The intricate world of automotive technology often presents challenges that require specialized knowledge. A vital component in modern vehicles, responsible for regulating various engine functions, can sometimes experience issues that need addressing. Understanding how to navigate these complexities is essential for both enthusiasts and professionals alike.

This section delves into essential techniques and strategies for troubleshooting and enhancing the functionality of these critical systems. By equipping yourself with the right information, you can better diagnose problems and implement effective solutions, ensuring optimal performance and longevity of the vehicle.

From identifying symptoms to applying corrective measures, mastering the intricacies of these electronic systems can empower individuals to tackle common issues confidently. The following insights aim to provide clarity and guidance, making the process more accessible and less daunting for all users.

Toyota ECU Repair Overview

This section provides a comprehensive look at the processes involved in addressing issues related to the electronic control unit of vehicles. Understanding the intricacies of this component is crucial for effective diagnostics and troubleshooting, ensuring optimal performance of the vehicle’s systems.

The importance of this unit cannot be overstated, as it plays a vital role in managing various functions. Here are some key aspects to consider:

- Identification of Issues: Recognizing symptoms that indicate malfunction.

- Diagnostic Tools: Utilizing specialized equipment to assess performance.

- Common Faults: Awareness of frequent problems encountered with this unit.

- Repair Techniques: Exploring methods for fixing or recalibrating the unit.

To ensure a successful intervention, it’s essential to follow a structured approach:

- Gather all necessary tools and equipment.

- Conduct a thorough diagnostic evaluation.

- Identify specific faults and their underlying causes.

- Implement appropriate corrective measures.

- Test the unit to confirm that all functions are restored.

By adhering to these guidelines, individuals can effectively tackle challenges associated with the electronic control systems, thereby enhancing the overall reliability and efficiency of their vehicles.

Common ECU Issues in Toyota Vehicles

Electronic control units play a crucial role in the functioning of modern automobiles. They manage various aspects of the vehicle’s performance, and when malfunctions occur, it can lead to a range of problems. Understanding the typical issues that may arise can help in diagnosing and addressing these challenges effectively.

Here are some prevalent concerns associated with electronic control units:

- Communication Failures: Often, these units may experience disruptions in communication with other components, leading to inconsistent performance.

- Software Glitches: Outdated or corrupted software can cause erratic behavior, affecting engine performance and fuel efficiency.

- Sensors Malfunction: When the sensors connected to the unit fail, it can result in incorrect readings, impacting the vehicle’s operation.

- Power Supply Issues: Inadequate voltage or short circuits can prevent the unit from functioning properly, leading to various operational problems.

- Overheating: Excessive heat can damage internal components, causing the unit to fail prematurely.

Identifying these issues early can save time and resources, ensuring the vehicle remains reliable and efficient. Regular diagnostics and updates are essential for maintaining optimal performance.

