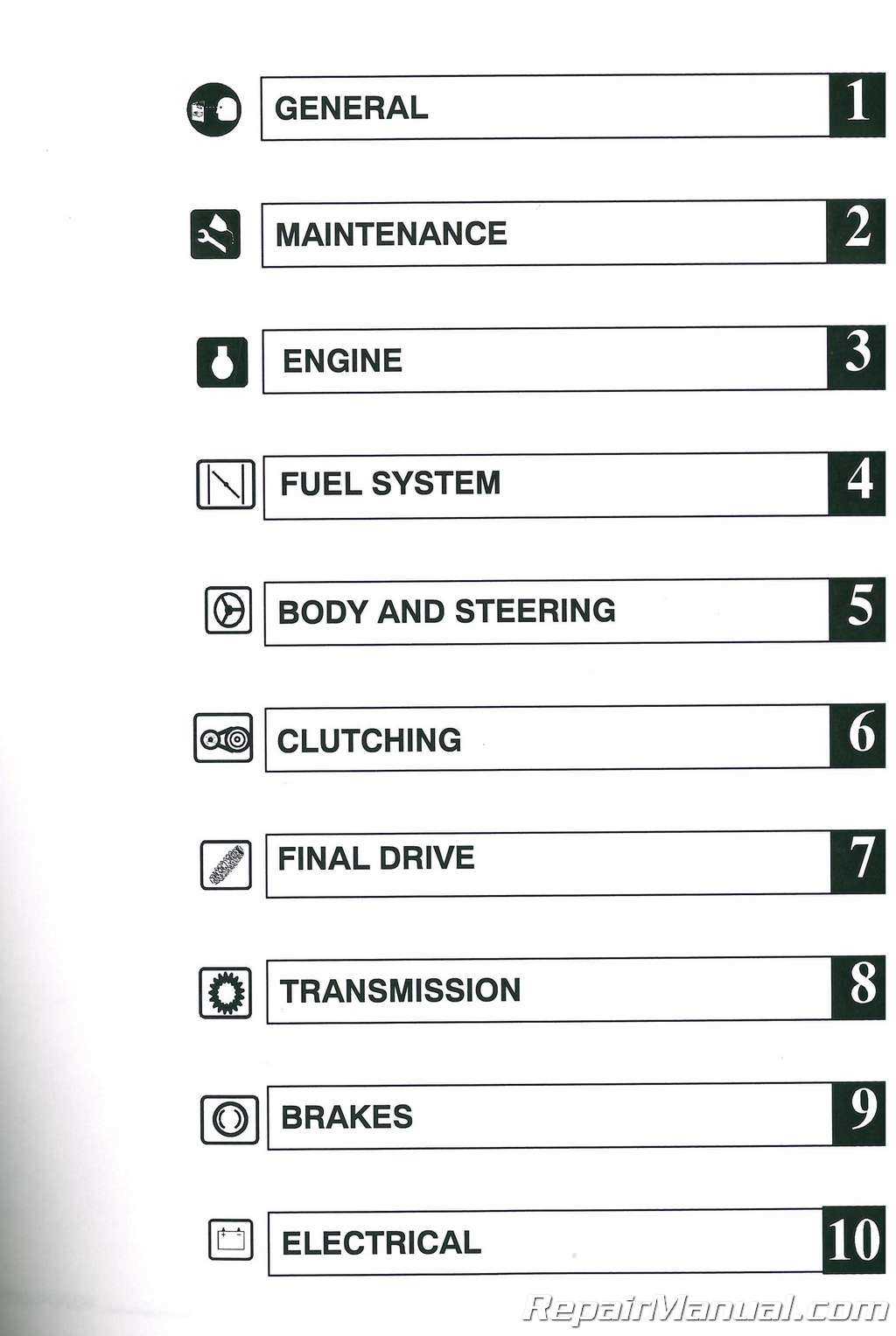

Ensuring the longevity and performance of an all-terrain vehicle (ATV) requires a detailed understanding of its maintenance needs and common troubleshooting procedures. This guide offers a structured approach to understanding each essential aspect of vehicle upkeep, from routine inspections to more in-depth technical adjustments. Designed to assist both newcomers and seasoned users, the following sections emphasize clear steps and essential tips to keep your vehicle in optimal condition.

Critical Systems and Components of an ATV often demand regular attention to prevent common issues and enhance overall durability. By familiarizing yourself with the core functions of each part, you can anticipate potential wear points and address minor issues before they lead to more extensive repairs. This guide dives into the key components, including the engine, transmission, and electrical systems, providing insights into best practices for each.

Whether you’re addressing minor adjustments or larger mechanical needs, this resource aims to serve as a practical reference. With step-by-step guidance and a focus on safety, you can build a thorough understanding of your ATV’s mechanical structure, enhancing both your confidence and capabilities in vehicle upkeep.

