When winter approaches, ensuring your outdoor machinery is in optimal condition becomes essential. Proper upkeep not only extends the lifespan of your tools but also enhances their performance during the colder months. This section provides a comprehensive overview of the best practices for maintaining your winter apparatus, ensuring it operates smoothly when you need it most.

Understanding the intricacies of your equipment can seem daunting, but with a bit of guidance, anyone can tackle basic upkeep tasks. Familiarizing yourself with essential components, troubleshooting common issues, and knowing when to seek professional assistance are all critical aspects of ownership. This knowledge empowers you to address minor problems before they escalate, keeping your machinery running efficiently throughout the season.

Additionally, proper care routines can prevent unnecessary wear and tear, saving you time and money in the long run. From simple cleaning techniques to checking fluid levels and belts, mastering these tasks will allow you to enjoy the winter months with peace of mind. Dive into the details to discover how to ensure your equipment remains reliable and effective all winter long.

Toro 824 Snowblower Overview

This section provides a comprehensive examination of a powerful machine designed to tackle winter’s challenges. Renowned for its efficiency and reliability, it is an essential tool for homeowners facing heavy snowfall. Understanding its features and functionalities will help users maximize its performance and ensure longevity.

Equipped with advanced engineering, this model boasts an array of specifications that cater to various snow-clearing tasks. Below is a table summarizing its key attributes:

| Feature | Description |

|---|---|

| Engine Type | Four-cycle engine for optimal power |

| Clearing Width | 24 inches, ideal for medium to large driveways |

| Auger System | Heavy-duty auger for effective snow removal |

| Transmission | Multiple speeds for enhanced maneuverability |

| Weight | Approximately 200 lbs for stability in harsh conditions |

In summary, this model combines durability with performance, making it a valuable asset for anyone needing to manage snow effectively. Its thoughtful design elements contribute to a user-friendly experience, allowing for efficient operation during the cold months.

Common Problems and Solutions

This section addresses frequent issues that users may encounter with their outdoor equipment, along with effective solutions to enhance performance and reliability. Understanding these common challenges can help maintain optimal operation and extend the life of your machinery.

| Problem | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Empty fuel tank, clogged fuel line, or faulty spark plug | Refill with fresh fuel, clean or replace the fuel line, and check or replace the spark plug. |

| Reduced throwing distance | Worn impeller, dull blades, or improper speed settings | Inspect and replace the impeller, sharpen the blades, and adjust the speed settings as needed. |

| Uneven snow clearing | Incorrect height adjustment or uneven wear on the scraper blade | Adjust the height settings and check the scraper blade for wear, replacing it if necessary. |

| Frequent stalling | Dirty air filter, fuel contamination, or overheating | Replace or clean the air filter, use clean fuel, and allow the engine to cool down if overheating occurs. |

| Noisy operation | Loose components or worn bearings | Tighten any loose bolts and lubricate bearings to reduce noise levels. |

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and efficiency of your equipment. By following a few key practices, you can significantly extend its lifespan and maintain optimal performance throughout the seasons.

Regular Inspections

Conducting frequent checks on your machinery is crucial. Look for signs of wear and tear, such as loose parts or corrosion. Addressing these issues promptly can prevent more significant problems in the future.

Seasonal Servicing

It’s important to perform maintenance tasks tailored to each season. For example, before winter, ensure all components are functioning correctly and lubricated. After the season ends, clean and store the equipment properly to protect it from environmental damage.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect belts and cables | Monthly | Replace if frayed or damaged. |

| Change oil | After every 25 hours of use | Use manufacturer-recommended oil. |

| Clean air filter | Every 10 hours of use | Replace if excessively dirty. |

| Sharpen blades | At the beginning of the season | Ensure efficient operation. |

Step-by-Step Repair Procedures

This section outlines a comprehensive guide for addressing common issues encountered in snow-clearing equipment. By following these procedures, users can effectively troubleshoot and restore functionality to their machinery, ensuring reliable performance during the winter months.

