In the world of personal care appliances, understanding how to maintain and troubleshoot your devices is crucial for their longevity and optimal performance. This section delves into essential information and techniques that can help you restore functionality to various models of elevating apparatuses. Equipped with the right knowledge, users can address common issues efficiently, ensuring that their equipment remains reliable and effective.

Each device is designed with specific components that may require occasional attention. By familiarizing yourself with the inner workings of your apparatus, you empower yourself to tackle minor malfunctions and prevent more significant problems. This guide provides step-by-step instructions and valuable tips to aid you in this endeavor, ultimately enhancing your experience and satisfaction with your device.

Whether you’re experiencing operational hiccups or simply seeking to perform routine maintenance, understanding the fundamental aspects of your equipment will prove invaluable. Embracing a proactive approach not only saves time and resources but also extends the lifespan of your essential appliances, allowing you to enjoy their benefits for years to come.

Braun Lift Repair Manual Overview

This section provides a comprehensive guide aimed at understanding the intricacies of the device’s maintenance and troubleshooting processes. It encompasses essential information necessary for effectively addressing common issues, ensuring optimal functionality, and enhancing the overall lifespan of the appliance.

Key Features of the Guide

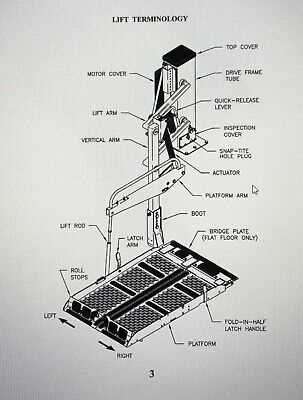

The documentation emphasizes critical aspects of the apparatus, including its structural components and operational principles. By delving into systematic approaches, users can gain insights into diagnosing malfunctions, applying corrective actions, and performing routine checks.

Importance of Regular Maintenance

Regular upkeep is vital for sustaining peak performance. This guide underscores the significance of preventative measures that can mitigate potential failures, allowing for a seamless experience. Understanding these practices not only fosters efficiency but also extends the durability of the equipment.

Common Issues with Braun Lifts

Many users encounter recurring challenges with their elevating devices, which can impact functionality and performance. Understanding these frequent problems is essential for effective troubleshooting and ensuring optimal operation.

One common concern involves irregular movement, where the mechanism may hesitate or not respond smoothly. This can result from mechanical wear or issues within the control system, leading to frustration during use.

Another prevalent issue is power-related malfunctions. Devices may fail to start or exhibit inconsistent power levels, often linked to faulty connections or battery problems. Regular maintenance checks can help identify these issues before they escalate.

Noise during operation is also a frequently reported problem. Unusual sounds can indicate loose components or the need for lubrication, signaling that attention is required to prevent further damage.

Finally, improper alignment can lead to safety hazards. Users should routinely inspect the positioning and functionality to ensure everything is operating as intended, promoting a safe experience.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for effective and efficient outcomes. Proper instruments ensure that the process is smooth, minimizing the risk of damage to components while enhancing the quality of the work performed. Below is a detailed list of tools that will aid in these tasks.

Essential Equipment

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers to accommodate different types of screws. |

| Pliers | Used for gripping, twisting, and cutting wires or small components. |

| Multimeter | Essential for measuring voltage, current, and resistance, helping to diagnose issues. |

| Wrench Set | Different sizes to ensure a secure grip on nuts and bolts. |

| Wire Strippers | For removing insulation from electrical wires, crucial for any electrical work. |

Additional Tools

| Tool | Description |

|---|---|

| Heat Gun | Useful for shrinking tubing or softening adhesive materials. |

| Flashlight | Illuminates hard-to-reach areas, ensuring visibility during the process. |

| Cleaning Supplies | Brushes and cloths to remove dust and debris from surfaces. |

| Storage Containers | Helps keep small parts organized and prevents loss during the task. |

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues that may arise with your device. By following these structured guidelines, you can effectively troubleshoot and restore functionality without requiring specialized knowledge.