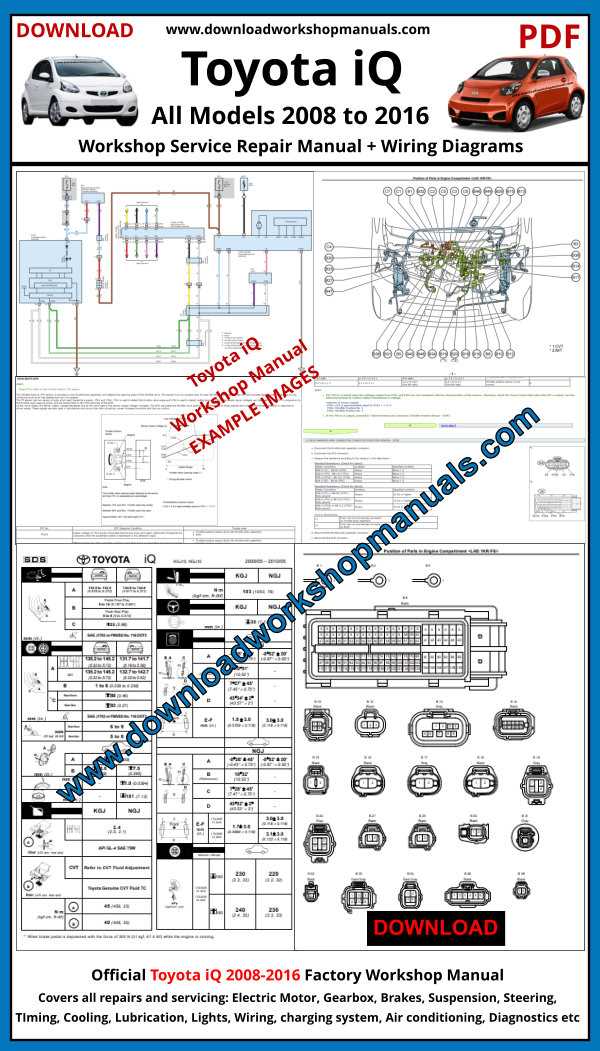

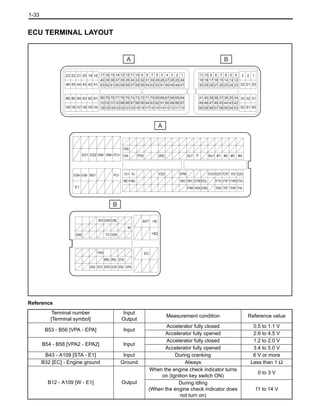

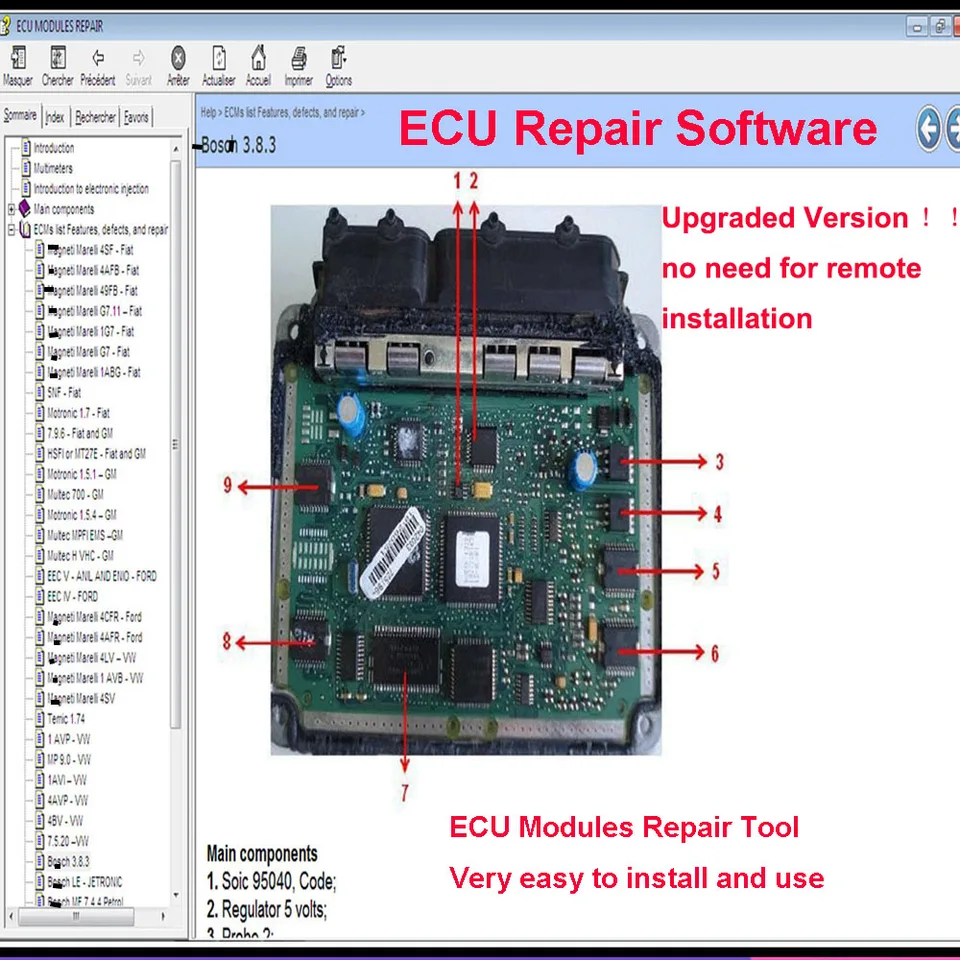

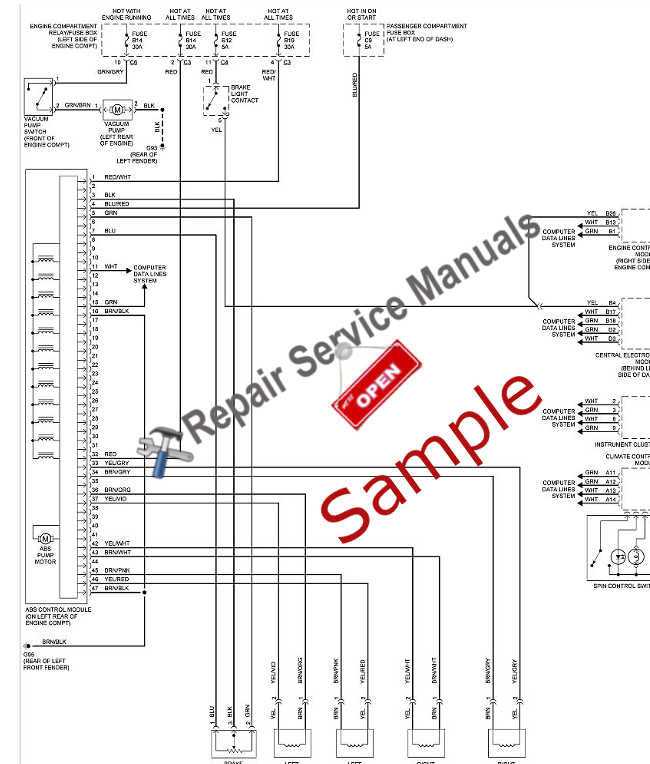

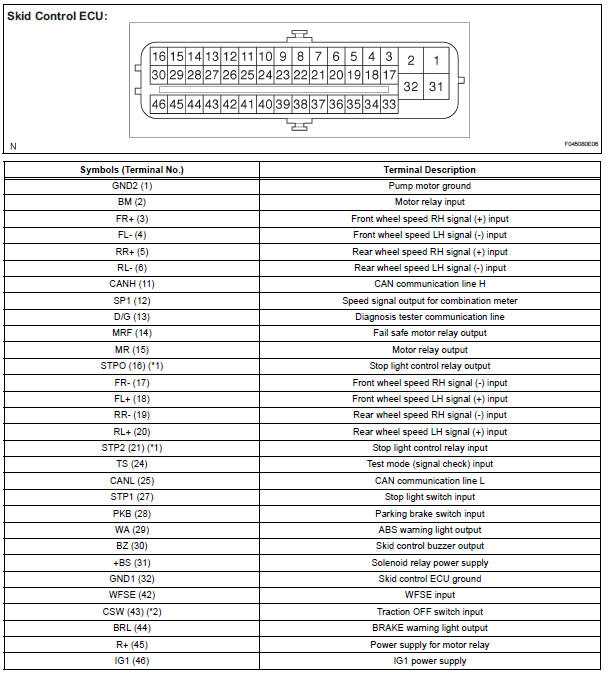

Diagnostic Tools for ECU Repair

In the realm of vehicle maintenance, effective troubleshooting relies heavily on specialized instruments designed to analyze and diagnose electronic control units. These tools not only provide insights into system performance but also help identify faults that may hinder optimal functionality.

Diagnostic Scanners are essential for accessing error codes and real-time data from various vehicle systems. They facilitate a comprehensive understanding of potential issues, allowing technicians to pinpoint malfunctions quickly.

Multimeters are invaluable for measuring voltage, current, and resistance. This versatility enables the detection of electrical problems within circuits, ensuring that every connection operates as intended.

Oscilloscopes allow for the visualization of electronic signals over time, making it easier to diagnose complex issues related to waveform patterns. This capability is crucial for identifying intermittent faults that might otherwise go unnoticed.

Additionally, Software Tools are increasingly popular for their ability to analyze data logs and simulate various conditions. By using these programs, professionals can replicate scenarios to understand how the control systems respond under different circumstances.

Employing the right combination of these instruments enhances the accuracy of diagnostics, leading to efficient resolutions and improved vehicle performance.