Essential Maintenance Tips for 2005 Polaris Ranger

Regular upkeep of any utility vehicle ensures its peak performance and extends its operational lifespan. By following a structured maintenance routine, owners can prevent unexpected breakdowns and costly repairs, enhancing both safety and reliability.

- Fluid Checks: Regularly inspect and refill fluids such as engine oil, brake fluid, and coolant. Consistent fluid levels help maintain engine health, efficient braking, and temperature control.

- Air Filter Replacement: Periodically check and replace the air filter. A clean filter improves engine efficiency by allowing proper air intake and preventing dust and debris from entering the engine.

- Tire Inspection: Monitor tire pressure and tread wear routinely. Well-maintained tires provide better traction, fuel efficiency, and handling, especially on rugged terrain.

- Battery Care: Inspect battery terminals and clean them if corrosion appears. Ensure the battery is securely connected and has a reliable charge, especially before long storage periods or heavy usage.

- Brake System Examination: Regularly assess the brake pads, rotors, and cables. Keeping the braking system in good condition ensures safe stopping and reduces wear on other vehicle components.

- Suspension Check: Examine the suspension for signs of wear or damage. Proper suspension maintenance provides a smoother ride and protects other parts from excessive vibration.

- Greasing Moving Parts: Lubricate key moving parts, such as joints and bearings, to reduce friction and wear. This practice prolongs part longevity and minimizes noise and resistance

Understanding Common Utility Vehicle Issues

Utility vehicles often encounter a variety of operational challenges due to demanding environments and regular heavy use. Recognizing common symptoms and understanding their root causes is essential for ensuring consistent performance and minimizing downtime.

Starting and Electrical Problems: One of the most frequently encountered issues involves the vehicle’s starting system, often linked to the battery, wiring, or ignition components. Regular checks on electrical connections, fuses, and battery terminals can help identify and resolve issues before they escalate.

Engine Performance Fluctuations: Engine trouble, including poor acceleration, stalling, or inconsistent power output, can be related to fuel system blockages, air intake restrictions, or ignition faults. Maintaining clean filters and ensuring proper fuel flow can significantly improve engine reliability.

Transmission and Gear Shifting: Difficulties with smooth gear transitions or slipping gears are often associated with transmission wear or fluid levels. Consistently monitoring and maintaining transmission fluids and inspecting for wear in critical parts can prevent costly repairs.

Preventive maintenance remains crucial to extending the lifespan of any utility vehicle. Addressing these typical issues proactively allows for a safer and more dependable driving experience.

Engine Troubleshooting and Solutions

Understanding how to identify and resolve common engine issues is crucial for maintaining vehicle performance. This section provides an overview of typical engine problems, their possible causes, and effective solutions, helping users to address these issues with confidence and care.

Common Engine Issues

- Engine Not Starting: Often related to fuel system issues, ignition problems, or electrical connections. Carefully examine each area to locate the issue.

- Rough Idling: May result from clogged air filters, fuel delivery problems, or malfunctioning spark plugs. A thorough inspection of these components can help restore smooth operation.

- Overheating: Commonly caused by coolant leaks, blocked radiators, or failing fans. Addressing these areas promptly can prevent severe engine damage.

Step-by-Step Diagnostic Approach

- Check Fuel System: Inspect fuel lines, filters, and injectors for any blockages or leaks that could be affecting performance.

- Inspect Ignition Components: Look for worn or corroded spark plugs, damaged wires, or other ignition parts that could disrupt engine function.

- Examine Cooling System: Ensure coolant levels are adequate, and check for radiator blockages and fan operation to prevent overheating.

Following these steps and regular maintenance checks can greatly improve engine reliability, ensuring a smoother and more dependable driving experience.

Braking System Repairs and Adjustments

In this section, we’ll focus on the essential steps to maintain and fine-tune the braking mechanisms for consistent performance. A well-functioning braking system is crucial for safe operation, and periodic checks and adjustments help prevent wear and ensure responsiveness under various conditions.

Inspecting Brake Components: Begin by carefully examining each part of the braking setup. Look for any signs of wear, corrosion, or damage on the brake pads, rotors, and calipers. Even minor flaws can affect braking efficiency, so take time to evaluate the condition of each element thoroughly.

Replacing Worn Parts: Worn brake pads or drums should be replaced as needed to maintain optimal stopping power. Ensure that replacement parts meet quality standards to avoid issues with compatibility and longevity. Proper installation and alignment are critical to the functionality of new components.