Before beginning any maintenance work, it is essential to gather the necessary tools and parts. The following table provides an overview of the tools required for various tasks:

| Task | Required Tools |

|---|---|

| Inspecting and cleaning the carburetor | Screwdriver, cleaning brush, carburetor cleaner |

| Replacing the spark plug | Socket wrench, spark plug wrench |

| Changing the oil | Oil filter wrench, oil pan, funnel |

| Checking the belts | Adjustable wrench, pliers |

| Lubricating moving parts | Grease gun, lubricant |

Each task listed requires careful attention to detail to ensure optimal performance. Begin with the most pressing issue and systematically work through each procedure, documenting any irregularities for future reference. Proper maintenance not only extends the lifespan of the equipment but also enhances its efficiency and safety during operation.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for ensuring efficient and effective work. The appropriate instruments not only facilitate the process but also enhance safety and precision, ultimately leading to better outcomes.

To start, a mechanic’s toolkit is indispensable. This set typically includes various sockets, wrenches, and ratchets, which are essential for loosening and tightening bolts and nuts. A quality toolkit allows you to tackle a variety of fasteners with ease.

Next, consider investing in a screwdriver set. Different types of screws require different screwdrivers, making a comprehensive set invaluable. Look for both flat-head and Phillips options to accommodate all types of assemblies.

A torque wrench is another vital instrument. This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage due to overtightening or loosening during operation.

Don’t overlook the importance of safety gear. Protective gloves and eyewear are essential for safeguarding against potential injuries while working with machinery.

Lastly, a worklight can significantly enhance visibility in dimly lit areas. Proper illumination allows for detailed inspections and more accurate work, reducing the likelihood of mistakes.

Understanding the User Manual

A comprehensive guide serves as an essential resource for users, providing valuable insights into the operation and maintenance of equipment. This document is designed to enhance user experience by offering clear instructions and crucial information that ensures optimal performance.

Key Components of the Guide

- Introduction: Offers an overview of the equipment, including its features and capabilities.

- Safety Information: Highlights essential safety precautions to prevent accidents and ensure proper usage.

- Operating Instructions: Step-by-step guidance on how to effectively use the equipment for various tasks.

- Maintenance Guidelines: Detailed procedures for routine care and troubleshooting to prolong the lifespan of the device.

- Specifications: Technical details regarding dimensions, power requirements, and operational capacities.

Utilizing the Guide Effectively

To make the most of the guide, users should:

- Familiarize themselves with the contents before use.

- Refer to the safety section to ensure safe operation.

- Follow the operating instructions closely for best results.

- Regularly review maintenance tips to keep the equipment in top condition.

Safety Precautions During Repairs

When performing maintenance tasks on outdoor equipment, adhering to safety measures is crucial to prevent accidents and ensure a successful process. Taking the time to prepare adequately can protect both the user and the machinery involved.

Before starting any service, it’s essential to follow these guidelines:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use safety goggles, gloves, and appropriate footwear to minimize injury risks. |

| Work in a Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes from fuel or chemicals. |

| Disconnect Power Source | Always remove the power source to prevent accidental starts during maintenance. |

| Follow Manufacturer Instructions | Refer to the equipment guidelines for specific safety measures related to your model. |

| Keep Workspace Organized | A clutter-free environment reduces the chance of tripping or losing tools. |

By implementing these safety measures, individuals can ensure a secure environment while handling maintenance tasks, leading to more effective and efficient work. Always prioritize safety to safeguard both yourself and the equipment being serviced.

Replacement Parts Guide

This section provides essential information for sourcing and selecting components needed for maintenance and service. Understanding the various parts and their specifications is crucial for ensuring optimal performance and longevity of your equipment.

| Part Name | Part Number | Description | Compatibility |

|---|---|---|---|

| Drive Belt | 12345A | Durable rubber belt for power transmission | Model Series X |

| Auger Assembly | 67890B | Complete auger for snow removal | Model Series X |

| Fuel Filter | 11121C | High-efficiency filter to ensure clean fuel | Model Series X |

| Chassis Bolt Set | 31415D | Set of bolts for securing the frame | Model Series X |

| Shear Pin | 16171E | Pin designed to protect the auger | Model Series X |

Ensuring you have the right parts on hand can significantly enhance the efficiency of your equipment. Always refer to specifications and compatibility to make informed choices.