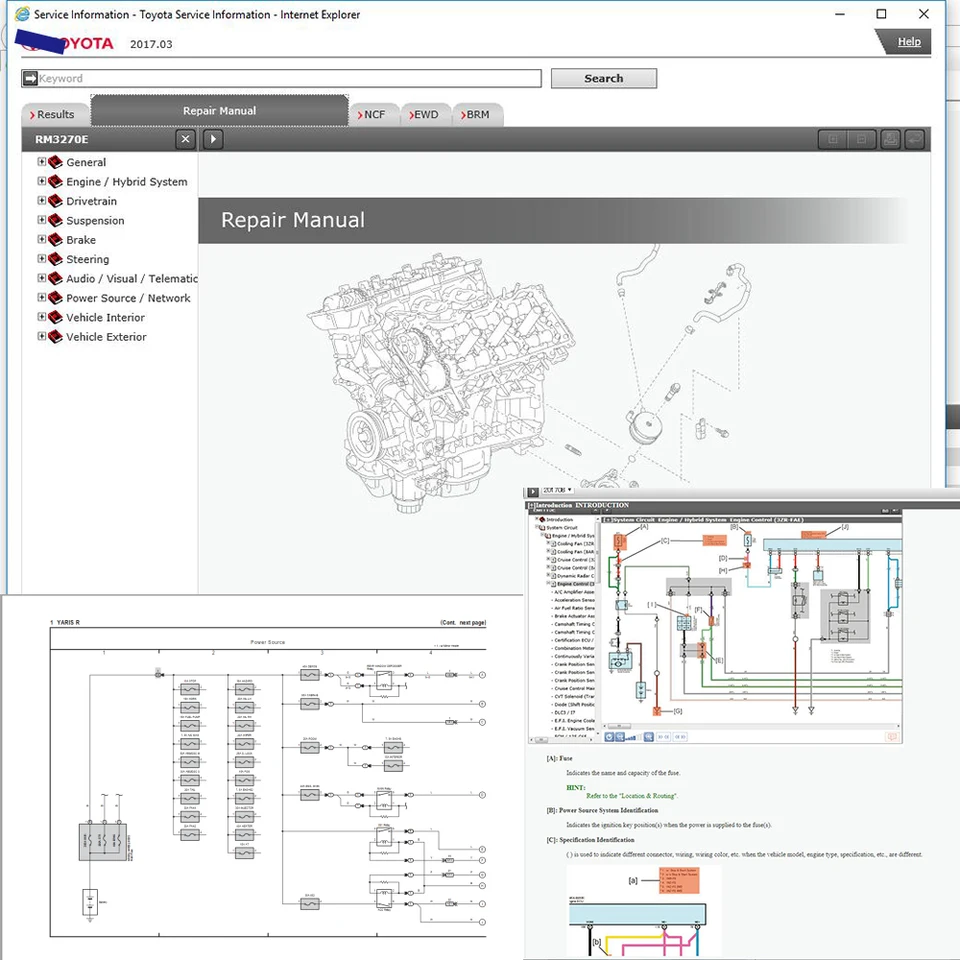

Understanding Toyota ECU Functionality

The electronic control unit plays a vital role in modern automotive systems, acting as the brain that manages various engine and vehicle functions. This unit processes data from numerous sensors, ensuring optimal performance, efficiency, and compliance with emission standards. By interpreting real-time information, it can make instantaneous adjustments to improve driving experience and vehicle safety.

Key Functions of the Control Unit

One of the primary responsibilities of this unit is to regulate the fuel injection process. By analyzing factors such as air intake and engine temperature, it determines the precise amount of fuel needed for combustion, which significantly influences both power output and fuel economy. Additionally, it monitors the ignition timing, ensuring that the spark plugs ignite the fuel-air mixture at the optimal moment for maximum efficiency.

Diagnostic Capabilities

Another essential aspect of this unit is its diagnostic functionality. It continuously checks the performance of various components and systems, storing trouble codes when anomalies are detected. This feature enables technicians to quickly identify issues, leading to timely maintenance and repairs. The advanced algorithms used in these units also allow for software updates, enhancing performance and addressing potential vulnerabilities over the vehicle’s lifespan.