Adjusting the Brake System: Brake adjustment can vary based on the type of braking mechanism. For disc brakes, ensure caliper alignment and correct positioning of the pads. Drum brakes require proper clearance adjustment to balance braking pressure. Always test the brakes after adjustments to confirm that they engage smoothly without excess resistance.

Testing for Proper Function: Once repairs or adjustments are complete, perform a brake test in a controlled environment. Start by applying light pressure, then gradually increase to ensure the system responds accurately and evenly. Address any inconsistencies immediately to maintain a safe operating condition.

Electrical System Diagnosis and Fixes

Understanding and addressing issues in the electrical system requires a systematic approach, as electrical components play a critical role in ensuring reliable operation. This section provides insights into identifying common faults within the system, from power distribution to component functionality, and offers clear guidance on effective troubleshooting.

Initial Inspection: Begin with a visual examination of wiring connections and fuses. Check for loose, corroded, or damaged wires, as these are often the primary sources of electrical problems. Pay attention to battery terminals; corrosion can disrupt power flow and should be cleaned carefully.

Battery Health Check: A healthy battery is essential for all electrical components. Use a multimeter to measure the voltage, ensuring it aligns with standard operating values. A drop in voltage often indicates that the battery may need replacement or recharging.

Testing the Ignition Circuit: If starting issues are observed, the ignition circuit may require testing. Inspect the ignition switch and key components for continuity using an ohmmeter. Replace any worn parts to ensure efficient current flow.

Examining the Charging System: The charging system maintains battery levels during operation. Inspect the alternator and voltage regulator for proper function. Use a voltmeter to test the output; any inconsistencies may require part replacement or adjustment.

Addressing Component-Specific Failures: Electrical faults can often affect specific features, such as lights, indicators, or auxiliary power points. Test each component individually to identify weak or broken connections. Repair or replace parts as necessary to restore

Cooling System Checks and Maintenance

Ensuring the optimal performance of the cooling system is essential for the longevity and reliability of your vehicle. Regular checks and appropriate maintenance can prevent overheating and related issues, which can significantly impact engine performance. This section outlines key procedures and considerations for maintaining the cooling system effectively.

Inspection Procedures

- Check the coolant level regularly. Ensure it is within the recommended range indicated on the reservoir.

- Inspect hoses for any signs of wear or leaks. Cracks or soft spots may indicate a need for replacement.

- Examine the radiator for any debris or blockages that could impede airflow. Clean as necessary to ensure optimal cooling.

- Monitor the temperature gauge during operation. Fluctuations outside the normal range may indicate a malfunction.

Maintenance Tips

- Flush the cooling system periodically to remove sediment and buildup. This helps maintain efficient heat transfer.

- Replace the coolant according to the manufacturer’s guidelines, using the recommended type for your vehicle.

- Inspect the water pump for any signs of leakage or unusual noise, which may indicate wear.

- Ensure the radiator cap is functioning properly, as it plays a crucial role in maintaining the correct pressure within the system.

Transmission Repair and Gear Maintenance

Ensuring the optimal performance of your vehicle’s drivetrain is essential for longevity and reliability. Regular attention to transmission systems and gear components can prevent serious issues and enhance overall functionality. This section focuses on essential practices for maintaining these critical systems.

Key Maintenance Practices

- Fluid Checks: Regularly inspect and replace transmission fluid to ensure smooth operation and avoid overheating.

- Filter Replacement: Change filters periodically to prevent debris buildup that can hinder performance.

- Seal Inspections: Routinely examine seals for wear and leaks to maintain fluid integrity and avoid contamination.

Common Issues and Solutions

- Slipping Gears: Often indicates low fluid levels or worn components. Check fluid levels and inspect for leaks.

- Unusual Noises: Grinding or whining sounds may suggest gear wear. Examine gears and bearings for damage.

- Overheating: Ensure the cooling system is functioning correctly and that fluid is at the proper level to prevent damage.

By adhering to these maintenance guidelines, vehicle owners can ensure their transmission and gear systems remain in top condition, enhancing performance and extending the life of their machines.

Fuel System Inspection and Cleaning

The performance of any motorized vehicle heavily relies on the efficiency of its fuel system. Regular examination and maintenance of this system are essential to ensure optimal functionality and longevity. This section outlines the procedures for inspecting and cleaning the fuel delivery components to prevent issues such as blockages or improper fuel flow.

During the inspection process, it is important to check for signs of wear, leaks, and buildup of contaminants. Regular cleaning can help maintain the efficiency of the fuel injectors and lines, contributing to improved engine performance. Below are the key components to focus on during your inspection and cleaning routine:

Component Inspection Steps Cleaning Method Fuel Filter Check for clogs or leaks. Replace if necessary; clean if reusable. Fuel Lines Inspect for cracks or wear. Clean with suitable solvent; replace if damaged. Fuel Injectors Examine for proper spray pattern and leakage. Use a specialized cleaner to flush out deposits. Fuel Tank Look for rust or debris accumulation. Clean thoroughly; consider a liner for protection. By diligently following these inspection and cleaning procedures, vehicle operators can ensure that the fuel system remains in optimal condition, enhancing overall performance and reliability.