Troubleshooting Engine Issues

Engine malfunctions can significantly hinder performance, making it essential to identify and resolve these problems effectively. This section provides guidance on diagnosing common symptoms, pinpointing potential causes, and implementing solutions to restore functionality.

| Symptom | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine won’t start | Empty fuel tank, faulty spark plug, clogged air filter | Refill with fresh fuel, replace or clean spark plug, check and clean air filter |

| Engine runs rough | Dirty carburetor, incorrect fuel mixture, worn ignition components | Clean carburetor, adjust fuel mixture, inspect and replace ignition parts |

| Excessive smoke | Overfilled oil, burning oil, fuel leakage | Check oil level and drain excess, inspect for leaks, replace seals if necessary |

| Engine overheating | Blocked cooling fins, low oil level, dirty air filter | Clear cooling fins, check and replenish oil, clean or replace air filter |

By systematically addressing these symptoms and their corresponding solutions, users can enhance the longevity and efficiency of their equipment.

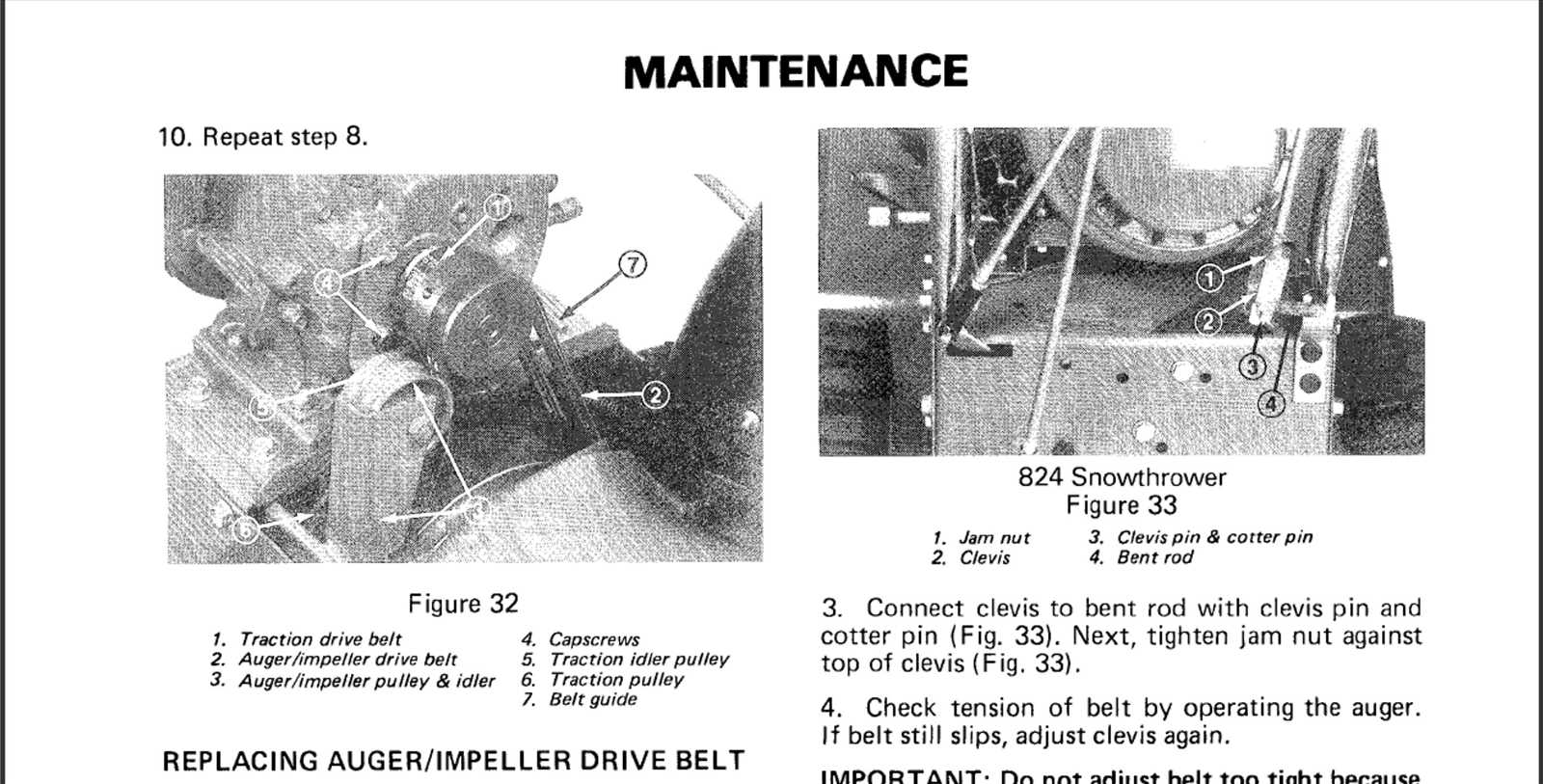

Adjusting the Auger and Impeller

Properly tuning the components responsible for snow intake and discharge is essential for optimal performance during winter tasks. Ensuring these parts are correctly aligned and functioning can significantly enhance efficiency and reduce wear over time. This process involves assessing the positioning and clearance between the intake mechanism and the fan, which are crucial for effective snow removal.

Start by inspecting the auger and impeller for any signs of wear or damage. If either component appears bent or excessively worn, consider replacing it. Next, adjust the height of the auger so that it sits just above the ground surface. This ensures maximum snow pickup without risking damage to the pavement or underlying surfaces. The impeller should be positioned to create a strong airflow, effectively directing snow away from the machine.

Once adjustments are made, test the equipment in a controlled environment to confirm that it operates smoothly. Listen for unusual noises and watch for any irregularities in performance. Fine-tuning may be necessary to achieve the desired functionality, ensuring a seamless operation throughout the season.

Winter Preparation and Storage

As the colder months approach, ensuring that your equipment is ready for use is essential for efficient performance and longevity. Proper preparation involves not only maintenance checks but also appropriate storage practices to safeguard against harsh winter conditions.

Preparation Steps