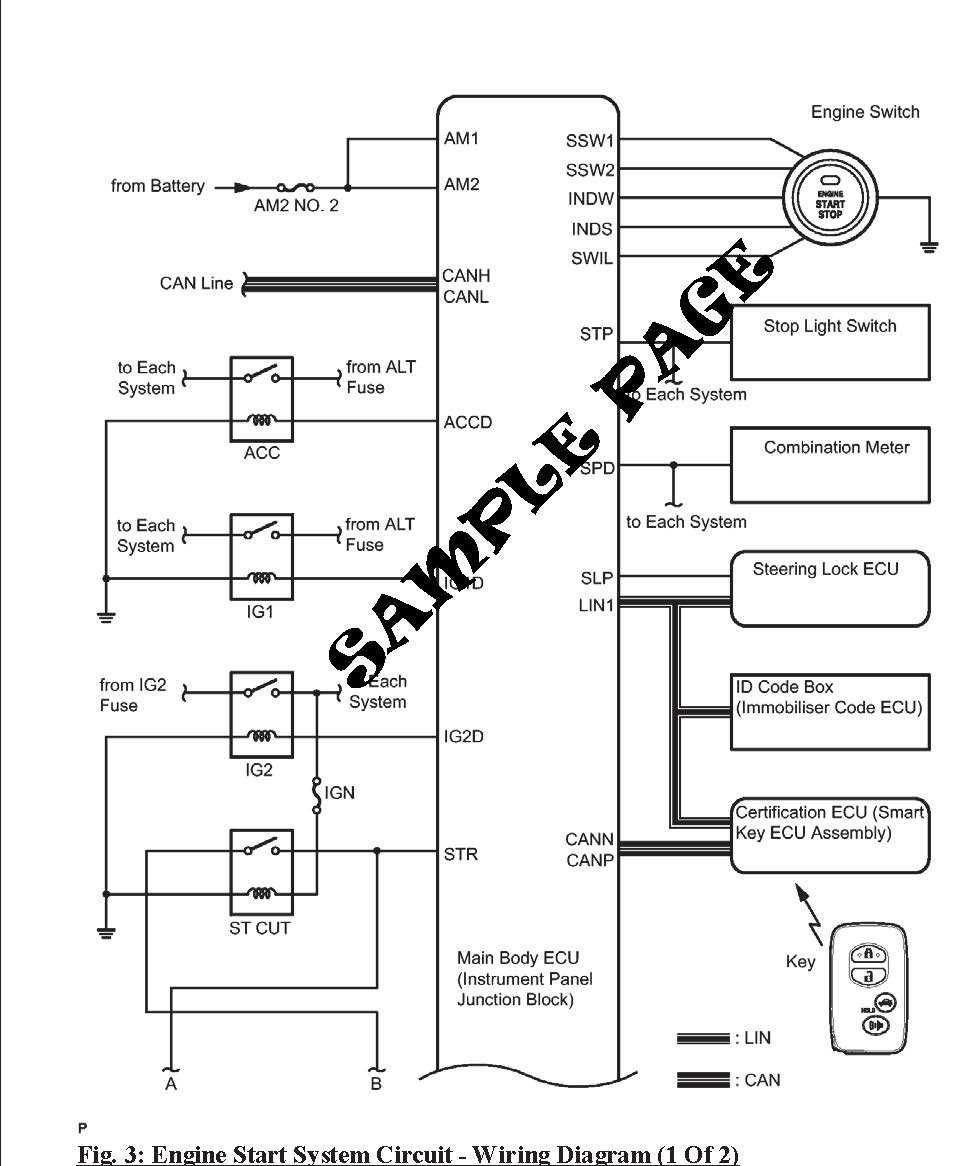

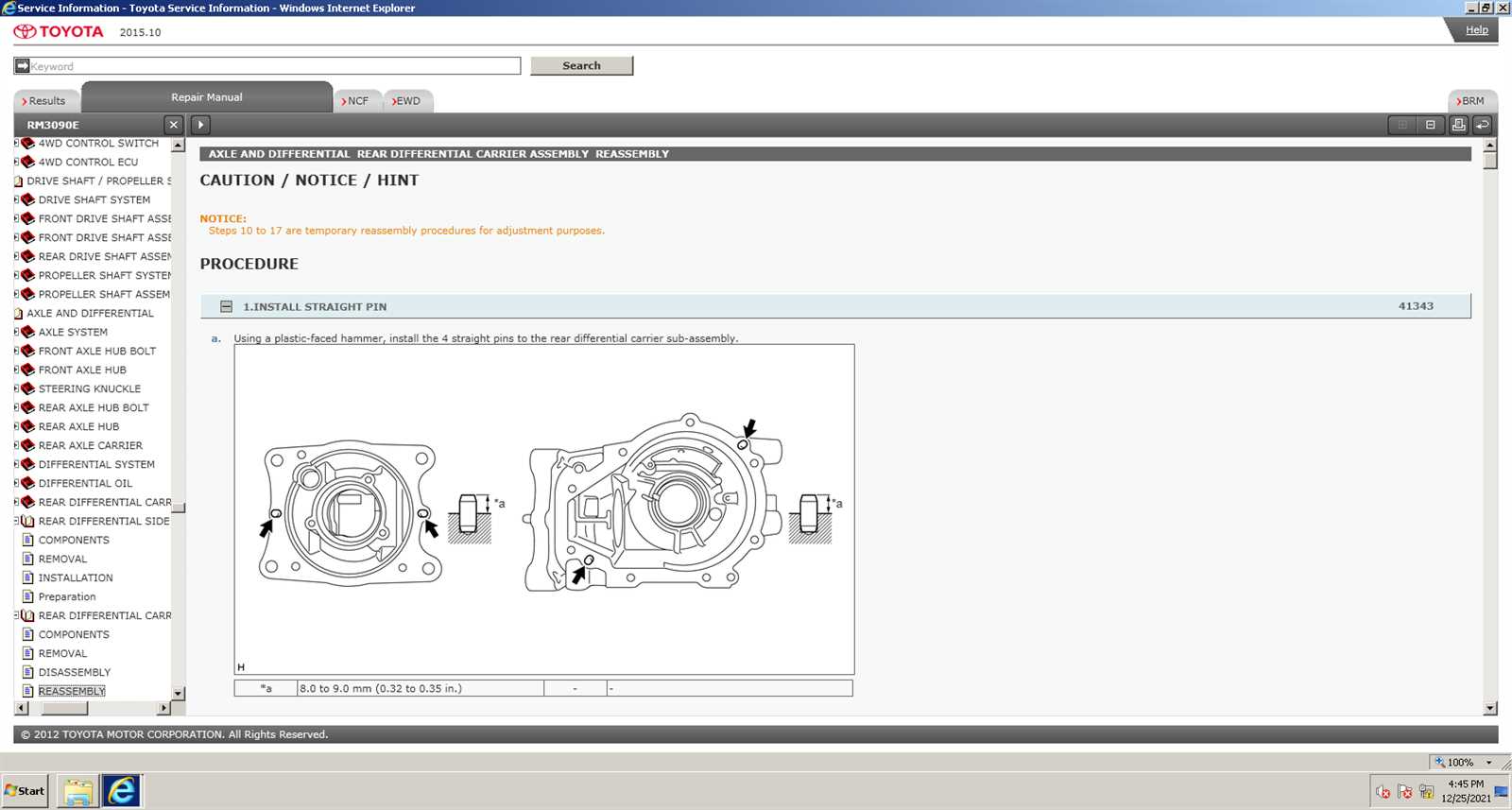

Step-by-Step ECU Troubleshooting Guide

This guide provides a systematic approach to diagnosing and resolving issues related to the electronic control unit of vehicles. By following these steps, you can identify malfunctions and restore optimal performance without unnecessary replacements.

Initial Assessment

Begin with a thorough assessment of the situation:

- Check for any warning lights on the dashboard.

- Review any recorded error codes using a diagnostic scanner.

- Inspect all visible wiring and connectors for signs of damage or corrosion.

Systematic Troubleshooting Steps

- Verify the power supply to the control unit by checking fuses and relays.

- Examine ground connections to ensure they are secure and free of rust.

- Test the unit’s functionality by using a known good unit, if available.

- Inspect sensors connected to the system for proper operation and alignment.

- Clear error codes and perform a road test to monitor performance.

By following these steps, you can effectively troubleshoot and address issues, leading to improved functionality and reliability of your vehicle’s electronic system.

Key Symptoms of ECU Failure

When the central control unit of a vehicle starts to malfunction, it can lead to a range of noticeable issues. These symptoms often manifest in various ways, impacting the overall performance and functionality of the automobile. Recognizing these indicators early can help prevent further complications.

- Check Engine Light: One of the most common signs is the illumination of the check engine light, which may indicate a range of underlying problems.

- Performance Issues: Decreased power, poor acceleration, or sluggish performance can signal control unit problems affecting engine efficiency.

- Fuel Efficiency Decline: A noticeable drop in miles per gallon could be linked to a malfunctioning unit that fails to regulate fuel injection properly.

- Starting Problems: Difficulty in starting the engine or intermittent starting issues may arise due to control unit failure.

- Electrical Malfunctions: Unresponsive electronic components, such as power windows or locks, can indicate a failure in the central system.

Being aware of these symptoms can assist in identifying issues promptly, potentially saving time and money on repairs down the line.