1. Preparation: Begin by gathering all necessary tools and components. Ensure you have a clean, well-lit workspace to facilitate efficient work.

2. Disassembly: Carefully remove the outer casing, taking note of any screws or fasteners. Keep them organized to simplify reassembly later.

3. Inspection: Examine internal parts for signs of wear, damage, or loose connections. Pay close attention to electrical components and wiring.

4. Component Replacement: If any parts are faulty, replace them with compatible alternatives. Ensure that the new components are securely installed to prevent future issues.

5. Reassembly: Once all necessary modifications have been made, reattach the outer casing, ensuring all screws and fasteners are tightened properly.

6. Testing: Power on the device to confirm that it operates correctly. Monitor its performance to ensure that the issue has been resolved.

7. Final Checks: Conduct a thorough inspection of the exterior and interior to confirm everything is in order. Clean the device as needed to maintain its appearance.

Safety Precautions for Maintenance

Ensuring safety during servicing tasks is paramount to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding environment. Adhering to established guidelines can greatly reduce risks associated with maintenance activities.

Personal Protective Equipment

Always wear appropriate personal protective gear, such as gloves, goggles, and sturdy footwear. This equipment acts as a barrier against potential hazards, including sharp edges, electrical components, and falling objects. Ensuring that all protective items are in good condition is essential for maximum effectiveness.

Workspace Organization

Maintain a clean and organized workspace to minimize risks. Clear away any unnecessary tools and materials that could cause tripping hazards or obstruct access to vital components. A tidy area allows for better focus on the task and reduces the likelihood of accidents.

Replacing Components Effectively

When it comes to ensuring optimal functionality of your device, replacing worn or malfunctioning elements is crucial. This process not only enhances performance but also extends the lifespan of the equipment. By following systematic approaches and utilizing proper techniques, one can achieve seamless replacements that restore the device to its intended operation.

Prior to initiating any component substitution, it is essential to gather the necessary tools and parts. This preparation minimizes downtime and allows for a more efficient workflow. Additionally, having a clear understanding of the device’s layout and the specific components involved is vital. This knowledge aids in avoiding potential errors during the replacement process.

When removing the existing components, exercise caution to avoid damaging surrounding parts. Employing appropriate tools designed for precision can make a significant difference. Once the old components are extracted, thoroughly inspect the area for any debris or residue that may hinder the installation of new elements.

Installing new components requires careful alignment and secure fastening. Ensure that each part is properly positioned before tightening screws or clips, as improper installation can lead to further complications. After the new elements are in place, perform a thorough check to confirm that everything functions as intended.

Finally, document the replacement process for future reference. Keeping a record of changes made can be beneficial for troubleshooting and maintenance down the line. Adopting these practices can lead to effective and successful component replacements, ensuring your device remains in peak condition.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can often be a challenging task, yet it is essential for ensuring optimal functionality of your device. This section provides guidance on common electrical malfunctions and offers practical solutions to rectify them.

Common Issues and Solutions

When experiencing electrical difficulties, it is crucial to recognize the symptoms and follow a systematic approach to diagnosis. Below are some frequent problems along with their potential solutions:

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Device Not Powering On | Faulty power source, damaged cord | Check outlet, replace power cord |

| Intermittent Operation | Loose connections, overheating | Inspect connections, allow cooling |

| Unusual Noises | Worn components, debris | Examine internal parts, clean thoroughly |

Preventive Measures

To minimize the risk of electrical failures, regular maintenance is key. Ensure all connections are secure, and perform periodic checks of the power source and internal components. Keeping the equipment clean and well-maintained can significantly extend its lifespan and improve performance.

Preventive Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following simple maintenance practices, you can minimize potential issues and enhance reliability over time.

Routine Checks

- Inspect components regularly for signs of wear and tear.

- Ensure all connections are secure and free from corrosion.

- Clean any debris or buildup that may affect functionality.