Replacing Worn Suspension Components

Maintaining the integrity of the suspension system is crucial for optimal vehicle performance and safety. Over time, various components may experience wear and tear, leading to diminished handling, stability, and comfort. Regular inspection and timely replacement of these elements can enhance the overall driving experience and prolong the lifespan of the vehicle.

Common signs of worn suspension parts include:

- Excessive bouncing or swaying during driving

- Uneven tire wear

- Unusual noises when navigating bumps or rough terrain

- Difficulty steering or maintaining control

To effectively replace worn suspension components, follow these steps:

- Begin with a thorough inspection to identify all damaged parts.

- Gather the necessary tools and replacement components for the task.

- Lift the vehicle securely using jack stands, ensuring it is stable.

- Carefully remove the old components, taking note of their arrangement for proper installation of the new parts.

- Install the new suspension components, ensuring they are tightened to the manufacturer’s specifications.

- Lower the vehicle and conduct a test drive to verify proper functionality.

Regular maintenance and timely replacement of suspension components are essential for a smooth and safe ride. By addressing issues promptly, you can enhance both performance and comfort while extending the life of your vehicle.

Step-by-Step Guide for Oil Change

Performing an oil change is an essential maintenance task that ensures the longevity and optimal performance of your vehicle. This process involves draining the old lubricant, replacing it with fresh oil, and changing the filter to maintain the engine’s health. Following a systematic approach can help you complete this task efficiently and effectively.

Preparation for the Procedure

Begin by gathering the necessary tools and materials, including a wrench, an oil filter wrench, a drain pan, a funnel, and the appropriate oil type. Ensure that the vehicle is parked on a level surface and the engine is cool. This preparation will help prevent spills and make the process smoother.

Executing the Oil Change

Start by locating the oil drain plug beneath the engine and carefully remove it to allow the old oil to flow into the drain pan. Once all the oil has drained, replace the drain plug securely. Next, use the oil filter wrench to remove the old filter, ensuring to lubricate the rubber gasket of the new filter with a bit of fresh oil before installing it. Finally, pour the new oil into the engine using a funnel, checking the level with the dipstick to ensure it’s within the recommended range. After completing the process, start the engine and let it run for a few minutes, checking for leaks and confirming that the oil pressure is stable.

Battery Care and Replacement Process

Maintaining the longevity and performance of the power source is crucial for ensuring the efficient operation of any vehicle. Proper care and timely replacement can prevent unexpected failures and enhance the overall reliability of the machinery. This section outlines essential practices for managing the battery, including monitoring its condition and the steps necessary for replacement when required.

Regular Maintenance Tips

To extend the life of the battery, routine checks are essential. Inspect the terminals for corrosion and clean them if necessary. Ensure that the connections are secure and free from dirt or moisture. Additionally, monitor the electrolyte levels if applicable, topping them up with distilled water to maintain optimal performance.

Steps for Battery Replacement

When it becomes necessary to replace the battery, follow a systematic approach. Start by disconnecting the negative terminal followed by the positive terminal to prevent short circuits. Remove any securing mechanisms and carefully lift the battery out of its compartment. Place the new battery in the same position, reconnect the positive terminal first, followed by the negative terminal, and ensure all connections are tight. Dispose of the old battery in accordance with local regulations to promote environmental responsibility.

Upgrading Lights and Electrical Accessories

Enhancing the illumination and electrical capabilities of your vehicle can significantly improve its functionality and safety. Whether for off-road adventures or night driving, upgrading lighting systems and adding electrical accessories can provide better visibility and increased convenience. This section will explore various options for enhancing your vehicle’s lighting and electrical features, ensuring optimal performance and reliability.

Choosing the Right Lighting Options

When selecting new lights, consider both the intensity and type of illumination needed for your specific activities. Options such as LED light bars, fog lights, and spotlights can provide targeted lighting for off-road conditions. Ensuring compatibility with the existing electrical system is crucial, so always check the power requirements before installation. Additionally, mounting locations should be chosen carefully to maximize effectiveness and minimize interference with the vehicle’s operation.

Integrating Electrical Accessories

Beyond lighting, integrating additional electrical accessories like winches, sound systems, or navigation devices can enhance the overall experience. Ensure that the electrical system can support the added load by upgrading wiring and adding relays or fuses as necessary. Proper installation of these accessories not only improves functionality but also contributes to the overall safety and enjoyment of your vehicle.