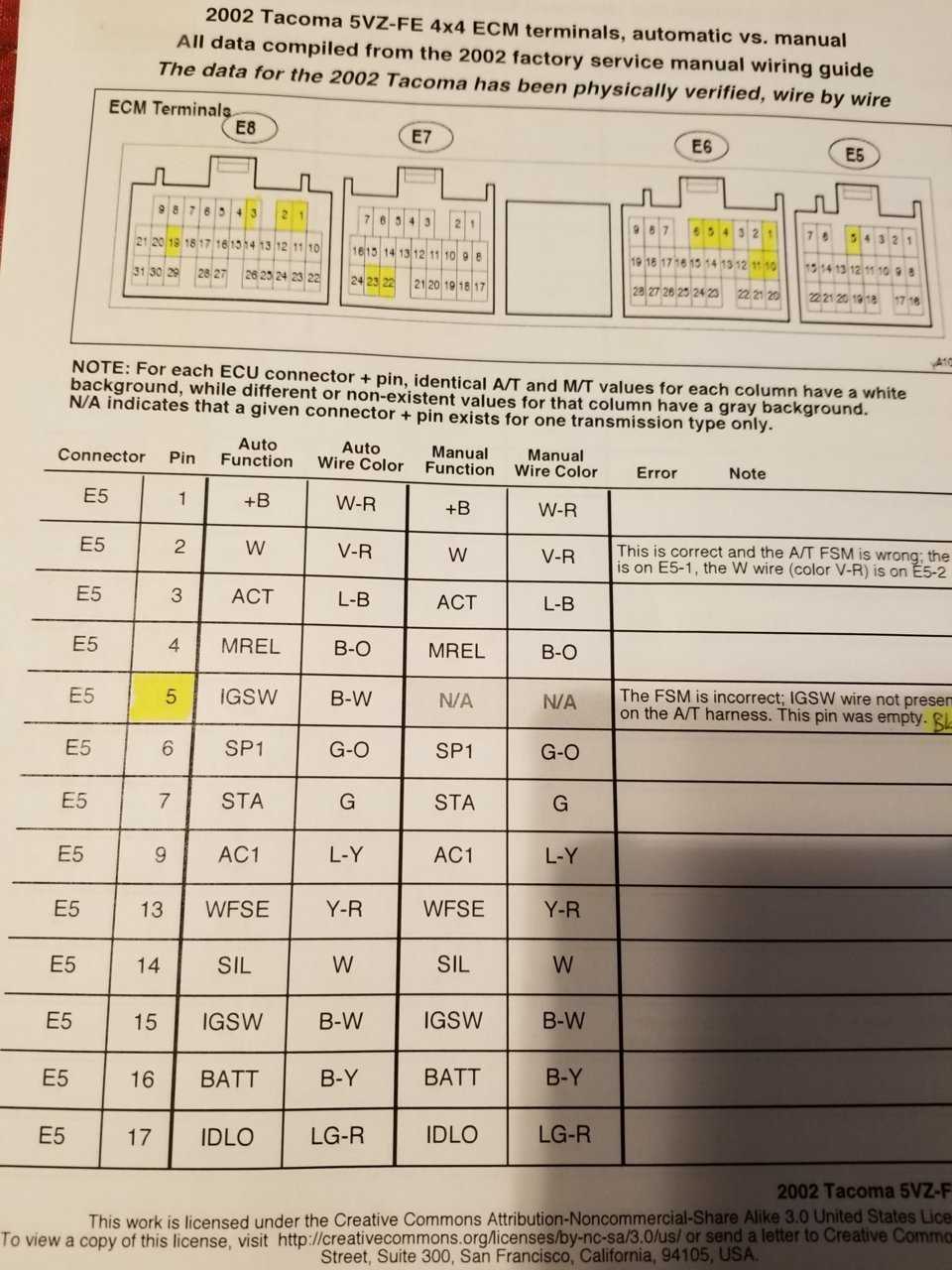

Tools Required for ECU Repair

When addressing electronic control unit issues, having the right equipment is crucial for efficient diagnostics and adjustments. The following tools are essential for professionals and enthusiasts alike, ensuring a smooth and effective troubleshooting process.

- Multimeter: Essential for measuring voltage, current, and resistance, helping to diagnose electrical issues.

- OBD-II Scanner: A diagnostic tool that reads trouble codes and provides insight into system performance.

- Screwdrivers: A set of various sizes and types is necessary for accessing components.

- Socket Set: Useful for removing and securing bolts and screws on the unit and surrounding components.

- Wire Strippers: Important for preparing electrical connections, allowing for clean and secure joins.

- Heat Gun: Often used for heat-shrink tubing and soldering applications, ensuring reliable connections.

- Soldering Iron: Vital for repairing circuit board connections and other electronic components.

- Safety Gear: Protective glasses and gloves to ensure safety during handling and repair processes.

By gathering these tools, you can effectively troubleshoot and resolve issues with the electronic control unit, enhancing performance and reliability.

How to Reset Toyota ECU

Resetting the electronic control unit can often resolve various performance issues in vehicles. This process essentially restores the system to its factory settings, clearing any error codes and allowing for recalibration. It is a straightforward procedure that can be performed with minimal tools.

To initiate the reset, start by ensuring the vehicle is turned off. Disconnect the battery by removing the negative terminal. This step is crucial as it cuts off power to the control unit, allowing it to reset completely. Wait for at least 10 minutes to ensure all residual power is discharged from the system.