Lubrication

Proper lubrication is critical for smooth operation. Utilize the following practices:

- Use manufacturer-recommended lubricants.

- Apply lubricant to moving parts according to the specified intervals.

- Avoid over-lubrication, which can attract dirt and grime.

By adhering to these guidelines, you can significantly extend the lifespan of your machinery and reduce the likelihood of unexpected failures.

Finding Replacement Parts

Locating suitable components for maintenance can significantly enhance the functionality and longevity of your appliance. Understanding where to source these items is essential for a seamless restoration process. This section outlines effective strategies for identifying and obtaining the necessary elements to ensure optimal performance.

When searching for specific parts, consider the following avenues:

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often lists available parts and provides options for direct purchase. |

| Authorized Dealers | Local retailers or service providers can offer genuine components and expertise. |

| Online Marketplaces | Websites like eBay or Amazon may have both new and used parts from various sellers. |

| Repair Forums | Communities often share valuable insights and links to reliable sources for hard-to-find items. |

| Second-Hand Shops | Local shops might stock components from discarded units that are still in good condition. |

Utilizing these resources will facilitate a successful search for the components you need, ultimately ensuring your device continues to operate efficiently.

Repairing Hydraulic Systems

Maintaining fluid power mechanisms is essential for ensuring optimal performance and longevity. These systems rely on the precise movement of liquids to operate various components effectively. Over time, issues such as leaks or reduced pressure can arise, necessitating careful examination and intervention.

Identifying Problems

The first step in addressing issues within these systems involves recognizing the symptoms. Common indicators include unusual noises, erratic movements, or visible fluid leaks. Conducting a thorough assessment allows for pinpointing the source of the malfunction.

Disassembly and Inspection

Once a fault is detected, the next phase involves carefully dismantling the affected components. It is crucial to document the assembly process to facilitate reassembly later. Inspect each part for signs of wear, corrosion, or damage, paying particular attention to seals and hoses, as these are frequent culprits in system failures.

Replacing Components

After identifying defective parts, sourcing appropriate replacements is vital. Ensure that all new components meet the required specifications to maintain system integrity. Installing these parts correctly is essential for restoring functionality and preventing future issues.

Testing and Calibration

Following the reassembly, conduct tests to verify that the system operates as intended. Monitor for any irregularities in pressure or movement. Calibration may be necessary to align the system’s performance with operational standards, ensuring efficiency and reliability.

By following these outlined steps, individuals can effectively troubleshoot and enhance the longevity of fluid power mechanisms, fostering a deeper understanding of their operation.

Customer Support Resources

Accessing assistance for product-related inquiries can significantly enhance user experience. Whether facing operational challenges or seeking maintenance tips, having reliable support options is essential. Below are various resources designed to provide effective solutions and guidance for customers.

| Resource Type | Description | Availability |

|---|---|---|

| Online Help Center | A comprehensive database of FAQs, troubleshooting guides, and tips for optimal use. | 24/7 Access |

| Customer Service Hotline | Direct access to trained representatives for personalized assistance. | Mon-Fri, 9 AM – 5 PM |

| Email Support | Submit detailed inquiries and receive prompt responses from support staff. | Response within 48 hours |

| Community Forums | Engage with fellow users to share experiences, tips, and solutions. | Ongoing |

Best Practices for Long-Term Use

Ensuring the longevity of your device involves adopting certain strategies that promote efficient performance and reliability over time. By following these guidelines, you can maintain optimal functionality and extend the lifespan of your equipment.

Regular Maintenance

- Clean the device frequently to remove dust and debris.

- Inspect moving parts for wear and tear and lubricate as necessary.

- Store in a dry and cool environment to prevent moisture damage.

Usage Guidelines

- Utilize the device according to manufacturer recommendations.

- Avoid overloading or subjecting it to excessive strain.

- Monitor performance regularly and address any irregularities promptly.

By implementing these practices, users can significantly enhance the durability and effectiveness of their equipment, ensuring it serves well for years to come.