- Inspect all moving parts for wear and tear, ensuring everything is functioning smoothly.

- Change the oil and replace any worn-out filters to keep the engine in optimal condition.

- Check the fuel system, adding stabilizer to prevent deterioration during the off-season.

- Sharpen or replace the blades to ensure effective snow clearing when the need arises.

- Test all safety features to confirm they are operational and reliable.

Storage Guidelines

- Clean the exterior thoroughly to remove any dirt or debris.

- Store in a dry, sheltered location, protecting it from moisture and extreme temperatures.

- Disconnect the battery if applicable, and store it separately in a cool, dry place.

- Cover with a breathable tarp or storage cover to prevent dust accumulation while allowing ventilation.

- Review and organize any tools or accessories to ensure they are readily available for the next winter season.

How to Clean Your Snowblower

Maintaining your winter machine is crucial for optimal performance and longevity. Regular cleaning helps prevent buildup of snow, ice, and debris that can impair functionality. Following a systematic approach ensures your equipment remains in top condition throughout the cold months.

Gather Your Supplies

Before you begin, assemble the necessary tools and materials. You will need a sturdy brush, warm water, a bucket, mild detergent, and a cloth for drying. Ensure you have protective gloves to keep your hands safe while working.

Cleaning Steps

Start by disconnecting the spark plug for safety. Use the brush to remove any loose dirt and snow from the exterior. Prepare a soapy solution in the bucket, dip the cloth into it, and wipe down the surfaces. Pay special attention to the auger and chute to eliminate any stubborn residue. Rinse with warm water and dry thoroughly to prevent rust.

By following these steps, you’ll enhance the efficiency and lifespan of your winter equipment, ensuring it’s ready to tackle the next snowstorm.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting of winter equipment. Whether you’re a novice or an experienced user, these questions provide valuable insights to enhance your understanding and improve performance.

General Inquiries

- What are the signs that my equipment needs servicing?

- How often should I perform routine checks?

- What type of fuel is recommended for optimal operation?

Troubleshooting Common Issues

- My machine won’t start. What should I check first?

- Inspect the fuel level.

- Check the spark plug for wear.

- Examine the battery connections.

- Why is my equipment making unusual noises?

- Look for loose components.

- Check for obstructions in the chute.

- Listen for signs of wear on the motor.