Once the waiting period is over, reconnect the negative terminal to the battery. Make sure the connection is secure to prevent any interruptions. After reconnecting, turn the ignition to the “on” position without starting the engine. This allows the system to perform self-checks and reinitialize various components.

If your vehicle is equipped with diagnostic tools, you may also consider using a scanner to clear any stored codes after the reset. This can enhance the effectiveness of the process by ensuring that all previous error signals are eliminated.

Finally, start the engine and let it idle for a few minutes. Monitor the dashboard for any warning lights that may indicate persistent issues. If all is well, the system should function smoothly, with any previous malfunctions resolved.

Replacing a Faulty ECU Module

When the control unit responsible for managing various vehicle functions malfunctions, it can lead to a range of issues affecting performance and safety. Addressing this problem promptly is crucial for maintaining optimal vehicle operation. This section outlines the essential steps for removing and installing a defective control module, ensuring your vehicle returns to its reliable state.

Preparation is Key

Before starting the replacement process, ensure you have the necessary tools and a compatible unit ready. Disconnect the battery to avoid any electrical shorts. Familiarize yourself with the specific location of the control unit in your vehicle, as this can vary significantly between models.

Removing the Faulty Unit

Carefully locate the control module, and if needed, remove any surrounding components that obstruct access. Disconnect all wiring harnesses by gently pressing on the release tabs. Take note of the connections, as this will aid in the reinstallation of the new unit.

Installing the New Unit

Position the replacement control module in place and reconnect the wiring harnesses, ensuring each connection is secure. Once everything is connected, reassemble any removed components and double-check that no tools or debris are left in the workspace.

Final Steps

Reconnect the battery and start the vehicle to test the new control module. Monitor for any warning lights or irregularities in performance. If everything functions correctly, you have successfully replaced the faulty component, restoring your vehicle’s efficiency and reliability.

Importance of ECU Software Updates

Regular updates to vehicle control systems are essential for optimal performance and safety. These enhancements address various aspects of vehicle functionality, ensuring that drivers benefit from the latest technological advancements and fixes for previously identified issues.

Benefits of Regular Updates

- Improved Performance: Updates often include modifications that enhance engine efficiency and response times.

- Enhanced Safety Features: New software can improve safety systems, such as traction control and stability management.

- Compatibility with New Technologies: As vehicles incorporate more advanced technologies, updates ensure systems remain compatible with new features.

Potential Risks of Neglecting Updates

- Decreased Performance: Outdated software can lead to sluggishness or inefficiencies.

- Increased Risk of Malfunctions: Ignoring updates may result in unresolved bugs that could affect vehicle operation.

- Limited Access to Support: Manufacturers often require the latest software for diagnostic and repair assistance.

Maintaining up-to-date vehicle software is crucial for maximizing both performance and safety, ultimately contributing to a more reliable driving experience.

DIY ECU Repair vs. Professional Help

When faced with the challenge of fixing electronic control units, car owners often find themselves at a crossroads: should they attempt to tackle the issue on their own or seek assistance from a qualified technician? This decision can significantly impact both the vehicle’s performance and the owner’s wallet. Understanding the pros and cons of each approach is essential for making an informed choice.

Advantages of DIY Approaches

Choosing a do-it-yourself method allows enthusiasts to save money and gain hands-on experience. Many resources are available online, offering guidance and tutorials that can help in diagnosing and fixing common issues. Additionally, the satisfaction derived from successfully resolving a problem independently can be quite rewarding.

Benefits of Professional Assistance

On the other hand, enlisting the help of an expert brings a level of assurance and reliability that can be crucial for complex electronic problems. Professionals possess the necessary tools, knowledge, and experience to address intricate issues that may be beyond the capabilities of a novice. Furthermore, they can provide warranties for their work, offering peace of mind that the problem will be thoroughly resolved.

Preventive Maintenance for ECU Longevity

Ensuring the long-lasting performance of your vehicle’s electronic systems requires consistent care and attention. By implementing specific strategies, you can significantly enhance the durability and functionality of these crucial components. Regular check-ups and preventive measures will ultimately lead to a more reliable driving experience.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect Wiring Connections | Every 6 months | Prevents corrosion and loose connections |

| Update Software | Annually | Enhances performance and fixes bugs |

| Check Power Supply | Quarterly | Ensures stable voltage levels |

| Clean Connector Pins | Every 6 months | Improves signal integrity |

| Monitor Temperature Levels | Monthly | Prevents overheating and failure |