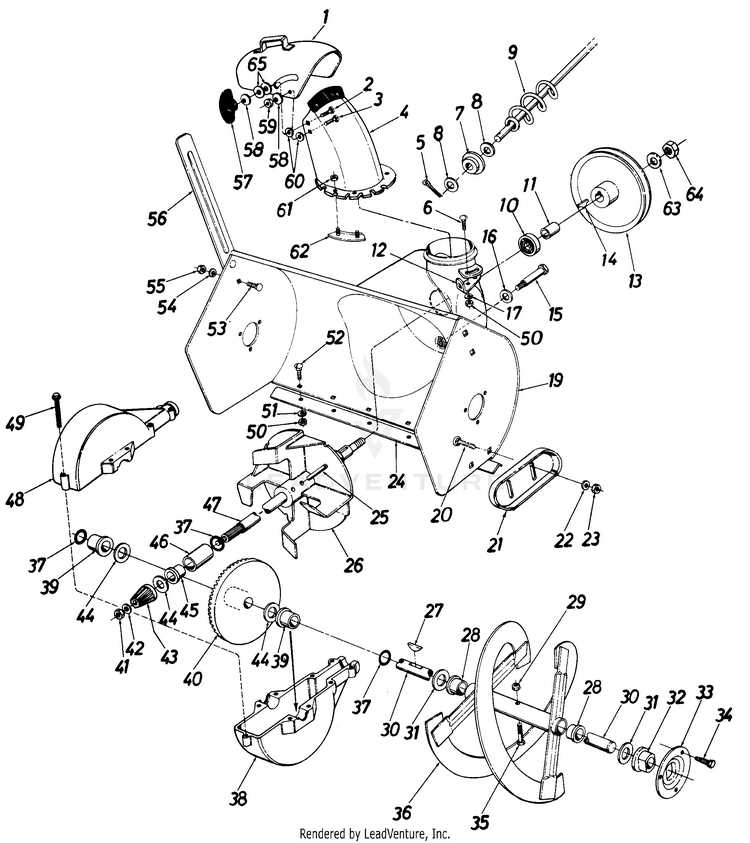

Replacing the Auger Assembly

Replacing the auger mechanism is a crucial task for maintaining optimal performance during snow removal. This component is responsible for breaking up and gathering snow, making its functionality essential for efficient operation. Over time, wear and tear may necessitate its replacement to ensure reliable performance.

Begin by ensuring the equipment is turned off and disconnected from any power source. This safety measure is vital before performing any maintenance. Once secured, locate the auger assembly, which is typically situated at the front of the machine. Inspect for any visible signs of damage or excessive wear.

To proceed with the replacement, remove any screws or bolts securing the assembly in place. Carefully detach the old unit, taking note of how it was installed to assist with the installation of the new one. Ensure that the new auger assembly matches the specifications required for your equipment.

Install the new mechanism by aligning it with the mounting points and securing it with the previously removed fasteners. It’s important to tighten these connections properly to avoid future issues. Once secured, reconnect any necessary cables or components that were detached during the process.

After the installation is complete, conduct a thorough check to confirm that everything is in place. Finally, test the equipment to ensure the new auger assembly operates smoothly and efficiently, ready to tackle winter weather challenges.

Fuel System Care and Adjustments

Maintaining the efficiency of the fuel delivery system is essential for optimal performance of your equipment. Proper attention to this component ensures that the engine operates smoothly and reliably. This section outlines the necessary steps and considerations for caring for and fine-tuning the fuel system.

Regular Inspection is crucial. Routinely check for any leaks, cracks, or wear in fuel lines and connections. Make sure the fuel filter is clean and free from debris, as a clogged filter can hinder performance. Replacing it periodically helps maintain a steady flow of fuel.

Adjusting the carburetor settings can greatly enhance engine performance. Ensure that the air-fuel mixture is balanced according to the manufacturer’s specifications. Too rich or too lean of a mixture can lead to inefficiencies and increased emissions. Use a tuning screwdriver to make fine adjustments while monitoring engine response.

Additionally, ensure that the fuel used is fresh and appropriate for your machine. Stale fuel can cause starting issues and operational problems. Consider using a fuel stabilizer if the equipment will be stored for an extended period to prevent degradation.

Finally, seasonal maintenance is important. Before and after prolonged use, drain any leftover fuel to prevent varnish buildup in the system. Thoroughly cleaning all components will aid in longevity and reliability, ensuring that your equipment is always ready for action.

Seasonal Preparation Tips

Preparing your outdoor equipment for the changing seasons is essential for ensuring optimal performance and longevity. Taking proactive steps can help you avoid common issues and ensure your machinery is ready for the demands of the upcoming weather conditions.

1. Clean Thoroughly: Before storing your equipment, make sure to clean it thoroughly. Remove any dirt, debris, or residue that may have accumulated during use. A clean surface not only prevents rust but also ensures smooth operation when you bring it out again.

2. Check Fluids: Inspect and change the fluids as needed. This includes oil, fuel, and any other essential liquids. Fresh fluids can enhance performance and reduce wear on critical components.

3. Inspect Components: Take the time to check all parts for signs of wear or damage. Look for cracks, rust, or any loose connections. Addressing minor issues now can prevent costly repairs later.

4. Sharpen Blades: If your equipment includes cutting tools, ensure that blades are sharpened and properly aligned. Sharp blades improve efficiency and provide cleaner cuts, making your tasks easier.

5. Store Properly: When the season comes to an end, store your machinery in a dry, sheltered area. Use protective covers if necessary, and ensure that it is stored in a position that allows for good airflow to prevent moisture buildup.

By following these tips, you can prepare your outdoor equipment effectively, ensuring it remains in peak condition for when you need it most.

When to Seek Professional Help

Recognizing when to call in an expert can be crucial for maintaining equipment effectively. Certain situations may arise where the complexity of the issue exceeds personal knowledge or tools available. Understanding these scenarios can save time and prevent further complications.

Signs That Indicate Professional Assistance is Needed

- Persistent Issues: If the same problem recurs despite your attempts to fix it, it’s time to consider external expertise.

- Unusual Noises: Sounds that are out of the ordinary may signal a deeper problem requiring specialized tools for diagnosis.

- Fluid Leaks: Any leaking substances should be addressed promptly by a professional to prevent potential damage.

- Electrical Problems: Issues involving wiring or electrical components should be handled by certified technicians for safety reasons.

Benefits of Professional Assistance

- Expert Knowledge: Professionals have extensive training and experience to identify and resolve issues efficiently.

- Time-Saving: Engaging an expert can significantly reduce downtime compared to troubleshooting on your own.

- Warranty Protection: Professional servicing may help maintain warranties that could be voided through improper repairs.